Applications of lepidolite in nano-material synthesis techniques

AUG 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lepidolite Nano-Synthesis Background and Objectives

Lepidolite, a lithium-rich mica mineral, has emerged as a promising material in the field of nanotechnology, particularly in the synthesis of advanced nanomaterials. The exploration of lepidolite's applications in nano-material synthesis techniques represents a convergence of traditional mineralogy and cutting-edge nanotechnology, offering new avenues for material science and engineering.

The journey of lepidolite from a mere lithium ore to a key component in nanomaterial synthesis began with the increasing demand for lithium in various industries, especially in battery technology. As researchers delved deeper into the properties of lepidolite, they discovered its potential beyond lithium extraction, particularly its unique chemical composition and structure that could be leveraged in nanoscale applications.

The evolution of nano-synthesis techniques has been driven by the need for materials with enhanced properties and functionalities. Lepidolite, with its complex crystal structure and diverse elemental composition, presents an intriguing candidate for developing novel nanomaterials with tailored characteristics. The presence of lithium, potassium, aluminum, and silicon in lepidolite offers a rich palette for creating multifunctional nanostructures.

Recent advancements in materials science and nanotechnology have paved the way for innovative approaches to utilize lepidolite in nano-synthesis. These techniques aim to exploit the mineral's unique properties to create nanoparticles, nanocomposites, and other nanostructured materials with applications ranging from energy storage and catalysis to environmental remediation and advanced electronics.

The primary objective of research in this field is to develop efficient and scalable methods for synthesizing nanomaterials from lepidolite. This includes optimizing extraction processes to isolate key components, developing novel synthesis routes to create nanostructures, and exploring ways to control the size, shape, and composition of the resulting nanomaterials.

Another crucial goal is to understand the fundamental mechanisms governing the transformation of lepidolite into nanomaterials. This knowledge is essential for fine-tuning the synthesis processes and predicting the properties of the resulting materials. Researchers are also focused on exploring the potential synergies between lepidolite-derived nanomaterials and other nanoscale systems, aiming to create hybrid materials with enhanced functionalities.

As the field progresses, there is a growing emphasis on sustainable and environmentally friendly synthesis methods. This aligns with the broader trend in nanotechnology towards green synthesis approaches, making lepidolite an attractive option due to its natural origin and potential for eco-friendly processing.

The exploration of lepidolite in nano-material synthesis techniques represents a frontier in materials science, promising to unlock new possibilities in nanotechnology and contribute to advancements across multiple industries. As research in this area continues to evolve, it holds the potential to revolutionize material design and open up new applications in fields ranging from energy to medicine.

The journey of lepidolite from a mere lithium ore to a key component in nanomaterial synthesis began with the increasing demand for lithium in various industries, especially in battery technology. As researchers delved deeper into the properties of lepidolite, they discovered its potential beyond lithium extraction, particularly its unique chemical composition and structure that could be leveraged in nanoscale applications.

The evolution of nano-synthesis techniques has been driven by the need for materials with enhanced properties and functionalities. Lepidolite, with its complex crystal structure and diverse elemental composition, presents an intriguing candidate for developing novel nanomaterials with tailored characteristics. The presence of lithium, potassium, aluminum, and silicon in lepidolite offers a rich palette for creating multifunctional nanostructures.

Recent advancements in materials science and nanotechnology have paved the way for innovative approaches to utilize lepidolite in nano-synthesis. These techniques aim to exploit the mineral's unique properties to create nanoparticles, nanocomposites, and other nanostructured materials with applications ranging from energy storage and catalysis to environmental remediation and advanced electronics.

The primary objective of research in this field is to develop efficient and scalable methods for synthesizing nanomaterials from lepidolite. This includes optimizing extraction processes to isolate key components, developing novel synthesis routes to create nanostructures, and exploring ways to control the size, shape, and composition of the resulting nanomaterials.

Another crucial goal is to understand the fundamental mechanisms governing the transformation of lepidolite into nanomaterials. This knowledge is essential for fine-tuning the synthesis processes and predicting the properties of the resulting materials. Researchers are also focused on exploring the potential synergies between lepidolite-derived nanomaterials and other nanoscale systems, aiming to create hybrid materials with enhanced functionalities.

As the field progresses, there is a growing emphasis on sustainable and environmentally friendly synthesis methods. This aligns with the broader trend in nanotechnology towards green synthesis approaches, making lepidolite an attractive option due to its natural origin and potential for eco-friendly processing.

The exploration of lepidolite in nano-material synthesis techniques represents a frontier in materials science, promising to unlock new possibilities in nanotechnology and contribute to advancements across multiple industries. As research in this area continues to evolve, it holds the potential to revolutionize material design and open up new applications in fields ranging from energy to medicine.

Market Analysis for Lepidolite-Based Nanomaterials

The market for lepidolite-based nanomaterials is experiencing significant growth, driven by the increasing demand for advanced materials in various industries. Lepidolite, a lithium-rich mineral, has emerged as a promising source for nano-material synthesis due to its unique properties and potential applications in energy storage, electronics, and environmental remediation.

In the energy storage sector, lepidolite-derived nanomaterials are gaining traction for their use in lithium-ion batteries. The global lithium-ion battery market is projected to expand rapidly, with a compound annual growth rate (CAGR) exceeding 12% over the next five years. This growth is primarily fueled by the rising adoption of electric vehicles and renewable energy systems, creating a substantial demand for high-performance battery materials.

The electronics industry is another key market for lepidolite-based nanomaterials. These materials show promise in the development of flexible and wearable electronics, as well as in the production of advanced sensors and displays. The global market for flexible electronics is expected to grow at a CAGR of over 11% in the coming years, presenting significant opportunities for lepidolite-derived nanomaterials.

Environmental applications represent a growing niche for lepidolite-based nanomaterials. Their potential use in water purification and air filtration systems is attracting attention from both industry and government sectors. The global water treatment market, which includes nanomaterial-based solutions, is anticipated to expand at a CAGR of around 7% over the next five years.

Geographically, Asia-Pacific is expected to dominate the market for lepidolite-based nanomaterials, driven by the region's robust electronics manufacturing sector and increasing investments in energy storage technologies. North America and Europe are also significant markets, with a focus on research and development of advanced applications.

However, the market faces challenges related to the scalability of production processes and the need for standardization in nanomaterial characterization. Additionally, concerns about the environmental impact of nanomaterial production and disposal may influence market growth and regulatory landscapes.

Despite these challenges, the overall market outlook for lepidolite-based nanomaterials remains positive. The increasing focus on sustainable and high-performance materials across industries is likely to drive continued investment and innovation in this field, opening up new opportunities for market expansion and technological advancements.

In the energy storage sector, lepidolite-derived nanomaterials are gaining traction for their use in lithium-ion batteries. The global lithium-ion battery market is projected to expand rapidly, with a compound annual growth rate (CAGR) exceeding 12% over the next five years. This growth is primarily fueled by the rising adoption of electric vehicles and renewable energy systems, creating a substantial demand for high-performance battery materials.

The electronics industry is another key market for lepidolite-based nanomaterials. These materials show promise in the development of flexible and wearable electronics, as well as in the production of advanced sensors and displays. The global market for flexible electronics is expected to grow at a CAGR of over 11% in the coming years, presenting significant opportunities for lepidolite-derived nanomaterials.

Environmental applications represent a growing niche for lepidolite-based nanomaterials. Their potential use in water purification and air filtration systems is attracting attention from both industry and government sectors. The global water treatment market, which includes nanomaterial-based solutions, is anticipated to expand at a CAGR of around 7% over the next five years.

Geographically, Asia-Pacific is expected to dominate the market for lepidolite-based nanomaterials, driven by the region's robust electronics manufacturing sector and increasing investments in energy storage technologies. North America and Europe are also significant markets, with a focus on research and development of advanced applications.

However, the market faces challenges related to the scalability of production processes and the need for standardization in nanomaterial characterization. Additionally, concerns about the environmental impact of nanomaterial production and disposal may influence market growth and regulatory landscapes.

Despite these challenges, the overall market outlook for lepidolite-based nanomaterials remains positive. The increasing focus on sustainable and high-performance materials across industries is likely to drive continued investment and innovation in this field, opening up new opportunities for market expansion and technological advancements.

Current Challenges in Lepidolite Nano-Synthesis

The synthesis of nanomaterials from lepidolite presents several significant challenges that researchers and industry professionals are currently grappling with. One of the primary obstacles is the complex composition of lepidolite, which contains various elements such as lithium, potassium, aluminum, and silicon. This heterogeneous nature makes it difficult to achieve consistent and pure nanostructures without unwanted impurities or defects.

Another major challenge lies in the extraction and isolation of specific components from lepidolite for nano-synthesis. The process of selectively extracting lithium, for instance, while maintaining its nano-scale properties, requires sophisticated techniques that are still being refined. Current methods often result in low yields or compromised material quality, hindering large-scale production and commercial viability.

The control of particle size and morphology during nano-synthesis is also a significant hurdle. Achieving uniform size distribution and desired shapes of nanoparticles derived from lepidolite is crucial for their performance in various applications. However, the multi-element nature of lepidolite makes it challenging to precisely manipulate these parameters without introducing variability in the final product.

Energy efficiency and environmental concerns pose additional challenges in lepidolite nano-synthesis. Traditional extraction and processing methods often involve high-temperature treatments or the use of harsh chemicals, which are energy-intensive and potentially harmful to the environment. Developing greener, more sustainable synthesis routes that maintain product quality while reducing energy consumption and environmental impact is an ongoing area of research.

Scalability remains a critical issue in transitioning lepidolite-based nanomaterial synthesis from laboratory to industrial scale. The complexities involved in maintaining consistent quality, yield, and properties when scaling up production processes present significant technical and economic challenges. This is particularly evident in applications requiring large quantities of nanomaterials, such as energy storage devices or advanced composites.

Furthermore, the characterization and quality control of lepidolite-derived nanomaterials pose unique challenges. The multi-element composition of the source material necessitates advanced analytical techniques to accurately assess the purity, structure, and properties of the synthesized nanoparticles. Developing standardized methods for reliable and reproducible characterization is essential for the widespread adoption of these materials in various industries.

Another major challenge lies in the extraction and isolation of specific components from lepidolite for nano-synthesis. The process of selectively extracting lithium, for instance, while maintaining its nano-scale properties, requires sophisticated techniques that are still being refined. Current methods often result in low yields or compromised material quality, hindering large-scale production and commercial viability.

The control of particle size and morphology during nano-synthesis is also a significant hurdle. Achieving uniform size distribution and desired shapes of nanoparticles derived from lepidolite is crucial for their performance in various applications. However, the multi-element nature of lepidolite makes it challenging to precisely manipulate these parameters without introducing variability in the final product.

Energy efficiency and environmental concerns pose additional challenges in lepidolite nano-synthesis. Traditional extraction and processing methods often involve high-temperature treatments or the use of harsh chemicals, which are energy-intensive and potentially harmful to the environment. Developing greener, more sustainable synthesis routes that maintain product quality while reducing energy consumption and environmental impact is an ongoing area of research.

Scalability remains a critical issue in transitioning lepidolite-based nanomaterial synthesis from laboratory to industrial scale. The complexities involved in maintaining consistent quality, yield, and properties when scaling up production processes present significant technical and economic challenges. This is particularly evident in applications requiring large quantities of nanomaterials, such as energy storage devices or advanced composites.

Furthermore, the characterization and quality control of lepidolite-derived nanomaterials pose unique challenges. The multi-element composition of the source material necessitates advanced analytical techniques to accurately assess the purity, structure, and properties of the synthesized nanoparticles. Developing standardized methods for reliable and reproducible characterization is essential for the widespread adoption of these materials in various industries.

Existing Lepidolite Nano-Synthesis Techniques

01 Lepidolite as a lithium source

Lepidolite is utilized as a valuable source of lithium in various industrial applications. It is processed to extract lithium for use in batteries, ceramics, and other products. The mineral's high lithium content makes it an important raw material in the growing lithium market.- Lepidolite as a lithium source: Lepidolite is utilized as a valuable source of lithium in various industrial applications. It is processed to extract lithium for use in batteries, ceramics, and other products. The mineral's high lithium content makes it an important raw material in the production of lithium compounds.

- Lepidolite in cosmetic formulations: Lepidolite is incorporated into cosmetic products due to its beneficial properties for skin care. It is used in formulations for its potential soothing and calming effects, as well as its mineral content. The mineral may be included in various cosmetic products such as creams, lotions, and masks.

- Lepidolite in jewelry and ornamental applications: Lepidolite is used in the creation of jewelry and ornamental objects due to its attractive appearance and unique properties. The mineral's purple to pink color and pearly luster make it popular for use in beads, cabochons, and other decorative items. It is also incorporated into various ornamental products and collectibles.

- Lepidolite in energy storage and electronic devices: Lepidolite is utilized in the development of energy storage systems and electronic devices. Its lithium content makes it valuable for the production of lithium-ion batteries and other energy storage technologies. The mineral is also explored for potential applications in electronic components and devices.

- Lepidolite in environmental and industrial applications: Lepidolite finds applications in environmental remediation and industrial processes. It is used in water treatment systems, as a component in certain industrial catalysts, and in the production of specialized glass and ceramics. The mineral's unique properties make it suitable for various industrial and environmental applications.

02 Lepidolite in cosmetic and skincare products

Lepidolite is incorporated into cosmetic and skincare formulations due to its beneficial properties. It is used in products such as face masks, creams, and lotions to provide soothing and calming effects on the skin. The mineral's composition is believed to offer potential anti-inflammatory and stress-reducing benefits.Expand Specific Solutions03 Lepidolite in water treatment and purification

Lepidolite is employed in water treatment and purification processes. Its unique properties allow it to effectively remove certain contaminants from water, making it useful in both industrial and residential water treatment applications. The mineral's ion exchange capabilities contribute to its effectiveness in this field.Expand Specific Solutions04 Lepidolite in energy storage and battery technology

Lepidolite plays a role in energy storage and battery technology development. Its lithium content makes it a potential material for use in lithium-ion batteries and other energy storage devices. Research is ongoing to optimize the extraction and utilization of lepidolite in this rapidly evolving field.Expand Specific Solutions05 Lepidolite in jewelry and ornamental applications

Lepidolite is used in jewelry making and ornamental applications due to its attractive appearance and metaphysical properties. The mineral's purple to pink color and pearly luster make it popular for creating gemstones, beads, and decorative objects. It is also believed to have calming and balancing effects in crystal healing practices.Expand Specific Solutions

Key Players in Lepidolite Nanomaterial Industry

The applications of lepidolite in nano-material synthesis techniques represent an emerging field with significant potential. The market is in its early growth stage, characterized by increasing research activities and limited commercial applications. While the market size remains relatively small, it is expected to expand rapidly as new applications are developed. Technologically, the field is still evolving, with research institutions like Chengdu University of Technology and Northwestern University leading fundamental studies. Companies such as LG Display and Johnson Matthey are exploring practical applications, particularly in electronics and catalysis. NASA's involvement suggests potential aerospace applications. The technology's maturity varies across different applications, ranging from experimental to early commercialization stages.

The Regents of the University of California

Technical Solution: The University of California has developed innovative techniques for synthesizing nano-materials using lepidolite as a precursor. Their method involves a hydrothermal process to extract lithium from lepidolite, followed by a sol-gel approach to create nanostructured materials[1]. This process allows for precise control over particle size and morphology, resulting in high-quality nano-materials with tailored properties. The researchers have successfully synthesized lithium-based nanoparticles, nanowires, and nanocomposites with applications in energy storage, catalysis, and advanced ceramics[2]. Additionally, they have explored the use of lepidolite-derived nanomaterials in environmental remediation, particularly for the removal of heavy metals from wastewater[3].

Strengths: Precise control over nanoparticle properties, versatile applications across multiple industries. Weaknesses: Potentially high production costs, scalability challenges for industrial-scale synthesis.

Northwestern University

Technical Solution: Northwestern University has pioneered a green synthesis approach for nano-materials using lepidolite as a sustainable source. Their technique employs a microwave-assisted extraction process to efficiently isolate lithium and other valuable elements from lepidolite[4]. The extracted components are then used in a one-pot synthesis method to create multi-functional nanocomposites. This eco-friendly approach significantly reduces energy consumption and chemical waste compared to traditional methods. The resulting nano-materials have shown promising applications in energy storage devices, particularly for next-generation lithium-ion batteries[5]. Furthermore, the research team has developed lepidolite-derived nanomaterials with unique catalytic properties, which have potential uses in environmental catalysis and fine chemical synthesis[6].

Strengths: Environmentally friendly process, energy-efficient synthesis, multi-functional nanocomposites. Weaknesses: Limited to specific types of nano-materials, may require specialized equipment.

Innovative Lepidolite Nano-Synthesis Patents

Nano-leucite for slow release nitrogen fertilizer and green environment

PatentInactiveUS20140190226A1

Innovation

- Synthesis of potassium aluminium silicate nanoparticles using a hydrothermal method with anionic surfactants to create a porous nanoleucite material, which occludes calcium ammonium nitrate, enhancing nutrient retention and controlled release through controlled porosity and cation exchange capacity.

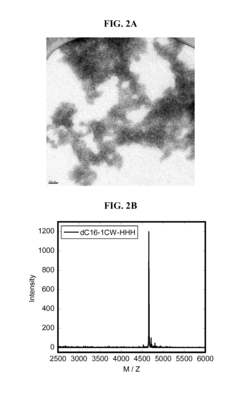

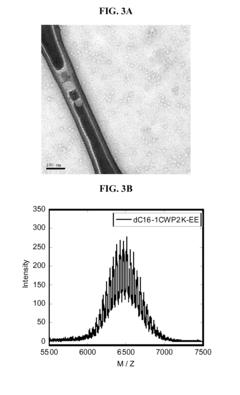

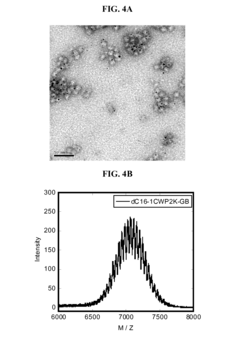

Lipid-peptide-polymer conjugates and nanoparticles thereof

PatentInactiveUS20160009770A1

Innovation

- The development of peptide-polymer-lipid conjugates that self-assemble into helix bundles and subsequently form nanoparticles with diameters between 10-20 nm, which can encapsulate therapeutic or diagnostic agents, using a peptide with a helical structure covalently linked to a polymer and a hydrophobic moiety, allowing for controlled size and stability.

Environmental Impact of Lepidolite Nano-Synthesis

The environmental impact of lepidolite nano-synthesis techniques is a critical consideration in the development and application of this emerging technology. Lepidolite, a lithium-rich mica mineral, has gained attention for its potential in nano-material synthesis, particularly in the production of lithium-based nanoparticles and nanocomposites. However, the extraction and processing of lepidolite, as well as the subsequent nano-synthesis procedures, can have significant environmental implications.

One of the primary environmental concerns is the mining and extraction of lepidolite. Open-pit mining, often used to obtain this mineral, can lead to habitat destruction, soil erosion, and landscape alteration. The extraction process may also result in the release of dust particles and potentially harmful chemicals into the surrounding air and water systems, affecting local ecosystems and biodiversity.

Water consumption is another crucial environmental factor in lepidolite nano-synthesis. The purification and processing of lepidolite, as well as the synthesis of nanomaterials, typically require substantial amounts of water. This can strain local water resources, particularly in arid regions where lepidolite deposits are often found. Additionally, the wastewater generated from these processes may contain dissolved metals and other contaminants, necessitating proper treatment before discharge to prevent water pollution.

Energy consumption is a significant environmental consideration in nano-synthesis techniques involving lepidolite. The high-temperature processes often required for nanomaterial production, such as calcination and sintering, consume considerable amounts of energy. This energy demand can contribute to increased greenhouse gas emissions if fossil fuels are the primary energy source, thus impacting climate change.

The use of chemicals in lepidolite nano-synthesis also poses environmental risks. Various acids, bases, and organic solvents are commonly employed in the extraction and synthesis processes. Improper handling or disposal of these chemicals can lead to soil and water contamination, potentially harming both terrestrial and aquatic ecosystems.

Nanoparticle release into the environment is an emerging concern associated with lepidolite nano-synthesis. The small size of nanoparticles makes them highly mobile and potentially bioavailable to organisms. While research is ongoing, there are concerns about the potential toxicity of certain nanoparticles to microorganisms, plants, and animals, which could disrupt ecological balance.

To mitigate these environmental impacts, researchers and industries are exploring more sustainable approaches to lepidolite nano-synthesis. These include developing closed-loop systems for water and chemical recycling, implementing energy-efficient synthesis methods, and investigating green chemistry principles to reduce the use of harmful substances. Additionally, efforts are being made to improve the recovery and recycling of nanomaterials to minimize waste and environmental release.

One of the primary environmental concerns is the mining and extraction of lepidolite. Open-pit mining, often used to obtain this mineral, can lead to habitat destruction, soil erosion, and landscape alteration. The extraction process may also result in the release of dust particles and potentially harmful chemicals into the surrounding air and water systems, affecting local ecosystems and biodiversity.

Water consumption is another crucial environmental factor in lepidolite nano-synthesis. The purification and processing of lepidolite, as well as the synthesis of nanomaterials, typically require substantial amounts of water. This can strain local water resources, particularly in arid regions where lepidolite deposits are often found. Additionally, the wastewater generated from these processes may contain dissolved metals and other contaminants, necessitating proper treatment before discharge to prevent water pollution.

Energy consumption is a significant environmental consideration in nano-synthesis techniques involving lepidolite. The high-temperature processes often required for nanomaterial production, such as calcination and sintering, consume considerable amounts of energy. This energy demand can contribute to increased greenhouse gas emissions if fossil fuels are the primary energy source, thus impacting climate change.

The use of chemicals in lepidolite nano-synthesis also poses environmental risks. Various acids, bases, and organic solvents are commonly employed in the extraction and synthesis processes. Improper handling or disposal of these chemicals can lead to soil and water contamination, potentially harming both terrestrial and aquatic ecosystems.

Nanoparticle release into the environment is an emerging concern associated with lepidolite nano-synthesis. The small size of nanoparticles makes them highly mobile and potentially bioavailable to organisms. While research is ongoing, there are concerns about the potential toxicity of certain nanoparticles to microorganisms, plants, and animals, which could disrupt ecological balance.

To mitigate these environmental impacts, researchers and industries are exploring more sustainable approaches to lepidolite nano-synthesis. These include developing closed-loop systems for water and chemical recycling, implementing energy-efficient synthesis methods, and investigating green chemistry principles to reduce the use of harmful substances. Additionally, efforts are being made to improve the recovery and recycling of nanomaterials to minimize waste and environmental release.

Scalability of Lepidolite Nano-Production

The scalability of lepidolite nano-production is a critical factor in determining the viability of large-scale applications of lepidolite-derived nanomaterials. As the demand for advanced materials continues to grow, the ability to produce lepidolite nanoparticles in significant quantities becomes increasingly important.

One of the primary challenges in scaling up lepidolite nano-production is the development of efficient extraction and processing methods. Traditional techniques often involve energy-intensive grinding and milling processes, which can be costly and time-consuming when applied to large volumes of raw material. Recent advancements in hydrothermal and solvothermal synthesis methods have shown promise in improving the efficiency and yield of lepidolite nanoparticle production.

The use of continuous flow reactors has emerged as a potential solution for increasing production capacity. These systems allow for the continuous synthesis of nanoparticles, offering better control over particle size distribution and morphology compared to batch processes. Additionally, microfluidic devices have demonstrated the ability to produce lepidolite nanoparticles with high uniformity and at a faster rate than conventional methods.

Another aspect of scalability involves the purification and separation of the synthesized nanoparticles. Advances in centrifugation and filtration techniques have improved the ability to isolate lepidolite nanoparticles from reaction mixtures efficiently. However, further research is needed to develop more cost-effective and environmentally friendly separation methods that can handle large-scale production volumes.

The environmental impact of scaled-up lepidolite nano-production is an important consideration. Sustainable practices, such as the use of green solvents and the implementation of closed-loop systems for reagent recycling, are being explored to minimize waste and reduce the ecological footprint of production processes.

Economic factors play a crucial role in the scalability of lepidolite nano-production. The cost of raw materials, energy consumption, and equipment investment must be carefully balanced against the potential market value of the produced nanomaterials. As production scales increase, economies of scale may help reduce per-unit costs, making lepidolite-based nanomaterials more competitive in various applications.

In conclusion, while significant progress has been made in improving the scalability of lepidolite nano-production, there remain several challenges to overcome before large-scale industrial production becomes feasible. Continued research and development efforts are needed to optimize synthesis methods, improve purification techniques, and address environmental and economic considerations to fully realize the potential of lepidolite-derived nanomaterials in commercial applications.

One of the primary challenges in scaling up lepidolite nano-production is the development of efficient extraction and processing methods. Traditional techniques often involve energy-intensive grinding and milling processes, which can be costly and time-consuming when applied to large volumes of raw material. Recent advancements in hydrothermal and solvothermal synthesis methods have shown promise in improving the efficiency and yield of lepidolite nanoparticle production.

The use of continuous flow reactors has emerged as a potential solution for increasing production capacity. These systems allow for the continuous synthesis of nanoparticles, offering better control over particle size distribution and morphology compared to batch processes. Additionally, microfluidic devices have demonstrated the ability to produce lepidolite nanoparticles with high uniformity and at a faster rate than conventional methods.

Another aspect of scalability involves the purification and separation of the synthesized nanoparticles. Advances in centrifugation and filtration techniques have improved the ability to isolate lepidolite nanoparticles from reaction mixtures efficiently. However, further research is needed to develop more cost-effective and environmentally friendly separation methods that can handle large-scale production volumes.

The environmental impact of scaled-up lepidolite nano-production is an important consideration. Sustainable practices, such as the use of green solvents and the implementation of closed-loop systems for reagent recycling, are being explored to minimize waste and reduce the ecological footprint of production processes.

Economic factors play a crucial role in the scalability of lepidolite nano-production. The cost of raw materials, energy consumption, and equipment investment must be carefully balanced against the potential market value of the produced nanomaterials. As production scales increase, economies of scale may help reduce per-unit costs, making lepidolite-based nanomaterials more competitive in various applications.

In conclusion, while significant progress has been made in improving the scalability of lepidolite nano-production, there remain several challenges to overcome before large-scale industrial production becomes feasible. Continued research and development efforts are needed to optimize synthesis methods, improve purification techniques, and address environmental and economic considerations to fully realize the potential of lepidolite-derived nanomaterials in commercial applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!