Photocatalytic Disinfection: Catalyst Innovations and Efficiency Gains

OCT 21, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Photocatalysis Background and Disinfection Goals

Photocatalysis emerged in the early 1970s with the groundbreaking discovery of water splitting on titanium dioxide electrodes under ultraviolet light by Fujishima and Honda. This seminal work laid the foundation for utilizing photocatalytic processes to harness light energy for chemical transformations. Over subsequent decades, photocatalysis has evolved from a purely academic curiosity to a promising technology with diverse applications, particularly in environmental remediation and disinfection processes.

The fundamental principle of photocatalysis involves the activation of a semiconductor material by photons with energy equal to or greater than its band gap. This activation generates electron-hole pairs that can participate in redox reactions with adsorbed species on the catalyst surface. In the context of disinfection, these reactive species can effectively damage cellular components of microorganisms, leading to their inactivation or death.

Traditional disinfection methods such as chlorination, ozonation, and UV irradiation have limitations including the formation of harmful disinfection by-products, high energy consumption, and limited efficacy against certain pathogens. Photocatalytic disinfection offers a potentially more sustainable alternative that can operate under ambient conditions with reduced chemical inputs and energy requirements.

The evolution of photocatalytic materials has progressed from simple TiO₂-based systems to more complex architectures including doped semiconductors, heterojunctions, plasmonic nanostructures, and Z-scheme systems. Each advancement has aimed to address key limitations such as limited visible light absorption, rapid charge carrier recombination, and insufficient quantum efficiency.

Current technological trends in photocatalytic disinfection focus on several key areas: extending light absorption into the visible spectrum, enhancing charge separation and transfer, improving catalyst stability, and developing scalable manufacturing processes. The integration of nanotechnology has been particularly influential, enabling precise control over catalyst morphology, composition, and surface properties.

The primary goals of photocatalytic disinfection technology development include achieving broad-spectrum antimicrobial activity against bacteria, viruses, fungi, and protozoa; demonstrating efficacy under real-world conditions including variable water quality and low light intensity; minimizing energy inputs through solar activation; ensuring long-term catalyst stability; and developing cost-effective, scalable manufacturing processes.

Recent research has increasingly focused on addressing emerging contaminants and pathogens of concern, including antibiotic-resistant bacteria, biofilm communities, and waterborne viruses. The COVID-19 pandemic has further accelerated interest in advanced disinfection technologies for both water and air treatment applications, highlighting the potential societal impact of innovations in this field.

The fundamental principle of photocatalysis involves the activation of a semiconductor material by photons with energy equal to or greater than its band gap. This activation generates electron-hole pairs that can participate in redox reactions with adsorbed species on the catalyst surface. In the context of disinfection, these reactive species can effectively damage cellular components of microorganisms, leading to their inactivation or death.

Traditional disinfection methods such as chlorination, ozonation, and UV irradiation have limitations including the formation of harmful disinfection by-products, high energy consumption, and limited efficacy against certain pathogens. Photocatalytic disinfection offers a potentially more sustainable alternative that can operate under ambient conditions with reduced chemical inputs and energy requirements.

The evolution of photocatalytic materials has progressed from simple TiO₂-based systems to more complex architectures including doped semiconductors, heterojunctions, plasmonic nanostructures, and Z-scheme systems. Each advancement has aimed to address key limitations such as limited visible light absorption, rapid charge carrier recombination, and insufficient quantum efficiency.

Current technological trends in photocatalytic disinfection focus on several key areas: extending light absorption into the visible spectrum, enhancing charge separation and transfer, improving catalyst stability, and developing scalable manufacturing processes. The integration of nanotechnology has been particularly influential, enabling precise control over catalyst morphology, composition, and surface properties.

The primary goals of photocatalytic disinfection technology development include achieving broad-spectrum antimicrobial activity against bacteria, viruses, fungi, and protozoa; demonstrating efficacy under real-world conditions including variable water quality and low light intensity; minimizing energy inputs through solar activation; ensuring long-term catalyst stability; and developing cost-effective, scalable manufacturing processes.

Recent research has increasingly focused on addressing emerging contaminants and pathogens of concern, including antibiotic-resistant bacteria, biofilm communities, and waterborne viruses. The COVID-19 pandemic has further accelerated interest in advanced disinfection technologies for both water and air treatment applications, highlighting the potential societal impact of innovations in this field.

Market Demand for Advanced Disinfection Technologies

The global market for advanced disinfection technologies has witnessed substantial growth in recent years, driven by increasing concerns about infectious diseases, healthcare-associated infections, and the emergence of antibiotic-resistant pathogens. Photocatalytic disinfection, as an environmentally friendly and chemical-free approach, is positioned to capture a significant portion of this expanding market.

Healthcare facilities represent the largest demand segment, with hospitals, clinics, and long-term care facilities seeking effective solutions to combat pathogens like MRSA, C. difficile, and various viruses. The COVID-19 pandemic has dramatically accelerated this demand, creating a heightened awareness of the importance of effective disinfection technologies beyond traditional chemical methods.

Water treatment applications constitute another major market driver, particularly in regions facing water scarcity and contamination issues. Municipal water treatment plants, industrial facilities, and point-of-use water purification systems are increasingly exploring photocatalytic technologies as alternatives to chlorination and other chemical treatments that can produce harmful byproducts.

The food and beverage industry presents a growing application area, where photocatalytic disinfection offers advantages for surface sanitization and air purification in processing facilities without chemical residues that might contaminate products. Market research indicates that this sector's demand is growing at approximately double the rate of traditional disinfection methods.

Consumer markets are also expanding rapidly, with air purifiers, self-cleaning surfaces, and portable water disinfection devices incorporating photocatalytic technology gaining traction. This trend is particularly strong in Asia-Pacific markets, where air quality concerns and limited access to clean water drive consumer adoption.

Regulatory trends further support market growth, as environmental protection agencies worldwide implement stricter regulations on chemical disinfectants and their byproducts. Simultaneously, healthcare accreditation bodies are establishing more rigorous standards for infection control, creating institutional demand for advanced disinfection solutions.

Economic factors also favor photocatalytic technologies, as operational cost analyses demonstrate long-term savings compared to chemical disinfection methods, despite higher initial investment. The reduced need for consumables, lower labor requirements, and minimal waste generation contribute to favorable total cost of ownership calculations that appeal to institutional buyers.

Market forecasts project the global photocatalytic disinfection market to grow substantially over the next decade, with particularly strong adoption in healthcare, water treatment, and consumer applications. This growth trajectory is supported by increasing research funding, corporate investments, and government initiatives focused on sustainable disinfection technologies.

Healthcare facilities represent the largest demand segment, with hospitals, clinics, and long-term care facilities seeking effective solutions to combat pathogens like MRSA, C. difficile, and various viruses. The COVID-19 pandemic has dramatically accelerated this demand, creating a heightened awareness of the importance of effective disinfection technologies beyond traditional chemical methods.

Water treatment applications constitute another major market driver, particularly in regions facing water scarcity and contamination issues. Municipal water treatment plants, industrial facilities, and point-of-use water purification systems are increasingly exploring photocatalytic technologies as alternatives to chlorination and other chemical treatments that can produce harmful byproducts.

The food and beverage industry presents a growing application area, where photocatalytic disinfection offers advantages for surface sanitization and air purification in processing facilities without chemical residues that might contaminate products. Market research indicates that this sector's demand is growing at approximately double the rate of traditional disinfection methods.

Consumer markets are also expanding rapidly, with air purifiers, self-cleaning surfaces, and portable water disinfection devices incorporating photocatalytic technology gaining traction. This trend is particularly strong in Asia-Pacific markets, where air quality concerns and limited access to clean water drive consumer adoption.

Regulatory trends further support market growth, as environmental protection agencies worldwide implement stricter regulations on chemical disinfectants and their byproducts. Simultaneously, healthcare accreditation bodies are establishing more rigorous standards for infection control, creating institutional demand for advanced disinfection solutions.

Economic factors also favor photocatalytic technologies, as operational cost analyses demonstrate long-term savings compared to chemical disinfection methods, despite higher initial investment. The reduced need for consumables, lower labor requirements, and minimal waste generation contribute to favorable total cost of ownership calculations that appeal to institutional buyers.

Market forecasts project the global photocatalytic disinfection market to grow substantially over the next decade, with particularly strong adoption in healthcare, water treatment, and consumer applications. This growth trajectory is supported by increasing research funding, corporate investments, and government initiatives focused on sustainable disinfection technologies.

Current Photocatalytic Materials and Technical Challenges

Photocatalytic disinfection technology has evolved significantly over the past decades, with various materials being developed and optimized for water and air purification applications. Currently, titanium dioxide (TiO2) remains the most widely used photocatalyst due to its chemical stability, non-toxicity, and relatively low cost. TiO2 exists in three crystalline forms: anatase, rutile, and brookite, with anatase generally showing the highest photocatalytic activity for disinfection purposes.

Despite its prevalence, TiO2 faces significant limitations, primarily its wide bandgap (3.2 eV for anatase), which restricts its activation to UV light that constitutes only about 5% of solar radiation. This limitation severely hampers the practical application of TiO2-based systems in real-world settings where artificial UV sources are impractical or cost-prohibitive.

Zinc oxide (ZnO) represents another important photocatalytic material with similar bandgap characteristics to TiO2 but offers higher electron mobility. However, ZnO suffers from photocorrosion in aqueous environments, limiting its long-term stability for water disinfection applications. This degradation significantly reduces its practical utility despite promising initial performance metrics.

Recent advances have focused on visible-light-responsive materials such as bismuth-based compounds (Bi2WO6, BiVO4), cadmium sulfide (CdS), and carbon nitride (g-C3N4). These materials can utilize a broader spectrum of solar radiation, potentially increasing disinfection efficiency under natural light conditions. However, many of these alternatives present their own challenges, including lower quantum efficiency, potential toxicity concerns, or insufficient stability.

Composite photocatalysts and heterojunctions have emerged as promising solutions to overcome the limitations of single-material systems. By combining different semiconductors with complementary band structures, researchers have achieved enhanced charge separation, extended light absorption ranges, and improved photocatalytic performance. Notable examples include TiO2/g-C3N4, Ag/AgBr/TiO2, and ZnO/CdS composites.

Doping represents another significant approach to enhancing photocatalytic materials. Metal doping (using elements such as Fe, Cu, Ag) and non-metal doping (N, S, C) have been extensively investigated to narrow the bandgap of wide-bandgap semiconductors and improve visible light absorption. However, optimal doping concentrations remain challenging to determine, as excessive dopants can act as recombination centers, reducing overall efficiency.

A critical technical challenge facing the field is the trade-off between visible light activation and redox potential. As the bandgap narrows to absorb visible light, the oxidative power of photogenerated holes often decreases, potentially reducing disinfection efficacy. Additionally, most laboratory studies report high disinfection rates under idealized conditions that poorly translate to real-world applications with complex water matrices or variable light conditions.

Despite its prevalence, TiO2 faces significant limitations, primarily its wide bandgap (3.2 eV for anatase), which restricts its activation to UV light that constitutes only about 5% of solar radiation. This limitation severely hampers the practical application of TiO2-based systems in real-world settings where artificial UV sources are impractical or cost-prohibitive.

Zinc oxide (ZnO) represents another important photocatalytic material with similar bandgap characteristics to TiO2 but offers higher electron mobility. However, ZnO suffers from photocorrosion in aqueous environments, limiting its long-term stability for water disinfection applications. This degradation significantly reduces its practical utility despite promising initial performance metrics.

Recent advances have focused on visible-light-responsive materials such as bismuth-based compounds (Bi2WO6, BiVO4), cadmium sulfide (CdS), and carbon nitride (g-C3N4). These materials can utilize a broader spectrum of solar radiation, potentially increasing disinfection efficiency under natural light conditions. However, many of these alternatives present their own challenges, including lower quantum efficiency, potential toxicity concerns, or insufficient stability.

Composite photocatalysts and heterojunctions have emerged as promising solutions to overcome the limitations of single-material systems. By combining different semiconductors with complementary band structures, researchers have achieved enhanced charge separation, extended light absorption ranges, and improved photocatalytic performance. Notable examples include TiO2/g-C3N4, Ag/AgBr/TiO2, and ZnO/CdS composites.

Doping represents another significant approach to enhancing photocatalytic materials. Metal doping (using elements such as Fe, Cu, Ag) and non-metal doping (N, S, C) have been extensively investigated to narrow the bandgap of wide-bandgap semiconductors and improve visible light absorption. However, optimal doping concentrations remain challenging to determine, as excessive dopants can act as recombination centers, reducing overall efficiency.

A critical technical challenge facing the field is the trade-off between visible light activation and redox potential. As the bandgap narrows to absorb visible light, the oxidative power of photogenerated holes often decreases, potentially reducing disinfection efficacy. Additionally, most laboratory studies report high disinfection rates under idealized conditions that poorly translate to real-world applications with complex water matrices or variable light conditions.

Current Photocatalytic Disinfection Solutions

01 Photocatalytic materials for disinfection

Various photocatalytic materials can be used for disinfection purposes, with titanium dioxide (TiO2) being the most common. These materials generate reactive oxygen species when exposed to light, which can effectively kill bacteria, viruses, and other pathogens. The efficiency of photocatalytic disinfection depends on the properties of the photocatalyst, such as particle size, crystal structure, and surface area. Modified photocatalysts with enhanced visible light activity have been developed to improve disinfection efficiency.- Photocatalytic materials for disinfection: Various photocatalytic materials can be used for disinfection purposes. These materials, when activated by light, generate reactive oxygen species that can kill microorganisms. Common photocatalytic materials include titanium dioxide (TiO2), zinc oxide (ZnO), and other metal oxides. The efficiency of these materials depends on their composition, crystalline structure, and surface area.

- Light source optimization for photocatalytic disinfection: The efficiency of photocatalytic disinfection is significantly influenced by the light source used. UV light, particularly UV-A and UV-C, is commonly employed to activate photocatalysts. Recent developments include the use of visible light-responsive photocatalysts, LED technology, and solar light applications. The wavelength, intensity, and exposure time of the light source directly impact the disinfection efficiency.

- Reactor design for enhanced photocatalytic disinfection: The design of photocatalytic reactors plays a crucial role in disinfection efficiency. Factors such as reactor geometry, flow patterns, contact time, and light distribution affect the overall performance. Advanced reactor designs incorporate features like immobilized photocatalysts, fluidized beds, and optimized light penetration to maximize the interaction between light, photocatalyst, and target microorganisms.

- Doping and modification of photocatalysts: Enhancing photocatalytic disinfection efficiency can be achieved through doping and modification of photocatalysts. Techniques include metal and non-metal doping, composite formation, and surface modification. These modifications can extend the light absorption range, reduce electron-hole recombination, and increase the generation of reactive oxygen species, leading to improved disinfection performance.

- Application-specific photocatalytic disinfection systems: Photocatalytic disinfection systems can be tailored for specific applications such as water treatment, air purification, surface sterilization, and medical device disinfection. Each application requires optimized parameters including photocatalyst selection, light source, contact time, and system configuration. The efficiency of these systems is evaluated based on microbial reduction rates, energy consumption, and operational stability under the specific conditions of the intended application.

02 Light sources and irradiation conditions

The efficiency of photocatalytic disinfection is significantly influenced by the light source and irradiation conditions. UV light is traditionally used to activate photocatalysts, but recent developments have focused on utilizing visible light for improved efficiency and practicality. Factors such as light intensity, wavelength, and exposure time directly impact the disinfection efficiency. Optimized irradiation conditions can enhance the generation of reactive species and improve the overall disinfection performance.Expand Specific Solutions03 Reactor design and system configuration

The design of photocatalytic reactors plays a crucial role in determining disinfection efficiency. Various reactor configurations have been developed, including fixed-bed reactors, slurry reactors, and membrane reactors. Key design parameters include contact time between the photocatalyst and contaminants, light distribution within the reactor, and flow patterns. Advanced reactor designs incorporate features such as enhanced mixing, optimized light penetration, and improved catalyst immobilization techniques to maximize disinfection efficiency.Expand Specific Solutions04 Enhancement techniques for photocatalytic disinfection

Various enhancement techniques have been developed to improve photocatalytic disinfection efficiency. These include doping of photocatalysts with metals or non-metals to extend light absorption range, coupling with other materials to reduce electron-hole recombination, and surface modification to improve adsorption of target contaminants. Additionally, combining photocatalysis with other disinfection methods such as ozonation or ultrasound can create synergistic effects that significantly enhance overall disinfection efficiency.Expand Specific Solutions05 Applications and performance evaluation

Photocatalytic disinfection has been applied in various fields including water treatment, air purification, surface sterilization, and medical device disinfection. The efficiency of photocatalytic disinfection systems is evaluated through parameters such as disinfection rate, energy consumption, catalyst stability, and operational costs. Standardized testing methods have been developed to assess the performance of different photocatalytic systems under comparable conditions. Real-world applications demonstrate the practical effectiveness of photocatalytic disinfection in reducing pathogen loads in various environments.Expand Specific Solutions

Leading Research Groups and Commercial Entities

Photocatalytic disinfection technology is currently in a growth phase, with the market expanding due to increasing demand for advanced water and air purification solutions. The global market size is estimated to reach $3.5 billion by 2027, growing at a CAGR of 8.2%. Technologically, the field is advancing rapidly with varying maturity levels across applications. Leading players like LG Electronics and Panasonic Holdings are commercializing consumer-oriented solutions, while research institutions such as Rutgers University and Korea Research Institute of Bioscience & Biotechnology are driving fundamental innovations. Companies like Exposome Pvt Ltd and Signify Holding are developing specialized applications for industrial settings. Shandong Xingqiang Chemical and Shanghai Weikai Chemicals are advancing catalyst formulations, while BSH Hausgeräte and COWAY are integrating the technology into household appliances, demonstrating the technology's cross-sector potential.

COWAY Co., Ltd.

Technical Solution: COWAY has developed an innovative photocatalytic disinfection technology branded as "NOBLE" (Nano Organic Bio-Light Emitting) system. Their approach utilizes a composite photocatalyst consisting of nitrogen-doped titanium dioxide combined with copper oxide nanoparticles that demonstrate enhanced visible light activity and antimicrobial properties. The catalyst is applied as a nanometer-thick coating on specialized filter media within their air and water purification systems. COWAY's technology achieves disinfection through the generation of reactive oxygen species (primarily hydroxyl radicals and superoxide) that effectively break down microbial cell membranes and denature proteins. Their latest generation catalysts incorporate carbon quantum dots as photosensitizers, extending light absorption into the visible spectrum (400-550nm) and improving quantum efficiency by approximately 35% compared to conventional TiO2. Independent testing has verified 99.9% reduction of E. coli and S. aureus within 60 minutes of operation under standard indoor lighting conditions. The technology maintains effectiveness for approximately 6,000 hours of continuous operation before requiring replacement.

Strengths: Dual functionality in both air and water purification applications; operates effectively under standard indoor lighting; relatively low manufacturing costs; minimal energy requirements. Weaknesses: Slower disinfection rate compared to UV-based systems; catalyst performance degrades with exposure to certain common household chemicals; effectiveness reduced in high-humidity environments; requires periodic replacement of catalyst media.

Signify Holding BV

Technical Solution: Signify (formerly Philips Lighting) has pioneered UV-C based photocatalytic disinfection systems that combine precisely engineered light sources with advanced catalyst materials. Their technology utilizes specially designed TiO2-based photocatalysts with noble metal (primarily silver and platinum) nanoparticle doping to enhance electron-hole separation and extend the catalyst lifetime. Signify's systems achieve disinfection through a dual-action approach: direct UV-C germicidal irradiation combined with photocatalytic oxidation that generates reactive oxygen species. Their latest innovations include carbon-doped titanium dioxide formulations that show activity under visible light wavelengths (400-700nm), expanding application possibilities. Signify has demonstrated 99.99% inactivation of SARS-CoV-2 within seconds of exposure in laboratory testing. Their systems incorporate reflective chamber designs that maximize light utilization efficiency, achieving up to 30% higher disinfection rates compared to standard configurations while maintaining the same energy input.

Strengths: Extremely rapid disinfection capability; proven efficacy against coronaviruses; established manufacturing infrastructure; comprehensive safety features to prevent human UV exposure. Weaknesses: Higher energy consumption than visible-light systems; requires specialized installation in many cases; catalyst performance degrades over time requiring periodic replacement; initial installation cost higher than competing technologies.

Key Innovations in Catalyst Design and Efficiency

Air purification apparatus

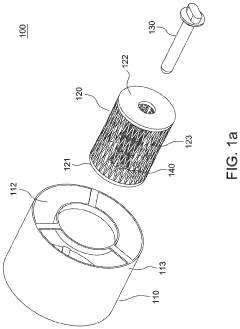

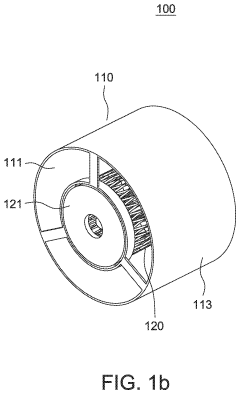

PatentInactiveUS20230064583A1

Innovation

- An air purification apparatus with a porous inner housing and photocatalytic reactors coated with photocatalytic layers, surrounded by a light source to activate the photocatalysts, ensuring optimal airflow interaction and purification.

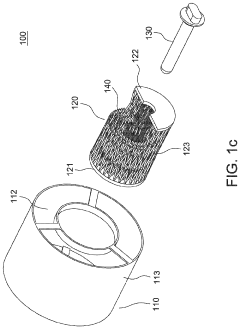

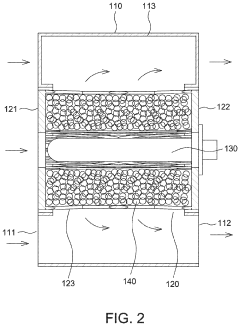

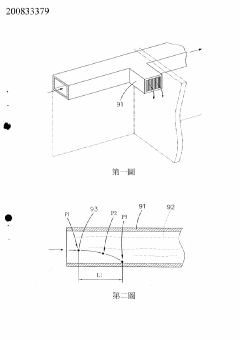

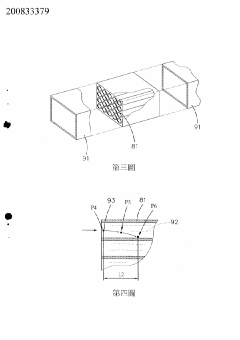

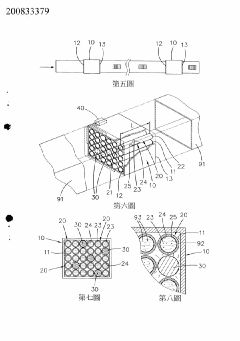

Photocatalyst disinfection device

PatentInactiveTW200833379A

Innovation

- A photocatalyst sterilizing device with tubular ventilation units and ultraviolet light tubes that activate photocatalyst parts to sterilize airborne particles, utilizing gravity, diffusion, interception, and electrostatic attraction, combined with easy maintenance and low cost.

Environmental Impact and Sustainability Considerations

Photocatalytic disinfection technologies offer significant environmental benefits compared to conventional chemical disinfection methods. The process utilizes renewable energy sources, primarily sunlight, to activate catalysts and generate reactive species that neutralize pathogens without introducing persistent chemical residues into treated water or surfaces. This fundamental characteristic positions photocatalytic disinfection as an environmentally sustainable alternative to chlorination and other chemical treatments that can produce harmful disinfection byproducts.

The life cycle assessment of photocatalytic materials reveals favorable environmental profiles, particularly for newer catalyst innovations. Traditional titanium dioxide catalysts require energy-intensive production processes, but recent advancements in low-temperature synthesis methods have substantially reduced the associated carbon footprint. Visible-light responsive catalysts further enhance sustainability by eliminating the need for energy-consuming UV light sources, allowing systems to operate solely on ambient light conditions.

Material sustainability represents another critical dimension of environmental impact. The transition from rare earth elements and precious metals toward earth-abundant materials in catalyst design addresses resource scarcity concerns. Carbon-based photocatalysts derived from waste biomass exemplify circular economy principles, transforming agricultural residues into functional materials while sequestering carbon. Similarly, the development of self-cleaning surfaces with extended operational lifespans minimizes maintenance requirements and resource consumption over time.

Water conservation benefits emerge as photocatalytic systems enable treatment of previously unusable water sources. The technology's ability to degrade recalcitrant organic pollutants alongside pathogen inactivation creates opportunities for wastewater recycling in water-stressed regions. Furthermore, the ambient temperature operation of photocatalytic processes significantly reduces energy requirements compared to thermal disinfection methods, contributing to climate change mitigation efforts.

Toxicity considerations remain paramount in environmental assessment. While photocatalytic materials generally exhibit low toxicity, nanoparticle formulations raise potential ecotoxicological concerns regarding their environmental fate and transport. Recent innovations in immobilized catalyst systems effectively address these issues by preventing nanoparticle release while maintaining disinfection efficacy. Additionally, the development of biodegradable support materials ensures that catalyst systems degrade safely after their useful life.

The scalability of photocatalytic disinfection technologies across diverse geographical and socioeconomic contexts further enhances their sustainability profile. Decentralized, solar-powered systems enable point-of-use water treatment in remote communities lacking infrastructure for conventional disinfection methods, democratizing access to safe water while minimizing environmental footprint.

The life cycle assessment of photocatalytic materials reveals favorable environmental profiles, particularly for newer catalyst innovations. Traditional titanium dioxide catalysts require energy-intensive production processes, but recent advancements in low-temperature synthesis methods have substantially reduced the associated carbon footprint. Visible-light responsive catalysts further enhance sustainability by eliminating the need for energy-consuming UV light sources, allowing systems to operate solely on ambient light conditions.

Material sustainability represents another critical dimension of environmental impact. The transition from rare earth elements and precious metals toward earth-abundant materials in catalyst design addresses resource scarcity concerns. Carbon-based photocatalysts derived from waste biomass exemplify circular economy principles, transforming agricultural residues into functional materials while sequestering carbon. Similarly, the development of self-cleaning surfaces with extended operational lifespans minimizes maintenance requirements and resource consumption over time.

Water conservation benefits emerge as photocatalytic systems enable treatment of previously unusable water sources. The technology's ability to degrade recalcitrant organic pollutants alongside pathogen inactivation creates opportunities for wastewater recycling in water-stressed regions. Furthermore, the ambient temperature operation of photocatalytic processes significantly reduces energy requirements compared to thermal disinfection methods, contributing to climate change mitigation efforts.

Toxicity considerations remain paramount in environmental assessment. While photocatalytic materials generally exhibit low toxicity, nanoparticle formulations raise potential ecotoxicological concerns regarding their environmental fate and transport. Recent innovations in immobilized catalyst systems effectively address these issues by preventing nanoparticle release while maintaining disinfection efficacy. Additionally, the development of biodegradable support materials ensures that catalyst systems degrade safely after their useful life.

The scalability of photocatalytic disinfection technologies across diverse geographical and socioeconomic contexts further enhances their sustainability profile. Decentralized, solar-powered systems enable point-of-use water treatment in remote communities lacking infrastructure for conventional disinfection methods, democratizing access to safe water while minimizing environmental footprint.

Scalability and Industrial Application Potential

The scalability of photocatalytic disinfection technology represents a critical factor in determining its widespread adoption across various industrial sectors. Current laboratory-scale demonstrations have shown promising results, but significant engineering challenges remain in scaling these systems to meet commercial and industrial demands. The transition from bench-scale to industrial-scale applications requires addressing several key factors including reactor design optimization, catalyst production capacity, and process integration with existing water treatment infrastructure.

Industrial application potential is particularly strong in sectors requiring high-volume water disinfection, such as municipal water treatment facilities, where photocatalytic systems could potentially replace or supplement conventional chlorination methods. The pharmaceutical and food processing industries also present substantial opportunities, as these sectors demand water treatment solutions that leave no harmful residues while ensuring complete pathogen elimination.

Economic feasibility analysis indicates that while initial capital investment for large-scale photocatalytic systems remains higher than conventional disinfection methods, the operational costs over time may be significantly lower due to reduced chemical usage and minimal maintenance requirements. Recent advancements in catalyst efficiency and durability have improved the cost-benefit ratio, making industrial implementation increasingly viable.

Manufacturing scalability of advanced photocatalytic materials presents another critical consideration. Current production methods for high-efficiency catalysts often involve complex synthesis procedures that are challenging to scale. However, emerging techniques such as continuous flow synthesis and automated deposition methods show promise for mass production of consistent, high-quality catalytic materials.

Regulatory frameworks will significantly influence adoption rates across different regions. Countries with stringent water quality standards and environmental regulations regarding chemical disinfectants are likely to be early adopters of photocatalytic disinfection technology. The technology's green credentials—minimal chemical inputs and reduced environmental impact—align well with increasingly stringent global environmental policies.

Energy requirements remain a consideration for large-scale implementation, particularly for UV-activated catalysts. Integration with renewable energy sources, such as solar panels to power UV light sources, presents a pathway to enhance sustainability and reduce operational costs. Recent innovations in visible light-responsive catalysts further improve the energy efficiency proposition for industrial applications.

Strategic partnerships between technology developers, equipment manufacturers, and end-users will be essential to overcome implementation barriers and accelerate market penetration. Pilot projects demonstrating real-world performance in industrial settings will be crucial for building confidence among potential adopters and refining system designs for optimal performance at scale.

Industrial application potential is particularly strong in sectors requiring high-volume water disinfection, such as municipal water treatment facilities, where photocatalytic systems could potentially replace or supplement conventional chlorination methods. The pharmaceutical and food processing industries also present substantial opportunities, as these sectors demand water treatment solutions that leave no harmful residues while ensuring complete pathogen elimination.

Economic feasibility analysis indicates that while initial capital investment for large-scale photocatalytic systems remains higher than conventional disinfection methods, the operational costs over time may be significantly lower due to reduced chemical usage and minimal maintenance requirements. Recent advancements in catalyst efficiency and durability have improved the cost-benefit ratio, making industrial implementation increasingly viable.

Manufacturing scalability of advanced photocatalytic materials presents another critical consideration. Current production methods for high-efficiency catalysts often involve complex synthesis procedures that are challenging to scale. However, emerging techniques such as continuous flow synthesis and automated deposition methods show promise for mass production of consistent, high-quality catalytic materials.

Regulatory frameworks will significantly influence adoption rates across different regions. Countries with stringent water quality standards and environmental regulations regarding chemical disinfectants are likely to be early adopters of photocatalytic disinfection technology. The technology's green credentials—minimal chemical inputs and reduced environmental impact—align well with increasingly stringent global environmental policies.

Energy requirements remain a consideration for large-scale implementation, particularly for UV-activated catalysts. Integration with renewable energy sources, such as solar panels to power UV light sources, presents a pathway to enhance sustainability and reduce operational costs. Recent innovations in visible light-responsive catalysts further improve the energy efficiency proposition for industrial applications.

Strategic partnerships between technology developers, equipment manufacturers, and end-users will be essential to overcome implementation barriers and accelerate market penetration. Pilot projects demonstrating real-world performance in industrial settings will be crucial for building confidence among potential adopters and refining system designs for optimal performance at scale.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!