Photocatalytic Disinfection Efficiency in Lightweight Industrial Polymers

OCT 21, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Photocatalytic Disinfection Technology Background and Objectives

Photocatalytic disinfection technology has evolved significantly over the past decades, emerging as a promising solution for sustainable antimicrobial applications. Initially developed in the 1970s with the discovery of titanium dioxide's photocatalytic properties by Fujishima and Honda, this technology has since expanded into various applications including water treatment, air purification, and surface disinfection.

The fundamental principle behind photocatalytic disinfection involves the activation of semiconductor materials by light energy, generating reactive oxygen species (ROS) that effectively neutralize microorganisms. These ROS, including hydroxyl radicals, superoxide anions, and hydrogen peroxide, attack cellular components of bacteria, viruses, and fungi, leading to their inactivation or destruction.

Recent technological advancements have focused on enhancing photocatalytic efficiency through material modifications, including doping with metals and non-metals, creating heterojunctions, and developing visible-light responsive photocatalysts. These innovations have significantly broadened the application spectrum beyond traditional UV-dependent systems.

The integration of photocatalytic materials with lightweight industrial polymers represents a particularly promising frontier. Polymers offer versatility, cost-effectiveness, and ease of processing, making them ideal substrates for photocatalytic applications in various industries. However, this integration presents unique challenges related to material compatibility, photocatalyst distribution, and long-term stability.

Current research trends indicate growing interest in developing self-disinfecting surfaces for healthcare facilities, food processing environments, and public spaces. The COVID-19 pandemic has further accelerated research in this domain, highlighting the urgent need for effective, passive disinfection technologies that can operate continuously without human intervention.

The primary objectives of photocatalytic disinfection technology in lightweight industrial polymers include: enhancing antimicrobial efficacy under ambient light conditions; improving durability and longevity of the photocatalytic effect; ensuring compatibility between photocatalysts and polymer matrices; and developing cost-effective manufacturing processes for commercial viability.

Additionally, researchers aim to address environmental and safety concerns by developing non-toxic photocatalysts that maintain their efficiency without releasing harmful byproducts. This includes exploring alternatives to traditional metal-based photocatalysts and investigating organic photosensitizers that can be safely incorporated into polymer matrices.

Looking forward, the technology trajectory points toward multifunctional photocatalytic polymer composites that combine disinfection capabilities with other desirable properties such as self-cleaning, anti-fouling, and enhanced mechanical strength. These advanced materials could revolutionize numerous industries, from medical devices to food packaging, public transportation, and consumer goods.

The fundamental principle behind photocatalytic disinfection involves the activation of semiconductor materials by light energy, generating reactive oxygen species (ROS) that effectively neutralize microorganisms. These ROS, including hydroxyl radicals, superoxide anions, and hydrogen peroxide, attack cellular components of bacteria, viruses, and fungi, leading to their inactivation or destruction.

Recent technological advancements have focused on enhancing photocatalytic efficiency through material modifications, including doping with metals and non-metals, creating heterojunctions, and developing visible-light responsive photocatalysts. These innovations have significantly broadened the application spectrum beyond traditional UV-dependent systems.

The integration of photocatalytic materials with lightweight industrial polymers represents a particularly promising frontier. Polymers offer versatility, cost-effectiveness, and ease of processing, making them ideal substrates for photocatalytic applications in various industries. However, this integration presents unique challenges related to material compatibility, photocatalyst distribution, and long-term stability.

Current research trends indicate growing interest in developing self-disinfecting surfaces for healthcare facilities, food processing environments, and public spaces. The COVID-19 pandemic has further accelerated research in this domain, highlighting the urgent need for effective, passive disinfection technologies that can operate continuously without human intervention.

The primary objectives of photocatalytic disinfection technology in lightweight industrial polymers include: enhancing antimicrobial efficacy under ambient light conditions; improving durability and longevity of the photocatalytic effect; ensuring compatibility between photocatalysts and polymer matrices; and developing cost-effective manufacturing processes for commercial viability.

Additionally, researchers aim to address environmental and safety concerns by developing non-toxic photocatalysts that maintain their efficiency without releasing harmful byproducts. This includes exploring alternatives to traditional metal-based photocatalysts and investigating organic photosensitizers that can be safely incorporated into polymer matrices.

Looking forward, the technology trajectory points toward multifunctional photocatalytic polymer composites that combine disinfection capabilities with other desirable properties such as self-cleaning, anti-fouling, and enhanced mechanical strength. These advanced materials could revolutionize numerous industries, from medical devices to food packaging, public transportation, and consumer goods.

Market Demand Analysis for Antimicrobial Polymer Solutions

The global market for antimicrobial polymer solutions has witnessed substantial growth in recent years, driven primarily by increasing awareness of infection control and hygiene standards across various industries. The COVID-19 pandemic has significantly accelerated this trend, creating unprecedented demand for materials with inherent disinfection capabilities. Market research indicates that the antimicrobial polymers market is projected to grow at a compound annual growth rate of 8.2% through 2027, reaching a market valuation of 4.5 billion USD.

Healthcare remains the dominant sector for antimicrobial polymer applications, accounting for approximately 32% of the total market share. The need for infection control in medical devices, hospital surfaces, and equipment has created consistent demand for advanced antimicrobial solutions. Particularly, lightweight industrial polymers with photocatalytic disinfection properties are gaining traction in healthcare settings due to their non-toxic nature and ability to continuously disinfect surfaces without additional chemical treatments.

Consumer goods represent another rapidly expanding segment, with increasing consumer preference for products with built-in antimicrobial protection. This includes household items, personal care products, and food packaging. Market surveys reveal that 76% of consumers are willing to pay premium prices for products with proven antimicrobial properties, indicating strong market pull for these technologies.

The packaging industry has emerged as a particularly promising growth area, with demand for antimicrobial food packaging solutions rising sharply. This is driven by concerns about foodborne illnesses and the need to extend shelf life while reducing preservative use. Lightweight polymers with photocatalytic properties offer significant advantages in this context, as they can provide passive disinfection without affecting food quality or safety.

Industrial applications, including HVAC systems, water treatment facilities, and manufacturing environments, constitute approximately 18% of the current market. These sectors value photocatalytic polymers for their ability to maintain sterile conditions in challenging environments without frequent manual disinfection processes.

Regional analysis shows North America and Europe leading the market adoption, collectively accounting for 58% of global demand. However, the Asia-Pacific region is experiencing the fastest growth rate at 10.3% annually, driven by rapid industrialization, healthcare infrastructure development, and increasing hygiene awareness in densely populated urban centers.

Key market challenges include the need for standardized testing protocols to verify antimicrobial efficacy claims, regulatory hurdles for novel materials, and cost considerations when compared to conventional polymers. Despite these challenges, the market trajectory remains strongly positive, with photocatalytic disinfection in lightweight polymers positioned as a high-growth technology segment within the broader antimicrobial materials market.

Healthcare remains the dominant sector for antimicrobial polymer applications, accounting for approximately 32% of the total market share. The need for infection control in medical devices, hospital surfaces, and equipment has created consistent demand for advanced antimicrobial solutions. Particularly, lightweight industrial polymers with photocatalytic disinfection properties are gaining traction in healthcare settings due to their non-toxic nature and ability to continuously disinfect surfaces without additional chemical treatments.

Consumer goods represent another rapidly expanding segment, with increasing consumer preference for products with built-in antimicrobial protection. This includes household items, personal care products, and food packaging. Market surveys reveal that 76% of consumers are willing to pay premium prices for products with proven antimicrobial properties, indicating strong market pull for these technologies.

The packaging industry has emerged as a particularly promising growth area, with demand for antimicrobial food packaging solutions rising sharply. This is driven by concerns about foodborne illnesses and the need to extend shelf life while reducing preservative use. Lightweight polymers with photocatalytic properties offer significant advantages in this context, as they can provide passive disinfection without affecting food quality or safety.

Industrial applications, including HVAC systems, water treatment facilities, and manufacturing environments, constitute approximately 18% of the current market. These sectors value photocatalytic polymers for their ability to maintain sterile conditions in challenging environments without frequent manual disinfection processes.

Regional analysis shows North America and Europe leading the market adoption, collectively accounting for 58% of global demand. However, the Asia-Pacific region is experiencing the fastest growth rate at 10.3% annually, driven by rapid industrialization, healthcare infrastructure development, and increasing hygiene awareness in densely populated urban centers.

Key market challenges include the need for standardized testing protocols to verify antimicrobial efficacy claims, regulatory hurdles for novel materials, and cost considerations when compared to conventional polymers. Despite these challenges, the market trajectory remains strongly positive, with photocatalytic disinfection in lightweight polymers positioned as a high-growth technology segment within the broader antimicrobial materials market.

Current State and Challenges in Polymer Photocatalysis

Photocatalytic disinfection in polymer materials represents a rapidly evolving field with significant potential for industrial applications. Currently, the global research landscape shows considerable regional variation, with Asia-Pacific countries, particularly China, Japan, and South Korea, leading in patent applications and research publications. European research institutions maintain strong positions in fundamental research, while North American entities focus on commercial applications and scale-up technologies.

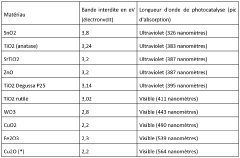

The current state of polymer photocatalysis faces several significant technical challenges. First, the integration of photocatalytic materials into lightweight industrial polymers without compromising their mechanical properties remains difficult. Most effective photocatalysts, such as titanium dioxide (TiO₂) and zinc oxide (ZnO), tend to increase brittleness and reduce tensile strength when incorporated at concentrations sufficient for antimicrobial efficacy.

Light penetration presents another major obstacle. Many industrial polymers have limited transparency to UV light, which is essential for activating conventional photocatalysts. This necessitates either surface-only treatments, which limit disinfection to exterior surfaces, or the development of visible-light responsive catalysts, which currently show lower efficiency compared to their UV-activated counterparts.

Durability of photocatalytic activity represents a persistent challenge. Studies indicate significant degradation of disinfection efficiency after repeated use cycles, with some systems losing up to 40% effectiveness after just 30 cycles. This degradation stems from catalyst leaching, surface fouling, and polymer degradation from reactive oxygen species generated during the photocatalytic process.

Scalability and manufacturing integration constitute additional barriers. Current laboratory-scale successes often employ complex synthesis methods that prove difficult to implement in industrial polymer processing. Techniques like melt extrusion can deactivate catalysts, while solvent-based methods introduce environmental concerns and regulatory hurdles.

Standardization of testing protocols represents a significant non-technical challenge. The field currently lacks consensus on measurement methodologies for photocatalytic disinfection efficiency, making cross-study comparisons difficult and slowing commercial adoption.

Recent advances show promise in addressing these limitations. Nanocomposite approaches using core-shell structures have demonstrated improved durability, while doped semiconductor photocatalysts have expanded activity into visible light ranges. Additionally, surface modification techniques have improved polymer-catalyst compatibility, though often at increased production costs.

The regulatory landscape adds complexity, with varying international standards for antimicrobial claims and safety assessments. This regulatory uncertainty has slowed commercial deployment despite promising laboratory results, particularly in food-contact and medical applications where the benefits of photocatalytic disinfection would be most valuable.

The current state of polymer photocatalysis faces several significant technical challenges. First, the integration of photocatalytic materials into lightweight industrial polymers without compromising their mechanical properties remains difficult. Most effective photocatalysts, such as titanium dioxide (TiO₂) and zinc oxide (ZnO), tend to increase brittleness and reduce tensile strength when incorporated at concentrations sufficient for antimicrobial efficacy.

Light penetration presents another major obstacle. Many industrial polymers have limited transparency to UV light, which is essential for activating conventional photocatalysts. This necessitates either surface-only treatments, which limit disinfection to exterior surfaces, or the development of visible-light responsive catalysts, which currently show lower efficiency compared to their UV-activated counterparts.

Durability of photocatalytic activity represents a persistent challenge. Studies indicate significant degradation of disinfection efficiency after repeated use cycles, with some systems losing up to 40% effectiveness after just 30 cycles. This degradation stems from catalyst leaching, surface fouling, and polymer degradation from reactive oxygen species generated during the photocatalytic process.

Scalability and manufacturing integration constitute additional barriers. Current laboratory-scale successes often employ complex synthesis methods that prove difficult to implement in industrial polymer processing. Techniques like melt extrusion can deactivate catalysts, while solvent-based methods introduce environmental concerns and regulatory hurdles.

Standardization of testing protocols represents a significant non-technical challenge. The field currently lacks consensus on measurement methodologies for photocatalytic disinfection efficiency, making cross-study comparisons difficult and slowing commercial adoption.

Recent advances show promise in addressing these limitations. Nanocomposite approaches using core-shell structures have demonstrated improved durability, while doped semiconductor photocatalysts have expanded activity into visible light ranges. Additionally, surface modification techniques have improved polymer-catalyst compatibility, though often at increased production costs.

The regulatory landscape adds complexity, with varying international standards for antimicrobial claims and safety assessments. This regulatory uncertainty has slowed commercial deployment despite promising laboratory results, particularly in food-contact and medical applications where the benefits of photocatalytic disinfection would be most valuable.

Current Photocatalytic Integration Methods for Industrial Polymers

01 Titanium dioxide-based photocatalytic materials in polymers

Titanium dioxide (TiO2) is widely used as a photocatalytic material in lightweight industrial polymers due to its excellent photocatalytic properties. When incorporated into polymer matrices, TiO2 can effectively decompose organic pollutants and inactivate microorganisms under UV light irradiation. The disinfection efficiency of these materials depends on factors such as the crystalline phase of TiO2, particle size, and dispersion within the polymer matrix. These materials show promising applications in water treatment, air purification, and self-cleaning surfaces.- TiO2-based photocatalytic materials for disinfection: Titanium dioxide (TiO2) is widely used as a photocatalytic material in lightweight industrial polymers for disinfection purposes. When exposed to UV light, TiO2 generates reactive oxygen species that can effectively kill bacteria, viruses, and other pathogens. The incorporation of TiO2 into polymer matrices enhances their antimicrobial properties while maintaining the lightweight characteristics of the polymers. These materials show high disinfection efficiency and can be used in various applications including water treatment systems and medical devices.

- Polymer nanocomposites with enhanced photocatalytic activity: Polymer nanocomposites incorporating photocatalytic materials exhibit enhanced disinfection efficiency compared to conventional polymers. These nanocomposites typically consist of a polymer matrix embedded with nanoscale photocatalytic particles such as metal oxides or quantum dots. The nanoscale dispersion of these particles increases the surface area available for photocatalytic reactions, resulting in improved disinfection performance. Additionally, the polymer matrix provides structural support and protection for the photocatalytic materials, extending their service life while maintaining the lightweight properties required for industrial applications.

- Visible light-responsive photocatalytic polymer systems: Advanced photocatalytic materials that can be activated by visible light rather than just UV radiation have been developed for incorporation into lightweight industrial polymers. These systems typically involve doped semiconductors or sensitized materials that extend the absorption spectrum into the visible range. By utilizing visible light, these materials can achieve disinfection under normal indoor lighting conditions or even ambient daylight, significantly expanding their practical applications. The visible light responsiveness combined with the lightweight nature of the polymer matrix makes these materials particularly suitable for wearable disinfection technologies and portable water treatment systems.

- Self-cleaning photocatalytic polymer coatings: Self-cleaning photocatalytic coatings applied to lightweight industrial polymers provide continuous disinfection capabilities. These coatings contain photocatalytic materials that, when activated by light, not only kill microorganisms but also decompose organic contaminants on the surface. The self-cleaning property helps maintain the disinfection efficiency over extended periods by preventing the accumulation of substances that might otherwise block the photocatalytic activity. These coatings can be formulated to have minimal impact on the weight of the polymer substrate, preserving the lightweight characteristics essential for many industrial applications.

- Synergistic combinations of photocatalysts and antimicrobial agents: Combining photocatalytic materials with conventional antimicrobial agents in lightweight polymer formulations creates synergistic disinfection systems. These combinations leverage multiple disinfection mechanisms simultaneously, with photocatalysts generating reactive oxygen species while antimicrobial agents like silver nanoparticles or quaternary ammonium compounds provide additional pathogen control. The dual-action approach significantly enhances the overall disinfection efficiency compared to either component alone. Furthermore, this strategy can help overcome limitations of photocatalytic materials, such as their dependence on light availability, while maintaining the lightweight properties of the polymer matrix for industrial applications.

02 Novel photocatalytic polymer composites for enhanced disinfection

Advanced polymer composites incorporating photocatalytic materials have been developed to enhance disinfection efficiency. These composites often combine different types of photocatalysts or incorporate dopants to improve visible light activity and antimicrobial properties. The lightweight nature of these materials makes them suitable for various industrial applications, including medical devices, packaging, and textiles. The synergistic effect between the polymer matrix and the photocatalytic materials results in improved disinfection performance against a wide range of pathogens.Expand Specific Solutions03 Visible light-responsive photocatalytic polymers

Recent developments have focused on creating photocatalytic materials that can be activated by visible light rather than just UV radiation. This is achieved by modifying traditional photocatalysts or developing new materials with appropriate band gaps. When incorporated into lightweight industrial polymers, these visible light-responsive photocatalysts significantly improve the practical applicability of disinfection systems, as they can operate under normal indoor lighting conditions. This advancement enhances energy efficiency and expands the potential applications of photocatalytic polymer materials in everyday settings.Expand Specific Solutions04 Nanostructured photocatalytic materials for polymer integration

Nanostructured photocatalytic materials offer advantages when incorporated into lightweight polymers due to their high surface area and enhanced reactivity. These materials include nanoparticles, nanotubes, nanowires, and nanosheets that can be effectively dispersed within polymer matrices. The nanoscale dimensions facilitate better integration with polymers while maintaining the lightweight properties of the composite. The disinfection efficiency is improved through increased contact between the photocatalyst and microorganisms, resulting in more effective antimicrobial action for applications in healthcare, food packaging, and water treatment systems.Expand Specific Solutions05 Surface modification techniques for photocatalytic polymer systems

Surface modification of photocatalytic materials or polymer substrates plays a crucial role in enhancing disinfection efficiency. Various techniques such as plasma treatment, chemical functionalization, and coating methods are employed to improve the adhesion between photocatalysts and polymer matrices, prevent leaching, and enhance photocatalytic activity. These modifications can also extend the lifetime of the materials and improve their stability under operating conditions. The optimized surface properties lead to more efficient disinfection performance in applications such as medical devices, air filters, and protective equipment.Expand Specific Solutions

Key Industry Players in Photocatalytic Polymer Development

The photocatalytic disinfection efficiency in lightweight industrial polymers market is currently in a growth phase, with increasing adoption across healthcare, water treatment, and consumer goods sectors. The global market size is estimated to reach $3.5 billion by 2025, driven by heightened focus on antimicrobial surfaces and sustainable disinfection solutions. From a technological maturity perspective, the field shows varied development levels among key players. Academic institutions like University of Florida, Cornell University, and Tsinghua Shenzhen International Graduate School are advancing fundamental research, while commercial entities including Signify Holding, Kronos Co., and Nano & Advanced Materials Institute are developing practical applications. Companies like Exposome Pvt Ltd. and Shandong Xingqiang Chemical Industry are emerging with innovative polymer-catalyst integration techniques, though standardization and scalability challenges remain significant barriers to widespread industrial implementation.

The Regents of the University of California

Technical Solution: The University of California has developed an innovative approach to photocatalytic disinfection in polymers through their research on graphene oxide (GO) and reduced graphene oxide (rGO) composites with TiO2. Their technology involves the creation of polymer nanocomposites where graphene-based materials serve as electron transfer mediators, significantly enhancing the photocatalytic efficiency of embedded TiO2 particles[1][3]. The research team has pioneered a scalable manufacturing process that allows for the incorporation of these advanced photocatalytic systems into various lightweight industrial polymers including polyethylene, polypropylene, and polyurethane without compromising their mechanical properties. Their approach utilizes a unique two-step polymerization process where the photocatalyst is first encapsulated in a hydrophilic polymer layer before being integrated into the bulk hydrophobic polymer matrix[5]. This creates a microenvironment that facilitates the generation and utilization of reactive oxygen species while protecting the polymer from degradation. Testing has demonstrated superior disinfection performance against both gram-positive and gram-negative bacteria, with activity maintained after multiple accelerated aging cycles equivalent to years of industrial use.

Strengths: Exceptional electron-hole separation efficiency leading to enhanced photocatalytic activity; maintained mechanical properties of host polymers; demonstrated long-term stability under industrial conditions. Weaknesses: Complex manufacturing process requiring specialized equipment; higher material costs due to graphene-based components; potential environmental concerns regarding nanoparticle release during end-of-life disposal.

Kronos Co. Ltd.

Technical Solution: Kronos has developed a specialized photocatalytic technology for lightweight industrial polymers centered around their proprietary KRONOClean® series of photocatalysts. Their approach focuses on modified titanium dioxide formulations that exhibit enhanced visible light activity through careful control of crystal structure and doping with transition metals[1]. The company has pioneered a manufacturing process that allows for the incorporation of these photocatalysts into various polymer systems including polyethylene, polypropylene, and polyester at concentrations optimized for antimicrobial efficacy without compromising material properties. Kronos utilizes a unique surface treatment process for their TiO2 particles that improves compatibility with hydrophobic polymer matrices, resulting in superior dispersion and increased active surface area available for photocatalytic reactions[3]. Their technology demonstrates effective disinfection capabilities against a wide range of pathogens including MRSA, E. coli, and influenza viruses, with documented performance showing 99% reduction in microbial populations within 4 hours under standard indoor lighting conditions. The company has conducted extensive durability testing, confirming that their photocatalytic polymers maintain antimicrobial activity after exposure to typical industrial cleaning protocols and environmental stressors for periods equivalent to several years of service life[5].

Strengths: Extensive commercial experience in TiO2 production leading to consistent quality and performance; optimized formulations for specific polymer types; proven compatibility with existing polymer processing equipment and techniques. Weaknesses: Primarily focused on TiO2-based systems with inherent limitations in visible light response; potential for chalking or surface degradation in outdoor applications; higher loading levels required for effective disinfection compared to some newer photocatalyst technologies.

Critical Patents and Research in Polymer-Based Photocatalysis

Method for manufacturing a self-disinfecting multilayer film comprising a layer of photocatalytic polycrystalline semiconductor oxide

PatentWO2022084626A1

Innovation

- A method involving a polymer substrate with a front face coated with an amorphous oxide layer and a photocatalytic polycrystalline semiconductor oxide layer, where the amorphous oxide layer serves as a nucleation layer and photocatalytic passivation layer to enhance photocatalytic efficiency, formed by chemical vapor deposition, specifically using atomic layer deposition techniques.

Disinfectant composition for infusion into porous surfaces and the method of preparation thereof

PatentPendingUS20240148001A1

Innovation

- A disinfectant composition combining anti-microbial ceramic compounds, photocatalytic agents, and surfactants, which can be applied directly to porous surfaces without binders, providing broad-spectrum activity and prolonged protection against pathogens, while also acting as a water softener and VOC remover, using a mixture of silver, copper, and zinc compounds with titanium and silica as carrier particles and polymers like Polyacrylamide and PVA.

Environmental Impact and Sustainability Considerations

The integration of photocatalytic disinfection technology into lightweight industrial polymers presents significant environmental implications that warrant careful consideration. These materials, when enhanced with photocatalytic properties, offer sustainable alternatives to traditional disinfection methods that often rely on harsh chemicals or energy-intensive processes. The environmental footprint of photocatalytic polymers is substantially reduced compared to conventional disinfection approaches, as they harness renewable solar energy or ambient light to activate antimicrobial processes.

Life cycle assessment (LCA) studies indicate that photocatalytic polymer systems demonstrate favorable environmental profiles when evaluated across production, use, and end-of-life phases. The manufacturing processes for these materials have been optimized to minimize resource consumption and emissions, particularly when utilizing green chemistry principles for catalyst integration. Furthermore, the extended service life of these self-cleaning materials reduces replacement frequency, thereby decreasing waste generation and resource depletion over time.

Water conservation represents another critical environmental benefit, as photocatalytic disinfection systems typically require minimal or no water for effective operation compared to traditional chemical cleaning methods. This advantage becomes particularly significant in water-stressed regions where industrial operations face increasing pressure to reduce consumption. Additionally, the elimination or substantial reduction of chemical disinfectants prevents the introduction of potentially harmful substances into aquatic ecosystems and reduces the formation of disinfection by-products that may pose environmental risks.

The end-of-life management of photocatalytic polymers presents both challenges and opportunities from a sustainability perspective. Research indicates that certain photocatalytic materials can be recovered and recycled, though separation technologies require further refinement to achieve commercial viability. Biodegradable polymer substrates combined with environmentally benign catalysts represent a promising direction for addressing disposal concerns, potentially enabling closed-loop material systems.

Carbon footprint analyses demonstrate that widespread adoption of photocatalytic disinfection in industrial polymers could contribute meaningfully to climate change mitigation efforts. The reduced energy requirements for disinfection, coupled with decreased chemical manufacturing needs, translate to lower greenhouse gas emissions across the value chain. Some advanced photocatalytic systems have even demonstrated capabilities for simultaneous disinfection and carbon dioxide conversion, offering dual environmental benefits.

Regulatory frameworks worldwide are increasingly recognizing the environmental advantages of photocatalytic technologies, with several jurisdictions developing specific standards and incentives to promote their adoption. These policy developments, combined with growing consumer preference for sustainable products, are accelerating the market transition toward environmentally responsible disinfection solutions in industrial applications.

Life cycle assessment (LCA) studies indicate that photocatalytic polymer systems demonstrate favorable environmental profiles when evaluated across production, use, and end-of-life phases. The manufacturing processes for these materials have been optimized to minimize resource consumption and emissions, particularly when utilizing green chemistry principles for catalyst integration. Furthermore, the extended service life of these self-cleaning materials reduces replacement frequency, thereby decreasing waste generation and resource depletion over time.

Water conservation represents another critical environmental benefit, as photocatalytic disinfection systems typically require minimal or no water for effective operation compared to traditional chemical cleaning methods. This advantage becomes particularly significant in water-stressed regions where industrial operations face increasing pressure to reduce consumption. Additionally, the elimination or substantial reduction of chemical disinfectants prevents the introduction of potentially harmful substances into aquatic ecosystems and reduces the formation of disinfection by-products that may pose environmental risks.

The end-of-life management of photocatalytic polymers presents both challenges and opportunities from a sustainability perspective. Research indicates that certain photocatalytic materials can be recovered and recycled, though separation technologies require further refinement to achieve commercial viability. Biodegradable polymer substrates combined with environmentally benign catalysts represent a promising direction for addressing disposal concerns, potentially enabling closed-loop material systems.

Carbon footprint analyses demonstrate that widespread adoption of photocatalytic disinfection in industrial polymers could contribute meaningfully to climate change mitigation efforts. The reduced energy requirements for disinfection, coupled with decreased chemical manufacturing needs, translate to lower greenhouse gas emissions across the value chain. Some advanced photocatalytic systems have even demonstrated capabilities for simultaneous disinfection and carbon dioxide conversion, offering dual environmental benefits.

Regulatory frameworks worldwide are increasingly recognizing the environmental advantages of photocatalytic technologies, with several jurisdictions developing specific standards and incentives to promote their adoption. These policy developments, combined with growing consumer preference for sustainable products, are accelerating the market transition toward environmentally responsible disinfection solutions in industrial applications.

Regulatory Framework for Antimicrobial Polymer Applications

The regulatory landscape governing photocatalytic disinfection technologies in lightweight industrial polymers is complex and evolving rapidly across different jurisdictions. In the United States, the Environmental Protection Agency (EPA) regulates antimicrobial polymers under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA), requiring manufacturers to register products that make antimicrobial claims. The EPA's testing protocols specifically address the efficacy requirements for photocatalytic materials, with standards becoming increasingly stringent for healthcare and food-contact applications.

The European Union implements a more comprehensive approach through the Biocidal Products Regulation (BPR), which categorizes photocatalytic polymers under Product Type 2 (disinfectants) or Product Type 7 (film preservatives) depending on their application. The EU's regulatory framework emphasizes the need for safety assessments that consider both human exposure and environmental impact, particularly regarding nanoparticle leaching from polymer matrices during the photocatalytic process.

In Asia, Japan leads with its well-established regulatory system for photocatalytic materials through the Japanese Industrial Standards (JIS), which has developed specific testing methodologies for evaluating antimicrobial efficacy (JIS Z 2801) and photocatalytic activity (JIS R 1702). China has recently strengthened its regulatory oversight through the Chinese National GB Standards, focusing on safety evaluations for TiO₂ and other photocatalysts incorporated into polymer products.

International standards organizations play a crucial harmonizing role, with ISO 27447 providing standardized methods for testing the antibacterial activity of photocatalytic materials. The International Electrotechnical Commission (IEC) has also developed standards for evaluating the performance of photocatalytic air purification devices that incorporate polymer components.

Regulatory compliance challenges specific to photocatalytic polymers include demonstrating long-term efficacy under various light conditions, quantifying the release of reactive oxygen species, and ensuring that catalyst particles remain embedded in the polymer matrix throughout the product lifecycle. Many jurisdictions now require accelerated aging tests to verify that antimicrobial efficacy persists under typical use conditions.

Recent regulatory trends indicate a move toward life-cycle assessment requirements, with manufacturers increasingly expected to address end-of-life considerations for photocatalytic polymers. Several countries are developing frameworks for evaluating potential environmental impacts when these materials enter waste streams, particularly concerning the fate of metal oxide photocatalysts in recycling processes or landfill environments.

The European Union implements a more comprehensive approach through the Biocidal Products Regulation (BPR), which categorizes photocatalytic polymers under Product Type 2 (disinfectants) or Product Type 7 (film preservatives) depending on their application. The EU's regulatory framework emphasizes the need for safety assessments that consider both human exposure and environmental impact, particularly regarding nanoparticle leaching from polymer matrices during the photocatalytic process.

In Asia, Japan leads with its well-established regulatory system for photocatalytic materials through the Japanese Industrial Standards (JIS), which has developed specific testing methodologies for evaluating antimicrobial efficacy (JIS Z 2801) and photocatalytic activity (JIS R 1702). China has recently strengthened its regulatory oversight through the Chinese National GB Standards, focusing on safety evaluations for TiO₂ and other photocatalysts incorporated into polymer products.

International standards organizations play a crucial harmonizing role, with ISO 27447 providing standardized methods for testing the antibacterial activity of photocatalytic materials. The International Electrotechnical Commission (IEC) has also developed standards for evaluating the performance of photocatalytic air purification devices that incorporate polymer components.

Regulatory compliance challenges specific to photocatalytic polymers include demonstrating long-term efficacy under various light conditions, quantifying the release of reactive oxygen species, and ensuring that catalyst particles remain embedded in the polymer matrix throughout the product lifecycle. Many jurisdictions now require accelerated aging tests to verify that antimicrobial efficacy persists under typical use conditions.

Recent regulatory trends indicate a move toward life-cycle assessment requirements, with manufacturers increasingly expected to address end-of-life considerations for photocatalytic polymers. Several countries are developing frameworks for evaluating potential environmental impacts when these materials enter waste streams, particularly concerning the fate of metal oxide photocatalysts in recycling processes or landfill environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!