Comparative LCA Of Natural Dyeing Versus Synthetic Dyeing Processes

SEP 2, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Natural vs Synthetic Dyeing Background & Objectives

The textile dyeing industry has undergone significant transformation since its inception thousands of years ago. Natural dyeing, utilizing plant, animal, and mineral sources, dominated the industry until the mid-19th century when William Henry Perkin's accidental discovery of mauveine in 1856 revolutionized the field. This marked the beginning of synthetic dye production, which rapidly expanded due to its cost-effectiveness, color consistency, and scalability advantages. Today, synthetic dyes account for approximately 90% of global textile coloration, with an estimated annual production exceeding 700,000 tons.

The environmental and health implications of synthetic dyeing processes have become increasingly concerning in recent decades. These processes typically consume substantial water resources (70-150 liters per kg of fabric), utilize hazardous chemicals, and generate significant wastewater containing toxic substances. Conversely, natural dyeing has reemerged as a potential sustainable alternative, though it faces challenges in scalability, color consistency, and economic viability in modern industrial contexts.

This technical research aims to conduct a comprehensive Life Cycle Assessment (LCA) comparing natural and synthetic dyeing processes across their entire value chains. The primary objective is to quantify and evaluate the environmental impacts of both approaches, including resource consumption, energy usage, greenhouse gas emissions, water pollution, and waste generation. Additionally, this assessment seeks to identify potential optimization pathways for both technologies to enhance their sustainability profiles.

The research will examine various natural dyeing methods utilizing common sources such as indigo, madder, cochineal, and cutch, alongside prevalent synthetic dyeing processes employing reactive, disperse, acid, and vat dyes. The assessment will consider regional variations in practices, resource availability, and regulatory frameworks to provide a nuanced understanding of contextual factors influencing environmental performance.

Beyond environmental metrics, this research aims to evaluate the technical performance characteristics of both dyeing approaches, including colorfastness, light stability, wash resistance, and overall durability. These factors significantly influence product longevity and consequently affect the overall life cycle environmental footprint of dyed textiles.

The findings from this comparative LCA will serve as a foundation for developing more sustainable dyeing technologies that potentially combine the best attributes of both natural and synthetic approaches. The ultimate goal is to provide evidence-based guidance for industry stakeholders, policymakers, and researchers to advance more environmentally responsible textile coloration practices while meeting modern market demands for performance, consistency, and economic viability.

The environmental and health implications of synthetic dyeing processes have become increasingly concerning in recent decades. These processes typically consume substantial water resources (70-150 liters per kg of fabric), utilize hazardous chemicals, and generate significant wastewater containing toxic substances. Conversely, natural dyeing has reemerged as a potential sustainable alternative, though it faces challenges in scalability, color consistency, and economic viability in modern industrial contexts.

This technical research aims to conduct a comprehensive Life Cycle Assessment (LCA) comparing natural and synthetic dyeing processes across their entire value chains. The primary objective is to quantify and evaluate the environmental impacts of both approaches, including resource consumption, energy usage, greenhouse gas emissions, water pollution, and waste generation. Additionally, this assessment seeks to identify potential optimization pathways for both technologies to enhance their sustainability profiles.

The research will examine various natural dyeing methods utilizing common sources such as indigo, madder, cochineal, and cutch, alongside prevalent synthetic dyeing processes employing reactive, disperse, acid, and vat dyes. The assessment will consider regional variations in practices, resource availability, and regulatory frameworks to provide a nuanced understanding of contextual factors influencing environmental performance.

Beyond environmental metrics, this research aims to evaluate the technical performance characteristics of both dyeing approaches, including colorfastness, light stability, wash resistance, and overall durability. These factors significantly influence product longevity and consequently affect the overall life cycle environmental footprint of dyed textiles.

The findings from this comparative LCA will serve as a foundation for developing more sustainable dyeing technologies that potentially combine the best attributes of both natural and synthetic approaches. The ultimate goal is to provide evidence-based guidance for industry stakeholders, policymakers, and researchers to advance more environmentally responsible textile coloration practices while meeting modern market demands for performance, consistency, and economic viability.

Market Demand Analysis for Sustainable Dyeing Solutions

The global market for sustainable dyeing solutions has witnessed significant growth in recent years, driven by increasing consumer awareness about environmental issues and the harmful impacts of conventional synthetic dyeing processes. The textile industry, being one of the largest industrial polluters globally, is facing mounting pressure to adopt more sustainable practices, particularly in dyeing operations which account for approximately 20% of global industrial water pollution.

Consumer demand for eco-friendly products has created a substantial market opportunity for natural dyeing processes. Market research indicates that the sustainable textile market is growing at a compound annual growth rate of 12%, with naturally dyed textiles representing a rapidly expanding segment. This growth is particularly pronounced in developed economies across North America and Europe, where consumers are increasingly willing to pay premium prices for environmentally responsible products.

Regulatory frameworks are also reshaping market dynamics. The European Union's REACH regulations, along with similar initiatives in other regions, are restricting the use of certain synthetic dyes and chemicals, creating regulatory incentives for manufacturers to explore natural alternatives. Major fashion brands are responding to these pressures by establishing sustainability targets that explicitly include transitions to more environmentally friendly dyeing processes.

The B2B market segment shows promising growth potential as well. Corporate sustainability commitments are driving textile manufacturers to seek suppliers who can provide naturally dyed materials. This trend is particularly evident in the luxury fashion sector, where brands are leveraging sustainable practices as a competitive differentiator and brand value enhancer.

Despite positive market signals, several factors constrain wider adoption of natural dyeing processes. Price sensitivity remains a significant barrier, with naturally dyed textiles typically commanding a 15-30% premium over conventionally dyed alternatives. Additionally, scalability challenges and concerns about color consistency and fastness have limited penetration in mass-market segments.

Market forecasts suggest that as technological innovations address these limitations and economies of scale improve, the cost differential between natural and synthetic dyeing processes will narrow. The market for natural dyes is projected to expand beyond fashion into home textiles, automotive textiles, and other industrial applications, further driving demand growth.

Consumer education represents another critical market factor. Studies show that when consumers understand the environmental benefits of natural dyeing processes, purchase intent increases substantially. This indicates significant potential for market expansion through targeted awareness campaigns and transparent communication about the comparative environmental impacts of different dyeing methods.

Consumer demand for eco-friendly products has created a substantial market opportunity for natural dyeing processes. Market research indicates that the sustainable textile market is growing at a compound annual growth rate of 12%, with naturally dyed textiles representing a rapidly expanding segment. This growth is particularly pronounced in developed economies across North America and Europe, where consumers are increasingly willing to pay premium prices for environmentally responsible products.

Regulatory frameworks are also reshaping market dynamics. The European Union's REACH regulations, along with similar initiatives in other regions, are restricting the use of certain synthetic dyes and chemicals, creating regulatory incentives for manufacturers to explore natural alternatives. Major fashion brands are responding to these pressures by establishing sustainability targets that explicitly include transitions to more environmentally friendly dyeing processes.

The B2B market segment shows promising growth potential as well. Corporate sustainability commitments are driving textile manufacturers to seek suppliers who can provide naturally dyed materials. This trend is particularly evident in the luxury fashion sector, where brands are leveraging sustainable practices as a competitive differentiator and brand value enhancer.

Despite positive market signals, several factors constrain wider adoption of natural dyeing processes. Price sensitivity remains a significant barrier, with naturally dyed textiles typically commanding a 15-30% premium over conventionally dyed alternatives. Additionally, scalability challenges and concerns about color consistency and fastness have limited penetration in mass-market segments.

Market forecasts suggest that as technological innovations address these limitations and economies of scale improve, the cost differential between natural and synthetic dyeing processes will narrow. The market for natural dyes is projected to expand beyond fashion into home textiles, automotive textiles, and other industrial applications, further driving demand growth.

Consumer education represents another critical market factor. Studies show that when consumers understand the environmental benefits of natural dyeing processes, purchase intent increases substantially. This indicates significant potential for market expansion through targeted awareness campaigns and transparent communication about the comparative environmental impacts of different dyeing methods.

Current LCA Methodologies and Technical Challenges

Life Cycle Assessment (LCA) methodologies for textile dyeing processes have evolved significantly over the past decades, with standardized frameworks established by ISO 14040 and 14044 providing the foundation for most analyses. Current LCA approaches typically divide the assessment into four phases: goal and scope definition, inventory analysis, impact assessment, and interpretation. However, when comparing natural and synthetic dyeing processes, several methodological challenges emerge that complicate accurate assessment.

The boundary definition represents a primary challenge in dyeing LCAs. For synthetic dyes, system boundaries must encompass petrochemical extraction, chemical synthesis, and waste treatment. Natural dyeing processes require consideration of agricultural production, harvesting, extraction, and biomass disposal. These fundamentally different supply chains create inconsistencies in comparative analyses, particularly regarding land use allocation and agricultural inputs for natural dyes.

Data quality and availability present significant obstacles, especially for natural dyeing processes. While synthetic dyeing has established industrial databases with relatively consistent input-output metrics, natural dyeing processes often lack standardized production data due to regional variations in cultivation practices, extraction methods, and artisanal production techniques. This data asymmetry frequently results in higher uncertainty margins for natural dyeing LCAs.

Impact category selection poses another critical challenge. Traditional LCAs focus predominantly on environmental indicators like global warming potential, acidification, and eutrophication, where synthetic processes often show quantifiable impacts. However, these frameworks may inadequately capture the toxicological benefits of natural dyes or their biodegradability advantages. Emerging impact categories such as microplastic pollution and chemical persistence in ecosystems remain inconsistently applied across comparative studies.

Temporal considerations further complicate assessment validity. Synthetic dyeing processes represent mature technologies with optimized efficiency, while natural dyeing methods often reflect traditional practices with significant potential for technological improvement. Static LCA models struggle to account for this innovation disparity, potentially disadvantaging natural dyeing in comparative analyses.

Allocation methods for co-products and by-products represent another methodological challenge. Natural dyeing often generates valuable agricultural residues that can be repurposed, while synthetic dyeing waste typically requires specialized treatment. Current allocation approaches vary widely across studies, from economic allocation to system expansion, creating inconsistencies in comparative results.

Functional unit definition remains particularly problematic when comparing these dyeing technologies. While color fastness, consistency, and scalability are readily achieved with synthetic dyes, natural dyes often exhibit variable performance characteristics. Establishing equivalent functional units that account for these differences without biasing results requires more sophisticated methodological approaches than currently employed in most comparative studies.

The boundary definition represents a primary challenge in dyeing LCAs. For synthetic dyes, system boundaries must encompass petrochemical extraction, chemical synthesis, and waste treatment. Natural dyeing processes require consideration of agricultural production, harvesting, extraction, and biomass disposal. These fundamentally different supply chains create inconsistencies in comparative analyses, particularly regarding land use allocation and agricultural inputs for natural dyes.

Data quality and availability present significant obstacles, especially for natural dyeing processes. While synthetic dyeing has established industrial databases with relatively consistent input-output metrics, natural dyeing processes often lack standardized production data due to regional variations in cultivation practices, extraction methods, and artisanal production techniques. This data asymmetry frequently results in higher uncertainty margins for natural dyeing LCAs.

Impact category selection poses another critical challenge. Traditional LCAs focus predominantly on environmental indicators like global warming potential, acidification, and eutrophication, where synthetic processes often show quantifiable impacts. However, these frameworks may inadequately capture the toxicological benefits of natural dyes or their biodegradability advantages. Emerging impact categories such as microplastic pollution and chemical persistence in ecosystems remain inconsistently applied across comparative studies.

Temporal considerations further complicate assessment validity. Synthetic dyeing processes represent mature technologies with optimized efficiency, while natural dyeing methods often reflect traditional practices with significant potential for technological improvement. Static LCA models struggle to account for this innovation disparity, potentially disadvantaging natural dyeing in comparative analyses.

Allocation methods for co-products and by-products represent another methodological challenge. Natural dyeing often generates valuable agricultural residues that can be repurposed, while synthetic dyeing waste typically requires specialized treatment. Current allocation approaches vary widely across studies, from economic allocation to system expansion, creating inconsistencies in comparative results.

Functional unit definition remains particularly problematic when comparing these dyeing technologies. While color fastness, consistency, and scalability are readily achieved with synthetic dyes, natural dyes often exhibit variable performance characteristics. Establishing equivalent functional units that account for these differences without biasing results requires more sophisticated methodological approaches than currently employed in most comparative studies.

Comparative LCA Frameworks and Implementation

01 Natural dyeing processes with reduced environmental impact

Natural dyeing processes utilize plant-based or other natural sources to create dyes that have significantly lower environmental impact compared to synthetic alternatives. These processes often use renewable resources, biodegradable materials, and require less toxic chemicals. Natural dyeing methods can reduce water pollution, energy consumption, and carbon emissions while still achieving desirable coloration results for various textiles and materials.- Eco-friendly natural dyeing processes: Natural dyeing processes utilize plant-based or other natural sources for coloration, significantly reducing environmental impact compared to synthetic methods. These processes typically use renewable resources, biodegradable materials, and require less toxic chemicals. Natural dyeing techniques often incorporate traditional knowledge with modern sustainable practices, resulting in lower water pollution and reduced carbon footprint while still achieving desirable color outcomes.

- Water conservation and treatment in dyeing processes: Innovative dyeing processes focus on water conservation and treatment to minimize environmental impact. These technologies include closed-loop water systems, advanced filtration methods, and wastewater treatment processes specifically designed for dye effluents. By reducing water consumption and treating contaminated water before discharge, these methods significantly decrease pollution of water bodies and help preserve this vital resource while maintaining dyeing efficiency.

- Reduced chemical usage in synthetic dyeing: Modern synthetic dyeing processes aim to reduce chemical usage through optimized formulations and application methods. These approaches include developing concentrated dyes that require smaller quantities, substituting harmful chemicals with environmentally benign alternatives, and creating more efficient dyeing processes that achieve better color fixation with fewer chemicals. These innovations help minimize toxic waste generation and reduce the overall environmental footprint of synthetic dyeing operations.

- Energy-efficient dyeing technologies: Energy-efficient dyeing technologies focus on reducing the substantial energy consumption typically associated with dyeing processes. These innovations include low-temperature dyeing methods, ultrasonic-assisted dyeing, microwave dyeing technologies, and improved machinery design that optimizes heat transfer and retention. By decreasing energy requirements, these technologies reduce greenhouse gas emissions and contribute to more sustainable manufacturing practices in the textile and other dyeing industries.

- Waste reduction and recycling in dyeing processes: Advanced dyeing processes incorporate waste reduction and recycling strategies to minimize environmental impact. These approaches include recovering and reusing dyes and auxiliaries from process baths, converting dyeing waste into useful byproducts, and implementing zero-waste manufacturing principles. Solid waste management techniques specific to dyeing operations help reduce landfill burden, while innovative recycling methods transform what was once considered waste into valuable resources for continued use in manufacturing.

02 Water conservation and treatment in dyeing processes

Innovative dyeing technologies focus on water conservation through closed-loop systems, water recycling, and advanced treatment methods. These approaches significantly reduce freshwater consumption and minimize the discharge of contaminated effluents. Treatment processes include biological remediation, advanced oxidation, membrane filtration, and adsorption techniques that remove dyes, chemicals, and other pollutants from wastewater before release, thereby reducing the environmental footprint of dyeing operations.Expand Specific Solutions03 Energy-efficient dyeing technologies

Energy-efficient dyeing technologies aim to reduce the substantial energy consumption associated with traditional dyeing processes. These innovations include low-temperature dyeing methods, ultrasonic-assisted dyeing, microwave dyeing, and supercritical CO2 dyeing. By reducing heating requirements, processing times, and overall energy needs, these technologies help minimize greenhouse gas emissions and reduce the carbon footprint of textile coloration processes.Expand Specific Solutions04 Reduction of harmful chemicals in synthetic dyeing

Modern approaches to synthetic dyeing focus on reducing or eliminating harmful chemicals such as heavy metals, formaldehyde, and other toxic substances traditionally used in dyeing processes. These innovations include the development of biodegradable synthetic dyes, non-toxic mordants, and environmentally friendly auxiliaries. By replacing hazardous chemicals with safer alternatives, these methods reduce environmental pollution, worker exposure to toxins, and ecological damage while maintaining color quality and fastness.Expand Specific Solutions05 Waste reduction and byproduct utilization in dyeing processes

Advanced dyeing processes incorporate waste reduction strategies and byproduct utilization to minimize environmental impact. These approaches include precise dye application methods that reduce excess dye usage, recovery systems for unused dyes, and technologies that convert dyeing waste into valuable byproducts. Some innovations focus on creating closed manufacturing systems where waste from one process becomes input for another, significantly reducing the overall environmental footprint of textile coloration.Expand Specific Solutions

Key Industry Players in Natural and Synthetic Dyeing

The natural dyeing versus synthetic dyeing LCA landscape is currently in a transitional phase, with growing market interest driven by sustainability concerns despite relatively modest market size compared to conventional dyeing. The industry is characterized by academic-industrial collaborations, with research institutions like Dalian University of Technology, California Institute of Technology, and University of São Paulo advancing fundamental research. While synthetic dyeing dominates commercially due to established processes, companies including Interface, ECCO Sko A/S, Milliken & Co., and Toray Industries are investing in sustainable dyeing technologies. Technical maturity varies significantly - synthetic processes are highly optimized while natural dyeing techniques are evolving through innovations from organizations like Commonwealth Scientific & Industrial Research Organisation and Indian Council of Agricultural Research to address scalability and consistency challenges.

Interface, Inc.

Technical Solution: Interface has pioneered sustainable dyeing processes through their "Cool Blue" technology, which eliminates the need for water in the dyeing process of carpet tiles. Their Life Cycle Assessment (LCA) framework compares traditional dyeing methods with their innovative solution-dyed nylon process. This technology embeds color directly into the fiber during manufacturing rather than dyeing the fiber after it's made, reducing water usage by up to 90% compared to conventional dyeing. Interface's comprehensive LCA evaluates environmental impacts across multiple categories including water consumption, energy usage, greenhouse gas emissions, and chemical waste. Their analysis shows that solution dyeing reduces the carbon footprint by approximately 30% compared to traditional batch dyeing processes. Interface has also implemented a closed-loop water system in facilities where traditional dyeing is still necessary, recovering and reusing up to 95% of process water.

Strengths: Significant reduction in water usage (90% less), lower energy consumption, and reduced chemical waste. The solution dyeing process creates more colorfast products with better UV resistance and stain resistance. Weaknesses: Limited color palette compared to conventional dyeing, higher initial production costs, and requires specialized equipment for manufacturing.

Commonwealth Scientific & Industrial Research Organisation

Technical Solution: CSIRO has developed a comprehensive LCA framework specifically for comparing natural and synthetic dyeing processes in textile production. Their research includes detailed analysis of traditional natural dyes derived from plants, insects, and minerals against petroleum-based synthetic dyes. CSIRO's methodology evaluates environmental impacts across 18 different categories including climate change, water depletion, ecotoxicity, and land use. Their studies show that while natural dyes typically have lower toxicity and reduced end-of-life environmental impacts, they often require more intensive land and water use during cultivation. CSIRO has pioneered innovative extraction techniques for natural colorants that reduce water consumption by up to 80% compared to traditional methods. Their research includes development of enzymatic processes that enhance dye uptake and color fastness of natural dyes, addressing key performance limitations. CSIRO's comparative LCA demonstrates that optimized natural dyeing processes can reduce overall environmental impact by 35-45% compared to synthetic dyeing when considering the full life cycle, including cultivation impacts.

Strengths: Holistic assessment methodology that considers regional variations in environmental impacts, innovative extraction techniques that significantly improve efficiency of natural dye production, and development of bio-mordants that eliminate heavy metal usage. Weaknesses: Natural dyes still face challenges in color consistency, scalability issues for commercial production, and higher land use requirements for growing dyestuff plants.

Critical Environmental Impact Indicators and Metrics

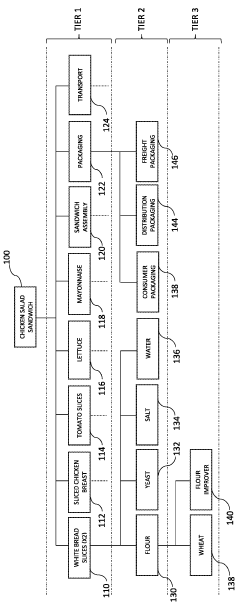

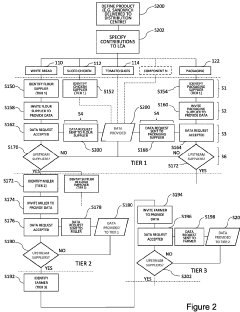

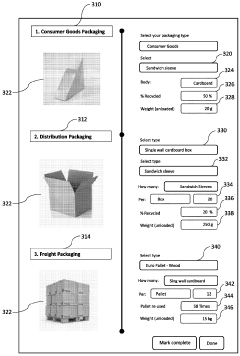

Method of calculating life cycle assessment

PatentInactiveGB2614243A

Innovation

- A method that automatically retrieves and calculates LCA data from a product information database, devolving data collection to suppliers in the supply chain, allowing for more accurate and up-to-date information specific to each component and process, reducing the need for manual intervention and reliance on third-party databases.

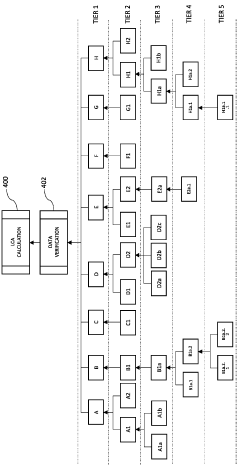

Method and system for assessing environmental impact of a processing device

PatentInactiveUS8855991B2

Innovation

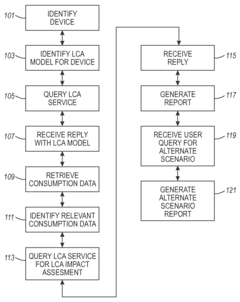

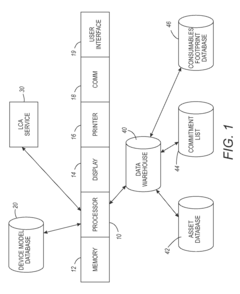

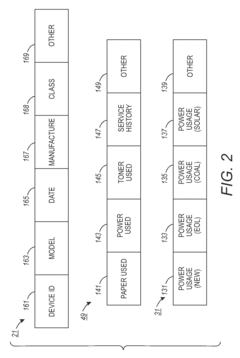

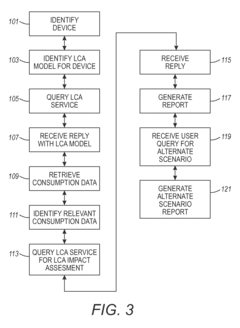

- A system that uses a life cycle assessment (LCA) model to assess the environmental impact of print devices by querying an LCA service, receiving consumption data, and generating reports on environmental impact, including cradle-to-gate and cradle-to-grave assessments, with options for hypothetical scenarios and user-specified life cycle phases.

Regulatory Compliance and Global Standards

The regulatory landscape governing dyeing processes has become increasingly stringent as environmental concerns gain prominence globally. The European Union leads with comprehensive frameworks such as REACH (Registration, Evaluation, Authorization and Restriction of Chemicals), which specifically restricts certain azo dyes and other harmful substances commonly used in synthetic dyeing processes. Similarly, the EU Ecolabel sets strict criteria for textile products, encouraging manufacturers to adopt more sustainable dyeing methods.

In North America, the EPA regulates wastewater discharge from textile facilities under the Clean Water Act, imposing limits on heavy metals and toxic chemicals typically associated with synthetic dyes. Canada's Environmental Protection Act similarly addresses pollution concerns related to textile manufacturing processes.

Asian markets demonstrate varying regulatory approaches. Japan's stringent chemical substance control law closely mirrors EU standards, while China has recently strengthened its environmental protection laws with specific provisions targeting textile industry pollution. India's National Green Tribunal has issued landmark rulings affecting textile clusters with significant implications for dyeing operations.

Global certification systems play a crucial role in standardizing sustainable practices. GOTS (Global Organic Textile Standard) and OEKO-TEX Standard 100 have emerged as leading certifications that verify compliance with ecological requirements throughout the textile supply chain, including dyeing processes. These standards typically favor natural dyeing methods or synthetic processes with reduced environmental impact.

ISO 14040 and 14044 standards provide the methodological framework for conducting Life Cycle Assessments, ensuring consistency and comparability when evaluating environmental impacts of both natural and synthetic dyeing processes. These standards are essential for generating credible comparative analyses that can inform regulatory decisions.

The Sustainable Apparel Coalition's Higg Index has become an industry benchmark for measuring environmental performance, incorporating specific metrics related to dyeing processes. This tool enables manufacturers to quantify improvements when transitioning from conventional synthetic to natural dyeing methods or optimized synthetic processes.

Emerging regulatory trends indicate a shift toward extended producer responsibility, potentially making manufacturers accountable for the entire lifecycle environmental impact of their dyeing choices. Several jurisdictions are exploring chemical footprint disclosure requirements that would compel greater transparency regarding dye selection and application methods.

In North America, the EPA regulates wastewater discharge from textile facilities under the Clean Water Act, imposing limits on heavy metals and toxic chemicals typically associated with synthetic dyes. Canada's Environmental Protection Act similarly addresses pollution concerns related to textile manufacturing processes.

Asian markets demonstrate varying regulatory approaches. Japan's stringent chemical substance control law closely mirrors EU standards, while China has recently strengthened its environmental protection laws with specific provisions targeting textile industry pollution. India's National Green Tribunal has issued landmark rulings affecting textile clusters with significant implications for dyeing operations.

Global certification systems play a crucial role in standardizing sustainable practices. GOTS (Global Organic Textile Standard) and OEKO-TEX Standard 100 have emerged as leading certifications that verify compliance with ecological requirements throughout the textile supply chain, including dyeing processes. These standards typically favor natural dyeing methods or synthetic processes with reduced environmental impact.

ISO 14040 and 14044 standards provide the methodological framework for conducting Life Cycle Assessments, ensuring consistency and comparability when evaluating environmental impacts of both natural and synthetic dyeing processes. These standards are essential for generating credible comparative analyses that can inform regulatory decisions.

The Sustainable Apparel Coalition's Higg Index has become an industry benchmark for measuring environmental performance, incorporating specific metrics related to dyeing processes. This tool enables manufacturers to quantify improvements when transitioning from conventional synthetic to natural dyeing methods or optimized synthetic processes.

Emerging regulatory trends indicate a shift toward extended producer responsibility, potentially making manufacturers accountable for the entire lifecycle environmental impact of their dyeing choices. Several jurisdictions are exploring chemical footprint disclosure requirements that would compel greater transparency regarding dye selection and application methods.

Supply Chain Sustainability and Traceability

The textile industry's supply chain has undergone significant scrutiny regarding sustainability practices, particularly in dyeing processes. Natural dyeing and synthetic dyeing represent two fundamentally different approaches with varying environmental impacts throughout their supply chains. Implementing robust traceability systems has become essential for manufacturers to verify sustainability claims and meet increasing consumer demands for transparency.

For natural dyeing processes, supply chain traceability begins with agricultural practices for growing dye-yielding plants or sustainable harvesting of natural materials. Documentation of cultivation methods, including organic certification, water usage, and biodiversity impact assessments, provides critical data points for life cycle assessment. The chain of custody must track these materials from farm to processing facility, documenting transportation methods and associated carbon emissions.

Synthetic dye supply chains present different traceability challenges, primarily centered around chemical sourcing, manufacturing processes, and waste management. Petrochemical feedstocks require documentation of extraction methods, refining processes, and transportation. Chemical synthesis facilities must maintain detailed records of energy consumption, water usage, and emissions to air and water. Waste treatment protocols and their effectiveness represent another critical data point for comprehensive LCA comparisons.

Digital traceability tools have emerged as essential technologies for both natural and synthetic dyeing supply chains. Blockchain applications enable immutable record-keeping across multiple supply chain participants, while QR codes and RFID tags facilitate physical tracking of materials. These technologies allow manufacturers to verify sustainability claims and provide consumers with transparent information about product origins and environmental impacts.

Third-party certification systems play a vital role in validating supply chain sustainability claims. Standards such as GOTS (Global Organic Textile Standard), Oeko-Tex, and BlueSign provide frameworks for assessing environmental performance across the textile supply chain. These certification bodies conduct regular audits and verification processes that strengthen the credibility of sustainability claims for both natural and synthetic dyeing processes.

Water footprint tracking represents a particularly important aspect of supply chain sustainability for dyeing processes. Natural dyeing typically requires substantial water volumes for extraction and mordanting processes, while synthetic dyeing may use less water initially but generate more contaminated effluent. Comprehensive water stewardship programs that track consumption, treatment, and discharge quality throughout the supply chain provide essential data for comparative LCA studies.

For natural dyeing processes, supply chain traceability begins with agricultural practices for growing dye-yielding plants or sustainable harvesting of natural materials. Documentation of cultivation methods, including organic certification, water usage, and biodiversity impact assessments, provides critical data points for life cycle assessment. The chain of custody must track these materials from farm to processing facility, documenting transportation methods and associated carbon emissions.

Synthetic dye supply chains present different traceability challenges, primarily centered around chemical sourcing, manufacturing processes, and waste management. Petrochemical feedstocks require documentation of extraction methods, refining processes, and transportation. Chemical synthesis facilities must maintain detailed records of energy consumption, water usage, and emissions to air and water. Waste treatment protocols and their effectiveness represent another critical data point for comprehensive LCA comparisons.

Digital traceability tools have emerged as essential technologies for both natural and synthetic dyeing supply chains. Blockchain applications enable immutable record-keeping across multiple supply chain participants, while QR codes and RFID tags facilitate physical tracking of materials. These technologies allow manufacturers to verify sustainability claims and provide consumers with transparent information about product origins and environmental impacts.

Third-party certification systems play a vital role in validating supply chain sustainability claims. Standards such as GOTS (Global Organic Textile Standard), Oeko-Tex, and BlueSign provide frameworks for assessing environmental performance across the textile supply chain. These certification bodies conduct regular audits and verification processes that strengthen the credibility of sustainability claims for both natural and synthetic dyeing processes.

Water footprint tracking represents a particularly important aspect of supply chain sustainability for dyeing processes. Natural dyeing typically requires substantial water volumes for extraction and mordanting processes, while synthetic dyeing may use less water initially but generate more contaminated effluent. Comprehensive water stewardship programs that track consumption, treatment, and discharge quality throughout the supply chain provide essential data for comparative LCA studies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!