Sustainable Natural Dye Extraction: Ultrasonic And Supercritical Methods

SEP 2, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Natural Dye Technology Background and Objectives

Natural dyes have been utilized by human civilizations for thousands of years, with evidence of their application dating back to the Neolithic period. Traditional extraction methods relied on simple techniques such as boiling, soaking, and fermentation to release colorants from plant materials, animal sources, and minerals. However, these conventional approaches often suffer from low efficiency, inconsistent yields, and significant environmental impacts due to high water and energy consumption.

The global textile industry has experienced a resurgence of interest in natural dyes over the past two decades, driven by increasing consumer awareness of sustainability issues and growing concerns about the environmental and health impacts of synthetic dyes. Synthetic colorants, which currently dominate approximately 95% of the commercial dyeing market, are associated with significant pollution, toxicity concerns, and non-biodegradability challenges.

This technological evolution has created an urgent need for more efficient, sustainable extraction methodologies that can bridge the gap between traditional natural dyeing practices and modern industrial requirements. The development trajectory clearly points toward advanced extraction technologies that can maximize yield while minimizing resource consumption and environmental footprint.

Ultrasonic and supercritical fluid extraction methods represent cutting-edge approaches in this field. Ultrasonic extraction utilizes sound waves to create cavitation bubbles in a liquid medium, which collapse and generate localized high pressure and temperature conditions that enhance mass transfer and cell disruption. This technology has demonstrated potential to significantly reduce extraction time, solvent usage, and energy consumption compared to conventional methods.

Supercritical fluid extraction, particularly using carbon dioxide (CO2), offers a solvent-free alternative that operates by manipulating pressure and temperature to create a supercritical state where CO2 exhibits both gas-like diffusivity and liquid-like density. This unique phase behavior enables efficient penetration into plant matrices and selective extraction of target compounds without leaving harmful residues.

The primary objectives of advancing these technologies include: establishing standardized protocols for consistent color quality and fastness properties; scaling extraction processes to meet industrial production demands; reducing water, energy, and chemical inputs; and developing closed-loop systems that minimize waste generation and enable recovery of valuable by-products.

Additionally, these technologies aim to expand the application range of natural dyes beyond textiles to sectors such as food, cosmetics, pharmaceuticals, and advanced materials, thereby creating new market opportunities and value chains for sustainable bio-based colorants.

The global textile industry has experienced a resurgence of interest in natural dyes over the past two decades, driven by increasing consumer awareness of sustainability issues and growing concerns about the environmental and health impacts of synthetic dyes. Synthetic colorants, which currently dominate approximately 95% of the commercial dyeing market, are associated with significant pollution, toxicity concerns, and non-biodegradability challenges.

This technological evolution has created an urgent need for more efficient, sustainable extraction methodologies that can bridge the gap between traditional natural dyeing practices and modern industrial requirements. The development trajectory clearly points toward advanced extraction technologies that can maximize yield while minimizing resource consumption and environmental footprint.

Ultrasonic and supercritical fluid extraction methods represent cutting-edge approaches in this field. Ultrasonic extraction utilizes sound waves to create cavitation bubbles in a liquid medium, which collapse and generate localized high pressure and temperature conditions that enhance mass transfer and cell disruption. This technology has demonstrated potential to significantly reduce extraction time, solvent usage, and energy consumption compared to conventional methods.

Supercritical fluid extraction, particularly using carbon dioxide (CO2), offers a solvent-free alternative that operates by manipulating pressure and temperature to create a supercritical state where CO2 exhibits both gas-like diffusivity and liquid-like density. This unique phase behavior enables efficient penetration into plant matrices and selective extraction of target compounds without leaving harmful residues.

The primary objectives of advancing these technologies include: establishing standardized protocols for consistent color quality and fastness properties; scaling extraction processes to meet industrial production demands; reducing water, energy, and chemical inputs; and developing closed-loop systems that minimize waste generation and enable recovery of valuable by-products.

Additionally, these technologies aim to expand the application range of natural dyes beyond textiles to sectors such as food, cosmetics, pharmaceuticals, and advanced materials, thereby creating new market opportunities and value chains for sustainable bio-based colorants.

Market Analysis for Sustainable Dye Solutions

The global market for sustainable dye solutions is experiencing significant growth, driven by increasing consumer awareness and regulatory pressures regarding environmental impact. The natural dye market was valued at approximately $1.5 billion in 2022 and is projected to grow at a CAGR of 11.3% through 2030, reaching an estimated $3.6 billion. This growth trajectory reflects a fundamental shift in consumer preferences toward environmentally responsible products across multiple industries.

Textile and fashion sectors represent the largest market segment for sustainable dyes, accounting for roughly 65% of current demand. Major fashion brands including H&M, Patagonia, and Stella McCartney have implemented sustainable dyeing initiatives in their production processes, signaling a market-wide transition. The food and beverage industry constitutes the second-largest market segment at 18%, followed by cosmetics at 12%.

Geographically, Europe leads the sustainable dye market with approximately 38% market share, driven by stringent environmental regulations and consumer awareness. The Asia-Pacific region follows at 32%, with particularly rapid growth in countries like India and China, where traditional natural dyeing techniques are being revitalized through modern extraction methods. North America accounts for 24% of the market, with strong growth in premium and organic product segments.

The market dynamics reveal a significant price premium for sustainably produced dyes, typically 30-45% higher than conventional synthetic alternatives. However, this gap is narrowing as extraction technologies improve and economies of scale develop. Ultrasonic extraction methods have demonstrated cost reductions of up to 25% compared to traditional extraction processes, while supercritical fluid extraction offers higher purity products that command premium pricing in specialized applications.

Consumer willingness to pay this premium varies by sector, with highest acceptance in premium fashion, organic cosmetics, and natural food colorants. Market research indicates that 72% of consumers express preference for products using natural dyes, though actual purchasing decisions remain price-sensitive for mass-market applications.

Supply chain considerations represent a critical market factor, with challenges in scaling production and ensuring consistent quality from natural sources. Companies that have successfully integrated vertical supply chains from agricultural production through extraction have gained significant competitive advantages. The development of hybrid business models combining traditional knowledge with advanced extraction technologies presents promising market opportunities, particularly in regions with rich biodiversity and dyeing traditions.

Textile and fashion sectors represent the largest market segment for sustainable dyes, accounting for roughly 65% of current demand. Major fashion brands including H&M, Patagonia, and Stella McCartney have implemented sustainable dyeing initiatives in their production processes, signaling a market-wide transition. The food and beverage industry constitutes the second-largest market segment at 18%, followed by cosmetics at 12%.

Geographically, Europe leads the sustainable dye market with approximately 38% market share, driven by stringent environmental regulations and consumer awareness. The Asia-Pacific region follows at 32%, with particularly rapid growth in countries like India and China, where traditional natural dyeing techniques are being revitalized through modern extraction methods. North America accounts for 24% of the market, with strong growth in premium and organic product segments.

The market dynamics reveal a significant price premium for sustainably produced dyes, typically 30-45% higher than conventional synthetic alternatives. However, this gap is narrowing as extraction technologies improve and economies of scale develop. Ultrasonic extraction methods have demonstrated cost reductions of up to 25% compared to traditional extraction processes, while supercritical fluid extraction offers higher purity products that command premium pricing in specialized applications.

Consumer willingness to pay this premium varies by sector, with highest acceptance in premium fashion, organic cosmetics, and natural food colorants. Market research indicates that 72% of consumers express preference for products using natural dyes, though actual purchasing decisions remain price-sensitive for mass-market applications.

Supply chain considerations represent a critical market factor, with challenges in scaling production and ensuring consistent quality from natural sources. Companies that have successfully integrated vertical supply chains from agricultural production through extraction have gained significant competitive advantages. The development of hybrid business models combining traditional knowledge with advanced extraction technologies presents promising market opportunities, particularly in regions with rich biodiversity and dyeing traditions.

Current Extraction Challenges and Limitations

Despite the growing interest in natural dyes as sustainable alternatives to synthetic colorants, the conventional extraction methods present significant challenges that hinder widespread industrial adoption. Traditional extraction techniques such as maceration, decoction, and Soxhlet extraction are characterized by low efficiency, requiring extended processing times ranging from several hours to days. This prolonged duration not only increases energy consumption but also elevates operational costs, making natural dye extraction economically less competitive compared to synthetic dye production.

Water consumption represents another critical limitation, with conventional methods typically requiring large volumes of water—often exceeding 100 liters per kilogram of plant material. This intensive water usage contributes to resource depletion and generates substantial volumes of wastewater containing residual chemicals and organic matter, necessitating additional treatment before discharge.

The use of chemical solvents in conventional extraction processes raises significant environmental and health concerns. Organic solvents like methanol, ethanol, and acetone, while effective for extraction, are associated with toxicity, flammability, and environmental persistence. Their disposal requires specialized handling procedures, and residual solvents in the final product may compromise compliance with increasingly stringent regulatory standards for consumer products.

Yield inconsistency presents a major technical challenge, with extraction efficiency varying significantly based on plant source, harvesting season, and processing conditions. This variability makes standardization difficult and affects color consistency in final applications—a critical factor for commercial viability. Furthermore, the quality of extracted dyes often suffers from thermal degradation during prolonged heating, resulting in altered hue properties and reduced tinctorial strength.

Scalability remains problematic as most conventional extraction methods were developed for laboratory or small-batch production. The transition to industrial scale introduces challenges related to equipment design, process control, and quality assurance. Many existing facilities lack the specialized infrastructure required for efficient large-scale natural dye extraction, necessitating significant capital investment.

Additionally, the selective extraction of target chromophores presents technical difficulties. Plant materials contain numerous compounds besides colorants, including tannins, flavonoids, and other secondary metabolites that may co-extract and interfere with dyeing performance. Current methods often lack the selectivity to isolate specific colorant compounds, resulting in complex mixtures that require additional purification steps, further increasing production costs and reducing overall process efficiency.

Water consumption represents another critical limitation, with conventional methods typically requiring large volumes of water—often exceeding 100 liters per kilogram of plant material. This intensive water usage contributes to resource depletion and generates substantial volumes of wastewater containing residual chemicals and organic matter, necessitating additional treatment before discharge.

The use of chemical solvents in conventional extraction processes raises significant environmental and health concerns. Organic solvents like methanol, ethanol, and acetone, while effective for extraction, are associated with toxicity, flammability, and environmental persistence. Their disposal requires specialized handling procedures, and residual solvents in the final product may compromise compliance with increasingly stringent regulatory standards for consumer products.

Yield inconsistency presents a major technical challenge, with extraction efficiency varying significantly based on plant source, harvesting season, and processing conditions. This variability makes standardization difficult and affects color consistency in final applications—a critical factor for commercial viability. Furthermore, the quality of extracted dyes often suffers from thermal degradation during prolonged heating, resulting in altered hue properties and reduced tinctorial strength.

Scalability remains problematic as most conventional extraction methods were developed for laboratory or small-batch production. The transition to industrial scale introduces challenges related to equipment design, process control, and quality assurance. Many existing facilities lack the specialized infrastructure required for efficient large-scale natural dye extraction, necessitating significant capital investment.

Additionally, the selective extraction of target chromophores presents technical difficulties. Plant materials contain numerous compounds besides colorants, including tannins, flavonoids, and other secondary metabolites that may co-extract and interfere with dyeing performance. Current methods often lack the selectivity to isolate specific colorant compounds, resulting in complex mixtures that require additional purification steps, further increasing production costs and reducing overall process efficiency.

Ultrasonic and Supercritical Extraction Techniques

01 Eco-friendly extraction methods for natural dyes

Sustainable extraction methods for natural dyes focus on reducing environmental impact through water conservation, energy efficiency, and minimizing chemical usage. These methods include ultrasonic extraction, microwave-assisted extraction, and supercritical fluid extraction, which require less solvent and energy compared to conventional methods. These techniques not only preserve the environment but also maintain the quality and yield of the natural colorants.- Eco-friendly extraction methods for natural dyes: Sustainable extraction methods for natural dyes focus on reducing environmental impact through techniques that minimize water usage, energy consumption, and chemical waste. These methods include ultrasonic-assisted extraction, microwave-assisted extraction, and supercritical fluid extraction, which can significantly reduce processing time and solvent requirements while maintaining dye quality. These green extraction technologies help preserve natural resources and reduce the carbon footprint of dye production processes.

- Plant-based sources for sustainable natural dyes: Various plant materials serve as renewable sources for natural dyes, including agricultural waste, by-products, and specifically cultivated dye plants. These sources include bark, leaves, roots, flowers, and fruits that can be harvested sustainably without depleting natural resources. The use of agricultural waste and by-products as dye sources contributes to circular economy principles by converting what would otherwise be waste into valuable colorants, reducing environmental burden while providing economic benefits.

- Water conservation and waste reduction in dye extraction: Innovative approaches to water conservation in natural dye extraction include closed-loop water systems, water recycling technologies, and low-water extraction methods. These techniques significantly reduce freshwater consumption and minimize wastewater generation. Additionally, solid waste from extraction processes can be repurposed as compost or biofuel, further enhancing sustainability. The implementation of these water and waste management strategies helps make natural dye production more environmentally responsible and economically viable.

- Biodegradable mordants and fixatives for natural dyes: Sustainable natural dye processes incorporate biodegradable mordants and fixatives derived from plant and mineral sources to replace toxic metal-based alternatives. These eco-friendly binding agents improve color fastness and expand the color palette of natural dyes while reducing environmental contamination. Examples include tannin-rich plant extracts, alum from natural sources, and biopolymers that enhance dye performance without the ecological drawbacks of conventional mordants, making the entire dyeing process more sustainable.

- Energy-efficient dye processing technologies: Energy-efficient technologies for natural dye processing include solar-powered drying systems, low-temperature extraction methods, and optimized heating processes that reduce fossil fuel consumption. These innovations decrease the carbon footprint of dye production while maintaining or improving dye quality. Integration of renewable energy sources and heat recovery systems further enhances energy efficiency throughout the extraction and processing stages, contributing to more sustainable manufacturing practices in the natural dye industry.

02 Plant-based sources for sustainable natural dyes

Various plant materials serve as renewable sources for natural dyes, including agricultural waste, by-products, and specifically cultivated crops. These sources include fruit peels, flower petals, leaves, bark, and roots that contain pigments suitable for textile dyeing. The use of these renewable resources reduces dependency on synthetic dyes and promotes biodiversity conservation while creating value from materials that might otherwise be discarded.Expand Specific Solutions03 Waste reduction and circular economy approaches

Implementing circular economy principles in natural dye production involves reusing extraction waste, recycling process water, and creating closed-loop systems. These approaches minimize waste generation and resource consumption while maximizing the value derived from raw materials. Extraction residues can be repurposed as fertilizers, biofuels, or other value-added products, creating additional revenue streams and reducing environmental footprint.Expand Specific Solutions04 Water and energy conservation techniques

Sustainable natural dye extraction incorporates water and energy conservation techniques such as low-liquor ratio processes, cold extraction methods, and solar-powered systems. These approaches significantly reduce the environmental impact of dye production by minimizing resource consumption. Innovations include water recycling systems, heat recovery mechanisms, and optimized extraction parameters that maintain dye quality while reducing utility requirements.Expand Specific Solutions05 Biodegradable mordants and fixatives

Developing and utilizing biodegradable mordants and fixatives enhances the sustainability of natural dyeing processes. These eco-friendly alternatives to traditional metal-based mordants include plant-derived tannins, bio-mordants from waste materials, and natural fixing agents. Such innovations improve color fastness and dye uptake while reducing environmental pollution and health hazards associated with conventional mordanting chemicals.Expand Specific Solutions

Key Industry Players and Research Institutions

The sustainable natural dye extraction market is in a growth phase, characterized by increasing demand for eco-friendly alternatives to synthetic dyes. The global market size is expanding rapidly, driven by consumer preference for sustainable products and stricter environmental regulations. Technologically, ultrasonic and supercritical extraction methods are advancing toward commercial maturity, with key players demonstrating varied levels of innovation. Academic institutions like Donghua University, Zhejiang University, and Soochow University are leading fundamental research, while companies such as DyeCoo Textile Systems have achieved commercial implementation of CO2-based dyeing technologies. Research organizations including CSIC, Fraunhofer-Gesellschaft, and ITRI are bridging the gap between laboratory research and industrial application, focusing on process optimization and scalability challenges for these environmentally superior extraction methods.

The Hong Kong Research Institute of Textiles & Apparel Ltd.

Technical Solution: The Hong Kong Research Institute of Textiles & Apparel (HKRITA) has developed an innovative hybrid extraction system for natural dyes that combines ultrasonic technology with subcritical water extraction. Their patented process utilizes precisely controlled ultrasonic waves (28-35 kHz) to enhance mass transfer during extraction, while maintaining temperatures between 100-180°C and pressures of 10-50 bar to keep water in a subcritical state. This approach leverages water's changing properties under these conditions, where it becomes less polar and more effective at extracting both hydrophilic and hydrophobic compounds from plant materials. HKRITA's system incorporates a continuous flow design with multiple extraction chambers operating in sequence, allowing for industrial-scale production with reduced energy consumption. Their technology includes specialized ultrasonic transducers designed to maintain efficiency even in high-temperature environments, with computer-controlled amplitude modulation to optimize extraction based on the specific plant material. The institute has also developed proprietary natural mordanting techniques using sustainable metal-free alternatives derived from agricultural waste, creating a fully sustainable dyeing process from extraction to application.

Strengths: Highly efficient extraction of both polar and non-polar compounds, reduced extraction times (up to 85% faster than conventional methods), water-based process eliminating organic solvents, scalable continuous flow design for industrial applications, and integration with sustainable mordanting technologies. Weaknesses: Higher energy requirements for maintaining subcritical conditions, potential thermal degradation of certain heat-sensitive compounds, equipment complexity requiring specialized maintenance, and challenges in process parameter optimization for consistent color quality.

Council of Scientific & Industrial Research

Technical Solution: The Council of Scientific & Industrial Research (CSIR) has developed comprehensive sustainable extraction technologies for natural dyes through its network of laboratories. Their flagship system combines pulsed ultrasonic extraction with enzyme-assisted pre-treatment for enhanced efficiency. The technology utilizes controlled ultrasonic frequencies (20-35 kHz) with optimized duty cycles to prevent thermal degradation while maximizing extraction yield. For more challenging colorants, CSIR has engineered a supercritical fluid extraction platform that operates with modified CO2 using natural bio-based co-solvents derived from agricultural waste. This approach allows for selective extraction of target compounds while minimizing the extraction of unwanted impurities. CSIR's integrated biorefinery approach ensures that residual biomass after dye extraction is further processed into value-added products like biofuels or agricultural amendments, creating a zero-waste process. Their technology has been successfully scaled to industrial levels through pilot plants established across India, with documented water savings of 80-95% compared to conventional extraction methods. CSIR has also developed specialized natural dye formulations that enhance color fastness without synthetic mordants, addressing a key limitation of natural dyes in commercial applications.

Strengths: Holistic biorefinery approach creating multiple value streams from plant materials, significant reduction in water consumption (80-95%), elimination of harmful chemicals, scalable technology with established pilot plants, and enhanced dye performance through specialized formulations. Weaknesses: Complex multi-stage process requiring careful integration of different technologies, higher initial investment costs, variations in yield based on plant material quality, and challenges in standardizing color consistency across production batches.

Core Patents in Advanced Extraction Technologies

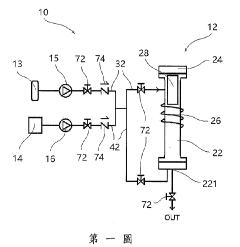

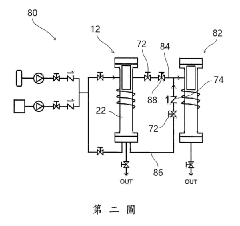

Highly efficient ultrasonic extraction device and method for improving supercritical extraction efficiency capable of improving extraction efficiency and shortening extraction time of a high-pressure reaction tank

PatentActiveTW202015802A

Innovation

- The implementation of an ultrasonic rod directly inserted into the high-pressure reaction tank during the extraction process, generating high-frequency oscillations to act on the liquid raw materials, combined with a system of high-pressure pumps and control valves, to enhance extraction efficiency and reduce time.

Environmental Impact Assessment

The environmental impact assessment of sustainable natural dye extraction methods reveals significant advantages over conventional techniques. Ultrasonic and supercritical extraction methods demonstrate substantially reduced environmental footprints across multiple ecological dimensions, positioning them as viable alternatives for the textile industry's transition toward sustainability.

Water consumption metrics indicate that ultrasonic extraction requires approximately 40-60% less water compared to traditional boiling methods. This reduction is particularly significant considering the textile industry's status as one of the largest industrial consumers of freshwater globally. The decreased water usage directly translates to reduced wastewater generation, alleviating pressure on water treatment facilities and natural water bodies.

Energy efficiency analyses demonstrate that ultrasonic-assisted extraction operates at lower temperatures (typically 30-60°C versus 90-100°C for conventional methods), resulting in energy savings of 30-50%. Supercritical CO2 extraction, while initially energy-intensive during pressurization, achieves overall energy efficiency through shorter processing times and elimination of post-extraction drying processes.

Chemical input requirements are dramatically reduced with these advanced methods. Ultrasonic extraction can decrease solvent usage by 50-70%, while supercritical CO2 extraction eliminates organic solvents entirely. This reduction minimizes the release of harmful chemicals into ecosystems and reduces the carbon footprint associated with chemical production and transportation.

Waste generation assessments reveal that both methods produce significantly less solid waste. Ultrasonic extraction increases yield efficiency by 15-25%, meaning more colorant is extracted from the same amount of raw material. Supercritical methods demonstrate even higher efficiency, with some studies reporting yield improvements of up to 40% compared to conventional techniques.

Carbon footprint calculations, when considering the entire extraction lifecycle, show potential reductions of 25-45% with ultrasonic methods and 30-60% with supercritical CO2 extraction. These figures account for equipment manufacturing, operational energy, and reduced waste management requirements.

Biodiversity impact studies indicate that the reduced demand for raw plant material (due to higher extraction efficiency) could decrease harvesting pressure on wild plant populations. This is particularly relevant for rare or slow-growing plant species used in natural dyeing processes, potentially contributing to conservation efforts in biodiversity hotspots.

The scalability of these environmental benefits remains a critical consideration, as industrial implementation may present different efficiency profiles compared to laboratory conditions. Ongoing lifecycle assessment studies are essential to validate these environmental advantages at commercial production scales.

Water consumption metrics indicate that ultrasonic extraction requires approximately 40-60% less water compared to traditional boiling methods. This reduction is particularly significant considering the textile industry's status as one of the largest industrial consumers of freshwater globally. The decreased water usage directly translates to reduced wastewater generation, alleviating pressure on water treatment facilities and natural water bodies.

Energy efficiency analyses demonstrate that ultrasonic-assisted extraction operates at lower temperatures (typically 30-60°C versus 90-100°C for conventional methods), resulting in energy savings of 30-50%. Supercritical CO2 extraction, while initially energy-intensive during pressurization, achieves overall energy efficiency through shorter processing times and elimination of post-extraction drying processes.

Chemical input requirements are dramatically reduced with these advanced methods. Ultrasonic extraction can decrease solvent usage by 50-70%, while supercritical CO2 extraction eliminates organic solvents entirely. This reduction minimizes the release of harmful chemicals into ecosystems and reduces the carbon footprint associated with chemical production and transportation.

Waste generation assessments reveal that both methods produce significantly less solid waste. Ultrasonic extraction increases yield efficiency by 15-25%, meaning more colorant is extracted from the same amount of raw material. Supercritical methods demonstrate even higher efficiency, with some studies reporting yield improvements of up to 40% compared to conventional techniques.

Carbon footprint calculations, when considering the entire extraction lifecycle, show potential reductions of 25-45% with ultrasonic methods and 30-60% with supercritical CO2 extraction. These figures account for equipment manufacturing, operational energy, and reduced waste management requirements.

Biodiversity impact studies indicate that the reduced demand for raw plant material (due to higher extraction efficiency) could decrease harvesting pressure on wild plant populations. This is particularly relevant for rare or slow-growing plant species used in natural dyeing processes, potentially contributing to conservation efforts in biodiversity hotspots.

The scalability of these environmental benefits remains a critical consideration, as industrial implementation may present different efficiency profiles compared to laboratory conditions. Ongoing lifecycle assessment studies are essential to validate these environmental advantages at commercial production scales.

Scalability and Industrial Implementation

The transition from laboratory-scale extraction to industrial implementation represents a critical challenge for sustainable natural dye extraction technologies. Ultrasonic and supercritical fluid extraction methods have demonstrated significant potential at research levels, but their commercial viability depends on successful scaling strategies that maintain efficiency while managing economic constraints.

For ultrasonic extraction systems, industrial scaling requires careful consideration of equipment design. Current industrial ultrasonic reactors typically operate in flow-through configurations, with capacities ranging from 100 to 5,000 liters per hour. The primary scaling challenge involves maintaining uniform ultrasonic wave distribution throughout larger volumes, as energy dissipation increases with distance from the transducer source. Multi-transducer arrays and optimized reactor geometries have emerged as promising solutions, with companies like Hielscher Ultrasonics and Industrial Sonomechanics offering specialized equipment for natural product extraction.

Supercritical CO2 extraction faces different scaling considerations, primarily centered around pressure vessel engineering and safety requirements. Industrial systems typically operate at pressures between 100-400 bar, necessitating substantial capital investment. Companies including Separex and Natex have developed modular extraction units with capacities ranging from 50-500 liters, allowing for incremental scaling as production demands increase. The high initial investment (€500,000-2,000,000) represents a significant barrier to entry, though operational costs remain competitive due to CO2 recycling capabilities.

Economic viability analysis indicates that ultrasonic extraction generally offers lower capital expenditure but higher operational costs due to energy consumption. Conversely, supercritical extraction requires substantial initial investment but demonstrates superior efficiency and solvent recovery, resulting in lower long-term operational expenses. Break-even analysis suggests ultrasonic systems become economically viable at smaller production scales (>500 kg/year), while supercritical systems require larger production volumes (>2,000 kg/year) to justify their implementation.

Recent industrial implementations demonstrate promising results. Archroma's ultrasonic-assisted natural dye production facility in Pakistan has achieved a 40% reduction in water consumption and 30% decrease in energy usage compared to conventional methods. Similarly, Sensient Technologies' supercritical extraction plant in Indianapolis has reported 95% solvent recovery rates and significantly reduced waste generation, though with higher capital costs.

Future scalability improvements will likely focus on hybrid systems that combine ultrasonic pre-treatment with supercritical extraction, potentially offering optimized efficiency across various production scales. Additionally, continuous flow systems are gaining traction as alternatives to batch processing, potentially reducing capital requirements while maintaining extraction efficiency.

For ultrasonic extraction systems, industrial scaling requires careful consideration of equipment design. Current industrial ultrasonic reactors typically operate in flow-through configurations, with capacities ranging from 100 to 5,000 liters per hour. The primary scaling challenge involves maintaining uniform ultrasonic wave distribution throughout larger volumes, as energy dissipation increases with distance from the transducer source. Multi-transducer arrays and optimized reactor geometries have emerged as promising solutions, with companies like Hielscher Ultrasonics and Industrial Sonomechanics offering specialized equipment for natural product extraction.

Supercritical CO2 extraction faces different scaling considerations, primarily centered around pressure vessel engineering and safety requirements. Industrial systems typically operate at pressures between 100-400 bar, necessitating substantial capital investment. Companies including Separex and Natex have developed modular extraction units with capacities ranging from 50-500 liters, allowing for incremental scaling as production demands increase. The high initial investment (€500,000-2,000,000) represents a significant barrier to entry, though operational costs remain competitive due to CO2 recycling capabilities.

Economic viability analysis indicates that ultrasonic extraction generally offers lower capital expenditure but higher operational costs due to energy consumption. Conversely, supercritical extraction requires substantial initial investment but demonstrates superior efficiency and solvent recovery, resulting in lower long-term operational expenses. Break-even analysis suggests ultrasonic systems become economically viable at smaller production scales (>500 kg/year), while supercritical systems require larger production volumes (>2,000 kg/year) to justify their implementation.

Recent industrial implementations demonstrate promising results. Archroma's ultrasonic-assisted natural dye production facility in Pakistan has achieved a 40% reduction in water consumption and 30% decrease in energy usage compared to conventional methods. Similarly, Sensient Technologies' supercritical extraction plant in Indianapolis has reported 95% solvent recovery rates and significantly reduced waste generation, though with higher capital costs.

Future scalability improvements will likely focus on hybrid systems that combine ultrasonic pre-treatment with supercritical extraction, potentially offering optimized efficiency across various production scales. Additionally, continuous flow systems are gaining traction as alternatives to batch processing, potentially reducing capital requirements while maintaining extraction efficiency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!