Optimization of Photocatalytic Disinfection Processes for Large-Scale Operations

OCT 21, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Photocatalytic Disinfection Background and Objectives

Photocatalytic disinfection has emerged as a promising advanced oxidation process for water and air treatment since its discovery in the early 1970s. This technology leverages the ability of certain semiconductor materials, most notably titanium dioxide (TiO₂), to generate reactive oxygen species (ROS) when activated by light of appropriate wavelength. These ROS, including hydroxyl radicals (•OH), superoxide anions (O₂⁻), and hydrogen peroxide (H₂O₂), effectively inactivate a wide spectrum of microorganisms by damaging their cell membranes, proteins, and genetic material.

The evolution of photocatalytic disinfection technology has progressed through several distinct phases. Initial research focused primarily on fundamental mechanisms and proof-of-concept laboratory studies. This was followed by the development of enhanced photocatalysts through doping, composite formation, and morphology control to improve visible light activity and quantum efficiency. Recent advancements have concentrated on reactor design optimization and integration with complementary technologies to overcome limitations in large-scale applications.

Current global challenges, including increasing water scarcity, emerging contaminants, antibiotic-resistant pathogens, and the need for sustainable disinfection methods, have intensified interest in scaling up photocatalytic disinfection processes. Unlike conventional disinfection methods such as chlorination, photocatalysis offers advantages including broad-spectrum antimicrobial activity, minimal harmful disinfection by-products, and potential for solar activation, making it particularly attractive for sustainable water treatment.

Despite these advantages, the transition from laboratory-scale success to large-scale implementation faces significant hurdles. These include limited light penetration in turbid water, catalyst recovery challenges, insufficient quantum efficiency under visible light, and reactor design constraints that impede treatment of large water volumes efficiently. The optimization of photocatalytic disinfection for large-scale operations thus represents a critical technological frontier.

The primary objectives of this technical research are to comprehensively evaluate current photocatalytic disinfection technologies, identify key bottlenecks limiting large-scale implementation, and explore innovative approaches to overcome these limitations. Specifically, we aim to investigate advanced reactor designs that maximize light utilization efficiency, develop strategies for effective catalyst immobilization and recovery, explore novel photocatalyst formulations with enhanced visible light activity, and establish standardized protocols for performance evaluation under realistic operational conditions.

Additionally, this research seeks to assess the economic feasibility and environmental sustainability of scaled-up photocatalytic disinfection systems compared to conventional alternatives, providing a roadmap for industrial adoption. The ultimate goal is to facilitate the transition of photocatalytic disinfection from a promising laboratory technology to a viable solution for large-scale water and air treatment applications across diverse settings, from municipal water treatment facilities to point-of-use systems in resource-limited environments.

The evolution of photocatalytic disinfection technology has progressed through several distinct phases. Initial research focused primarily on fundamental mechanisms and proof-of-concept laboratory studies. This was followed by the development of enhanced photocatalysts through doping, composite formation, and morphology control to improve visible light activity and quantum efficiency. Recent advancements have concentrated on reactor design optimization and integration with complementary technologies to overcome limitations in large-scale applications.

Current global challenges, including increasing water scarcity, emerging contaminants, antibiotic-resistant pathogens, and the need for sustainable disinfection methods, have intensified interest in scaling up photocatalytic disinfection processes. Unlike conventional disinfection methods such as chlorination, photocatalysis offers advantages including broad-spectrum antimicrobial activity, minimal harmful disinfection by-products, and potential for solar activation, making it particularly attractive for sustainable water treatment.

Despite these advantages, the transition from laboratory-scale success to large-scale implementation faces significant hurdles. These include limited light penetration in turbid water, catalyst recovery challenges, insufficient quantum efficiency under visible light, and reactor design constraints that impede treatment of large water volumes efficiently. The optimization of photocatalytic disinfection for large-scale operations thus represents a critical technological frontier.

The primary objectives of this technical research are to comprehensively evaluate current photocatalytic disinfection technologies, identify key bottlenecks limiting large-scale implementation, and explore innovative approaches to overcome these limitations. Specifically, we aim to investigate advanced reactor designs that maximize light utilization efficiency, develop strategies for effective catalyst immobilization and recovery, explore novel photocatalyst formulations with enhanced visible light activity, and establish standardized protocols for performance evaluation under realistic operational conditions.

Additionally, this research seeks to assess the economic feasibility and environmental sustainability of scaled-up photocatalytic disinfection systems compared to conventional alternatives, providing a roadmap for industrial adoption. The ultimate goal is to facilitate the transition of photocatalytic disinfection from a promising laboratory technology to a viable solution for large-scale water and air treatment applications across diverse settings, from municipal water treatment facilities to point-of-use systems in resource-limited environments.

Market Analysis for Large-Scale Disinfection Solutions

The global market for large-scale disinfection solutions has experienced significant growth in recent years, driven by increasing concerns about public health, water safety, and environmental protection. The photocatalytic disinfection sector represents a particularly promising segment within this broader market, with an estimated market value exceeding $3.5 billion in 2022 and projected to reach $6.2 billion by 2028, growing at a CAGR of 9.8%.

Healthcare facilities constitute the largest end-user segment, accounting for approximately 32% of the market share. This dominance stems from the critical need for effective, large-scale disinfection solutions in hospitals, clinics, and other healthcare settings to prevent healthcare-associated infections. Municipal water treatment facilities follow closely, representing about 28% of the market, as governments worldwide invest in upgrading water infrastructure to ensure safe drinking water supplies.

The industrial sector, particularly food and beverage processing, pharmaceutical manufacturing, and electronics production, collectively accounts for 25% of the market. These industries require stringent disinfection protocols to maintain product quality and safety. The remaining market share is distributed among commercial buildings, educational institutions, and other applications.

Regionally, North America leads the market with a 35% share, followed by Europe (30%), Asia-Pacific (25%), and the rest of the world (10%). However, the Asia-Pacific region is experiencing the fastest growth rate, driven by rapid industrialization, urbanization, and increasing government investments in water treatment infrastructure in countries like China and India.

Market demand for photocatalytic disinfection solutions is being shaped by several key factors. Stringent regulations regarding water quality and disinfection standards are compelling organizations to adopt more effective and environmentally friendly disinfection methods. The growing awareness of the limitations of traditional chemical disinfectants, including concerns about disinfection by-products and antimicrobial resistance, is driving interest in alternative technologies like photocatalysis.

Cost considerations remain a significant factor influencing market adoption. While the initial capital investment for photocatalytic systems is higher than conventional disinfection methods, the long-term operational costs can be lower due to reduced chemical usage and maintenance requirements. This total cost of ownership perspective is gradually shifting market preferences toward photocatalytic solutions, particularly for large-scale operations where economies of scale can be achieved.

Customer requirements are increasingly focused on disinfection solutions that offer high efficacy against a broad spectrum of pathogens, operational reliability, ease of integration with existing infrastructure, and minimal environmental impact. These evolving demands are shaping product development strategies among market players and creating opportunities for innovative solutions that can address multiple customer pain points simultaneously.

Healthcare facilities constitute the largest end-user segment, accounting for approximately 32% of the market share. This dominance stems from the critical need for effective, large-scale disinfection solutions in hospitals, clinics, and other healthcare settings to prevent healthcare-associated infections. Municipal water treatment facilities follow closely, representing about 28% of the market, as governments worldwide invest in upgrading water infrastructure to ensure safe drinking water supplies.

The industrial sector, particularly food and beverage processing, pharmaceutical manufacturing, and electronics production, collectively accounts for 25% of the market. These industries require stringent disinfection protocols to maintain product quality and safety. The remaining market share is distributed among commercial buildings, educational institutions, and other applications.

Regionally, North America leads the market with a 35% share, followed by Europe (30%), Asia-Pacific (25%), and the rest of the world (10%). However, the Asia-Pacific region is experiencing the fastest growth rate, driven by rapid industrialization, urbanization, and increasing government investments in water treatment infrastructure in countries like China and India.

Market demand for photocatalytic disinfection solutions is being shaped by several key factors. Stringent regulations regarding water quality and disinfection standards are compelling organizations to adopt more effective and environmentally friendly disinfection methods. The growing awareness of the limitations of traditional chemical disinfectants, including concerns about disinfection by-products and antimicrobial resistance, is driving interest in alternative technologies like photocatalysis.

Cost considerations remain a significant factor influencing market adoption. While the initial capital investment for photocatalytic systems is higher than conventional disinfection methods, the long-term operational costs can be lower due to reduced chemical usage and maintenance requirements. This total cost of ownership perspective is gradually shifting market preferences toward photocatalytic solutions, particularly for large-scale operations where economies of scale can be achieved.

Customer requirements are increasingly focused on disinfection solutions that offer high efficacy against a broad spectrum of pathogens, operational reliability, ease of integration with existing infrastructure, and minimal environmental impact. These evolving demands are shaping product development strategies among market players and creating opportunities for innovative solutions that can address multiple customer pain points simultaneously.

Current Challenges in Scaling Photocatalytic Technologies

Despite the promising potential of photocatalytic disinfection technologies, scaling these processes from laboratory to industrial applications presents significant challenges. The transition to large-scale operations is hindered by several technical limitations that require innovative solutions. One primary obstacle is the reactor design optimization for large volumes, as most successful demonstrations have been limited to bench-scale or small pilot systems. Current large-scale reactor configurations struggle with maintaining uniform light distribution throughout the reaction medium, resulting in inefficient photocatalyst activation and inconsistent disinfection performance.

Material constraints represent another critical challenge. While titanium dioxide (TiO₂) remains the most widely used photocatalyst due to its stability and effectiveness, its practical application in large systems is limited by recovery difficulties after treatment. Immobilization techniques on various substrates often lead to reduced active surface area and consequently lower disinfection efficiency compared to suspended systems. Additionally, catalyst deactivation occurs more rapidly in real-world conditions due to fouling from organic matter and mineral deposits present in complex water matrices.

Energy consumption poses a substantial barrier to commercial viability. Conventional UV light sources required for activating most photocatalysts consume significant electricity, making operational costs prohibitively high for continuous large-scale disinfection. Although visible light-responsive photocatalysts have been developed, their disinfection efficiency remains substantially lower than UV-activated materials, creating a challenging efficiency-cost tradeoff.

Water quality variability in real-world applications significantly impacts performance. Turbidity, dissolved organic matter, and competing ions can interfere with the photocatalytic process by light scattering, radical scavenging, and catalyst surface occupation. These factors are difficult to control in large-scale operations and vary considerably across different water sources and seasons.

Process control and monitoring systems for large-scale photocatalytic disinfection remain underdeveloped. Current technologies lack robust real-time monitoring capabilities for disinfection efficiency and photocatalyst activity, making it challenging to optimize operational parameters dynamically. This limitation becomes particularly problematic when dealing with fluctuating influent characteristics common in municipal or industrial water treatment scenarios.

Regulatory frameworks and standardization issues further complicate implementation. The absence of standardized testing protocols and performance metrics specifically for photocatalytic disinfection technologies creates uncertainty for technology adopters and regulators alike. Without clear compliance guidelines, large-scale adoption faces additional institutional barriers beyond technical challenges.

Material constraints represent another critical challenge. While titanium dioxide (TiO₂) remains the most widely used photocatalyst due to its stability and effectiveness, its practical application in large systems is limited by recovery difficulties after treatment. Immobilization techniques on various substrates often lead to reduced active surface area and consequently lower disinfection efficiency compared to suspended systems. Additionally, catalyst deactivation occurs more rapidly in real-world conditions due to fouling from organic matter and mineral deposits present in complex water matrices.

Energy consumption poses a substantial barrier to commercial viability. Conventional UV light sources required for activating most photocatalysts consume significant electricity, making operational costs prohibitively high for continuous large-scale disinfection. Although visible light-responsive photocatalysts have been developed, their disinfection efficiency remains substantially lower than UV-activated materials, creating a challenging efficiency-cost tradeoff.

Water quality variability in real-world applications significantly impacts performance. Turbidity, dissolved organic matter, and competing ions can interfere with the photocatalytic process by light scattering, radical scavenging, and catalyst surface occupation. These factors are difficult to control in large-scale operations and vary considerably across different water sources and seasons.

Process control and monitoring systems for large-scale photocatalytic disinfection remain underdeveloped. Current technologies lack robust real-time monitoring capabilities for disinfection efficiency and photocatalyst activity, making it challenging to optimize operational parameters dynamically. This limitation becomes particularly problematic when dealing with fluctuating influent characteristics common in municipal or industrial water treatment scenarios.

Regulatory frameworks and standardization issues further complicate implementation. The absence of standardized testing protocols and performance metrics specifically for photocatalytic disinfection technologies creates uncertainty for technology adopters and regulators alike. Without clear compliance guidelines, large-scale adoption faces additional institutional barriers beyond technical challenges.

Current Scale-Up Approaches and Engineering Solutions

01 Photocatalyst material selection and modification

The selection and modification of photocatalyst materials significantly impact disinfection efficiency. Various materials such as titanium dioxide (TiO2), zinc oxide, and composite photocatalysts can be optimized through doping, surface modification, or creating heterojunctions to enhance their photocatalytic activity. These modifications can improve light absorption range, reduce electron-hole recombination rates, and increase quantum efficiency, resulting in more effective microbial inactivation under various light conditions.- Photocatalyst material selection and modification: The selection and modification of photocatalyst materials significantly impact disinfection efficiency. Various materials such as titanium dioxide (TiO2), zinc oxide, and composite photocatalysts can be optimized through doping, surface modification, or combining with other materials to enhance their photocatalytic activity. These modifications can improve light absorption range, reduce electron-hole recombination rates, and increase overall disinfection performance under various light conditions.

- Reactor design and configuration optimization: The design and configuration of photocatalytic reactors play a crucial role in disinfection efficiency. Factors such as reactor geometry, light distribution, contact time, and flow patterns significantly affect the performance of photocatalytic disinfection processes. Optimized reactor designs can enhance mass transfer, increase surface area for photocatalytic reactions, and ensure uniform light distribution, resulting in improved disinfection efficiency and reduced energy consumption.

- Light source and irradiation parameters: The optimization of light sources and irradiation parameters is essential for efficient photocatalytic disinfection. Parameters such as light intensity, wavelength, and exposure time significantly influence the activation of photocatalysts and subsequent disinfection efficiency. Various light sources including UV lamps, solar light, and LED systems can be optimized to match the absorption spectrum of the photocatalyst, enhancing the generation of reactive oxygen species responsible for microbial inactivation.

- Process parameter optimization and control systems: Optimization of operational parameters such as pH, temperature, dissolved oxygen, and pollutant concentration is critical for effective photocatalytic disinfection. Advanced control systems incorporating sensors, real-time monitoring, and automated adjustment mechanisms can maintain optimal conditions throughout the disinfection process. Mathematical modeling and algorithm-based control strategies help predict and maintain ideal operating conditions, resulting in enhanced disinfection efficiency and reduced operational costs.

- Integration with complementary technologies: Combining photocatalytic disinfection with complementary technologies can significantly enhance overall performance. Integration with methods such as membrane filtration, ozonation, ultrasound, or electrochemical processes creates synergistic effects that overcome limitations of individual technologies. These hybrid systems can address a broader spectrum of contaminants, reduce treatment time, lower energy consumption, and provide more robust disinfection solutions for various water and air treatment applications.

02 Reactor design and configuration optimization

The design and configuration of photocatalytic reactors play a crucial role in disinfection efficiency. Factors such as reactor geometry, light distribution, catalyst immobilization methods, and flow dynamics can be optimized to enhance treatment performance. Advanced reactor designs may incorporate features like improved light penetration, efficient catalyst distribution, and optimized hydraulic retention time to maximize contact between contaminants, photocatalyst surfaces, and light irradiation.Expand Specific Solutions03 Process parameter optimization

Operational parameters significantly influence photocatalytic disinfection efficiency. Key parameters include light intensity and wavelength, pH level, temperature, dissolved oxygen concentration, catalyst loading, and contact time. Systematic optimization of these parameters through experimental design approaches can substantially improve disinfection performance while minimizing energy consumption and treatment costs. The interrelationships between these parameters often require multivariate optimization to achieve maximum efficiency.Expand Specific Solutions04 Integration with complementary technologies

Combining photocatalytic disinfection with complementary treatment technologies can create synergistic effects that enhance overall performance. Integration approaches include coupling with membrane filtration, ozonation, ultrasonication, electrochemical processes, or biological treatment methods. These hybrid systems can overcome limitations of individual technologies, improve treatment efficiency, reduce energy consumption, and broaden the range of treatable contaminants and pathogens.Expand Specific Solutions05 Real-time monitoring and control systems

Implementation of advanced monitoring and control systems enables real-time optimization of photocatalytic disinfection processes. These systems may incorporate sensors for measuring key parameters such as UV intensity, water quality, microbial counts, and photocatalyst activity. Machine learning algorithms and predictive models can be employed to dynamically adjust operational parameters based on influent characteristics and treatment objectives, ensuring consistent disinfection performance while minimizing resource consumption.Expand Specific Solutions

Leading Companies and Research Institutions in Photocatalysis

Photocatalytic disinfection technology is currently in a growth phase, with the market expanding due to increasing demand for sustainable water treatment solutions. The global market size is estimated to reach $3-4 billion by 2027, growing at a CAGR of approximately 8-10%. From a technical maturity perspective, the field shows varying levels of development across key players. Academic institutions like University of Florida, Fudan University, and Hunan University are advancing fundamental research, while companies such as Molekule, FUJIFILM, and Siemens AG are commercializing applications. Janssen Pharmaceutica and Fresenius Medical Care are integrating these technologies into healthcare applications. The primary challenge remains scaling laboratory successes to large-scale operations, with most technologies at TRL 6-8, requiring further optimization for industrial implementation.

Guangdong University of Technology

Technical Solution: Guangdong University of Technology has pioneered scalable photocatalytic disinfection systems utilizing bismuth-based semiconductor materials that demonstrate superior visible light activity compared to traditional TiO2. Their research has focused on developing Bi2WO6/g-C3N4 composite photocatalysts that achieve enhanced charge separation and extended carrier lifetime, critical factors for large-scale efficiency. The university has engineered modular reactor designs specifically for industrial wastewater treatment facilities, featuring optimized light penetration depths and hydraulic retention times. Their technology incorporates real-time monitoring systems with feedback control mechanisms to adjust operational parameters based on influent water quality and flow rates. Additionally, they've developed specialized catalyst immobilization techniques on 3D-printed supports that maintain high surface area while enabling efficient catalyst recovery in continuous flow operations.

Strengths: Exceptional visible light utilization through bismuth-based materials; modular design allowing for flexible scaling; sophisticated monitoring and control systems. Weaknesses: Higher material costs for specialized photocatalysts; requires more complex manufacturing processes; potential challenges with long-term stability in certain water matrices.

Fudan University

Technical Solution: Fudan University has developed an innovative approach to large-scale photocatalytic disinfection through their Z-scheme heterojunction photocatalysts. Their technology combines g-C3N4 with BiOBr to create systems with enhanced charge separation efficiency and broader spectrum light utilization. For large-scale applications, they've engineered fixed-bed reactor configurations with optimized light distribution systems using fiber optic technology to deliver uniform irradiation throughout large water volumes. Their process incorporates a unique catalyst regeneration system that extends operational lifetime in continuous flow operations. The university has also developed computational fluid dynamics models that optimize reactor geometry and flow patterns for maximum disinfection efficiency while minimizing energy consumption. Their technology includes specialized surface modification techniques that enhance bacterial adhesion to catalyst surfaces, increasing contact time and disinfection effectiveness in high-throughput systems.

Strengths: Advanced Z-scheme photocatalyst systems with superior charge separation; innovative light delivery systems for large reactors; sophisticated modeling capabilities for process optimization. Weaknesses: Complex manufacturing requirements for specialized catalysts; higher initial capital investment; requires specialized technical expertise for operation and maintenance.

Key Patents and Innovations in Large-Scale Photocatalysis

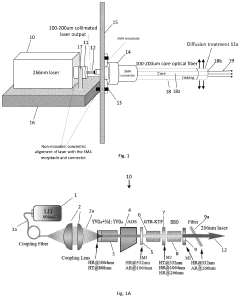

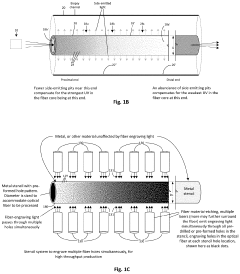

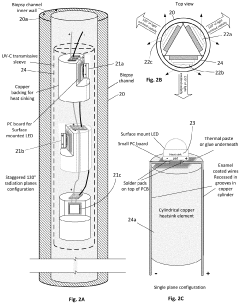

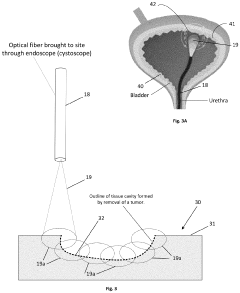

Increased effectiveness of UV pathogen eradication

PatentPendingUS20230310882A1

Innovation

- The use of high-powered UV lasers and LEDs, combined with side-emitting optical fibers and collimated transmission media, to increase the controllable output power and efficiency of UV light disinfection, allowing for deeper penetration and more effective pathogen disruption, along with protocols for enhanced pathogen eradication, including tissue clearing to increase transparency and UV light penetration.

Misting device provided with disinfection means and related disinfection method

PatentWO2010060979A1

Innovation

- Integration of a photocatalysis system within the misting device, utilizing ultraviolet C lamps and titanium dioxide or zinc oxide catalysts to disinfect water and the device itself, producing hydrogen peroxide for disinfection without the need for additional chemicals, and incorporating automated control and management for efficient disinfection.

Environmental Impact and Sustainability Assessment

The environmental impact of large-scale photocatalytic disinfection processes requires comprehensive assessment to ensure sustainable implementation. These systems, while offering effective water treatment solutions, consume significant energy and resources during operation and manufacturing. The primary environmental concern stems from energy usage during continuous operation, particularly for UV light sources that power many photocatalytic systems. This energy footprint varies considerably depending on the light source efficiency, with LED-based systems demonstrating up to 60% lower carbon emissions compared to traditional mercury vapor lamps.

Material sustainability presents another critical consideration, as photocatalysts often incorporate rare earth elements or precious metals like platinum and silver. The extraction and processing of these materials generate substantial environmental burdens, including habitat disruption, water pollution, and greenhouse gas emissions. Recent life cycle assessments indicate that TiO2-based systems generally offer better environmental profiles than more exotic catalyst formulations, though innovations in recovery and recycling technologies are gradually improving the sustainability of all catalyst types.

Water consumption during manufacturing and operational phases must also be evaluated, particularly in water-stressed regions. Advanced photocatalytic systems have demonstrated significant improvements, with newer designs reducing process water requirements by 30-45% compared to first-generation technologies. Additionally, the chemical inputs required for pH adjustment and catalyst activation contribute to the overall environmental footprint through their production, transportation, and potential release into ecosystems.

By-product formation represents a subtle but important environmental consideration. While photocatalytic processes aim to eliminate pathogens, they may generate disinfection by-products (DBPs) through reactions with organic matter. Recent studies have shown that optimized photocatalytic systems produce significantly fewer halogenated DBPs compared to conventional chlorination, though monitoring protocols remain essential for large-scale implementations.

From a sustainability perspective, photocatalytic disinfection offers notable advantages in operational longevity and waste reduction. Well-designed systems can maintain catalyst activity for 3-5 years before requiring regeneration, substantially reducing waste compared to chemical disinfection methods. Furthermore, the modular nature of many photocatalytic systems facilitates component replacement rather than complete system overhaul, enhancing the overall sustainability profile through extended service life and reduced material consumption.

Material sustainability presents another critical consideration, as photocatalysts often incorporate rare earth elements or precious metals like platinum and silver. The extraction and processing of these materials generate substantial environmental burdens, including habitat disruption, water pollution, and greenhouse gas emissions. Recent life cycle assessments indicate that TiO2-based systems generally offer better environmental profiles than more exotic catalyst formulations, though innovations in recovery and recycling technologies are gradually improving the sustainability of all catalyst types.

Water consumption during manufacturing and operational phases must also be evaluated, particularly in water-stressed regions. Advanced photocatalytic systems have demonstrated significant improvements, with newer designs reducing process water requirements by 30-45% compared to first-generation technologies. Additionally, the chemical inputs required for pH adjustment and catalyst activation contribute to the overall environmental footprint through their production, transportation, and potential release into ecosystems.

By-product formation represents a subtle but important environmental consideration. While photocatalytic processes aim to eliminate pathogens, they may generate disinfection by-products (DBPs) through reactions with organic matter. Recent studies have shown that optimized photocatalytic systems produce significantly fewer halogenated DBPs compared to conventional chlorination, though monitoring protocols remain essential for large-scale implementations.

From a sustainability perspective, photocatalytic disinfection offers notable advantages in operational longevity and waste reduction. Well-designed systems can maintain catalyst activity for 3-5 years before requiring regeneration, substantially reducing waste compared to chemical disinfection methods. Furthermore, the modular nature of many photocatalytic systems facilitates component replacement rather than complete system overhaul, enhancing the overall sustainability profile through extended service life and reduced material consumption.

Regulatory Framework for Water Treatment Technologies

The regulatory landscape for water treatment technologies, particularly photocatalytic disinfection processes, is complex and multifaceted across different jurisdictions. In the United States, the Environmental Protection Agency (EPA) establishes standards through the Safe Drinking Water Act (SDWA) and Clean Water Act (CWA), which govern permissible contaminant levels and treatment requirements. Large-scale photocatalytic operations must comply with these regulations, including specific provisions for disinfection byproducts (DBPs) that may form during treatment processes.

The European Union implements the Water Framework Directive (WFD) and Drinking Water Directive, which set comprehensive quality standards and monitoring protocols. These frameworks emphasize a risk-based approach to water safety, requiring regular assessment and reporting of treatment efficacy. For photocatalytic technologies seeking market approval in the EU, demonstration of compliance with these directives is mandatory, including extensive validation of disinfection performance.

International organizations such as the World Health Organization (WHO) provide guidelines that influence regulatory frameworks globally, particularly in developing nations. The WHO Guidelines for Drinking-water Quality establish reference points for microbial, chemical, and radiological parameters that photocatalytic systems must address to be considered effective treatment solutions.

Certification processes represent another critical regulatory component. NSF International and the Water Quality Association offer certification programs that validate treatment technologies against established standards. For large-scale photocatalytic operations, obtaining these certifications can facilitate regulatory approval and market acceptance, though the certification process often requires substantial documentation of performance data across various operating conditions.

Emerging regulations increasingly focus on energy efficiency and sustainability metrics. In many jurisdictions, water treatment facilities must now report energy consumption and carbon footprint, creating additional compliance considerations for photocatalytic systems, which must balance disinfection efficacy with energy requirements. Some regions offer incentives for technologies that demonstrate superior energy performance while maintaining treatment standards.

Regulatory compliance also extends to operational aspects, including operator certification requirements, monitoring protocols, and emergency response planning. Large-scale photocatalytic installations must develop comprehensive standard operating procedures (SOPs) that address these regulatory expectations while ensuring consistent disinfection performance. This includes protocols for system validation, routine monitoring, and performance verification that align with local regulatory frameworks.

The European Union implements the Water Framework Directive (WFD) and Drinking Water Directive, which set comprehensive quality standards and monitoring protocols. These frameworks emphasize a risk-based approach to water safety, requiring regular assessment and reporting of treatment efficacy. For photocatalytic technologies seeking market approval in the EU, demonstration of compliance with these directives is mandatory, including extensive validation of disinfection performance.

International organizations such as the World Health Organization (WHO) provide guidelines that influence regulatory frameworks globally, particularly in developing nations. The WHO Guidelines for Drinking-water Quality establish reference points for microbial, chemical, and radiological parameters that photocatalytic systems must address to be considered effective treatment solutions.

Certification processes represent another critical regulatory component. NSF International and the Water Quality Association offer certification programs that validate treatment technologies against established standards. For large-scale photocatalytic operations, obtaining these certifications can facilitate regulatory approval and market acceptance, though the certification process often requires substantial documentation of performance data across various operating conditions.

Emerging regulations increasingly focus on energy efficiency and sustainability metrics. In many jurisdictions, water treatment facilities must now report energy consumption and carbon footprint, creating additional compliance considerations for photocatalytic systems, which must balance disinfection efficacy with energy requirements. Some regions offer incentives for technologies that demonstrate superior energy performance while maintaining treatment standards.

Regulatory compliance also extends to operational aspects, including operator certification requirements, monitoring protocols, and emergency response planning. Large-scale photocatalytic installations must develop comprehensive standard operating procedures (SOPs) that address these regulatory expectations while ensuring consistent disinfection performance. This includes protocols for system validation, routine monitoring, and performance verification that align with local regulatory frameworks.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!