Integration Of Natural Dyes Into Existing Textile Dye Houses: Retrofit Paths

SEP 2, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Natural Dye Technology Background and Objectives

Natural dyes have been utilized for coloring textiles since ancient civilizations, with evidence dating back to the Neolithic period. These dyes, derived from plants, minerals, and animal sources, dominated the textile industry until the mid-19th century when synthetic dyes emerged following William Henry Perkin's accidental discovery of mauveine in 1856. The subsequent development of synthetic dyes rapidly transformed the textile industry due to their consistency, scalability, and cost-effectiveness, leading to the near-complete displacement of natural dyes in commercial applications.

In recent decades, however, there has been a resurgence of interest in natural dyes driven by increasing environmental concerns, consumer awareness about sustainability, and stricter regulations on chemical usage in textiles. The harmful environmental impacts of synthetic dyes—including toxic effluent discharge, high water consumption, and non-biodegradable waste—have prompted this renewed focus on natural alternatives.

The evolution of natural dye technology has progressed from traditional extraction methods to more sophisticated techniques that enhance color fastness, reproducibility, and scalability. Recent innovations include enzymatic extraction processes, ultrasonic-assisted dyeing, microwave-assisted extraction, and the development of natural mordants to replace metallic fixatives.

Current research aims to address the primary limitations of natural dyes: color consistency, fastness properties, scalability, and economic viability in industrial settings. The integration of these dyes into existing textile dyehouses represents a significant technical challenge, requiring modifications to established processes and equipment designed specifically for synthetic dyes.

The primary objective of natural dye integration technology is to develop retrofit pathways that enable conventional textile dyehouses to incorporate natural dyeing processes without major capital investments or operational disruptions. This includes creating standardized natural dye formulations, optimizing extraction and application methods, and developing compatible auxiliaries that work within existing infrastructure.

Additional goals include reducing water and energy consumption in natural dyeing processes, improving color consistency and reproducibility, enhancing fastness properties to meet industry standards, and establishing sustainable supply chains for natural dye materials. The technology also aims to develop hybrid approaches that combine the benefits of both natural and synthetic dyeing systems, potentially creating a transitional pathway for the industry.

The successful integration of natural dyes into conventional textile manufacturing represents a critical step toward more sustainable production practices in an industry that has significant environmental impact globally. This technological evolution aligns with broader sustainability goals and the growing market demand for environmentally responsible textile products.

In recent decades, however, there has been a resurgence of interest in natural dyes driven by increasing environmental concerns, consumer awareness about sustainability, and stricter regulations on chemical usage in textiles. The harmful environmental impacts of synthetic dyes—including toxic effluent discharge, high water consumption, and non-biodegradable waste—have prompted this renewed focus on natural alternatives.

The evolution of natural dye technology has progressed from traditional extraction methods to more sophisticated techniques that enhance color fastness, reproducibility, and scalability. Recent innovations include enzymatic extraction processes, ultrasonic-assisted dyeing, microwave-assisted extraction, and the development of natural mordants to replace metallic fixatives.

Current research aims to address the primary limitations of natural dyes: color consistency, fastness properties, scalability, and economic viability in industrial settings. The integration of these dyes into existing textile dyehouses represents a significant technical challenge, requiring modifications to established processes and equipment designed specifically for synthetic dyes.

The primary objective of natural dye integration technology is to develop retrofit pathways that enable conventional textile dyehouses to incorporate natural dyeing processes without major capital investments or operational disruptions. This includes creating standardized natural dye formulations, optimizing extraction and application methods, and developing compatible auxiliaries that work within existing infrastructure.

Additional goals include reducing water and energy consumption in natural dyeing processes, improving color consistency and reproducibility, enhancing fastness properties to meet industry standards, and establishing sustainable supply chains for natural dye materials. The technology also aims to develop hybrid approaches that combine the benefits of both natural and synthetic dyeing systems, potentially creating a transitional pathway for the industry.

The successful integration of natural dyes into conventional textile manufacturing represents a critical step toward more sustainable production practices in an industry that has significant environmental impact globally. This technological evolution aligns with broader sustainability goals and the growing market demand for environmentally responsible textile products.

Market Analysis for Natural Dyed Textiles

The global market for natural dyed textiles has been experiencing significant growth in recent years, driven primarily by increasing consumer awareness of environmental issues and a growing preference for sustainable products. The market size for natural dyed textiles was valued at approximately $2.5 billion in 2022 and is projected to reach $4.8 billion by 2028, representing a compound annual growth rate of 11.5% during the forecast period.

Consumer demand for natural dyed textiles is particularly strong in developed markets such as North America and Europe, where environmental consciousness and disposable income levels are higher. However, emerging economies in Asia-Pacific, particularly India and China, are showing rapid growth rates due to their traditional expertise in natural dyeing techniques and increasing domestic consumption of eco-friendly products.

The premium segment of the textile market has shown the strongest adoption of natural dyes, with luxury fashion brands increasingly incorporating naturally dyed fabrics into their collections as part of their sustainability initiatives. This trend is gradually expanding into mid-market segments as production costs decrease and consumer awareness increases.

Key market drivers include stringent environmental regulations limiting the use of synthetic dyes, growing consumer preference for chemical-free products, and corporate sustainability commitments across the textile supply chain. The fashion industry's push toward circular economy principles has further accelerated interest in biodegradable and renewable dyeing solutions.

Market challenges remain significant, including higher production costs compared to synthetic alternatives, color consistency issues, and limited scalability of traditional natural dyeing processes. The price premium for naturally dyed textiles ranges from 20-40% above conventionally dyed products, creating a barrier to mass market adoption.

Distribution channels for natural dyed textiles are diversifying, with e-commerce platforms showing the fastest growth at 18% annually. Specialty retailers focusing on sustainable and ethical products represent another significant channel, while mainstream retailers are gradually increasing their offerings of naturally dyed products.

Consumer willingness to pay premium prices for naturally dyed textiles varies significantly by demographic segment, with millennials and Gen Z consumers showing the highest acceptance rates. Market research indicates that 65% of consumers under 35 are willing to pay at least 15% more for naturally dyed products with verified sustainability credentials.

The contract manufacturing segment for natural dyes is expanding rapidly, with specialized dye houses reporting annual growth rates exceeding 25% as conventional textile manufacturers seek partners with natural dyeing expertise rather than developing in-house capabilities.

Consumer demand for natural dyed textiles is particularly strong in developed markets such as North America and Europe, where environmental consciousness and disposable income levels are higher. However, emerging economies in Asia-Pacific, particularly India and China, are showing rapid growth rates due to their traditional expertise in natural dyeing techniques and increasing domestic consumption of eco-friendly products.

The premium segment of the textile market has shown the strongest adoption of natural dyes, with luxury fashion brands increasingly incorporating naturally dyed fabrics into their collections as part of their sustainability initiatives. This trend is gradually expanding into mid-market segments as production costs decrease and consumer awareness increases.

Key market drivers include stringent environmental regulations limiting the use of synthetic dyes, growing consumer preference for chemical-free products, and corporate sustainability commitments across the textile supply chain. The fashion industry's push toward circular economy principles has further accelerated interest in biodegradable and renewable dyeing solutions.

Market challenges remain significant, including higher production costs compared to synthetic alternatives, color consistency issues, and limited scalability of traditional natural dyeing processes. The price premium for naturally dyed textiles ranges from 20-40% above conventionally dyed products, creating a barrier to mass market adoption.

Distribution channels for natural dyed textiles are diversifying, with e-commerce platforms showing the fastest growth at 18% annually. Specialty retailers focusing on sustainable and ethical products represent another significant channel, while mainstream retailers are gradually increasing their offerings of naturally dyed products.

Consumer willingness to pay premium prices for naturally dyed textiles varies significantly by demographic segment, with millennials and Gen Z consumers showing the highest acceptance rates. Market research indicates that 65% of consumers under 35 are willing to pay at least 15% more for naturally dyed products with verified sustainability credentials.

The contract manufacturing segment for natural dyes is expanding rapidly, with specialized dye houses reporting annual growth rates exceeding 25% as conventional textile manufacturers seek partners with natural dyeing expertise rather than developing in-house capabilities.

Current Status and Challenges in Natural Dye Integration

The global textile industry is currently experiencing a significant shift towards sustainable practices, with natural dyes emerging as a viable alternative to synthetic colorants. Assessment of the current integration status reveals that while interest in natural dyes has grown substantially over the past decade, actual implementation in commercial textile dyehouses remains limited. Currently, natural dyes account for less than 1% of the global textile dyeing market, with most applications confined to artisanal production, luxury segments, and specialized eco-friendly brands.

The technical infrastructure in existing dyehouses presents a major challenge for natural dye integration. Most modern facilities are optimized for synthetic dye processes, utilizing equipment and systems designed specifically for chemical colorants that operate at different temperatures, pH levels, and processing times than natural alternatives. Retrofitting these facilities requires significant modifications to heating systems, water treatment processes, and material handling equipment.

Standardization issues constitute another critical challenge. Natural dyes exhibit inherent variability in color yield and fastness properties due to fluctuations in plant growing conditions, harvesting times, and extraction methods. This inconsistency conflicts with the textile industry's demand for precise color matching and reproducibility across production batches. Current color management systems and spectrophotometric standards are calibrated for synthetic dyes, requiring substantial adaptation for natural colorants.

Supply chain limitations further complicate integration efforts. The current natural dye supply chain lacks the scale, reliability, and standardization necessary for industrial application. Most natural dye producers operate at small scales with limited capacity to meet the volume requirements of commercial dyehouses. Additionally, seasonal availability of raw materials creates inventory management challenges not present with synthetic alternatives.

Regulatory frameworks present both opportunities and obstacles. While sustainability certifications increasingly recognize natural dyes as environmentally preferable options, existing textile effluent regulations were developed primarily for synthetic dye processes. This creates compliance uncertainties for facilities transitioning to natural alternatives, particularly regarding mordant usage and wastewater characteristics.

Economic viability remains perhaps the most significant barrier to widespread adoption. Natural dyes typically cost 3-5 times more than synthetic equivalents, with additional expenses incurred through longer processing times, higher labor requirements, and potential retrofitting costs. Without premium pricing models or regulatory incentives, many dyehouses struggle to justify the investment required for transition.

Technical knowledge gaps compound these challenges, as expertise in natural dyeing techniques has diminished in industrial contexts over decades of synthetic dye dominance. The specialized knowledge required for successful natural dye application at scale—including mordanting techniques, color fixation methods, and process optimization—is not widely available in the current textile workforce.

The technical infrastructure in existing dyehouses presents a major challenge for natural dye integration. Most modern facilities are optimized for synthetic dye processes, utilizing equipment and systems designed specifically for chemical colorants that operate at different temperatures, pH levels, and processing times than natural alternatives. Retrofitting these facilities requires significant modifications to heating systems, water treatment processes, and material handling equipment.

Standardization issues constitute another critical challenge. Natural dyes exhibit inherent variability in color yield and fastness properties due to fluctuations in plant growing conditions, harvesting times, and extraction methods. This inconsistency conflicts with the textile industry's demand for precise color matching and reproducibility across production batches. Current color management systems and spectrophotometric standards are calibrated for synthetic dyes, requiring substantial adaptation for natural colorants.

Supply chain limitations further complicate integration efforts. The current natural dye supply chain lacks the scale, reliability, and standardization necessary for industrial application. Most natural dye producers operate at small scales with limited capacity to meet the volume requirements of commercial dyehouses. Additionally, seasonal availability of raw materials creates inventory management challenges not present with synthetic alternatives.

Regulatory frameworks present both opportunities and obstacles. While sustainability certifications increasingly recognize natural dyes as environmentally preferable options, existing textile effluent regulations were developed primarily for synthetic dye processes. This creates compliance uncertainties for facilities transitioning to natural alternatives, particularly regarding mordant usage and wastewater characteristics.

Economic viability remains perhaps the most significant barrier to widespread adoption. Natural dyes typically cost 3-5 times more than synthetic equivalents, with additional expenses incurred through longer processing times, higher labor requirements, and potential retrofitting costs. Without premium pricing models or regulatory incentives, many dyehouses struggle to justify the investment required for transition.

Technical knowledge gaps compound these challenges, as expertise in natural dyeing techniques has diminished in industrial contexts over decades of synthetic dye dominance. The specialized knowledge required for successful natural dye application at scale—including mordanting techniques, color fixation methods, and process optimization—is not widely available in the current textile workforce.

Current Retrofit Solutions for Conventional Dye Houses

01 Natural dye extraction methods

Various methods for extracting natural dyes from plant sources have been developed to create environmentally friendly colorants. These extraction processes typically involve using water, organic solvents, or enzymatic treatments to isolate pigments from natural materials. The methods focus on optimizing yield, color stability, and reducing environmental impact compared to synthetic dye production processes.- Natural dye extraction methods: Various methods for extracting natural dyes from plant sources have been developed to create environmentally friendly colorants. These processes typically involve solvent extraction, enzymatic treatment, or mechanical processing of plant materials to isolate pigments. The extraction methods are designed to maximize yield while preserving the color properties of the natural compounds, making them suitable for industrial applications as alternatives to synthetic dyes.

- Retrofit technologies for natural dye application: Retrofit technologies enable existing dyeing equipment and processes to be modified for use with natural dyes. These adaptations include modifications to temperature control systems, pH regulation mechanisms, and dye application methods to accommodate the specific requirements of natural colorants. Such retrofit paths allow textile manufacturers to transition from synthetic to natural dyes without complete replacement of their production infrastructure.

- Natural dye fixation and stability enhancement: Techniques for improving the fixation and stability of natural dyes on various substrates involve the use of mordants, binding agents, and surface treatments. These methods enhance color fastness, light stability, and wash resistance of naturally dyed materials. Innovations in this area focus on developing eco-friendly fixation processes that maintain the sustainability benefits of natural dyes while achieving performance comparable to synthetic alternatives.

- Industrial scale-up of natural dyeing processes: Methods for scaling up natural dyeing processes from laboratory to industrial production levels address challenges related to consistency, efficiency, and cost-effectiveness. These approaches include standardization of raw materials, optimization of process parameters, and development of quality control protocols specific to natural dyes. The industrial implementation pathways enable commercial viability of natural dye applications across textile, food, and cosmetic industries.

- Hybrid systems combining natural and synthetic dyeing technologies: Hybrid dyeing systems integrate natural dye components with conventional synthetic dyeing technologies to create transitional retrofit solutions. These systems may incorporate natural dyes as supplements to reduce the environmental impact of fully synthetic processes or use synthetic components to enhance the performance of natural dyes. The hybrid approach offers a practical pathway for gradual industry transition toward more sustainable coloration methods.

02 Application of natural dyes to textiles

Techniques for applying natural dyes to various textile materials involve developing mordanting processes, fixation methods, and application procedures that ensure color fastness and durability. These retrofit approaches allow conventional textile processing equipment to be adapted for natural dyeing operations, enabling more sustainable coloration processes while maintaining quality standards for commercial textile production.Expand Specific Solutions03 Natural dye formulation and stabilization

Formulation techniques for natural dyes focus on enhancing their stability, shelf life, and performance characteristics. These approaches include developing appropriate carriers, additives, and stabilizers that protect the chromophores in natural dyes from degradation. The formulations enable natural dyes to be used as drop-in replacements for synthetic colorants in existing industrial processes without significant equipment modifications.Expand Specific Solutions04 Industrial scale-up and retrofit solutions

Methods for scaling up natural dye production and application to industrial levels involve retrofitting existing dyeing equipment and processes. These approaches include modifying conventional dyeing machinery, developing compatible process parameters, and creating transition protocols that allow manufacturers to switch from synthetic to natural dyes without major capital investments. The retrofit paths focus on practical implementation strategies that minimize disruption to existing production lines.Expand Specific Solutions05 Sustainability and environmental benefits

Natural dye retrofit paths emphasize the environmental and sustainability advantages of transitioning from synthetic to natural colorants. These approaches quantify benefits such as reduced water pollution, lower carbon footprint, and decreased chemical waste. The methods also address lifecycle assessment of natural dye implementation, providing frameworks for evaluating the overall environmental impact of switching to natural dye systems in various industrial applications.Expand Specific Solutions

Key Industry Players in Natural Dye Sector

The natural dye integration market is currently in a transitional phase, with growing interest driven by sustainability demands but limited commercial-scale implementation. Market size is expanding as consumer preference for eco-friendly textiles increases, though it remains a niche segment within the $10 billion global textile dye industry. Technical maturity varies significantly across players: research institutions like The Hong Kong Research Institute of Textiles & Apparel and Soochow University are advancing fundamental research, while established chemical companies including Clariant International AG and Rohm & Haas are developing hybrid solutions. Innovative companies like Alchemie Technology and Make In Italy are pioneering retrofit technologies specifically designed for natural dye integration. Traditional textile manufacturers such as Arvind Ltd. and Trident Inc. are gradually adopting these technologies, though challenges in color consistency and scalability persist.

The Hong Kong Research Institute of Textiles & Apparel Ltd.

Technical Solution: The Hong Kong Research Institute of Textiles & Apparel (HKRITA) has developed a comprehensive natural dye integration system that combines traditional dyeing knowledge with modern technology. Their approach includes a standardized extraction process for natural dyes that ensures consistent color yield and quality. HKRITA has engineered retrofit solutions specifically designed to modify existing synthetic dye equipment with minimal capital investment, including specialized filtration systems to handle the particulate matter common in natural dyes. Their technology incorporates AI-driven color matching systems that can predict natural dye behavior and create reproducible formulations across different batches. Additionally, HKRITA has developed water recycling systems specifically optimized for natural dye effluent treatment, reducing water consumption by up to 40% compared to conventional natural dyeing processes.

Strengths: Strong focus on practical implementation with minimal disruption to existing infrastructure; comprehensive approach addressing extraction, application, and waste management; excellent color consistency through AI-driven formulation. Weaknesses: Higher initial implementation costs compared to some alternatives; requires specialized training for technicians; system optimization still needed for certain fiber types.

Fujian Institute of Research on The Structure of Matter

Technical Solution: The Fujian Institute has pioneered a molecular modification approach to natural dye integration that enhances dye-fiber affinity without synthetic additives. Their technology involves the structural modification of natural chromophores to improve binding with textile fibers, resulting in enhanced color fastness comparable to synthetic dyes. The institute has developed a unique ultrasonic-assisted extraction method that increases dye yield by approximately 30% while reducing extraction time by half compared to conventional methods. Their retrofit solution includes a modular pre-treatment system that can be installed in-line with existing dyeing equipment, modifying fiber surfaces to increase natural dye uptake. Additionally, they've created specialized mordanting processes using environmentally benign metal salts and bio-mordants derived from agricultural waste, eliminating the need for harmful chemicals typically associated with natural dyeing.

Strengths: Superior color fastness properties approaching synthetic dye performance; environmentally sustainable mordanting solutions; high extraction efficiency reducing raw material costs. Weaknesses: Complex implementation requiring scientific expertise; technology still scaling to industrial volumes; higher processing times compared to conventional synthetic dyeing.

Technical Analysis of Natural Dye Extraction Methods

Natural dyes

PatentWO2011012471A2

Innovation

- A method involving transferring dyes from biological materials to an aqueous medium, precipitating them with suitable agents, separating the precipitate, and then converting it back into a soluble form using complexing agents like polycarboxylates or aminopolycarboxylic acids to achieve a concentrated dye solution suitable for textile dyeing.

Natural dyeing method

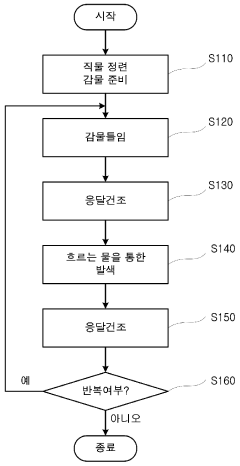

PatentInactiveKR1020100056060A

Innovation

- A natural dyeing method involving immersion in persimmon juice, followed by controlled moisture drying and immersion in flowing water to develop color, repeated as necessary, to enhance dye absorption and fastness.

Environmental Impact Assessment

The environmental impact assessment of integrating natural dyes into existing textile dye houses reveals significant potential for reducing the ecological footprint of textile production. Conventional synthetic dyeing processes are notorious for their high water consumption, chemical usage, and pollution generation. Natural dyes offer a promising alternative with substantially lower environmental impacts across multiple dimensions.

Water pollution from textile dyeing represents one of the industry's most pressing environmental challenges. Synthetic dyes typically contain heavy metals, salts, and other toxic compounds that contaminate waterways. Natural dyes, derived from plant, animal, or mineral sources, generally produce effluent with lower toxicity levels and higher biodegradability. Studies indicate that wastewater from natural dyeing processes contains 30-45% fewer harmful chemicals compared to synthetic alternatives.

Energy consumption presents another critical environmental consideration. The retrofit of existing dye houses to accommodate natural dyeing processes can lead to energy savings of 15-25% due to lower temperature requirements for many natural dyeing processes. While initial retrofit costs may be substantial, the long-term energy efficiency gains contribute to both environmental sustainability and operational cost reduction.

Carbon footprint analysis demonstrates that natural dyes typically generate 40-60% lower greenhouse gas emissions compared to synthetic counterparts when considering the entire lifecycle. This reduction stems primarily from less energy-intensive production processes and the renewable nature of natural dye sources. However, agricultural practices for growing dye plants must be carefully managed to maximize these benefits.

Resource utilization efficiency varies significantly between different natural dye sources. While some natural dyes can be derived from agricultural waste or by-products (such as onion skins or pomegranate rinds), others require dedicated cultivation. Land use implications must therefore be carefully assessed, particularly when scaling up natural dye production to industrial levels.

Biodiversity impacts represent both a challenge and opportunity. Sustainable harvesting of wild plants for dyes must be carefully managed to prevent ecosystem disruption. Conversely, the cultivation of diverse dye-producing plants can potentially enhance agricultural biodiversity compared to monoculture practices, creating positive ecological outcomes when properly implemented.

Waste management considerations reveal that solid waste from natural dyeing processes is generally more compostable and less hazardous than synthetic dye waste. However, retrofitting existing facilities requires developing new waste handling protocols and potentially investing in additional treatment infrastructure to manage the different waste stream characteristics.

Water pollution from textile dyeing represents one of the industry's most pressing environmental challenges. Synthetic dyes typically contain heavy metals, salts, and other toxic compounds that contaminate waterways. Natural dyes, derived from plant, animal, or mineral sources, generally produce effluent with lower toxicity levels and higher biodegradability. Studies indicate that wastewater from natural dyeing processes contains 30-45% fewer harmful chemicals compared to synthetic alternatives.

Energy consumption presents another critical environmental consideration. The retrofit of existing dye houses to accommodate natural dyeing processes can lead to energy savings of 15-25% due to lower temperature requirements for many natural dyeing processes. While initial retrofit costs may be substantial, the long-term energy efficiency gains contribute to both environmental sustainability and operational cost reduction.

Carbon footprint analysis demonstrates that natural dyes typically generate 40-60% lower greenhouse gas emissions compared to synthetic counterparts when considering the entire lifecycle. This reduction stems primarily from less energy-intensive production processes and the renewable nature of natural dye sources. However, agricultural practices for growing dye plants must be carefully managed to maximize these benefits.

Resource utilization efficiency varies significantly between different natural dye sources. While some natural dyes can be derived from agricultural waste or by-products (such as onion skins or pomegranate rinds), others require dedicated cultivation. Land use implications must therefore be carefully assessed, particularly when scaling up natural dye production to industrial levels.

Biodiversity impacts represent both a challenge and opportunity. Sustainable harvesting of wild plants for dyes must be carefully managed to prevent ecosystem disruption. Conversely, the cultivation of diverse dye-producing plants can potentially enhance agricultural biodiversity compared to monoculture practices, creating positive ecological outcomes when properly implemented.

Waste management considerations reveal that solid waste from natural dyeing processes is generally more compostable and less hazardous than synthetic dye waste. However, retrofitting existing facilities requires developing new waste handling protocols and potentially investing in additional treatment infrastructure to manage the different waste stream characteristics.

Cost-Benefit Analysis of Retrofit Implementation

The comprehensive cost-benefit analysis of retrofitting existing textile dye houses for natural dye integration reveals a complex financial landscape with significant initial investment requirements balanced against long-term economic and environmental advantages.

Initial capital expenditures represent the most substantial barrier to implementation, typically ranging from $150,000 to $750,000 depending on facility size and current infrastructure. These costs primarily encompass equipment modifications (30-40%), process control systems (20-25%), wastewater treatment upgrades (15-20%), and staff training (10-15%). Notably, facilities utilizing high-temperature synthetic dyeing processes require more extensive modifications to accommodate the lower temperature requirements of natural dyes.

Operational cost implications present a mixed picture. While natural dyes generally command premium prices (30-200% higher than synthetic alternatives), this is partially offset by reduced energy consumption (15-25% savings) due to lower processing temperatures. Water usage patterns shift rather than decrease, with natural dyes often requiring additional rinsing cycles but at lower temperatures, resulting in minimal net cost difference.

Environmental compliance benefits deliver quantifiable financial advantages through reduced wastewater treatment costs (10-30% savings) and lower regulatory compliance expenses. Facilities in regions with stringent environmental regulations report average annual savings of $25,000-$75,000 in compliance-related expenditures after retrofit completion.

Market positioning advantages represent perhaps the most compelling economic justification. Consumer willingness to pay premiums for naturally-dyed textiles (15-40% higher retail prices) creates substantial margin improvement opportunities. Case studies from early adopters demonstrate revenue increases of 20-35% within two years of retrofit implementation, particularly when targeting eco-conscious consumer segments.

Return on investment timelines vary significantly based on implementation approach. Phased retrofits, where natural dye capabilities are added incrementally alongside existing synthetic processes, demonstrate the most favorable financial outcomes with ROI periods of 2-4 years. Complete system replacements typically require 5-7 years to achieve positive returns.

Government incentives substantially improve the financial calculus in many regions. Available programs include tax credits (10-30% of retrofit costs), direct grants (covering 15-40% of implementation expenses), and low-interest financing options specifically targeting sustainable manufacturing transitions. These incentives can reduce payback periods by 30-50% when strategically leveraged.

Initial capital expenditures represent the most substantial barrier to implementation, typically ranging from $150,000 to $750,000 depending on facility size and current infrastructure. These costs primarily encompass equipment modifications (30-40%), process control systems (20-25%), wastewater treatment upgrades (15-20%), and staff training (10-15%). Notably, facilities utilizing high-temperature synthetic dyeing processes require more extensive modifications to accommodate the lower temperature requirements of natural dyes.

Operational cost implications present a mixed picture. While natural dyes generally command premium prices (30-200% higher than synthetic alternatives), this is partially offset by reduced energy consumption (15-25% savings) due to lower processing temperatures. Water usage patterns shift rather than decrease, with natural dyes often requiring additional rinsing cycles but at lower temperatures, resulting in minimal net cost difference.

Environmental compliance benefits deliver quantifiable financial advantages through reduced wastewater treatment costs (10-30% savings) and lower regulatory compliance expenses. Facilities in regions with stringent environmental regulations report average annual savings of $25,000-$75,000 in compliance-related expenditures after retrofit completion.

Market positioning advantages represent perhaps the most compelling economic justification. Consumer willingness to pay premiums for naturally-dyed textiles (15-40% higher retail prices) creates substantial margin improvement opportunities. Case studies from early adopters demonstrate revenue increases of 20-35% within two years of retrofit implementation, particularly when targeting eco-conscious consumer segments.

Return on investment timelines vary significantly based on implementation approach. Phased retrofits, where natural dye capabilities are added incrementally alongside existing synthetic processes, demonstrate the most favorable financial outcomes with ROI periods of 2-4 years. Complete system replacements typically require 5-7 years to achieve positive returns.

Government incentives substantially improve the financial calculus in many regions. Available programs include tax credits (10-30% of retrofit costs), direct grants (covering 15-40% of implementation expenses), and low-interest financing options specifically targeting sustainable manufacturing transitions. These incentives can reduce payback periods by 30-50% when strategically leveraged.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!