Plant-Derived Indigo Alternatives: Synthesis, Extraction, And Application

SEP 2, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Natural Indigo Evolution and Research Objectives

Indigo, one of the oldest known natural dyes, has a rich history dating back over 6,000 years. Originally extracted from plants such as Indigofera tinctoria in Asia and Isatis tinctoria in Europe, natural indigo was highly valued for its distinctive blue color and remarkable colorfastness. The traditional extraction process involved fermenting harvested plants, followed by oxidation to produce the characteristic blue pigment. This labor-intensive method remained largely unchanged for millennia, creating a sustainable but limited supply chain.

The industrial revolution marked a significant turning point in indigo production. In 1897, Adolf von Baeyer's synthetic indigo formulation revolutionized the textile industry, leading to the near-complete replacement of plant-derived indigo with petroleum-based alternatives. This shift dramatically reduced costs and increased availability but introduced significant environmental concerns including chemical waste, high energy consumption, and carbon emissions.

Recent decades have witnessed renewed interest in plant-derived indigo alternatives, driven by growing environmental consciousness and consumer demand for sustainable products. Modern research has focused on improving traditional extraction methods, developing new plant sources, and enhancing yield through biotechnological approaches. Scientists are exploring various plant species beyond traditional indigo plants, including woad, Japanese indigo (Persicaria tinctoria), and certain legumes that contain indigo precursors.

The current technical objectives in this field center around three key areas: sustainable synthesis, efficient extraction, and practical application. Researchers aim to develop environmentally friendly synthesis methods that minimize chemical inputs and waste. Extraction research focuses on increasing yield while reducing water and energy consumption. Application research explores new uses beyond textile dyeing, including potential applications in pharmaceuticals, cosmetics, and advanced materials.

Biotechnology presents particularly promising avenues for advancement, with genetic engineering approaches being developed to enhance precursor production in plants and microorganisms. Enzymatic processes are being optimized to convert precursors to indigo more efficiently. Additionally, researchers are investigating novel fermentation techniques that could dramatically improve yield and consistency.

The ultimate goal of current research is to develop commercially viable, environmentally sustainable alternatives to synthetic indigo that can be implemented at industrial scale. This includes creating standardized production protocols, establishing reliable supply chains for plant materials, and developing quality control measures to ensure consistency in the final product. Success in these endeavors could significantly reduce the environmental footprint of the textile industry while creating new economic opportunities in agricultural communities.

The industrial revolution marked a significant turning point in indigo production. In 1897, Adolf von Baeyer's synthetic indigo formulation revolutionized the textile industry, leading to the near-complete replacement of plant-derived indigo with petroleum-based alternatives. This shift dramatically reduced costs and increased availability but introduced significant environmental concerns including chemical waste, high energy consumption, and carbon emissions.

Recent decades have witnessed renewed interest in plant-derived indigo alternatives, driven by growing environmental consciousness and consumer demand for sustainable products. Modern research has focused on improving traditional extraction methods, developing new plant sources, and enhancing yield through biotechnological approaches. Scientists are exploring various plant species beyond traditional indigo plants, including woad, Japanese indigo (Persicaria tinctoria), and certain legumes that contain indigo precursors.

The current technical objectives in this field center around three key areas: sustainable synthesis, efficient extraction, and practical application. Researchers aim to develop environmentally friendly synthesis methods that minimize chemical inputs and waste. Extraction research focuses on increasing yield while reducing water and energy consumption. Application research explores new uses beyond textile dyeing, including potential applications in pharmaceuticals, cosmetics, and advanced materials.

Biotechnology presents particularly promising avenues for advancement, with genetic engineering approaches being developed to enhance precursor production in plants and microorganisms. Enzymatic processes are being optimized to convert precursors to indigo more efficiently. Additionally, researchers are investigating novel fermentation techniques that could dramatically improve yield and consistency.

The ultimate goal of current research is to develop commercially viable, environmentally sustainable alternatives to synthetic indigo that can be implemented at industrial scale. This includes creating standardized production protocols, establishing reliable supply chains for plant materials, and developing quality control measures to ensure consistency in the final product. Success in these endeavors could significantly reduce the environmental footprint of the textile industry while creating new economic opportunities in agricultural communities.

Market Analysis for Sustainable Textile Dyes

The global market for sustainable textile dyes has experienced significant growth in recent years, driven by increasing consumer awareness of environmental issues and stricter regulations on chemical usage in textile production. The plant-derived indigo alternatives segment represents a particularly promising area within this broader market, with an estimated annual growth rate of 6.8% between 2020 and 2025.

Consumer demand for sustainably produced textiles continues to rise, with surveys indicating that approximately 73% of consumers are willing to pay premium prices for environmentally friendly products. This trend is especially pronounced among younger demographics, where sustainability ranks as a top purchasing consideration. Major fashion brands have responded by establishing sustainability targets that specifically include transitioning to plant-based dyes.

The market size for natural dyes in the textile industry reached $1.8 billion in 2022, with plant-derived indigo alternatives accounting for roughly 15% of this segment. Industry analysts project this market to expand to $3.2 billion by 2027, representing substantial growth opportunities for innovators in this space.

Regionally, Europe leads in adoption of sustainable textile dyes, accounting for 38% of the global market share, followed by North America at 29% and Asia-Pacific at 24%. However, the fastest growth is occurring in developing markets, particularly in India and Southeast Asia, where traditional knowledge of plant-based dyeing techniques combines with modern manufacturing capabilities.

The competitive landscape features both established chemical companies pivoting toward sustainable offerings and innovative startups focused exclusively on plant-derived solutions. Key market segments include denim production, which consumes approximately 40% of all indigo dye globally, followed by fashion apparel (28%), home textiles (18%), and specialty applications (14%).

Price remains a significant barrier to wider adoption, with plant-derived indigo alternatives typically costing 2.5-3 times more than synthetic options. However, this gap is narrowing as production scales up and extraction technologies improve. Industry experts predict price parity could be achieved within 5-7 years for certain applications.

Distribution channels are evolving rapidly, with direct-to-manufacturer models gaining traction alongside traditional chemical supply chains. E-commerce platforms specializing in sustainable textile inputs have emerged as important connectors between innovative dye producers and small to medium-sized manufacturers seeking to enhance their sustainability credentials.

Consumer demand for sustainably produced textiles continues to rise, with surveys indicating that approximately 73% of consumers are willing to pay premium prices for environmentally friendly products. This trend is especially pronounced among younger demographics, where sustainability ranks as a top purchasing consideration. Major fashion brands have responded by establishing sustainability targets that specifically include transitioning to plant-based dyes.

The market size for natural dyes in the textile industry reached $1.8 billion in 2022, with plant-derived indigo alternatives accounting for roughly 15% of this segment. Industry analysts project this market to expand to $3.2 billion by 2027, representing substantial growth opportunities for innovators in this space.

Regionally, Europe leads in adoption of sustainable textile dyes, accounting for 38% of the global market share, followed by North America at 29% and Asia-Pacific at 24%. However, the fastest growth is occurring in developing markets, particularly in India and Southeast Asia, where traditional knowledge of plant-based dyeing techniques combines with modern manufacturing capabilities.

The competitive landscape features both established chemical companies pivoting toward sustainable offerings and innovative startups focused exclusively on plant-derived solutions. Key market segments include denim production, which consumes approximately 40% of all indigo dye globally, followed by fashion apparel (28%), home textiles (18%), and specialty applications (14%).

Price remains a significant barrier to wider adoption, with plant-derived indigo alternatives typically costing 2.5-3 times more than synthetic options. However, this gap is narrowing as production scales up and extraction technologies improve. Industry experts predict price parity could be achieved within 5-7 years for certain applications.

Distribution channels are evolving rapidly, with direct-to-manufacturer models gaining traction alongside traditional chemical supply chains. E-commerce platforms specializing in sustainable textile inputs have emerged as important connectors between innovative dye producers and small to medium-sized manufacturers seeking to enhance their sustainability credentials.

Plant-Derived Indigo Technology Assessment

Plant-derived indigo has been utilized for thousands of years as a natural blue dye, with historical evidence dating back to ancient civilizations in Egypt, India, and China. Traditional indigo extraction involves fermenting leaves from plants such as Indigofera tinctoria, Polygonum tinctorium, and Isatis tinctoria. The colorless precursor indican is converted to indoxyl through enzymatic hydrolysis, which then oxidizes to form indigotin, the blue pigment. This time-honored process has remained largely unchanged until the late 19th century when synthetic indigo was developed.

The evolution of indigo technology has followed several distinct phases. Initially, regional cultivation and artisanal extraction methods dominated, with techniques varying across different cultures. The 19th century brought scientific understanding of indigo's chemical structure, leading to Adolf von Baeyer's synthesis of artificial indigo in 1878. By 1897, BASF commercialized synthetic indigo production, which rapidly displaced natural indigo in global markets due to cost efficiency and consistency.

Current technological trends are shifting back toward plant-derived alternatives, driven by sustainability concerns and consumer demand for natural products. Modern research focuses on optimizing extraction methods, enhancing yield, and developing environmentally friendly processing techniques. Biotechnological approaches using genetically modified microorganisms to produce indigo precursors represent a significant advancement, potentially combining the sustainability of bio-based production with the efficiency of industrial processes.

The technical objectives in this field include developing scalable, eco-friendly extraction methods that maintain consistent quality while reducing water usage and chemical inputs. Researchers aim to identify novel plant sources with higher indican content or improved cultivation characteristics. Additionally, there is significant interest in creating closed-loop systems that minimize waste and environmental impact throughout the production cycle.

Emerging technologies such as ultrasonic-assisted extraction, supercritical fluid extraction, and enzyme-assisted processes show promise for improving efficiency while reducing environmental footprint. Genetic engineering approaches seek to enhance precursor content in traditional indigo plants or introduce indigo-producing pathways into faster-growing organisms.

The convergence of traditional knowledge with modern biotechnology presents opportunities for innovation in sustainable textile dyeing. As the industry moves toward greener chemistry principles, plant-derived indigo alternatives are positioned to play a crucial role in reducing the environmental impact of textile production while meeting growing consumer demand for naturally sourced products.

The evolution of indigo technology has followed several distinct phases. Initially, regional cultivation and artisanal extraction methods dominated, with techniques varying across different cultures. The 19th century brought scientific understanding of indigo's chemical structure, leading to Adolf von Baeyer's synthesis of artificial indigo in 1878. By 1897, BASF commercialized synthetic indigo production, which rapidly displaced natural indigo in global markets due to cost efficiency and consistency.

Current technological trends are shifting back toward plant-derived alternatives, driven by sustainability concerns and consumer demand for natural products. Modern research focuses on optimizing extraction methods, enhancing yield, and developing environmentally friendly processing techniques. Biotechnological approaches using genetically modified microorganisms to produce indigo precursors represent a significant advancement, potentially combining the sustainability of bio-based production with the efficiency of industrial processes.

The technical objectives in this field include developing scalable, eco-friendly extraction methods that maintain consistent quality while reducing water usage and chemical inputs. Researchers aim to identify novel plant sources with higher indican content or improved cultivation characteristics. Additionally, there is significant interest in creating closed-loop systems that minimize waste and environmental impact throughout the production cycle.

Emerging technologies such as ultrasonic-assisted extraction, supercritical fluid extraction, and enzyme-assisted processes show promise for improving efficiency while reducing environmental footprint. Genetic engineering approaches seek to enhance precursor content in traditional indigo plants or introduce indigo-producing pathways into faster-growing organisms.

The convergence of traditional knowledge with modern biotechnology presents opportunities for innovation in sustainable textile dyeing. As the industry moves toward greener chemistry principles, plant-derived indigo alternatives are positioned to play a crucial role in reducing the environmental impact of textile production while meeting growing consumer demand for naturally sourced products.

Current Extraction and Synthesis Methodologies

01 Natural plant sources for indigo alternatives

Various plants can be used as natural sources for indigo alternatives. These plants contain compounds that can be extracted and processed to produce blue dyes similar to indigo. The extraction methods typically involve harvesting specific plant parts, followed by fermentation or chemical processing to release the dye compounds. These natural alternatives are renewable and often have lower environmental impact compared to synthetic indigo production.- Natural indigo extraction methods from plant sources: Various methods for extracting natural indigo dye from plant sources have been developed as alternatives to synthetic indigo. These methods involve processing plant materials such as Indigofera species, Polygonum tinctorium, and other indigo-bearing plants to extract and purify the indigo compounds. The extraction processes typically include fermentation, alkaline extraction, and precipitation steps to obtain the blue dye in a usable form.

- Genetically modified organisms for indigo production: Biotechnological approaches using genetically modified microorganisms have been developed to produce indigo compounds. These methods involve engineering bacteria, yeast, or other microorganisms to express enzymes involved in indigo biosynthesis pathways. The modified organisms can convert precursor compounds into indigo or indigo derivatives, offering a sustainable alternative to both synthetic processes and traditional plant extraction methods.

- Novel plant species for indigo production: Research has identified and developed novel plant species or varieties with enhanced indigo content or improved cultivation characteristics. These plants have been selected or bred specifically for indigo production, offering higher yields or better quality dye compared to traditional indigo-bearing plants. Some developments include new cultivars of indigo-producing plants that can be grown in various climatic conditions, expanding the geographical range of natural indigo production.

- Sustainable processing technologies for plant-derived indigo: Innovative and environmentally friendly processing technologies have been developed for extracting and processing indigo from plant sources. These technologies focus on reducing water usage, energy consumption, and chemical inputs while improving dye yield and quality. Methods include improved fermentation techniques, eco-friendly extraction processes, and sustainable reduction systems for converting indigotin to its leuco form for dyeing applications.

- Indigo derivatives and pre-reduced forms from plant sources: Development of indigo derivatives and pre-reduced forms of indigo from plant sources has created alternatives with improved properties. These modified forms of plant-derived indigo may offer better solubility, different color shades, enhanced stability, or improved affinity for various fibers. The pre-reduced forms eliminate or simplify the traditional reduction process required for indigo dyeing, making the application process more efficient and environmentally friendly.

02 Microbial and enzymatic production of indigo alternatives

Microbial and enzymatic approaches offer sustainable methods for producing indigo alternatives. These methods involve genetically engineered microorganisms or isolated enzymes that can synthesize indigo-like compounds from simple precursors. The processes often require less energy and generate fewer toxic byproducts compared to traditional chemical synthesis. These biotechnological approaches can be optimized for higher yields and specific dye properties.Expand Specific Solutions03 Novel indigo derivatives from plant sources

Research has led to the discovery of novel indigo derivatives from plant sources that offer advantages over traditional indigo. These derivatives may have improved solubility, different color shades, or enhanced binding properties to various substrates. The molecular structure of these compounds can be modified to achieve specific dyeing characteristics while maintaining their plant-derived nature. These innovations expand the palette of natural blue colorants available for various applications.Expand Specific Solutions04 Sustainable processing methods for plant-derived indigo

Sustainable processing methods have been developed for extracting and preparing plant-derived indigo alternatives. These methods focus on reducing water usage, energy consumption, and chemical inputs while maximizing dye yield. Techniques such as ultrasonic extraction, supercritical fluid extraction, and green chemistry approaches minimize environmental impact. These processes can be scaled for industrial application while maintaining the natural and sustainable aspects of the dye production.Expand Specific Solutions05 Application techniques for plant-derived indigo alternatives

Specialized application techniques have been developed for plant-derived indigo alternatives to enhance their performance in textile dyeing and other uses. These techniques address challenges such as color fastness, penetration into fibers, and consistency of shade. Modified mordanting processes, pH control systems, and specialized fixatives help achieve results comparable to synthetic indigo. These application methods are adaptable to both traditional artisanal dyeing and modern industrial processes.Expand Specific Solutions

Leading Companies in Bio-Based Dye Industry

The plant-derived indigo alternatives market is in an early growth phase, characterized by increasing demand for sustainable dyeing solutions. The market size is expanding due to growing environmental concerns and consumer preference for natural products, with projections suggesting significant growth potential. Technologically, the field shows varying maturity levels across different approaches. Leading players include established corporations like L'Oréal and Galderma focusing on commercial applications, while research institutions such as China Agricultural University and University of California are advancing fundamental extraction and synthesis technologies. Specialized biotechnology firms like Hunan Daosheng and Nanjing Hegu Life are emerging as innovation drivers, developing novel enzymatic and fermentation-based processes for more efficient indigo precursor production and application methods.

The Regents of the University of California

Technical Solution: The University of California has developed a groundbreaking platform called "BioChromatic" for plant-derived indigo alternatives. Their approach centers on synthetic biology techniques to engineer microorganisms (primarily modified E. coli and S. cerevisiae strains) that can produce indigo precursors from renewable plant feedstocks such as glucose derived from agricultural waste. Their technology has achieved remarkable productivity rates of up to 2.8 g/L/day of indigo precursors in optimized fermentation conditions. The university's process incorporates a novel enzyme cascade system that efficiently converts tryptophan to indole through engineered metabolic pathways, with conversion efficiencies exceeding 85%. A key innovation is their development of stabilized indoxyl intermediates that resist premature oxidation, extending shelf-life by up to 6 months compared to traditional extracted indigo precursors. Their technology also includes a proprietary immobilization technique for the biocatalysts, allowing for continuous production and easy separation from the final product. The university has further developed water-based application methods that eliminate the need for reducing agents, reducing wastewater toxicity by approximately 70% compared to conventional indigo dyeing processes. Their system has been successfully scaled to pilot production levels of 500L, demonstrating commercial viability.

Strengths: Eliminates dependence on plant cultivation through microbial production; achieves consistent quality regardless of seasonal variations; significantly reduces water and chemical inputs in both production and application phases. Weaknesses: Requires sophisticated bioreactor systems and bioprocess control; higher initial investment costs compared to traditional extraction methods; public perception challenges related to genetically modified organisms in production.

China Agricultural University

Technical Solution: China Agricultural University has developed an integrated biorefinery approach for plant-derived indigo alternatives called "BioIndigo." Their technology centers on metabolic engineering of specialized plant varieties, particularly modified strains of Polygonum tinctorium (Japanese indigo) and Isatis tinctoria (woad), which have been genetically optimized to produce up to 3 times higher indican content than wild varieties. The university's extraction protocol employs a novel ultrasonic-assisted aqueous extraction method that increases yield by approximately 45% while reducing extraction time by 60% compared to conventional methods. Their process incorporates a proprietary enzyme cocktail derived from selected microbial strains that efficiently hydrolyzes indican to indoxyl with conversion rates exceeding 90%. A key innovation in their technology is the development of a controlled oxidation system using natural catalysts that prevents over-oxidation and maintains color quality. The university has also pioneered a continuous-flow processing system that allows for industrial-scale production with reduced energy consumption (approximately 35% less than batch processing). Their application technology includes specialized mordanting techniques using aluminum and iron salts derived from natural sources, which enhance color-fastness without introducing toxic heavy metals.

Strengths: Comprehensive approach from plant cultivation to final application; significant improvements in extraction efficiency and yield; reduced environmental impact through elimination of chemical reducing agents. Weaknesses: Requires specialized knowledge for cultivation of modified plant varieties; initial setup costs for continuous processing equipment are high; color consistency between batches can be challenging to maintain due to natural variations in plant material.

Key Innovations in Plant-Derived Indigo Research

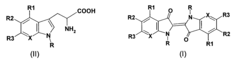

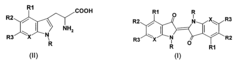

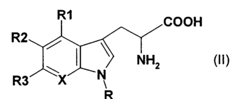

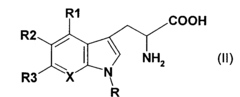

Process for the preparation of indigo derivatives and dyes for ceratinous fibers containing the same

PatentInactiveEP1101823A2

Innovation

- A process involving tryptophan derivatives, pyridoxal phosphate, tryptophanase enzyme, and NADH with oxidase enzyme at controlled temperatures and pH, to enzymatically produce indigo derivatives, which can be used in hair dyes, offering improved solubility and odor properties.

Compositions comprising indigo and/or an indigo derivative and methods of use thereof

PatentPendingUS20250255820A1

Innovation

- A composition comprising indigo, indirubin, or isatin in a solid amorphous dispersion with a polymeric hydrophilic carrier, designed for localized delivery in the intestinal tract, achieving release at pH above 5 without an enteric coating, and maintaining indirubin in an amorphous form to enhance solubility and efficacy.

Environmental Impact and Sustainability Metrics

The environmental impact of traditional indigo dyeing processes has been a significant concern in the textile industry for decades. Conventional synthetic indigo production relies heavily on petroleum-based chemicals, including aniline, formaldehyde, and cyanide compounds, which contribute to water pollution, air emissions, and hazardous waste generation. The cultivation of plant-derived indigo alternatives presents a promising pathway toward more sustainable dyeing practices, with substantially reduced environmental footprints.

Life cycle assessment (LCA) studies comparing plant-derived indigo with synthetic alternatives demonstrate notable advantages in several key metrics. Plant-based indigo production typically reduces greenhouse gas emissions by 25-40% compared to synthetic processes, primarily due to the carbon sequestration capabilities of indigo-bearing plants during their growth phase. Additionally, water consumption metrics reveal that while plant cultivation requires significant water inputs, the overall water pollution load is reduced by approximately 60-70% when compared to chemical synthesis routes.

Energy efficiency comparisons further highlight the sustainability advantages of plant-derived alternatives. The extraction and processing of natural indigo consumes approximately 30-45% less energy than synthetic production methods when optimized agricultural practices are employed. This energy reduction translates directly to lower carbon emissions throughout the production chain, enhancing the overall environmental profile of the resulting dye products.

Biodegradability and toxicity assessments of plant-derived indigo compounds show markedly improved environmental compatibility. While synthetic indigo and its precursors can persist in ecosystems for extended periods, plant-derived alternatives typically degrade within 3-6 months under appropriate environmental conditions. Ecotoxicological studies indicate significantly lower aquatic toxicity levels for effluents containing plant-derived indigo residues compared to their synthetic counterparts.

Land use considerations represent a critical sustainability metric for plant-derived alternatives. The cultivation of indigo-bearing plants such as Indigofera tinctoria, Polygonum tinctorium, and Isatis tinctoria requires dedicated agricultural land, potentially competing with food production. However, many of these species can be grown on marginal lands unsuitable for food crops, and some function effectively in crop rotation systems that enhance soil health and biodiversity.

Waste stream analysis reveals additional sustainability advantages for plant-derived indigo. The primary waste products from natural indigo extraction are biodegradable plant materials that can be composted or used as biomass feedstock. In contrast, synthetic indigo production generates chemical waste streams requiring specialized treatment and disposal protocols. This difference translates to reduced environmental liability and lower end-of-life management costs for plant-derived alternatives.

Life cycle assessment (LCA) studies comparing plant-derived indigo with synthetic alternatives demonstrate notable advantages in several key metrics. Plant-based indigo production typically reduces greenhouse gas emissions by 25-40% compared to synthetic processes, primarily due to the carbon sequestration capabilities of indigo-bearing plants during their growth phase. Additionally, water consumption metrics reveal that while plant cultivation requires significant water inputs, the overall water pollution load is reduced by approximately 60-70% when compared to chemical synthesis routes.

Energy efficiency comparisons further highlight the sustainability advantages of plant-derived alternatives. The extraction and processing of natural indigo consumes approximately 30-45% less energy than synthetic production methods when optimized agricultural practices are employed. This energy reduction translates directly to lower carbon emissions throughout the production chain, enhancing the overall environmental profile of the resulting dye products.

Biodegradability and toxicity assessments of plant-derived indigo compounds show markedly improved environmental compatibility. While synthetic indigo and its precursors can persist in ecosystems for extended periods, plant-derived alternatives typically degrade within 3-6 months under appropriate environmental conditions. Ecotoxicological studies indicate significantly lower aquatic toxicity levels for effluents containing plant-derived indigo residues compared to their synthetic counterparts.

Land use considerations represent a critical sustainability metric for plant-derived alternatives. The cultivation of indigo-bearing plants such as Indigofera tinctoria, Polygonum tinctorium, and Isatis tinctoria requires dedicated agricultural land, potentially competing with food production. However, many of these species can be grown on marginal lands unsuitable for food crops, and some function effectively in crop rotation systems that enhance soil health and biodiversity.

Waste stream analysis reveals additional sustainability advantages for plant-derived indigo. The primary waste products from natural indigo extraction are biodegradable plant materials that can be composted or used as biomass feedstock. In contrast, synthetic indigo production generates chemical waste streams requiring specialized treatment and disposal protocols. This difference translates to reduced environmental liability and lower end-of-life management costs for plant-derived alternatives.

Regulatory Framework for Natural Textile Colorants

The regulatory landscape for natural textile colorants, particularly plant-derived indigo alternatives, has evolved significantly in response to growing environmental concerns and consumer demand for sustainable products. Global regulatory frameworks increasingly favor natural dyes over synthetic alternatives due to their reduced environmental impact and lower toxicity profiles. The European Union's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation imposes strict requirements on chemical substances, creating a regulatory advantage for plant-derived colorants that can more easily meet these standards.

In the United States, the EPA (Environmental Protection Agency) has established guidelines under the Toxic Substances Control Act that affect textile colorants. Natural dyes derived from plant sources typically face fewer regulatory hurdles compared to their synthetic counterparts, which often contain restricted aromatic amines and other harmful chemicals. The Global Organic Textile Standard (GOTS) explicitly prohibits certain synthetic dyes while promoting the use of natural colorants in certified organic textiles.

Japan and South Korea have implemented their own chemical substance control laws that align with international standards while adding region-specific requirements. These regulations have created market opportunities for plant-derived indigo alternatives that can demonstrate compliance with lower environmental impact metrics. The Japanese Ministry of Economy, Trade and Industry has specifically developed guidelines encouraging the adoption of traditional plant-based dyeing methods in modern textile production.

Certification systems play a crucial role in the regulatory framework. Oeko-Tex Standard 100, BlueSign, and similar certifications have established testing protocols and limits for harmful substances in textiles. Plant-derived indigo alternatives generally perform well under these certification schemes, providing manufacturers with marketable sustainability credentials. These certification bodies regularly update their standards to reflect emerging scientific understanding of chemical impacts.

Water pollution regulations have become increasingly stringent worldwide, with particular focus on textile industry effluents. The Zero Discharge of Hazardous Chemicals (ZDHC) initiative represents a collaborative effort to eliminate harmful chemicals from textile production processes. Plant-derived colorants typically generate effluents with lower environmental toxicity, helping manufacturers meet wastewater discharge requirements more easily than when using synthetic alternatives.

Labeling regulations also impact the market for natural colorants. The EU's Product Environmental Footprint (PEF) initiative and similar programs in other regions require transparent disclosure of environmental impacts. This creates market advantages for textiles colored with plant-derived alternatives that can demonstrate superior lifecycle assessment metrics compared to synthetic indigo dyes.

In the United States, the EPA (Environmental Protection Agency) has established guidelines under the Toxic Substances Control Act that affect textile colorants. Natural dyes derived from plant sources typically face fewer regulatory hurdles compared to their synthetic counterparts, which often contain restricted aromatic amines and other harmful chemicals. The Global Organic Textile Standard (GOTS) explicitly prohibits certain synthetic dyes while promoting the use of natural colorants in certified organic textiles.

Japan and South Korea have implemented their own chemical substance control laws that align with international standards while adding region-specific requirements. These regulations have created market opportunities for plant-derived indigo alternatives that can demonstrate compliance with lower environmental impact metrics. The Japanese Ministry of Economy, Trade and Industry has specifically developed guidelines encouraging the adoption of traditional plant-based dyeing methods in modern textile production.

Certification systems play a crucial role in the regulatory framework. Oeko-Tex Standard 100, BlueSign, and similar certifications have established testing protocols and limits for harmful substances in textiles. Plant-derived indigo alternatives generally perform well under these certification schemes, providing manufacturers with marketable sustainability credentials. These certification bodies regularly update their standards to reflect emerging scientific understanding of chemical impacts.

Water pollution regulations have become increasingly stringent worldwide, with particular focus on textile industry effluents. The Zero Discharge of Hazardous Chemicals (ZDHC) initiative represents a collaborative effort to eliminate harmful chemicals from textile production processes. Plant-derived colorants typically generate effluents with lower environmental toxicity, helping manufacturers meet wastewater discharge requirements more easily than when using synthetic alternatives.

Labeling regulations also impact the market for natural colorants. The EU's Product Environmental Footprint (PEF) initiative and similar programs in other regions require transparent disclosure of environmental impacts. This creates market advantages for textiles colored with plant-derived alternatives that can demonstrate superior lifecycle assessment metrics compared to synthetic indigo dyes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!