Assessing Light And Wash Fastness Metrics For Natural-Dyed Fabrics

SEP 2, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Natural Dye Technology Background and Objectives

Natural dyeing technology represents one of humanity's oldest chemical processes, dating back to prehistoric times when early civilizations extracted colorants from plants, insects, minerals, and fungi to color textiles. Throughout history, these techniques evolved across different cultures, with significant developments in ancient Egypt, China, India, and Mesoamerica. Until the mid-19th century, all textiles were colored using natural dyes, with indigo, madder, cochineal, and logwood being among the most commercially important.

The synthetic dye revolution began in 1856 with William Henry Perkin's discovery of mauveine, which gradually displaced natural dyes in commercial applications due to superior color consistency, fastness properties, and cost-effectiveness. Natural dyes were largely relegated to artisanal and traditional applications for over a century.

Recent decades have witnessed a resurgence of interest in natural dyeing technologies, driven by increasing environmental awareness, concerns about synthetic dye toxicity, and consumer demand for sustainable products. This revival has prompted renewed scientific investigation into natural dye chemistry, application methods, and performance characteristics.

A critical challenge in the contemporary natural dye renaissance involves standardization and performance metrics. Unlike synthetic dyes with predictable molecular structures and documented performance, natural dyes exhibit significant variability based on source material, growing conditions, extraction methods, and application techniques. This variability directly impacts colorfastness properties, particularly light and wash fastness, which are crucial quality indicators for commercial viability.

The technical objective of this research focuses on developing standardized, reliable metrics for assessing light and wash fastness in natural-dyed fabrics. This endeavor aims to bridge the gap between traditional knowledge and modern scientific understanding, enabling consistent evaluation of natural dye performance across different fiber types, mordanting techniques, and dye sources.

Additional objectives include identifying optimal combinations of natural dyes, mordants, and application methods to enhance colorfastness properties; developing accelerated testing protocols that accurately predict long-term performance; and establishing industry-acceptable standards that could facilitate broader commercial adoption of natural dyeing technologies.

The ultimate goal is to position natural dyes as viable alternatives to synthetic colorants in specific market segments by addressing performance inconsistencies while preserving their inherent environmental and health advantages. This requires a multidisciplinary approach combining traditional craft knowledge with modern analytical chemistry, textile science, and standardization methodologies.

The synthetic dye revolution began in 1856 with William Henry Perkin's discovery of mauveine, which gradually displaced natural dyes in commercial applications due to superior color consistency, fastness properties, and cost-effectiveness. Natural dyes were largely relegated to artisanal and traditional applications for over a century.

Recent decades have witnessed a resurgence of interest in natural dyeing technologies, driven by increasing environmental awareness, concerns about synthetic dye toxicity, and consumer demand for sustainable products. This revival has prompted renewed scientific investigation into natural dye chemistry, application methods, and performance characteristics.

A critical challenge in the contemporary natural dye renaissance involves standardization and performance metrics. Unlike synthetic dyes with predictable molecular structures and documented performance, natural dyes exhibit significant variability based on source material, growing conditions, extraction methods, and application techniques. This variability directly impacts colorfastness properties, particularly light and wash fastness, which are crucial quality indicators for commercial viability.

The technical objective of this research focuses on developing standardized, reliable metrics for assessing light and wash fastness in natural-dyed fabrics. This endeavor aims to bridge the gap between traditional knowledge and modern scientific understanding, enabling consistent evaluation of natural dye performance across different fiber types, mordanting techniques, and dye sources.

Additional objectives include identifying optimal combinations of natural dyes, mordants, and application methods to enhance colorfastness properties; developing accelerated testing protocols that accurately predict long-term performance; and establishing industry-acceptable standards that could facilitate broader commercial adoption of natural dyeing technologies.

The ultimate goal is to position natural dyes as viable alternatives to synthetic colorants in specific market segments by addressing performance inconsistencies while preserving their inherent environmental and health advantages. This requires a multidisciplinary approach combining traditional craft knowledge with modern analytical chemistry, textile science, and standardization methodologies.

Market Analysis for Natural-Dyed Textile Products

The natural-dyed textile market has experienced significant growth in recent years, driven by increasing consumer awareness of environmental sustainability and health concerns associated with synthetic dyes. The global market for natural dyes was valued at approximately $1.8 billion in 2022 and is projected to reach $3.2 billion by 2028, representing a compound annual growth rate (CAGR) of 10.2% during the forecast period.

Consumer demand for natural-dyed textiles spans multiple segments, including fashion apparel, home textiles, and specialty products. The premium fashion sector has shown particular interest, with luxury brands incorporating natural-dyed fabrics into their collections to appeal to environmentally conscious consumers. This segment values the unique aesthetic qualities and storytelling potential of natural dyes, often marketing the cultural heritage and traditional craftsmanship associated with these products.

The home textile market represents another significant opportunity, with natural-dyed bedding, curtains, and decorative items gaining popularity among consumers seeking non-toxic living environments. This segment is particularly sensitive to light fastness metrics, as these products are often exposed to prolonged sunlight.

Geographically, Europe and North America currently dominate the natural-dyed textile market in terms of revenue, with consumers willing to pay premium prices for sustainable products. However, the Asia-Pacific region is expected to witness the fastest growth, driven by increasing disposable incomes, growing environmental awareness, and the presence of traditional natural dyeing expertise in countries like India, Japan, and Indonesia.

A key market challenge remains the perception of natural-dyed fabrics as having inferior colorfastness compared to synthetic alternatives. Consumer surveys indicate that 78% of potential buyers express concerns about color fading after washing or exposure to light. This highlights the critical importance of developing and standardizing reliable metrics for assessing light and wash fastness in natural-dyed textiles.

The B2B market segment shows increasing interest in natural dyes, with textile manufacturers seeking to diversify their product offerings to meet sustainability targets. However, industrial adoption faces challenges related to scalability, consistency in color reproduction, and meeting established performance standards for colorfastness.

Market forecasts suggest that improvements in natural dye technology, particularly in enhancing light and wash fastness properties, could significantly expand market penetration. Research indicates that achieving performance metrics comparable to synthetic dyes could potentially triple the market share of natural-dyed textiles within the broader textile industry over the next decade.

Consumer demand for natural-dyed textiles spans multiple segments, including fashion apparel, home textiles, and specialty products. The premium fashion sector has shown particular interest, with luxury brands incorporating natural-dyed fabrics into their collections to appeal to environmentally conscious consumers. This segment values the unique aesthetic qualities and storytelling potential of natural dyes, often marketing the cultural heritage and traditional craftsmanship associated with these products.

The home textile market represents another significant opportunity, with natural-dyed bedding, curtains, and decorative items gaining popularity among consumers seeking non-toxic living environments. This segment is particularly sensitive to light fastness metrics, as these products are often exposed to prolonged sunlight.

Geographically, Europe and North America currently dominate the natural-dyed textile market in terms of revenue, with consumers willing to pay premium prices for sustainable products. However, the Asia-Pacific region is expected to witness the fastest growth, driven by increasing disposable incomes, growing environmental awareness, and the presence of traditional natural dyeing expertise in countries like India, Japan, and Indonesia.

A key market challenge remains the perception of natural-dyed fabrics as having inferior colorfastness compared to synthetic alternatives. Consumer surveys indicate that 78% of potential buyers express concerns about color fading after washing or exposure to light. This highlights the critical importance of developing and standardizing reliable metrics for assessing light and wash fastness in natural-dyed textiles.

The B2B market segment shows increasing interest in natural dyes, with textile manufacturers seeking to diversify their product offerings to meet sustainability targets. However, industrial adoption faces challenges related to scalability, consistency in color reproduction, and meeting established performance standards for colorfastness.

Market forecasts suggest that improvements in natural dye technology, particularly in enhancing light and wash fastness properties, could significantly expand market penetration. Research indicates that achieving performance metrics comparable to synthetic dyes could potentially triple the market share of natural-dyed textiles within the broader textile industry over the next decade.

Current Fastness Testing Challenges for Natural Dyes

The assessment of light and wash fastness for natural-dyed fabrics presents significant challenges in today's textile industry. Traditional testing methods, primarily developed for synthetic dyes, often fail to accurately evaluate the performance characteristics of natural colorants. These standardized tests, such as ISO 105, AATCC Test Methods, and BS EN ISO standards, were established when synthetic dyes dominated the market and do not account for the unique chemical structures and bonding mechanisms of natural dyes.

One fundamental challenge lies in the inherent variability of natural dye sources. Unlike synthetic dyes with consistent molecular structures, natural dyes extracted from plants, insects, or minerals can vary significantly in composition based on growing conditions, harvesting time, extraction methods, and geographical origin. This variability makes it difficult to establish standardized testing protocols that yield reproducible results across different batches of naturally dyed fabrics.

The accelerated aging conditions used in conventional fastness tests often create unrealistic exposure scenarios for natural dyes. For instance, standard light fastness tests typically employ xenon arc lamps that produce light spectra and intensities far exceeding normal usage conditions. Natural dyes, which evolved to withstand natural sunlight rather than these intense artificial light sources, may show artificially poor performance in such tests despite performing adequately in real-world applications.

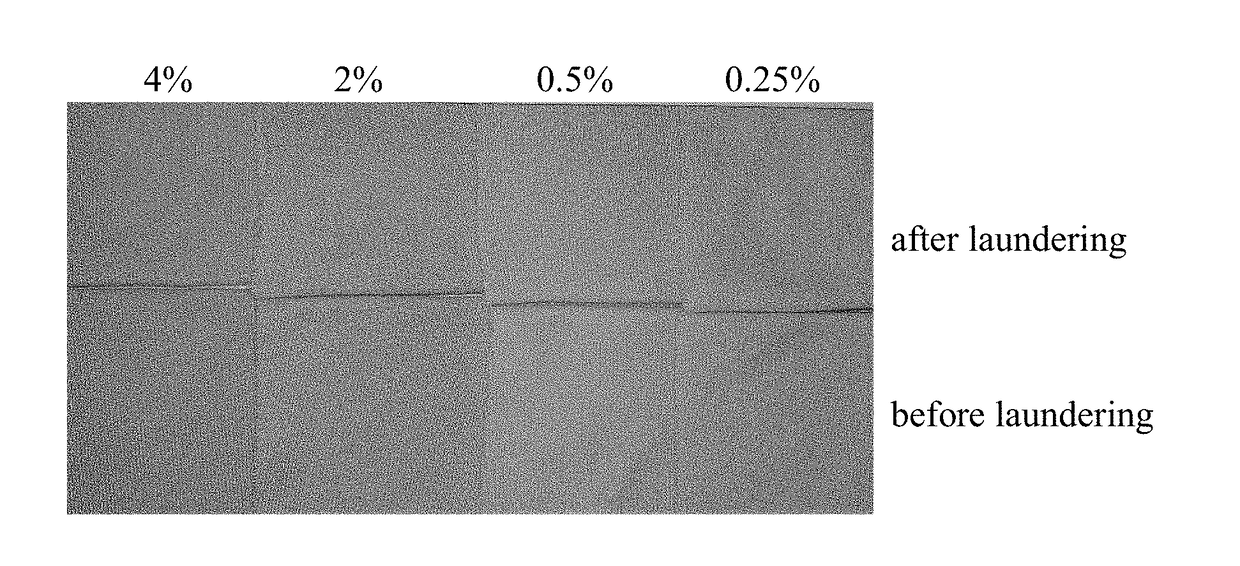

Current wash fastness testing methods present similar challenges. The harsh detergents and mechanical agitation specified in standard tests may not reflect typical consumer care practices for naturally dyed textiles. Additionally, many natural dyes form different types of bonds with fibers compared to synthetic counterparts, resulting in unique degradation patterns during washing that are not accurately captured by conventional metrics.

The subjective nature of color assessment in fastness testing introduces another layer of complexity. The Gray Scale for color change evaluation, while standardized, may not adequately capture the nuanced color shifts characteristic of natural dyes, which often "mature" or develop richer hues over time rather than simply fading.

Furthermore, there is a significant knowledge gap regarding the correlation between accelerated laboratory tests and real-world performance for natural dyes. Limited research exists comparing standard test results with actual wear and care experiences, making it difficult to establish meaningful benchmarks for acceptable fastness levels in naturally dyed products.

The lack of specialized reference standards for natural dyes compounds these issues. Current testing frameworks use synthetic dye references as benchmarks, creating an inherently biased comparison that rarely favors natural alternatives regardless of their actual performance in practical applications.

One fundamental challenge lies in the inherent variability of natural dye sources. Unlike synthetic dyes with consistent molecular structures, natural dyes extracted from plants, insects, or minerals can vary significantly in composition based on growing conditions, harvesting time, extraction methods, and geographical origin. This variability makes it difficult to establish standardized testing protocols that yield reproducible results across different batches of naturally dyed fabrics.

The accelerated aging conditions used in conventional fastness tests often create unrealistic exposure scenarios for natural dyes. For instance, standard light fastness tests typically employ xenon arc lamps that produce light spectra and intensities far exceeding normal usage conditions. Natural dyes, which evolved to withstand natural sunlight rather than these intense artificial light sources, may show artificially poor performance in such tests despite performing adequately in real-world applications.

Current wash fastness testing methods present similar challenges. The harsh detergents and mechanical agitation specified in standard tests may not reflect typical consumer care practices for naturally dyed textiles. Additionally, many natural dyes form different types of bonds with fibers compared to synthetic counterparts, resulting in unique degradation patterns during washing that are not accurately captured by conventional metrics.

The subjective nature of color assessment in fastness testing introduces another layer of complexity. The Gray Scale for color change evaluation, while standardized, may not adequately capture the nuanced color shifts characteristic of natural dyes, which often "mature" or develop richer hues over time rather than simply fading.

Furthermore, there is a significant knowledge gap regarding the correlation between accelerated laboratory tests and real-world performance for natural dyes. Limited research exists comparing standard test results with actual wear and care experiences, making it difficult to establish meaningful benchmarks for acceptable fastness levels in naturally dyed products.

The lack of specialized reference standards for natural dyes compounds these issues. Current testing frameworks use synthetic dye references as benchmarks, creating an inherently biased comparison that rarely favors natural alternatives regardless of their actual performance in practical applications.

Standard Protocols for Light and Wash Fastness Testing

01 Natural mordants for improving fastness properties

Various natural mordants can be used to enhance the light and wash fastness of natural-dyed fabrics. These mordants, derived from plant sources, minerals, or other natural materials, form complexes with dye molecules and fiber, resulting in stronger bonds that improve color retention during washing and exposure to light. The use of natural mordants is environmentally friendly and can significantly increase the commercial viability of natural dyes by addressing their traditional fastness limitations.- Natural mordants for improving fastness properties: Various natural mordants can be used to enhance the light and wash fastness of natural-dyed fabrics. These mordants, derived from plant sources, minerals, or other natural materials, form complexes with natural dyes to improve their binding to textile fibers. The mordanting process can be performed before, during, or after dyeing to achieve optimal fastness properties. This approach provides an environmentally friendly alternative to synthetic mordants while maintaining good color stability.

- Treatment methods for enhancing color stability: Specific treatment methods can significantly improve the light and wash fastness of natural-dyed fabrics. These include pre-treatment of fabrics with tannins, post-treatment with fixing agents, and specialized curing processes. Some treatments involve multiple steps such as scouring, mordanting, dyeing, and fixing to ensure optimal color retention. The application of these methods helps to overcome the inherent limitations of natural dyes regarding their fastness properties.

- Novel natural dye formulations: Innovative formulations of natural dyes can be developed to enhance light and wash fastness properties. These formulations may combine multiple natural colorants to achieve synergistic effects, incorporate stabilizing agents, or utilize microencapsulation techniques to protect the dye molecules. Some formulations include specific ratios of different plant extracts or modified extraction methods to preserve color-enhancing compounds. These approaches result in improved color retention while maintaining the eco-friendly benefits of natural dyes.

- Fiber modification techniques: Modifying textile fibers before dyeing can significantly improve the fastness properties of natural dyes. These modifications may include chemical treatments to increase dye-binding sites, plasma treatments to alter surface properties, or enzymatic processes to enhance fiber reactivity. Some techniques involve creating functional groups on the fiber surface that form strong bonds with natural colorants. These modifications enable better dye uptake and retention, resulting in superior light and wash fastness.

- Combination with synthetic additives: Combining natural dyes with specific synthetic additives can enhance their fastness properties while maintaining a predominantly natural product. These additives may include UV absorbers to improve light fastness, polymeric binders to enhance wash fastness, or specialized surfactants to improve dye penetration. The careful selection of compatible synthetic components in minimal quantities helps to overcome the limitations of purely natural systems without significantly compromising their environmental benefits.

02 Metal salt treatments for enhanced fastness

Metal salts, particularly those containing aluminum, iron, copper, and tin, can be applied as pre-treatments or post-treatments to natural-dyed fabrics to improve both light and wash fastness. These metal ions form coordination complexes with dye molecules, creating stronger bonds with the fabric substrate. The treatment process typically involves immersing the fabric in a solution of the metal salt at specific temperatures and pH levels, followed by rinsing and drying steps to fix the color permanently.Expand Specific Solutions03 Bio-enzyme treatments for fastness improvement

Bio-enzyme treatments represent an eco-friendly approach to improving the fastness properties of natural-dyed fabrics. Specific enzymes can modify the fiber surface or the dye molecules to create stronger bonds between them. These enzymatic processes can be applied either during the dyeing process or as a post-treatment. The controlled application of enzymes like laccase, peroxidase, or cellulase can significantly enhance both light and wash fastness while maintaining the ecological benefits of natural dyes.Expand Specific Solutions04 Innovative fixation techniques for natural dyes

Advanced fixation techniques have been developed to address the fastness limitations of natural dyes. These include plasma treatments, ultrasonic-assisted dyeing, microwave fixation, and UV curing methods. These techniques modify the fiber surface or enhance the penetration and fixation of natural dyes within the fiber structure. By altering the physical or chemical interaction between dye and fiber, these methods can significantly improve both light and wash fastness properties without requiring additional chemical agents.Expand Specific Solutions05 Natural polymer-based binders and coatings

Natural polymers such as chitosan, alginate, starch derivatives, and plant gums can be used as binders or coating agents to improve the fastness properties of natural-dyed fabrics. These polymers form a protective layer over the dyed fabric, shielding the color from washing and light exposure. Additionally, some natural polymers can form chemical bonds with both the dye molecules and the fiber, further enhancing color retention. This approach maintains the eco-friendly nature of natural dyeing while addressing its traditional limitations.Expand Specific Solutions

Leading Organizations in Natural Dye Research

The natural dye fastness market is in a growth phase, characterized by increasing demand for sustainable textile solutions despite technical challenges. The market size is expanding due to consumer preference for eco-friendly products, though it remains a niche segment within the broader textile industry. Regarding technical maturity, significant advancements are being made by key players. Companies like BASF, Toray Industries, and Lenzing AG lead in developing improved fastness technologies, while academic institutions such as Dalian Polytechnic University and Zhejiang Sci-Tech University contribute valuable research. Established textile manufacturers including Kolon Industries, Nan Ya Plastics, and Lu Thai Textile are incorporating natural dye innovations into their product lines. The collaboration between chemical companies and textile manufacturers is accelerating technical solutions to address light and wash fastness limitations in natural-dyed fabrics.

BASF Corp.

Technical Solution: BASF has developed a comprehensive technical solution for assessing light and wash fastness in natural-dyed fabrics through their "EcoFast™ Assessment System." This system combines traditional testing methods with advanced analytical techniques to provide quantitative and qualitative data on natural dye performance. BASF's approach utilizes controlled light exposure chambers equipped with spectral filters that can simulate various real-world lighting conditions, from indoor fluorescent lighting to outdoor sunlight with varying UV intensities. Their wash fastness assessment incorporates standardized testing protocols (AATCC Test Method 61) alongside proprietary detergent formulations specifically designed to challenge natural dyes in ways that reflect consumer usage patterns. BASF has also developed specialized image analysis software that quantifies color change beyond traditional gray scale assessments, providing detailed colorimetric data on hue shift, chroma reduction, and luminance changes. Additionally, their system incorporates accelerated weathering tests that combine light, moisture, and temperature cycling to predict long-term performance of natural-dyed textiles.

Strengths: BASF's comprehensive approach combines traditional standardized testing with advanced analytical techniques, providing more nuanced data than conventional methods alone. Their simulation of various real-world conditions offers practical relevance to actual consumer use cases. Weaknesses: The proprietary nature of some testing components may limit standardization across the industry. The system may require significant technical expertise and specialized equipment, potentially limiting accessibility for smaller manufacturers.

Zhejiang Sci-Tech University

Technical Solution: Zhejiang Sci-Tech University has developed an innovative "Comprehensive Natural Dye Assessment System" (CNDAS) that combines traditional testing methods with advanced analytical techniques specifically optimized for natural colorants. Their approach employs a multi-parameter evaluation framework that goes beyond standard light and wash fastness tests to include molecular-level analysis of dye-fiber interactions. The university's research team has pioneered the use of time-resolved spectroscopy to monitor the photodegradation kinetics of various natural chromophores under controlled light exposure conditions, providing deeper insights into degradation mechanisms. Their wash fastness assessment incorporates a novel "sequential extraction analysis" that quantifies dye removal across multiple washing cycles, offering more granular data than single-point measurements. Additionally, they've developed specialized image analysis algorithms that can detect subtle color changes invisible to the human eye, enabling early prediction of long-term performance. The CNDAS also includes a comprehensive database of natural dye performance across different fiber substrates, mordanting techniques, and processing conditions, serving as a valuable reference for optimizing natural dyeing processes.

Strengths: Zhejiang Sci-Tech University's molecular-level analysis provides deeper understanding of degradation mechanisms than conventional testing alone. Their comprehensive database offers valuable benchmarking capabilities for different natural dye systems. Weaknesses: The sophisticated analytical techniques may require specialized equipment not readily available in industrial settings. Some aspects of their methodology may be more research-oriented than production-focused, potentially limiting immediate industrial application.

Key Technical Innovations in Fastness Improvement

Natural dyeing method having high color fastness and dyed natural textile using the method

PatentInactiveKR1020100104585A

Innovation

- A natural dyeing method involving a scouring, dyeing, drying, and washing process, followed by immersion in a silver magnolia extract solution (10-15% by weight in 85-90% water, boiled for 30-40 minutes) for 30-60 minutes, enhances color fastness by improving light fastness.

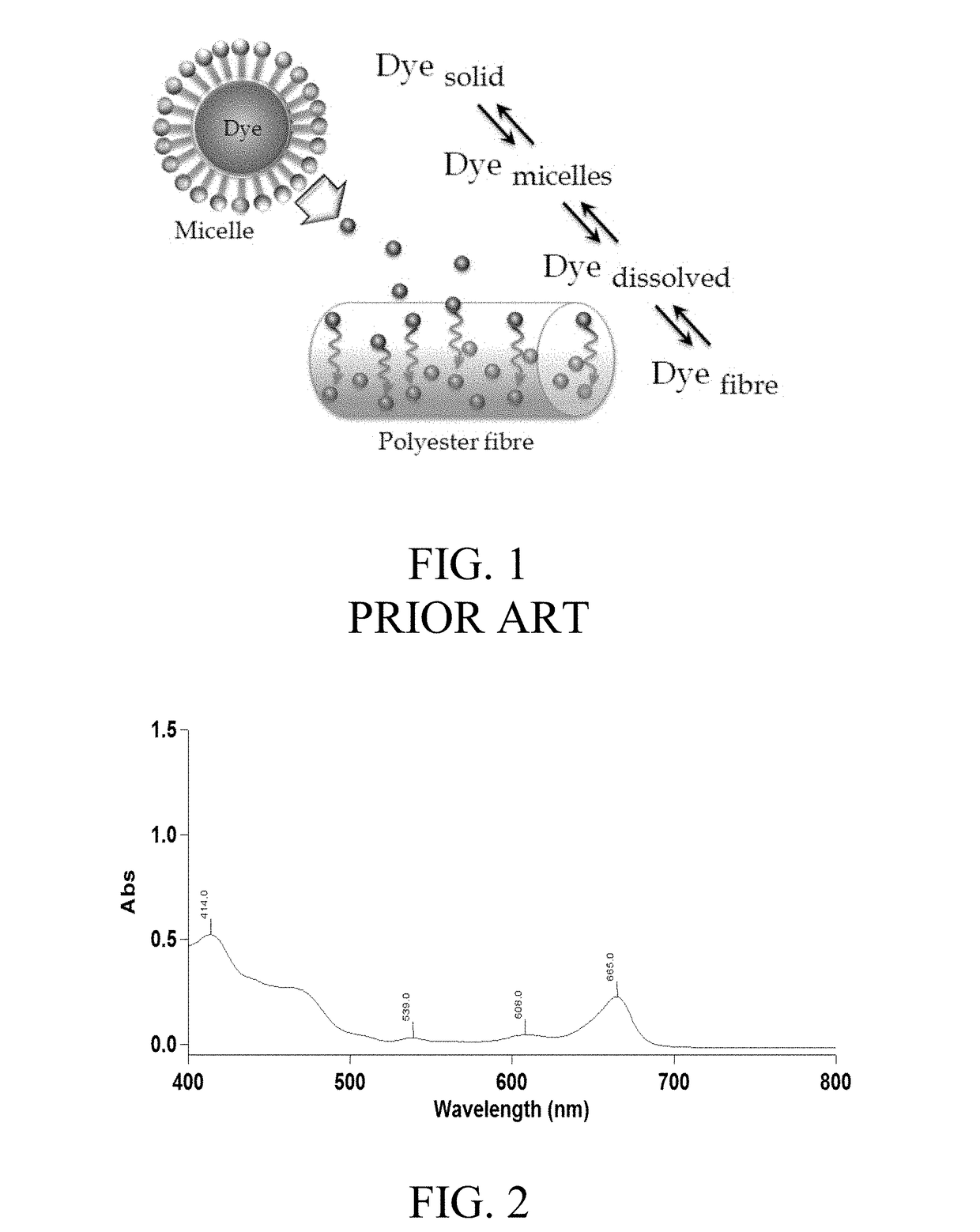

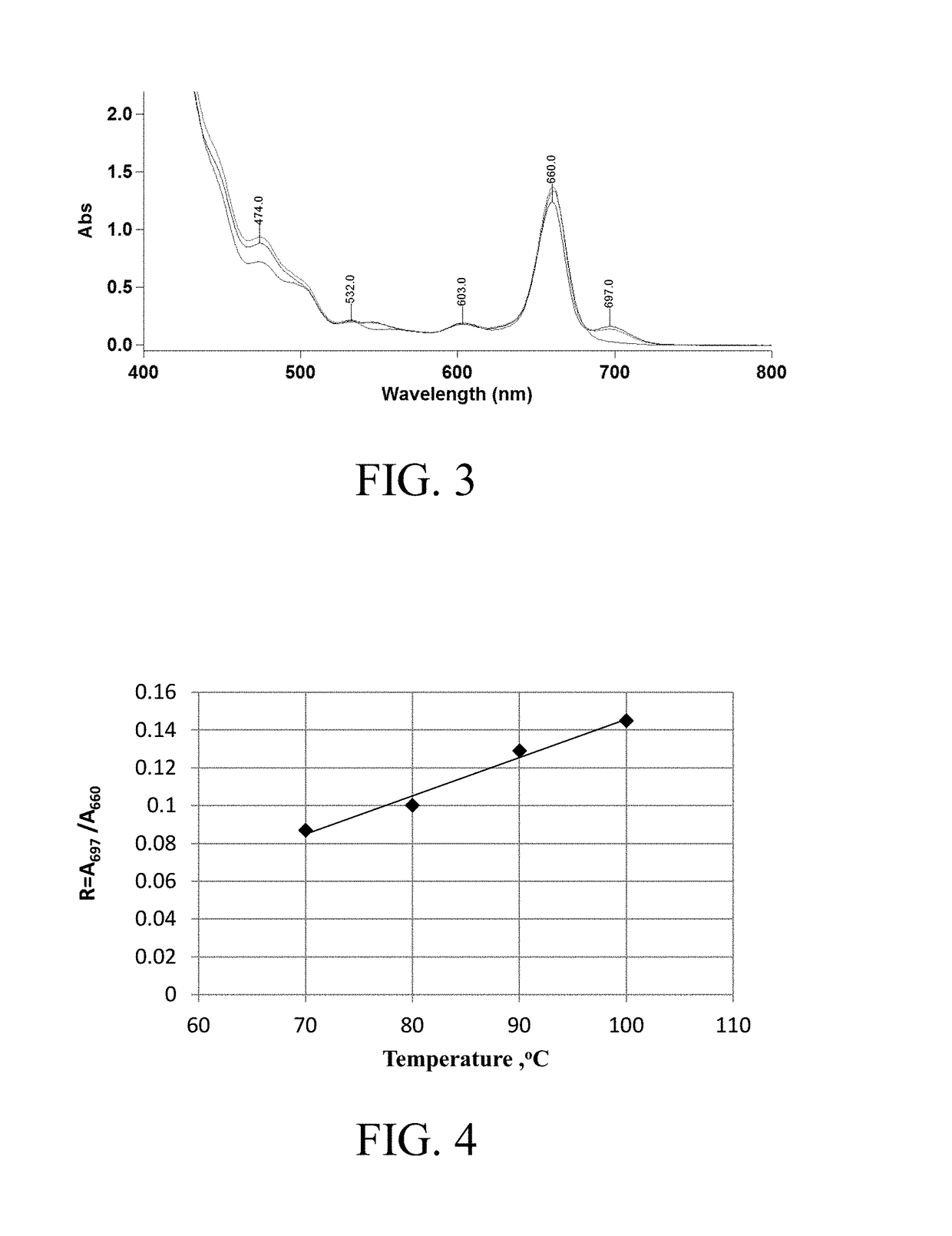

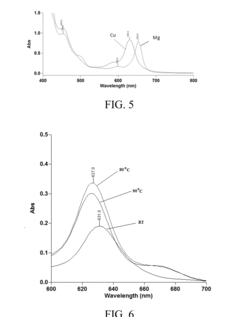

Biocompatible and biodegradable natural disperse dyes for dyeing polyester fabrics

PatentInactiveUS20180258287A1

Innovation

- Development of a chlorophyll-based disperse dye derived from green plants like duckweed, specifically using water-insoluble protonated M-chlorophyllin with divalent metal cations like Mg2+, Cu2+, Fe2+, and Zn2+, which forms an aqueous dispersion suitable for dyeing polyester fibers, improving fixation and reducing environmental impact.

Sustainability Impact of Natural Dyeing Processes

The environmental implications of natural dyeing processes represent a critical dimension in the evaluation of sustainable textile production systems. Natural dyes derived from plants, insects, minerals, and fungi offer significant ecological advantages compared to their synthetic counterparts, which typically involve petrochemical derivatives and generate substantial pollution throughout their lifecycle.

Natural dyeing processes generally consume less energy and water than conventional synthetic dyeing methods. Research indicates that natural dyeing operations can reduce energy consumption by 15-25% compared to synthetic processes, primarily due to lower temperature requirements during dye fixation. Additionally, wastewater from natural dyeing contains biodegradable compounds that decompose more readily in the environment, reducing the ecological footprint of textile production.

Carbon footprint analyses reveal that natural dyes can reduce greenhouse gas emissions by up to 40% compared to synthetic alternatives. This reduction stems from both the renewable nature of the raw materials and the less energy-intensive processing requirements. Furthermore, natural dye cultivation can contribute to carbon sequestration when integrated into sustainable agricultural systems.

The biodegradability of natural dyes represents another significant sustainability advantage. While synthetic dyes may persist in ecosystems for decades, most natural colorants degrade within 6-12 months under normal environmental conditions. This characteristic substantially reduces long-term ecological impacts associated with textile production and disposal.

However, sustainability assessments must also consider the agricultural impacts of natural dye production. Land use efficiency, water consumption for crop cultivation, and potential competition with food crops present challenges that require careful management. Life cycle assessments indicate that locally sourced natural dyes can minimize these concerns by reducing transportation emissions and supporting regional agricultural economies.

Mordant selection significantly influences the overall sustainability profile of natural dyeing processes. Traditional metallic mordants like chromium and copper pose environmental hazards, but alternative bio-mordants derived from plant tannins, myrobalan, and pomegranate rinds offer promising eco-friendly alternatives with minimal environmental impact while maintaining acceptable fastness properties.

The scalability of natural dyeing processes remains a challenge for widespread industrial adoption. Current production methods often require significant manual intervention and exhibit batch-to-batch variability. Technological innovations in extraction efficiency, mordanting techniques, and process standardization are essential to enhance the commercial viability of natural dyes while preserving their sustainability benefits.

Natural dyeing processes generally consume less energy and water than conventional synthetic dyeing methods. Research indicates that natural dyeing operations can reduce energy consumption by 15-25% compared to synthetic processes, primarily due to lower temperature requirements during dye fixation. Additionally, wastewater from natural dyeing contains biodegradable compounds that decompose more readily in the environment, reducing the ecological footprint of textile production.

Carbon footprint analyses reveal that natural dyes can reduce greenhouse gas emissions by up to 40% compared to synthetic alternatives. This reduction stems from both the renewable nature of the raw materials and the less energy-intensive processing requirements. Furthermore, natural dye cultivation can contribute to carbon sequestration when integrated into sustainable agricultural systems.

The biodegradability of natural dyes represents another significant sustainability advantage. While synthetic dyes may persist in ecosystems for decades, most natural colorants degrade within 6-12 months under normal environmental conditions. This characteristic substantially reduces long-term ecological impacts associated with textile production and disposal.

However, sustainability assessments must also consider the agricultural impacts of natural dye production. Land use efficiency, water consumption for crop cultivation, and potential competition with food crops present challenges that require careful management. Life cycle assessments indicate that locally sourced natural dyes can minimize these concerns by reducing transportation emissions and supporting regional agricultural economies.

Mordant selection significantly influences the overall sustainability profile of natural dyeing processes. Traditional metallic mordants like chromium and copper pose environmental hazards, but alternative bio-mordants derived from plant tannins, myrobalan, and pomegranate rinds offer promising eco-friendly alternatives with minimal environmental impact while maintaining acceptable fastness properties.

The scalability of natural dyeing processes remains a challenge for widespread industrial adoption. Current production methods often require significant manual intervention and exhibit batch-to-batch variability. Technological innovations in extraction efficiency, mordanting techniques, and process standardization are essential to enhance the commercial viability of natural dyes while preserving their sustainability benefits.

Regulatory Framework for Natural Textile Colorants

The regulatory landscape governing natural textile colorants has evolved significantly in response to growing environmental concerns and consumer demand for sustainable products. International standards such as ISO 105, AATCC Test Methods, and the Global Organic Textile Standard (GOTS) have established specific parameters for evaluating the performance of naturally dyed fabrics, including light and wash fastness metrics. These standards provide a framework for consistent quality assessment across different markets and production environments.

The European Union's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation imposes strict requirements on textile colorants, with particular attention to natural dyes that may contain allergenic or toxic compounds despite their natural origin. Manufacturers must demonstrate compliance through rigorous testing and documentation, ensuring that naturally dyed fabrics meet safety thresholds for human contact and environmental impact.

In the United States, the Consumer Product Safety Improvement Act (CPSIA) regulates lead content and other potentially harmful substances in textiles, while the Federal Trade Commission (FTC) oversees labeling claims related to "natural" and "organic" dyes. These regulations necessitate comprehensive testing protocols for light and wash fastness to substantiate durability claims and prevent consumer deception.

Asian markets, particularly Japan and South Korea, have implemented stringent eco-labeling systems that evaluate natural dyes based on their environmental footprint and performance characteristics. China's GB standards specifically address natural colorants in textiles, requiring documented evidence of colorfastness properties before market approval.

Emerging regulatory trends indicate a shift toward lifecycle assessment approaches for natural dyes, considering not only their performance metrics but also their cultivation, extraction processes, and end-of-life biodegradability. The International Working Group on Natural Dyes (IWGND) is developing harmonized testing methodologies specifically tailored to the unique properties of natural colorants, acknowledging that conventional synthetic dye testing protocols may not adequately capture their performance characteristics.

Industry self-regulation through initiatives like the Natural Dye Certification Program complements governmental frameworks, establishing voluntary standards that often exceed regulatory minimums. These programs typically require comprehensive documentation of light and wash fastness properties, with transparency regarding expected performance limitations compared to synthetic alternatives.

The regulatory complexity creates significant challenges for manufacturers utilizing natural dyes, as compliance requirements vary across markets and may involve multiple certification processes. However, this regulatory framework also drives innovation in natural dye technology, pushing researchers to develop enhanced fixation methods and stabilizers that improve fastness properties while maintaining environmental credentials.

The European Union's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation imposes strict requirements on textile colorants, with particular attention to natural dyes that may contain allergenic or toxic compounds despite their natural origin. Manufacturers must demonstrate compliance through rigorous testing and documentation, ensuring that naturally dyed fabrics meet safety thresholds for human contact and environmental impact.

In the United States, the Consumer Product Safety Improvement Act (CPSIA) regulates lead content and other potentially harmful substances in textiles, while the Federal Trade Commission (FTC) oversees labeling claims related to "natural" and "organic" dyes. These regulations necessitate comprehensive testing protocols for light and wash fastness to substantiate durability claims and prevent consumer deception.

Asian markets, particularly Japan and South Korea, have implemented stringent eco-labeling systems that evaluate natural dyes based on their environmental footprint and performance characteristics. China's GB standards specifically address natural colorants in textiles, requiring documented evidence of colorfastness properties before market approval.

Emerging regulatory trends indicate a shift toward lifecycle assessment approaches for natural dyes, considering not only their performance metrics but also their cultivation, extraction processes, and end-of-life biodegradability. The International Working Group on Natural Dyes (IWGND) is developing harmonized testing methodologies specifically tailored to the unique properties of natural colorants, acknowledging that conventional synthetic dye testing protocols may not adequately capture their performance characteristics.

Industry self-regulation through initiatives like the Natural Dye Certification Program complements governmental frameworks, establishing voluntary standards that often exceed regulatory minimums. These programs typically require comprehensive documentation of light and wash fastness properties, with transparency regarding expected performance limitations compared to synthetic alternatives.

The regulatory complexity creates significant challenges for manufacturers utilizing natural dyes, as compliance requirements vary across markets and may involve multiple certification processes. However, this regulatory framework also drives innovation in natural dye technology, pushing researchers to develop enhanced fixation methods and stabilizers that improve fastness properties while maintaining environmental credentials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!