Understanding the Environmental Applications of Photocatalytic Disinfection

OCT 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Photocatalytic Disinfection Background and Objectives

Photocatalytic disinfection has emerged as a promising environmental technology over the past four decades, evolving from fundamental photochemical research in the 1970s to practical applications in water and air purification systems today. This technology leverages the ability of certain semiconductor materials, primarily titanium dioxide (TiO₂), to generate reactive oxygen species (ROS) when activated by light of appropriate wavelength, typically in the UV spectrum. These ROS effectively inactivate a wide range of microorganisms including bacteria, viruses, fungi, and protozoa by damaging their cell membranes, proteins, and genetic material.

The evolution of photocatalytic disinfection technology has been marked by significant milestones, including the discovery of water splitting on TiO₂ electrodes by Fujishima and Honda in 1972, the development of visible light-responsive photocatalysts in the 1990s, and the commercialization of self-cleaning surfaces in the early 2000s. Recent advancements have focused on enhancing photocatalytic efficiency through material modifications, expanding the light absorption range, and improving the durability of photocatalytic systems.

Current technological trends in this field include the development of nanomaterial-based photocatalysts with increased surface area and reactivity, doping strategies to enable visible light activation, and hybrid systems that combine photocatalysis with other disinfection methods for synergistic effects. The integration of photocatalytic materials into membranes, filters, and coatings represents another significant trend, enabling more versatile application formats.

The primary objective of photocatalytic disinfection research is to develop efficient, sustainable, and cost-effective solutions for water and air purification that can operate under ambient conditions with minimal energy input. Specific goals include enhancing photocatalytic activity under visible light, improving the durability and reusability of photocatalytic materials, and developing scalable manufacturing processes for commercial applications.

Additional objectives include understanding the fundamental mechanisms of microbial inactivation by photocatalysis, establishing standardized testing protocols for performance evaluation, and addressing potential concerns regarding the formation of disinfection byproducts. The technology aims to provide decentralized water treatment solutions for regions lacking infrastructure, emergency response capabilities during natural disasters, and advanced air purification systems for indoor environments.

The long-term vision for photocatalytic disinfection technology encompasses its integration into smart water and air treatment systems, development of self-disinfecting surfaces for healthcare settings, and application in sustainable building designs. As global concerns about waterborne diseases, emerging pathogens, and indoor air quality continue to grow, photocatalytic disinfection stands poised to make significant contributions to environmental health and safety.

The evolution of photocatalytic disinfection technology has been marked by significant milestones, including the discovery of water splitting on TiO₂ electrodes by Fujishima and Honda in 1972, the development of visible light-responsive photocatalysts in the 1990s, and the commercialization of self-cleaning surfaces in the early 2000s. Recent advancements have focused on enhancing photocatalytic efficiency through material modifications, expanding the light absorption range, and improving the durability of photocatalytic systems.

Current technological trends in this field include the development of nanomaterial-based photocatalysts with increased surface area and reactivity, doping strategies to enable visible light activation, and hybrid systems that combine photocatalysis with other disinfection methods for synergistic effects. The integration of photocatalytic materials into membranes, filters, and coatings represents another significant trend, enabling more versatile application formats.

The primary objective of photocatalytic disinfection research is to develop efficient, sustainable, and cost-effective solutions for water and air purification that can operate under ambient conditions with minimal energy input. Specific goals include enhancing photocatalytic activity under visible light, improving the durability and reusability of photocatalytic materials, and developing scalable manufacturing processes for commercial applications.

Additional objectives include understanding the fundamental mechanisms of microbial inactivation by photocatalysis, establishing standardized testing protocols for performance evaluation, and addressing potential concerns regarding the formation of disinfection byproducts. The technology aims to provide decentralized water treatment solutions for regions lacking infrastructure, emergency response capabilities during natural disasters, and advanced air purification systems for indoor environments.

The long-term vision for photocatalytic disinfection technology encompasses its integration into smart water and air treatment systems, development of self-disinfecting surfaces for healthcare settings, and application in sustainable building designs. As global concerns about waterborne diseases, emerging pathogens, and indoor air quality continue to grow, photocatalytic disinfection stands poised to make significant contributions to environmental health and safety.

Environmental Market Demand Analysis

The global market for photocatalytic disinfection technologies has witnessed substantial growth in recent years, driven primarily by increasing concerns over water and air quality, healthcare-associated infections, and the emergence of antibiotic-resistant pathogens. The COVID-19 pandemic has further accelerated market demand, highlighting the critical need for effective, sustainable disinfection solutions across multiple sectors.

Water treatment represents the largest application segment for photocatalytic disinfection, valued at approximately $1.2 billion in 2022 with projected annual growth of 8.7% through 2028. This growth is particularly pronounced in regions facing severe water scarcity and contamination issues, including parts of Asia-Pacific, Africa, and Latin America. Municipal water treatment facilities are increasingly adopting photocatalytic systems as tertiary treatment options due to their ability to deactivate chlorine-resistant microorganisms without generating harmful disinfection byproducts.

The healthcare sector presents another significant market opportunity, with hospitals and medical facilities implementing photocatalytic surfaces and air purification systems to reduce healthcare-associated infections. Market analysis indicates that healthcare applications of photocatalytic disinfection are growing at 11.3% annually, outpacing the overall market growth rate of 9.1%.

Consumer applications have also expanded considerably, with photocatalytic coatings for household surfaces, self-cleaning glass, and portable water purification devices gaining traction. This segment is expected to reach $890 million by 2025, up from $520 million in 2021, representing a compound annual growth rate of 14.4%.

Regionally, Asia-Pacific dominates the market with a 38% share, followed by North America (27%) and Europe (24%). China and Japan lead in both production and consumption of photocatalytic materials, while significant growth is anticipated in India, Brazil, and parts of Southeast Asia where rapid industrialization and urbanization are creating urgent environmental remediation needs.

Regulatory drivers are also shaping market demand, with increasingly stringent water quality standards in developed economies and growing emphasis on reducing chemical disinfectants in favor of more sustainable alternatives. The European Union's restrictions on certain biocides and the USEPA's promotion of alternative disinfection technologies have created favorable conditions for photocatalytic solutions.

Industry surveys indicate that end-users prioritize three key factors when selecting disinfection technologies: effectiveness against a broad spectrum of pathogens, operational cost efficiency, and environmental sustainability. Photocatalytic disinfection scores highly on all three metrics when compared to conventional chemical disinfection methods, suggesting strong continued market growth potential as awareness of these advantages increases among potential adopters.

Water treatment represents the largest application segment for photocatalytic disinfection, valued at approximately $1.2 billion in 2022 with projected annual growth of 8.7% through 2028. This growth is particularly pronounced in regions facing severe water scarcity and contamination issues, including parts of Asia-Pacific, Africa, and Latin America. Municipal water treatment facilities are increasingly adopting photocatalytic systems as tertiary treatment options due to their ability to deactivate chlorine-resistant microorganisms without generating harmful disinfection byproducts.

The healthcare sector presents another significant market opportunity, with hospitals and medical facilities implementing photocatalytic surfaces and air purification systems to reduce healthcare-associated infections. Market analysis indicates that healthcare applications of photocatalytic disinfection are growing at 11.3% annually, outpacing the overall market growth rate of 9.1%.

Consumer applications have also expanded considerably, with photocatalytic coatings for household surfaces, self-cleaning glass, and portable water purification devices gaining traction. This segment is expected to reach $890 million by 2025, up from $520 million in 2021, representing a compound annual growth rate of 14.4%.

Regionally, Asia-Pacific dominates the market with a 38% share, followed by North America (27%) and Europe (24%). China and Japan lead in both production and consumption of photocatalytic materials, while significant growth is anticipated in India, Brazil, and parts of Southeast Asia where rapid industrialization and urbanization are creating urgent environmental remediation needs.

Regulatory drivers are also shaping market demand, with increasingly stringent water quality standards in developed economies and growing emphasis on reducing chemical disinfectants in favor of more sustainable alternatives. The European Union's restrictions on certain biocides and the USEPA's promotion of alternative disinfection technologies have created favorable conditions for photocatalytic solutions.

Industry surveys indicate that end-users prioritize three key factors when selecting disinfection technologies: effectiveness against a broad spectrum of pathogens, operational cost efficiency, and environmental sustainability. Photocatalytic disinfection scores highly on all three metrics when compared to conventional chemical disinfection methods, suggesting strong continued market growth potential as awareness of these advantages increases among potential adopters.

Current Photocatalytic Technology Status and Challenges

Photocatalytic disinfection technology has witnessed significant advancements globally, with TiO2-based systems dominating the current landscape due to their stability, cost-effectiveness, and non-toxicity. Research institutions across North America, Europe, and East Asia have established robust development ecosystems, with China, Japan, and the United States leading patent applications in this domain. Despite promising laboratory results, widespread commercial implementation remains limited, creating a noticeable gap between research outcomes and practical applications.

The primary technical challenges hindering broader adoption include low quantum efficiency under visible light, as most photocatalysts primarily respond to UV radiation which constitutes only about 5% of solar spectrum. This limitation significantly reduces real-world effectiveness in indoor environments or during cloudy conditions. Additionally, catalyst deactivation over time presents a substantial hurdle, as organic matter accumulation and chemical transformations on catalyst surfaces progressively diminish disinfection efficiency.

Geographical distribution of photocatalytic disinfection research shows concentration in regions with severe water contamination challenges or advanced technological infrastructure. Japan and South Korea have pioneered self-cleaning surfaces incorporating photocatalytic materials, while European research centers focus on drinking water applications. China has emerged as a significant contributor, particularly in addressing industrial wastewater treatment through photocatalytic approaches.

Scale-up difficulties represent another critical barrier, as laboratory-scale successes often fail to translate to industrial applications. Reactor design complexities, light penetration limitations in turbid water, and catalyst recovery challenges in large-scale systems significantly impact implementation feasibility. Furthermore, standardization issues persist across the field, with varying testing protocols making performance comparisons between different photocatalytic systems problematic.

Recent technological innovations have attempted to address these limitations through approaches such as doping TiO2 with metals or non-metals to enhance visible light absorption, developing heterojunction photocatalysts to improve charge separation, and creating novel reactor designs that maximize light utilization. Z-scheme photocatalytic systems have shown particular promise by mimicking natural photosynthesis mechanisms to achieve higher quantum efficiencies.

Economic constraints further complicate widespread adoption, as initial implementation costs remain high compared to conventional disinfection methods like chlorination. However, life-cycle assessments indicate potential long-term economic advantages due to reduced chemical inputs and lower operational costs, suggesting that photocatalytic disinfection may become increasingly competitive as technology matures and production scales increase.

The primary technical challenges hindering broader adoption include low quantum efficiency under visible light, as most photocatalysts primarily respond to UV radiation which constitutes only about 5% of solar spectrum. This limitation significantly reduces real-world effectiveness in indoor environments or during cloudy conditions. Additionally, catalyst deactivation over time presents a substantial hurdle, as organic matter accumulation and chemical transformations on catalyst surfaces progressively diminish disinfection efficiency.

Geographical distribution of photocatalytic disinfection research shows concentration in regions with severe water contamination challenges or advanced technological infrastructure. Japan and South Korea have pioneered self-cleaning surfaces incorporating photocatalytic materials, while European research centers focus on drinking water applications. China has emerged as a significant contributor, particularly in addressing industrial wastewater treatment through photocatalytic approaches.

Scale-up difficulties represent another critical barrier, as laboratory-scale successes often fail to translate to industrial applications. Reactor design complexities, light penetration limitations in turbid water, and catalyst recovery challenges in large-scale systems significantly impact implementation feasibility. Furthermore, standardization issues persist across the field, with varying testing protocols making performance comparisons between different photocatalytic systems problematic.

Recent technological innovations have attempted to address these limitations through approaches such as doping TiO2 with metals or non-metals to enhance visible light absorption, developing heterojunction photocatalysts to improve charge separation, and creating novel reactor designs that maximize light utilization. Z-scheme photocatalytic systems have shown particular promise by mimicking natural photosynthesis mechanisms to achieve higher quantum efficiencies.

Economic constraints further complicate widespread adoption, as initial implementation costs remain high compared to conventional disinfection methods like chlorination. However, life-cycle assessments indicate potential long-term economic advantages due to reduced chemical inputs and lower operational costs, suggesting that photocatalytic disinfection may become increasingly competitive as technology matures and production scales increase.

Current Photocatalytic Disinfection Solutions

01 Photocatalytic materials for disinfection

Various photocatalytic materials can be used for disinfection purposes. These materials, when exposed to light, generate reactive oxygen species that can kill bacteria, viruses, and other pathogens. Common photocatalytic materials include titanium dioxide (TiO2), zinc oxide (ZnO), and other metal oxides. These materials can be incorporated into different substrates or used as coatings to provide disinfection capabilities in various applications.- Photocatalytic materials for disinfection: Various photocatalytic materials can be used for disinfection purposes. These materials, when activated by light, generate reactive oxygen species that can kill or inactivate microorganisms. Common photocatalytic materials include titanium dioxide (TiO2), zinc oxide (ZnO), and other metal oxides. These materials can be incorporated into different substrates or used as coatings to create surfaces with antimicrobial properties.

- Water treatment systems using photocatalytic disinfection: Photocatalytic disinfection can be applied in water treatment systems to remove pathogens and contaminants. These systems typically incorporate photocatalytic materials and UV light sources to activate the photocatalytic process. The technology can be used for drinking water purification, wastewater treatment, and swimming pool disinfection. Such systems offer advantages including reduced chemical usage and effective removal of a wide range of microorganisms.

- Air purification and disinfection devices: Photocatalytic technology can be integrated into air purification and disinfection devices. These devices use photocatalysts activated by light to break down airborne pollutants and inactivate microorganisms. They can be designed as standalone units or incorporated into HVAC systems. Such devices are effective for improving indoor air quality in various settings including homes, offices, hospitals, and public spaces.

- Enhanced photocatalytic disinfection methods: Various methods have been developed to enhance the efficiency of photocatalytic disinfection. These include doping photocatalysts with metals or non-metals, creating composite materials, using visible light-responsive photocatalysts, and combining photocatalysis with other disinfection methods. These enhancements aim to improve the photocatalytic activity, extend the light absorption range, and increase the overall disinfection efficiency.

- Specialized applications of photocatalytic disinfection: Photocatalytic disinfection technology has been adapted for specialized applications across various fields. These include self-cleaning surfaces, medical device sterilization, food preservation, agricultural water treatment, and disinfection in challenging environments. The technology can be tailored to specific requirements by adjusting parameters such as photocatalyst composition, light source, and reactor design to achieve optimal disinfection performance for each application.

02 Water treatment systems using photocatalytic disinfection

Photocatalytic disinfection can be applied in water treatment systems to remove pathogens and contaminants. These systems typically incorporate photocatalytic materials and UV light sources to activate the photocatalytic process. The design of such systems may include reactors, filters, and circulation mechanisms to ensure effective contact between the photocatalyst, light, and the water being treated. These systems can be used for drinking water purification, wastewater treatment, and swimming pool disinfection.Expand Specific Solutions03 Air purification devices with photocatalytic functionality

Photocatalytic disinfection technology can be integrated into air purification devices to eliminate airborne pathogens and pollutants. These devices typically combine photocatalytic materials with light sources and air circulation systems. The design may include filters, fans, and reaction chambers to maximize the contact between air contaminants and the activated photocatalyst surface. Such devices are useful for indoor air quality improvement in homes, hospitals, and public spaces.Expand Specific Solutions04 Enhanced photocatalytic efficiency through material modifications

Various approaches can be used to enhance the efficiency of photocatalytic disinfection. These include doping photocatalytic materials with metals or non-metals, creating composite materials, adjusting particle size and morphology, and surface modifications. Such enhancements can extend the light absorption range, reduce electron-hole recombination, and increase reactive oxygen species generation, resulting in improved disinfection performance under various light conditions.Expand Specific Solutions05 Self-cleaning and antimicrobial surfaces using photocatalysis

Photocatalytic materials can be incorporated into coatings or directly applied to surfaces to create self-cleaning and antimicrobial properties. When exposed to light, these surfaces continuously disinfect themselves by destroying organic contaminants and killing microorganisms. Applications include medical equipment, touchscreens, door handles, and other high-touch surfaces in public spaces. These technologies can help reduce the spread of infections in healthcare settings and public facilities.Expand Specific Solutions

Key Industry Players and Competitors

Photocatalytic disinfection technology is currently in a growth phase, with the market expanding rapidly due to increasing environmental concerns and demand for sustainable water and air purification solutions. The global market size is estimated to reach several billion dollars by 2025, driven by applications in healthcare, water treatment, and indoor air quality management. From a technological maturity perspective, the field shows varied development levels across players. Academic institutions like University of Florida, Rutgers, and Arizona State University are advancing fundamental research, while commercial entities such as Signify Holding, LEDVANCE, and Molekule are developing market-ready applications. Companies like Current Lighting Solutions and Vyv are focusing on LED-based photocatalytic systems, while Exposome and MKUL are exploring innovative material formulations. The competitive landscape reveals a healthy mix of established lighting manufacturers, specialized environmental technology firms, and research institutions driving innovation.

Signify Holding BV

Technical Solution: Signify (formerly Philips Lighting) has developed advanced UV-C based photocatalytic disinfection systems that combine UV light with titanium dioxide (TiO2) catalysts. Their technology creates reactive oxygen species (ROS) that effectively break down organic pollutants and inactivate microorganisms. Their systems include both air and surface disinfection solutions, with documented 99.9% efficacy against bacteria, viruses, and fungi within minutes of exposure. Signify's latest innovations incorporate visible light-activated photocatalysts that can work under standard indoor lighting conditions, making continuous disinfection possible in occupied spaces. Their research shows that their photocatalytic coatings maintain antimicrobial activity for up to three years without degradation, providing long-term environmental protection.

Strengths: Global market leader with extensive R&D capabilities and established distribution networks; proprietary photocatalyst formulations with enhanced visible light activity. Weaknesses: Higher initial implementation costs compared to conventional disinfection methods; performance can be affected by humidity levels and organic loading.

Hunan University

Technical Solution: Hunan University has developed advanced bismuth-based photocatalysts (Bi2WO6 and BiOCl composites) that demonstrate exceptional visible-light-driven disinfection capabilities. Their research has focused on enhancing photocatalytic efficiency through novel nanostructure engineering and heterojunction formation, achieving significant improvements in charge separation and reactive oxygen species generation. Laboratory studies have demonstrated over 99% inactivation of E. coli and S. aureus within 30 minutes under visible light irradiation. The university's innovations include carbon quantum dot-modified photocatalysts that extend light absorption into the visible spectrum while enhancing electron-hole separation efficiency. Their technology has been successfully applied to water treatment systems, demonstrating effective removal of both microbial contaminants and persistent organic pollutants simultaneously, with minimal energy input requirements.

Strengths: Cutting-edge research in visible-light-active photocatalysts; innovative nanostructure engineering approaches; dual functionality for both disinfection and pollutant degradation. Weaknesses: Technologies still primarily at laboratory scale; challenges in mass production of complex nanostructured materials; potential concerns about nanoparticle release into the environment.

Core Photocatalytic Mechanisms and Materials

Photocatalytic element for purification and disinfection of air and water and method for the production thereof

PatentActiveUS9925529B2

Innovation

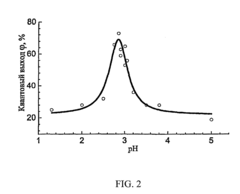

- A photocatalytic element with a porous sintered glass bead carrier having a defined shape and surface relief, treated with concentrated hydrofluoric and sulfuric acids, and coated with high-specific-surface-area titanium dioxide powder applied from an aqueous suspension at a controlled pH, ensuring strong bonding and enhanced mechanical strength and catalytic activity.

Regulatory Framework for Environmental Applications

The regulatory landscape governing photocatalytic disinfection technologies in environmental applications has evolved significantly in recent years, reflecting growing recognition of both their potential benefits and possible risks. At the international level, organizations such as the World Health Organization (WHO) and the International Organization for Standardization (ISO) have developed guidelines and standards that address water treatment technologies, including those utilizing photocatalytic processes. ISO/TC 229 specifically addresses nanotechnologies, which encompasses many photocatalytic materials used in disinfection applications.

In the United States, the Environmental Protection Agency (EPA) regulates photocatalytic disinfection technologies primarily through the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA) when these technologies make antimicrobial claims. Products incorporating photocatalytic materials for water treatment must also comply with the Safe Drinking Water Act (SDWA) standards. Additionally, the FDA oversees applications that may come into contact with food or be used in medical settings.

The European Union has implemented the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation, which applies to many photocatalytic materials. The EU's Biocidal Products Regulation (BPR) also governs photocatalytic technologies when used as disinfectants. These regulations require comprehensive safety assessments and efficacy testing before market approval.

In Asia, Japan has pioneered regulatory frameworks for photocatalytic technologies through the Japanese Industrial Standards (JIS), which include specific standards for photocatalytic materials' antimicrobial performance (JIS R 1702). China has incorporated requirements for photocatalytic technologies within its broader environmental protection regulations, particularly focusing on water and air quality standards.

A significant regulatory challenge remains the lack of standardized testing protocols specifically designed for photocatalytic disinfection technologies. This gap has led to inconsistent performance claims and difficulties in comparing different solutions. Regulatory bodies are increasingly working toward harmonized approaches to address this issue, with collaborative efforts between academia, industry, and government agencies.

Compliance costs represent another regulatory hurdle, particularly for smaller companies and startups. The extensive testing required to demonstrate both efficacy and safety can be prohibitively expensive, potentially limiting innovation in this field. Several jurisdictions are exploring regulatory sandboxes and expedited approval pathways for promising environmental technologies to address this concern.

In the United States, the Environmental Protection Agency (EPA) regulates photocatalytic disinfection technologies primarily through the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA) when these technologies make antimicrobial claims. Products incorporating photocatalytic materials for water treatment must also comply with the Safe Drinking Water Act (SDWA) standards. Additionally, the FDA oversees applications that may come into contact with food or be used in medical settings.

The European Union has implemented the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation, which applies to many photocatalytic materials. The EU's Biocidal Products Regulation (BPR) also governs photocatalytic technologies when used as disinfectants. These regulations require comprehensive safety assessments and efficacy testing before market approval.

In Asia, Japan has pioneered regulatory frameworks for photocatalytic technologies through the Japanese Industrial Standards (JIS), which include specific standards for photocatalytic materials' antimicrobial performance (JIS R 1702). China has incorporated requirements for photocatalytic technologies within its broader environmental protection regulations, particularly focusing on water and air quality standards.

A significant regulatory challenge remains the lack of standardized testing protocols specifically designed for photocatalytic disinfection technologies. This gap has led to inconsistent performance claims and difficulties in comparing different solutions. Regulatory bodies are increasingly working toward harmonized approaches to address this issue, with collaborative efforts between academia, industry, and government agencies.

Compliance costs represent another regulatory hurdle, particularly for smaller companies and startups. The extensive testing required to demonstrate both efficacy and safety can be prohibitively expensive, potentially limiting innovation in this field. Several jurisdictions are exploring regulatory sandboxes and expedited approval pathways for promising environmental technologies to address this concern.

Sustainability Impact Assessment

Photocatalytic disinfection technology represents a significant advancement in sustainable environmental management practices. When evaluating its sustainability impact, we must consider multiple dimensions including environmental, economic, and social factors that collectively determine the long-term viability and benefits of this technology.

From an environmental perspective, photocatalytic disinfection offers substantial advantages over conventional chemical disinfection methods. The process utilizes renewable energy sources (primarily sunlight) and typically requires minimal additional energy inputs, resulting in a significantly reduced carbon footprint. Furthermore, the technology eliminates the need for harmful chemical disinfectants that can produce toxic by-products and contribute to environmental contamination.

Life cycle assessment (LCA) studies indicate that photocatalytic systems generally demonstrate favorable environmental profiles when compared to traditional disinfection approaches. The production of photocatalytic materials does involve some environmental costs, particularly in the manufacturing of nanomaterials like TiO2, but these impacts are typically offset by the operational benefits over the technology's lifespan.

Economic sustainability analysis reveals both challenges and opportunities. While initial implementation costs for photocatalytic disinfection systems can be higher than conventional alternatives, operational expenses are generally lower due to reduced chemical requirements and potential energy savings. The technology's durability and minimal maintenance needs further enhance its long-term economic viability, particularly in remote or resource-constrained settings.

Social sustainability considerations highlight the technology's potential to improve public health outcomes through enhanced water and air quality. Photocatalytic disinfection can be particularly impactful in developing regions where access to safe water remains a critical challenge. The technology's scalability allows for implementation at both community and household levels, potentially democratizing access to disinfection capabilities.

Resource efficiency represents another key sustainability dimension. Photocatalytic systems typically require minimal material inputs during operation and can be designed for extended service lifespans. Recent advances in catalyst recovery and regeneration techniques have further improved the resource efficiency profile of these systems.

Regulatory frameworks increasingly recognize photocatalytic disinfection as a preferred environmental technology. Several jurisdictions have incorporated incentives for sustainable disinfection approaches into their environmental policies, potentially accelerating adoption rates and driving further innovation in this field.

From an environmental perspective, photocatalytic disinfection offers substantial advantages over conventional chemical disinfection methods. The process utilizes renewable energy sources (primarily sunlight) and typically requires minimal additional energy inputs, resulting in a significantly reduced carbon footprint. Furthermore, the technology eliminates the need for harmful chemical disinfectants that can produce toxic by-products and contribute to environmental contamination.

Life cycle assessment (LCA) studies indicate that photocatalytic systems generally demonstrate favorable environmental profiles when compared to traditional disinfection approaches. The production of photocatalytic materials does involve some environmental costs, particularly in the manufacturing of nanomaterials like TiO2, but these impacts are typically offset by the operational benefits over the technology's lifespan.

Economic sustainability analysis reveals both challenges and opportunities. While initial implementation costs for photocatalytic disinfection systems can be higher than conventional alternatives, operational expenses are generally lower due to reduced chemical requirements and potential energy savings. The technology's durability and minimal maintenance needs further enhance its long-term economic viability, particularly in remote or resource-constrained settings.

Social sustainability considerations highlight the technology's potential to improve public health outcomes through enhanced water and air quality. Photocatalytic disinfection can be particularly impactful in developing regions where access to safe water remains a critical challenge. The technology's scalability allows for implementation at both community and household levels, potentially democratizing access to disinfection capabilities.

Resource efficiency represents another key sustainability dimension. Photocatalytic systems typically require minimal material inputs during operation and can be designed for extended service lifespans. Recent advances in catalyst recovery and regeneration techniques have further improved the resource efficiency profile of these systems.

Regulatory frameworks increasingly recognize photocatalytic disinfection as a preferred environmental technology. Several jurisdictions have incorporated incentives for sustainable disinfection approaches into their environmental policies, potentially accelerating adoption rates and driving further innovation in this field.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!