Process Optimization For Consistent Shade Reproducibility In Natural Dyes

SEP 2, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Natural Dye Technology Background and Objectives

Natural dyes have been utilized by human civilizations for thousands of years, with evidence of their application dating back to the Neolithic period. These coloring agents, derived from plants, insects, minerals, and fungi, dominated the textile industry until the mid-19th century when synthetic dyes emerged following William Henry Perkin's accidental discovery of mauveine in 1856. The subsequent rapid development of synthetic alternatives led to a significant decline in natural dye usage due to their superior color consistency, fastness properties, and cost-effectiveness.

In recent decades, however, there has been a resurgence of interest in natural dyes driven by increasing environmental consciousness, concerns about the ecological impact of synthetic dye production, and growing consumer demand for sustainable products. This revival has highlighted a critical technological challenge: the inherent variability in shade reproducibility when using natural colorants.

Unlike their synthetic counterparts, natural dyes exhibit considerable variation in color outcomes due to multiple factors including geographical origin, harvesting season, extraction methods, mordanting techniques, and application processes. This inconsistency presents a significant barrier to their widespread commercial adoption, particularly in industries requiring precise color matching and reproducibility.

The evolution of natural dye technology has progressed through several distinct phases: traditional craft-based approaches, early scientific investigations in the 18th and 19th centuries, the marginalization period during synthetic dye dominance, and the current revival phase characterized by scientific optimization efforts. Today's research increasingly focuses on standardizing processes to achieve consistent results while maintaining sustainability principles.

Current technological trends in this field include the development of standardized extraction protocols, innovative mordanting techniques, precise process control methodologies, and the integration of digital color measurement systems. Additionally, there is growing interest in combining traditional knowledge with modern scientific approaches to create hybrid solutions that preserve cultural heritage while meeting contemporary industrial requirements.

The primary objective of process optimization for natural dyes is to establish reproducible methodologies that can deliver consistent shade outcomes across production batches while maintaining environmental sustainability. This involves developing standardized protocols for raw material selection, extraction parameters, mordanting procedures, and application techniques that can be reliably implemented in both artisanal and industrial settings.

Secondary objectives include reducing water and energy consumption in dyeing processes, minimizing waste generation, improving color fastness properties, and developing comprehensive documentation systems for color matching. The ultimate goal is to position natural dyes as viable alternatives to synthetic colorants in various market segments, from high-end fashion to mass-market textiles, while preserving their inherent ecological advantages.

In recent decades, however, there has been a resurgence of interest in natural dyes driven by increasing environmental consciousness, concerns about the ecological impact of synthetic dye production, and growing consumer demand for sustainable products. This revival has highlighted a critical technological challenge: the inherent variability in shade reproducibility when using natural colorants.

Unlike their synthetic counterparts, natural dyes exhibit considerable variation in color outcomes due to multiple factors including geographical origin, harvesting season, extraction methods, mordanting techniques, and application processes. This inconsistency presents a significant barrier to their widespread commercial adoption, particularly in industries requiring precise color matching and reproducibility.

The evolution of natural dye technology has progressed through several distinct phases: traditional craft-based approaches, early scientific investigations in the 18th and 19th centuries, the marginalization period during synthetic dye dominance, and the current revival phase characterized by scientific optimization efforts. Today's research increasingly focuses on standardizing processes to achieve consistent results while maintaining sustainability principles.

Current technological trends in this field include the development of standardized extraction protocols, innovative mordanting techniques, precise process control methodologies, and the integration of digital color measurement systems. Additionally, there is growing interest in combining traditional knowledge with modern scientific approaches to create hybrid solutions that preserve cultural heritage while meeting contemporary industrial requirements.

The primary objective of process optimization for natural dyes is to establish reproducible methodologies that can deliver consistent shade outcomes across production batches while maintaining environmental sustainability. This involves developing standardized protocols for raw material selection, extraction parameters, mordanting procedures, and application techniques that can be reliably implemented in both artisanal and industrial settings.

Secondary objectives include reducing water and energy consumption in dyeing processes, minimizing waste generation, improving color fastness properties, and developing comprehensive documentation systems for color matching. The ultimate goal is to position natural dyes as viable alternatives to synthetic colorants in various market segments, from high-end fashion to mass-market textiles, while preserving their inherent ecological advantages.

Market Analysis for Natural Dye Products

The global natural dye market has experienced significant growth in recent years, driven by increasing consumer awareness about environmental sustainability and health concerns associated with synthetic dyes. Currently valued at approximately $1.8 billion, the market is projected to grow at a CAGR of 11.3% from 2023 to 2028, potentially reaching $3.1 billion by the end of this period. This growth trajectory reflects a fundamental shift in consumer preferences toward eco-friendly and non-toxic products across various industries.

The textile and apparel sector represents the largest application segment for natural dyes, accounting for roughly 42% of the total market share. This dominance is attributed to the rising demand for sustainable fashion and the implementation of stringent regulations against harmful synthetic dyes in many countries. Following closely is the food and beverage industry, where natural colorants are increasingly preferred due to health consciousness among consumers and regulatory pressures to eliminate artificial additives.

Geographically, Asia Pacific leads the natural dye market with approximately 38% market share, primarily due to the traditional knowledge of natural dyeing techniques in countries like India, China, and Japan. Europe follows with 29% market share, driven by strict environmental regulations and high consumer awareness. North America represents about 22% of the market, with rapid growth fueled by the expanding organic product sector.

Consumer willingness to pay premium prices for naturally dyed products presents a significant market opportunity. Surveys indicate that 67% of consumers are willing to pay 15-20% more for products using natural colorants, particularly in high-end fashion, organic food, and personal care segments. This price premium helps offset the higher production costs associated with natural dyes.

However, the market faces several challenges, including inconsistent color reproducibility, limited color range, and higher production costs compared to synthetic alternatives. The inconsistency in shade reproduction represents a particularly significant barrier to wider industrial adoption, as modern manufacturing processes require standardized outputs. This technical limitation has restricted natural dyes primarily to artisanal and premium product segments.

Recent market trends show increasing collaboration between traditional knowledge holders and modern scientific research to overcome these technical barriers. Companies investing in R&D for improved natural dyeing processes are gaining competitive advantages, with several startups securing significant venture capital funding for innovations in this space. The development of standardized processes for consistent shade reproducibility could potentially unlock mainstream industrial applications, expanding the market significantly beyond its current niche status.

The textile and apparel sector represents the largest application segment for natural dyes, accounting for roughly 42% of the total market share. This dominance is attributed to the rising demand for sustainable fashion and the implementation of stringent regulations against harmful synthetic dyes in many countries. Following closely is the food and beverage industry, where natural colorants are increasingly preferred due to health consciousness among consumers and regulatory pressures to eliminate artificial additives.

Geographically, Asia Pacific leads the natural dye market with approximately 38% market share, primarily due to the traditional knowledge of natural dyeing techniques in countries like India, China, and Japan. Europe follows with 29% market share, driven by strict environmental regulations and high consumer awareness. North America represents about 22% of the market, with rapid growth fueled by the expanding organic product sector.

Consumer willingness to pay premium prices for naturally dyed products presents a significant market opportunity. Surveys indicate that 67% of consumers are willing to pay 15-20% more for products using natural colorants, particularly in high-end fashion, organic food, and personal care segments. This price premium helps offset the higher production costs associated with natural dyes.

However, the market faces several challenges, including inconsistent color reproducibility, limited color range, and higher production costs compared to synthetic alternatives. The inconsistency in shade reproduction represents a particularly significant barrier to wider industrial adoption, as modern manufacturing processes require standardized outputs. This technical limitation has restricted natural dyes primarily to artisanal and premium product segments.

Recent market trends show increasing collaboration between traditional knowledge holders and modern scientific research to overcome these technical barriers. Companies investing in R&D for improved natural dyeing processes are gaining competitive advantages, with several startups securing significant venture capital funding for innovations in this space. The development of standardized processes for consistent shade reproducibility could potentially unlock mainstream industrial applications, expanding the market significantly beyond its current niche status.

Current Challenges in Natural Dye Shade Consistency

Natural dye production faces significant challenges in achieving consistent shade reproducibility, which remains one of the most critical barriers to widespread industrial adoption. Unlike synthetic dyes that offer predictable and standardized results, natural dyes exhibit inherent variability due to numerous factors that affect their coloration properties. This inconsistency creates substantial obstacles for manufacturers seeking to incorporate natural dyes into their production processes.

The primary challenge stems from the biological variability of natural dye sources. Plant-based dyes, which constitute the majority of natural colorants, demonstrate significant fluctuations in their chromophore content based on growing conditions, harvest time, geographical location, and climate variations. For instance, indigo content in Indigofera tinctoria can vary by up to 40% depending on seasonal changes and soil conditions, directly impacting the intensity and hue of the resulting blue shade.

Extraction methodologies present another critical challenge. The efficiency of colorant extraction from natural sources depends on multiple parameters including solvent type, temperature, pH, extraction duration, and solid-to-liquid ratio. Current industrial practices lack standardized extraction protocols, resulting in batch-to-batch variations that compromise shade consistency. Research indicates that extraction yield and colorant profile can vary by 15-30% when using identical plant material but different extraction parameters.

The mordanting process, essential for improving colorfastness and expanding the color palette of natural dyes, introduces additional variables affecting shade reproducibility. The type, concentration, and application method of mordants (such as aluminum, iron, copper, or tin salts) dramatically influence the final color outcome. Studies show that even minor variations in mordant concentration (±0.5%) can produce visibly different shades, complicating efforts to achieve consistent results.

Water quality represents an often-overlooked factor that significantly impacts dyeing outcomes. Variations in water hardness, pH, and mineral content across different geographical locations affect dye-fiber interactions and color development. Industrial facilities using municipal water supplies may experience seasonal fluctuations in water composition, further complicating shade consistency efforts.

The absence of standardized measurement and quality control systems specifically designed for natural dyes compounds these challenges. While synthetic dye manufacturers employ sophisticated spectrophotometric methods and color matching systems, natural dye producers often rely on visual assessment, leading to subjective evaluations and inconsistent results. The lack of industry-wide color standards and reference systems for natural dyes makes objective quality control particularly difficult.

Finally, the complex interaction between natural dyes and different fiber types presents additional reproducibility challenges. The same dye extract can produce markedly different shades on cotton, wool, silk, or synthetic fibers due to variations in fiber structure, protein content, and surface properties. This fiber-dependent behavior necessitates specific process adjustments for each fiber type, further complicating standardization efforts.

The primary challenge stems from the biological variability of natural dye sources. Plant-based dyes, which constitute the majority of natural colorants, demonstrate significant fluctuations in their chromophore content based on growing conditions, harvest time, geographical location, and climate variations. For instance, indigo content in Indigofera tinctoria can vary by up to 40% depending on seasonal changes and soil conditions, directly impacting the intensity and hue of the resulting blue shade.

Extraction methodologies present another critical challenge. The efficiency of colorant extraction from natural sources depends on multiple parameters including solvent type, temperature, pH, extraction duration, and solid-to-liquid ratio. Current industrial practices lack standardized extraction protocols, resulting in batch-to-batch variations that compromise shade consistency. Research indicates that extraction yield and colorant profile can vary by 15-30% when using identical plant material but different extraction parameters.

The mordanting process, essential for improving colorfastness and expanding the color palette of natural dyes, introduces additional variables affecting shade reproducibility. The type, concentration, and application method of mordants (such as aluminum, iron, copper, or tin salts) dramatically influence the final color outcome. Studies show that even minor variations in mordant concentration (±0.5%) can produce visibly different shades, complicating efforts to achieve consistent results.

Water quality represents an often-overlooked factor that significantly impacts dyeing outcomes. Variations in water hardness, pH, and mineral content across different geographical locations affect dye-fiber interactions and color development. Industrial facilities using municipal water supplies may experience seasonal fluctuations in water composition, further complicating shade consistency efforts.

The absence of standardized measurement and quality control systems specifically designed for natural dyes compounds these challenges. While synthetic dye manufacturers employ sophisticated spectrophotometric methods and color matching systems, natural dye producers often rely on visual assessment, leading to subjective evaluations and inconsistent results. The lack of industry-wide color standards and reference systems for natural dyes makes objective quality control particularly difficult.

Finally, the complex interaction between natural dyes and different fiber types presents additional reproducibility challenges. The same dye extract can produce markedly different shades on cotton, wool, silk, or synthetic fibers due to variations in fiber structure, protein content, and surface properties. This fiber-dependent behavior necessitates specific process adjustments for each fiber type, further complicating standardization efforts.

Current Process Control Methods for Natural Dyes

01 Standardization methods for natural dye extraction

Various methods have been developed to standardize the extraction of natural dyes to ensure consistent shade reproducibility. These methods involve controlling parameters such as temperature, time, pH, and solvent ratios during the extraction process. Standardized extraction protocols help minimize batch-to-batch variations in color intensity and hue, which is crucial for commercial applications where consistency is required.- Standardization methods for natural dye extraction: Various methods have been developed to standardize the extraction process of natural dyes to ensure consistent shade reproducibility. These methods include optimized extraction parameters such as temperature, time, and solvent ratios that help maintain consistent dye concentration and color properties. Standardized extraction protocols enable manufacturers to achieve reliable color outcomes across different production batches, which is crucial for commercial applications where color consistency is required.

- Color measurement and matching technologies: Advanced color measurement technologies and spectrophotometric analysis are employed to quantify and reproduce natural dye shades accurately. These technologies include computerized color matching systems, digital color libraries, and spectral analysis tools that can identify subtle color variations. By creating precise color profiles for natural dyes, manufacturers can achieve consistent shade reproduction across different batches and substrates, allowing for reliable quality control in textile and other industries.

- Mordanting techniques for color fastness and reproducibility: Mordanting techniques play a crucial role in enhancing the shade reproducibility of natural dyes by improving their binding to fibers. Different mordants can significantly affect the final color, shade, and fastness properties of natural dyes. By standardizing mordanting procedures, including mordant type, concentration, application method, and treatment duration, consistent color outcomes can be achieved. These techniques help overcome the inherent variability of natural dyes and ensure reliable shade reproduction across different dyeing batches.

- Formulation of natural dye composites and blends: Creating standardized blends or composites of natural dyes helps achieve consistent shade reproducibility. By carefully formulating mixtures of different natural dye extracts in precise ratios, manufacturers can compensate for batch-to-batch variations in individual dye sources. These composite formulations often include stabilizers and pH regulators that help maintain color consistency. The development of these standardized dye blends enables more reliable color matching and reproduction in commercial applications where consistency is essential.

- Process control systems for natural dyeing: Automated process control systems have been developed to monitor and regulate critical parameters during natural dyeing processes. These systems control factors such as temperature, pH, dye concentration, and dyeing time to ensure consistent shade reproduction. By implementing precise process controls and feedback mechanisms, manufacturers can minimize variations in dyeing outcomes. These technological advancements help overcome the traditional challenges associated with natural dye reproducibility and make natural dyeing more viable for industrial-scale production where consistency is required.

02 Color measurement and matching systems

Advanced color measurement and matching systems are employed to achieve reproducible shades with natural dyes. These systems use spectrophotometric analysis and colorimetric techniques to quantify color parameters and create digital color profiles. Computer-aided color matching software helps formulators predict dye combinations needed to reproduce specific shades consistently, compensating for variations in natural dye sources.Expand Specific Solutions03 Chemical modification of natural dyes

Chemical modification techniques are applied to natural dyes to improve their shade reproducibility. These modifications can enhance color fastness, stability, and consistency. Processes such as mordanting, chelation, and molecular modification help standardize the dyeing behavior of natural colorants, making their application more predictable and reproducible across different batches and substrates.Expand Specific Solutions04 Formulation with auxiliaries and stabilizers

Natural dyes are formulated with various auxiliaries and stabilizers to enhance shade reproducibility. These formulations include pH buffers, antioxidants, UV stabilizers, and dispersing agents that help maintain color consistency during application and over time. The careful selection and standardization of these additives play a crucial role in achieving reproducible shades with natural colorants that are otherwise prone to variation.Expand Specific Solutions05 Biotechnological approaches for consistent dye production

Biotechnological methods are being developed to produce natural dyes with improved shade reproducibility. These approaches include fermentation processes, enzyme treatments, and genetic engineering of dye-producing organisms. By controlling the biosynthesis of colorants under standardized conditions, these techniques can deliver natural dyes with more consistent chemical compositions and coloring properties than traditionally extracted alternatives.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The natural dye reproducibility market is in a growth phase, characterized by increasing demand for sustainable coloration solutions across textile, fashion, and specialty applications. The global market size for natural dyes is expanding at approximately 12% CAGR, driven by consumer preference for eco-friendly products. Technologically, the field remains moderately mature with ongoing innovation challenges in standardization and consistency. Leading players include DyStar (owned by Zhejiang Longsheng Group), which has developed advanced natural dyeing processes, BASF Corp. with its bio-based colorant portfolio, and Lenzing AG integrating sustainable dyeing with cellulosic fibers. Academic institutions like Donghua University and Zhejiang University contribute significant research in reproducibility techniques, while traditional manufacturers like Nippon Kayaku and Henkel are investing in natural dye formulation improvements.

FUJIFILM Corp.

Technical Solution: FUJIFILM has leveraged its expertise in color science and imaging technology to develop "NaturaTint Precision" - a comprehensive system for natural dye standardization and reproducibility. The technology employs hyperspectral imaging analysis of raw natural dye materials to characterize their colorant composition before processing begins. This allows for precise blending of raw materials to achieve consistent starting points despite natural variations. FUJIFILM's process incorporates microfluidic extraction chambers that enable precise control of solvent ratios, temperature gradients (controlled within ±0.5°C), and extraction time to standardize dye component extraction. Their innovation includes a proprietary digital color management system that creates a "digital fingerprint" of successful dye batches, allowing for predictive adjustments to process parameters based on raw material characteristics. The system also features real-time spectrophotometric monitoring during the dyeing process with automated feedback controls to adjust dye bath conditions for consistent shade development.

Strengths: Exceptional color science expertise and advanced imaging technology that enables precise characterization of natural colorants before and during processing. Their digital color management systems provide superior predictive capabilities for process adjustments. Weaknesses: The technology requires significant capital investment in specialized equipment and may be overly complex for smaller-scale natural dye producers or traditional artisans.

Ciba Specialty Chemicals Holding, Inc.

Technical Solution: Ciba (now part of BASF) developed the "NatureTint Precision System" for natural dye reproducibility that focuses on standardizing both the extraction and application processes. Their approach begins with a comprehensive characterization of natural dye sources using a combination of spectroscopic and chromatographic techniques to establish a "colorant profile" for each batch of raw material. The system employs a controlled enzymatic pre-treatment process that standardizes the extraction of colorants from plant materials by breaking down cellular structures in a consistent manner. Ciba's innovation includes a proprietary mordanting system that uses precisely formulated metal salt complexes at controlled pH ranges (typically 4.0-6.0) to create consistent binding sites on natural fibers. Their process incorporates a feedback control system that monitors dye uptake rates in real-time and adjusts process parameters including temperature ramping (typically 1-2°C/minute), salt concentration, and dwell time to achieve consistent shade development regardless of minor variations in raw materials.

Strengths: Exceptional expertise in mordanting chemistry that enables precise control of dye-fiber interactions. Their enzymatic pre-treatment approach significantly improves extraction consistency from variable natural materials. Weaknesses: The technology was developed before Ciba's acquisition by BASF, so ongoing development may have been limited. The system requires specialized equipment and technical expertise that may be inaccessible to smaller producers.

Key Innovations in Natural Dye Standardization

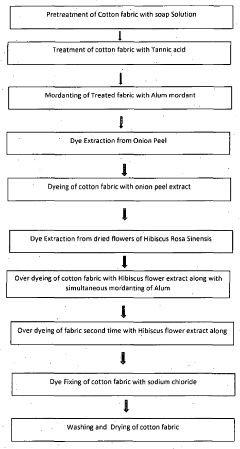

Dyeing process for obtaining shades in cotton fabric using two different natural dye sources applied in specific sequence

PatentPendingIN202041028684A

Innovation

- A sequential dyeing process utilizing onion peel extract and Hibiscus Rosa Sinensis extracts, combined with pretreatment steps including mordanting with Alum and dye fixing with sodium chloride, to enhance shade variation and achieve a light brown color with a greenish tinge on cotton fabrics.

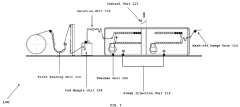

A process for optimized dyeing of textiles using natural dyes

PatentPendingIN202011057200A

Innovation

- A continuous dyeing mechanism involving padding with a natural dye liquor, followed by squeezing, wetting, and steaming to optimize dye fixation, using a CDR machine with controlled parameters like temperature, pH, and mordanting to ensure uniform and sustainable dyeing.

Environmental Impact and Sustainability Assessment

The environmental impact of natural dye processes represents a critical dimension in the broader sustainability discourse. Natural dyes, derived from plants, minerals, and insects, have gained renewed attention as alternatives to synthetic colorants due to their perceived environmental benefits. However, achieving consistent shade reproducibility while maintaining ecological integrity presents complex challenges that require systematic assessment.

Traditional natural dyeing processes often involve significant water consumption, with multiple rinse cycles and mordanting procedures that can strain local water resources. Recent innovations have focused on reducing water usage through closed-loop systems and water recycling technologies, demonstrating potential reductions of 30-45% in water consumption compared to conventional methods. These improvements directly contribute to the sustainability profile of natural dye production while supporting consistency in color outcomes.

Energy consumption patterns in natural dye processing vary considerably depending on extraction methods and temperature requirements. Cold extraction techniques, while less energy-intensive, typically yield lower color concentrations and less predictable shades. Conversely, hot extraction methods produce more consistent results but at higher energy costs. Hybrid approaches utilizing renewable energy sources for heating processes have emerged as promising solutions that balance reproducibility with environmental considerations.

Waste management represents another significant environmental concern in natural dyeing. Spent biomass from dye extraction can contribute to organic waste streams, though recent circular economy approaches have transformed this challenge into an opportunity. Agricultural applications for spent dye materials as compost or soil amendments have demonstrated dual benefits: waste reduction and carbon sequestration. These practices enhance the overall sustainability profile of natural dye production systems.

Chemical inputs, particularly mordants used to fix dyes to fibers, present potential ecotoxicological risks. Traditional metallic mordants containing aluminum, copper, or iron can accumulate in soil and water systems. The development of bio-mordants derived from tannin-rich plant materials offers promising alternatives that maintain color fastness while reducing environmental impact. Studies indicate that bio-mordants can achieve comparable shade consistency with 60-80% lower ecotoxicity profiles compared to conventional metal-based alternatives.

Carbon footprint analyses of optimized natural dye processes reveal complex trade-offs. While local sourcing of plant materials reduces transportation emissions, inefficient processing methods can offset these gains. Life cycle assessments indicate that improvements in extraction efficiency and process standardization can reduce the overall carbon footprint by 15-25% while simultaneously enhancing shade reproducibility, demonstrating the potential alignment between environmental and technical performance objectives.

Traditional natural dyeing processes often involve significant water consumption, with multiple rinse cycles and mordanting procedures that can strain local water resources. Recent innovations have focused on reducing water usage through closed-loop systems and water recycling technologies, demonstrating potential reductions of 30-45% in water consumption compared to conventional methods. These improvements directly contribute to the sustainability profile of natural dye production while supporting consistency in color outcomes.

Energy consumption patterns in natural dye processing vary considerably depending on extraction methods and temperature requirements. Cold extraction techniques, while less energy-intensive, typically yield lower color concentrations and less predictable shades. Conversely, hot extraction methods produce more consistent results but at higher energy costs. Hybrid approaches utilizing renewable energy sources for heating processes have emerged as promising solutions that balance reproducibility with environmental considerations.

Waste management represents another significant environmental concern in natural dyeing. Spent biomass from dye extraction can contribute to organic waste streams, though recent circular economy approaches have transformed this challenge into an opportunity. Agricultural applications for spent dye materials as compost or soil amendments have demonstrated dual benefits: waste reduction and carbon sequestration. These practices enhance the overall sustainability profile of natural dye production systems.

Chemical inputs, particularly mordants used to fix dyes to fibers, present potential ecotoxicological risks. Traditional metallic mordants containing aluminum, copper, or iron can accumulate in soil and water systems. The development of bio-mordants derived from tannin-rich plant materials offers promising alternatives that maintain color fastness while reducing environmental impact. Studies indicate that bio-mordants can achieve comparable shade consistency with 60-80% lower ecotoxicity profiles compared to conventional metal-based alternatives.

Carbon footprint analyses of optimized natural dye processes reveal complex trade-offs. While local sourcing of plant materials reduces transportation emissions, inefficient processing methods can offset these gains. Life cycle assessments indicate that improvements in extraction efficiency and process standardization can reduce the overall carbon footprint by 15-25% while simultaneously enhancing shade reproducibility, demonstrating the potential alignment between environmental and technical performance objectives.

Quality Control and Testing Methodologies

Quality control and testing methodologies are critical components in achieving consistent shade reproducibility with natural dyes. The inherent variability of natural dye sources necessitates rigorous testing protocols to ensure product consistency across production batches.

Spectrophotometric analysis serves as the primary quantitative method for color assessment in natural dye applications. Modern spectrophotometers can detect subtle color variations using CIE L*a*b* color space measurements, providing objective data on hue, saturation, and brightness. These instruments typically achieve a measurement precision of ±0.1 units, enabling manufacturers to establish acceptable color deviation thresholds for quality assurance purposes.

Accelerated aging tests represent another crucial methodology for evaluating the long-term stability of natural dye applications. These tests expose dyed materials to controlled conditions of light, temperature, and humidity to simulate extended use periods. Standard protocols such as ISO 105-B02 for light fastness and AATCC Test Method 16 provide industry-recognized frameworks for assessing color stability over time.

Chemical composition analysis through HPLC (High-Performance Liquid Chromatography) and LC-MS (Liquid Chromatography-Mass Spectrometry) enables the identification and quantification of specific colorant compounds within natural dye extracts. This analytical approach allows manufacturers to establish chemical fingerprints of successful dye batches, creating reference standards for future production. Research indicates that variations exceeding 5% in key chromophore concentrations often correlate with perceptible color differences in the final product.

Statistical process control (SPC) methodologies have been increasingly implemented in natural dye production facilities. By continuously monitoring critical process parameters and establishing control limits, manufacturers can detect process drift before it results in unacceptable color variation. Key monitored variables typically include extraction temperature, pH levels, mordant concentrations, and processing time.

Digital color management systems integrate spectrophotometric data with production parameters to create comprehensive color libraries. These systems enable precise color matching across different production runs by providing automated adjustment recommendations based on measured input variables. Advanced systems incorporate machine learning algorithms that improve prediction accuracy over time by analyzing historical production data and outcomes.

Standardized visual assessment protocols complement instrumental methods, particularly for evaluating subtle color characteristics that may not be fully captured by spectrophotometric analysis. These assessments typically involve trained color evaluators examining samples under standardized lighting conditions (D65 illuminant) against established color standards.

Spectrophotometric analysis serves as the primary quantitative method for color assessment in natural dye applications. Modern spectrophotometers can detect subtle color variations using CIE L*a*b* color space measurements, providing objective data on hue, saturation, and brightness. These instruments typically achieve a measurement precision of ±0.1 units, enabling manufacturers to establish acceptable color deviation thresholds for quality assurance purposes.

Accelerated aging tests represent another crucial methodology for evaluating the long-term stability of natural dye applications. These tests expose dyed materials to controlled conditions of light, temperature, and humidity to simulate extended use periods. Standard protocols such as ISO 105-B02 for light fastness and AATCC Test Method 16 provide industry-recognized frameworks for assessing color stability over time.

Chemical composition analysis through HPLC (High-Performance Liquid Chromatography) and LC-MS (Liquid Chromatography-Mass Spectrometry) enables the identification and quantification of specific colorant compounds within natural dye extracts. This analytical approach allows manufacturers to establish chemical fingerprints of successful dye batches, creating reference standards for future production. Research indicates that variations exceeding 5% in key chromophore concentrations often correlate with perceptible color differences in the final product.

Statistical process control (SPC) methodologies have been increasingly implemented in natural dye production facilities. By continuously monitoring critical process parameters and establishing control limits, manufacturers can detect process drift before it results in unacceptable color variation. Key monitored variables typically include extraction temperature, pH levels, mordant concentrations, and processing time.

Digital color management systems integrate spectrophotometric data with production parameters to create comprehensive color libraries. These systems enable precise color matching across different production runs by providing automated adjustment recommendations based on measured input variables. Advanced systems incorporate machine learning algorithms that improve prediction accuracy over time by analyzing historical production data and outcomes.

Standardized visual assessment protocols complement instrumental methods, particularly for evaluating subtle color characteristics that may not be fully captured by spectrophotometric analysis. These assessments typically involve trained color evaluators examining samples under standardized lighting conditions (D65 illuminant) against established color standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!