Waterless Dyeing Methods Compatible With Natural Colorants

SEP 2, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Waterless Dyeing Technology Background and Objectives

The textile industry has historically been one of the most resource-intensive manufacturing sectors, with conventional dyeing processes consuming approximately 100-150 liters of water per kilogram of textile material. This excessive water usage, coupled with the discharge of harmful chemical effluents, has positioned textile dyeing as the second largest polluter of clean water globally. The evolution of dyeing technology has progressed from traditional immersion techniques to more sophisticated methods, yet water consumption remains a critical environmental concern.

Waterless dyeing technology represents a paradigm shift in textile processing, aiming to eliminate or drastically reduce water usage while maintaining color quality and fastness. The concept emerged in the early 2000s but gained significant momentum after 2010 when major apparel brands began seeking sustainable alternatives to conventional wet processing. Technologies such as supercritical CO2 dyeing, digital printing, and plasma treatment have demonstrated the feasibility of waterless approaches, though primarily with synthetic dyes.

Natural colorants, derived from plants, minerals, and insects, have been used for millennia across civilizations but were largely displaced by synthetic dyes during the industrial revolution due to consistency and scalability challenges. Recent consumer demand for sustainable and non-toxic products has revitalized interest in natural dyestuffs, creating a technological intersection between waterless methods and natural colorants that remains largely unexplored.

The primary objective of this research is to investigate and develop waterless dyeing methodologies specifically compatible with natural colorants, addressing the dual challenges of environmental sustainability and chemical safety. This involves examining the molecular interactions between natural chromophores and various textile substrates under waterless conditions, identifying suitable binding mechanisms, and developing processes that ensure color uniformity, fastness, and scalability.

Secondary objectives include quantifying the environmental impact reduction potential compared to conventional methods, assessing the economic viability of implementation at industrial scale, and creating a technological roadmap for commercialization. The research also aims to establish standardized protocols for evaluating the performance of natural colorants in waterless systems, as current industry standards are primarily designed for synthetic dyes in aqueous environments.

This technological pursuit aligns with global sustainability initiatives, including the UN Sustainable Development Goals and various industry commitments to reduce water consumption and chemical pollution. Success in this domain could transform textile processing, offering a solution that addresses both the environmental footprint of dyeing operations and the growing consumer preference for naturally derived products.

Waterless dyeing technology represents a paradigm shift in textile processing, aiming to eliminate or drastically reduce water usage while maintaining color quality and fastness. The concept emerged in the early 2000s but gained significant momentum after 2010 when major apparel brands began seeking sustainable alternatives to conventional wet processing. Technologies such as supercritical CO2 dyeing, digital printing, and plasma treatment have demonstrated the feasibility of waterless approaches, though primarily with synthetic dyes.

Natural colorants, derived from plants, minerals, and insects, have been used for millennia across civilizations but were largely displaced by synthetic dyes during the industrial revolution due to consistency and scalability challenges. Recent consumer demand for sustainable and non-toxic products has revitalized interest in natural dyestuffs, creating a technological intersection between waterless methods and natural colorants that remains largely unexplored.

The primary objective of this research is to investigate and develop waterless dyeing methodologies specifically compatible with natural colorants, addressing the dual challenges of environmental sustainability and chemical safety. This involves examining the molecular interactions between natural chromophores and various textile substrates under waterless conditions, identifying suitable binding mechanisms, and developing processes that ensure color uniformity, fastness, and scalability.

Secondary objectives include quantifying the environmental impact reduction potential compared to conventional methods, assessing the economic viability of implementation at industrial scale, and creating a technological roadmap for commercialization. The research also aims to establish standardized protocols for evaluating the performance of natural colorants in waterless systems, as current industry standards are primarily designed for synthetic dyes in aqueous environments.

This technological pursuit aligns with global sustainability initiatives, including the UN Sustainable Development Goals and various industry commitments to reduce water consumption and chemical pollution. Success in this domain could transform textile processing, offering a solution that addresses both the environmental footprint of dyeing operations and the growing consumer preference for naturally derived products.

Market Analysis for Natural Colorant Dyeing Solutions

The global market for natural colorant dyeing solutions is experiencing significant growth, driven by increasing consumer awareness of environmental issues and health concerns related to synthetic dyes. The market size for natural dyes was valued at approximately $1.3 billion in 2022 and is projected to grow at a CAGR of 11.3% from 2023 to 2030. This growth trajectory is particularly pronounced in the textile and apparel sectors, where demand for sustainable and eco-friendly products continues to rise.

Consumer preferences are shifting dramatically toward environmentally responsible products, with recent surveys indicating that 73% of global consumers are willing to pay a premium for sustainable products. This trend is especially strong among millennials and Gen Z consumers, who prioritize brands with transparent supply chains and environmentally friendly manufacturing processes. The fashion industry, traditionally one of the most polluting sectors, is responding to this shift with increased investment in natural dyeing technologies.

Regional market analysis reveals varying adoption rates of natural colorant solutions. Europe leads the market with approximately 35% share, driven by stringent environmental regulations and high consumer awareness. North America follows at 28%, while the Asia-Pacific region, despite being the largest textile producer, accounts for 25% of the natural dye market but shows the fastest growth rate at 13.7% annually, primarily due to increasing regulatory pressure and growing export demands for eco-certified textiles.

The waterless dyeing segment within natural colorants represents a particularly promising niche, with projected growth rates exceeding the broader natural dye market by 3-4 percentage points. This acceleration is attributed to the dual benefits of water conservation and chemical reduction, addressing two critical sustainability challenges simultaneously. Industry reports indicate that waterless dyeing technologies compatible with natural colorants could reduce water consumption by up to 90% compared to conventional dyeing processes.

Market segmentation analysis shows that apparel accounts for 42% of the natural dye market, followed by home textiles (23%), technical textiles (18%), and other applications (17%). Within these segments, premium and luxury brands have been early adopters, but mass-market penetration is increasing as technology costs decrease and consumer demand grows.

Key market challenges include scalability issues, color consistency, and price competitiveness compared to synthetic alternatives. The cost differential between natural and synthetic dyes remains significant, with natural dyes typically commanding a 30-60% premium. However, this gap is narrowing as production technologies improve and economies of scale are achieved through increased adoption.

Consumer preferences are shifting dramatically toward environmentally responsible products, with recent surveys indicating that 73% of global consumers are willing to pay a premium for sustainable products. This trend is especially strong among millennials and Gen Z consumers, who prioritize brands with transparent supply chains and environmentally friendly manufacturing processes. The fashion industry, traditionally one of the most polluting sectors, is responding to this shift with increased investment in natural dyeing technologies.

Regional market analysis reveals varying adoption rates of natural colorant solutions. Europe leads the market with approximately 35% share, driven by stringent environmental regulations and high consumer awareness. North America follows at 28%, while the Asia-Pacific region, despite being the largest textile producer, accounts for 25% of the natural dye market but shows the fastest growth rate at 13.7% annually, primarily due to increasing regulatory pressure and growing export demands for eco-certified textiles.

The waterless dyeing segment within natural colorants represents a particularly promising niche, with projected growth rates exceeding the broader natural dye market by 3-4 percentage points. This acceleration is attributed to the dual benefits of water conservation and chemical reduction, addressing two critical sustainability challenges simultaneously. Industry reports indicate that waterless dyeing technologies compatible with natural colorants could reduce water consumption by up to 90% compared to conventional dyeing processes.

Market segmentation analysis shows that apparel accounts for 42% of the natural dye market, followed by home textiles (23%), technical textiles (18%), and other applications (17%). Within these segments, premium and luxury brands have been early adopters, but mass-market penetration is increasing as technology costs decrease and consumer demand grows.

Key market challenges include scalability issues, color consistency, and price competitiveness compared to synthetic alternatives. The cost differential between natural and synthetic dyes remains significant, with natural dyes typically commanding a 30-60% premium. However, this gap is narrowing as production technologies improve and economies of scale are achieved through increased adoption.

Current Status and Challenges in Waterless Natural Dyeing

Waterless dyeing with natural colorants represents a complex intersection of traditional knowledge and modern sustainable innovation. Currently, the global textile industry faces mounting pressure to reduce its environmental footprint, with conventional dyeing processes consuming approximately 100-150 liters of water per kilogram of textile material. This has accelerated research into waterless dyeing technologies, though most developments have focused on synthetic dyes rather than natural colorants.

The current landscape of waterless natural dyeing technologies includes several promising approaches. Supercritical carbon dioxide (scCO2) dyeing has emerged as a leading waterless method, where CO2 under high pressure serves as a non-polar solvent for dye transfer. While this technology has shown commercial success with synthetic dyes, its application with natural colorants remains challenging due to the polar nature of many natural dye compounds, limiting their solubility in scCO2 without significant modification.

Plasma treatment represents another innovative approach, where surface modification of fibers enhances dye uptake and fixation without water. Research indicates that low-temperature plasma treatments can increase the reactivity of natural fibers toward natural colorants, potentially reducing or eliminating water requirements in the dyeing process. However, scaling these technologies beyond laboratory settings presents significant engineering challenges.

Digital printing technologies adapted for natural colorants offer another waterless alternative. Recent advancements in micro-dispensing systems have enabled precise application of concentrated natural dye formulations directly onto textiles. These systems minimize resource consumption while maintaining color quality, though they currently face limitations in color fastness compared to conventional methods.

The primary technical challenges in waterless natural dyeing include the inherent hydrophilicity of most natural colorants, which complicates their integration into non-aqueous systems. Additionally, the molecular diversity of natural dyes—ranging from anthraquinones to flavonoids—requires tailored approaches rather than universal solutions. Color consistency and fastness properties also remain significant hurdles, as traditional mordanting techniques often rely on water-based processes.

Geographically, research in this field shows interesting distribution patterns. European research institutions lead in scCO2 technology development, with significant contributions from the Netherlands and Germany. Asian countries, particularly India and China with their rich natural dyeing traditions, are advancing plasma treatment applications for natural colorants. North American research centers have focused more on digital printing technologies and developing specialized binders for natural dyes.

Regulatory challenges further complicate advancement, as many countries lack specific frameworks for novel dyeing technologies, creating uncertainty for commercial adoption. Additionally, the limited standardization of natural colorant sources impacts consistency in research outcomes across different regions.

The current landscape of waterless natural dyeing technologies includes several promising approaches. Supercritical carbon dioxide (scCO2) dyeing has emerged as a leading waterless method, where CO2 under high pressure serves as a non-polar solvent for dye transfer. While this technology has shown commercial success with synthetic dyes, its application with natural colorants remains challenging due to the polar nature of many natural dye compounds, limiting their solubility in scCO2 without significant modification.

Plasma treatment represents another innovative approach, where surface modification of fibers enhances dye uptake and fixation without water. Research indicates that low-temperature plasma treatments can increase the reactivity of natural fibers toward natural colorants, potentially reducing or eliminating water requirements in the dyeing process. However, scaling these technologies beyond laboratory settings presents significant engineering challenges.

Digital printing technologies adapted for natural colorants offer another waterless alternative. Recent advancements in micro-dispensing systems have enabled precise application of concentrated natural dye formulations directly onto textiles. These systems minimize resource consumption while maintaining color quality, though they currently face limitations in color fastness compared to conventional methods.

The primary technical challenges in waterless natural dyeing include the inherent hydrophilicity of most natural colorants, which complicates their integration into non-aqueous systems. Additionally, the molecular diversity of natural dyes—ranging from anthraquinones to flavonoids—requires tailored approaches rather than universal solutions. Color consistency and fastness properties also remain significant hurdles, as traditional mordanting techniques often rely on water-based processes.

Geographically, research in this field shows interesting distribution patterns. European research institutions lead in scCO2 technology development, with significant contributions from the Netherlands and Germany. Asian countries, particularly India and China with their rich natural dyeing traditions, are advancing plasma treatment applications for natural colorants. North American research centers have focused more on digital printing technologies and developing specialized binders for natural dyes.

Regulatory challenges further complicate advancement, as many countries lack specific frameworks for novel dyeing technologies, creating uncertainty for commercial adoption. Additionally, the limited standardization of natural colorant sources impacts consistency in research outcomes across different regions.

Current Waterless Dyeing Methods for Natural Colorants

01 Supercritical fluid dyeing with natural colorants

Supercritical fluid technology, particularly using carbon dioxide, provides a waterless medium for dyeing textiles with natural colorants. This environmentally friendly process eliminates water consumption and reduces chemical usage. The supercritical fluid acts as a carrier for natural dyes, allowing them to penetrate fibers effectively while maintaining their natural properties. This method results in good color fastness and reduces energy consumption compared to conventional water-based dyeing processes.- Supercritical fluid dyeing methods: Supercritical fluid dyeing is a waterless technique that uses supercritical carbon dioxide as a medium to carry natural colorants into textile fibers. This environmentally friendly process eliminates water consumption and reduces energy usage. The method allows for effective penetration of natural dyes into various fiber types while maintaining color fastness. The process operates at controlled temperature and pressure conditions to optimize dye uptake and fixation of natural colorants.

- Solvent-based natural dyeing techniques: These methods utilize organic solvents instead of water as carriers for natural colorants. Various eco-friendly solvents can be employed to dissolve and apply natural dyes to textiles. The techniques often involve controlled application of the dye solution, followed by fixation processes that ensure color stability. These approaches reduce water consumption while maintaining compatibility with a wide range of natural pigments and colorants derived from plant and animal sources.

- Plasma and UV treatment for natural dye fixation: Advanced physical treatment methods using plasma technology or ultraviolet radiation can enhance the fixation of natural colorants to textile substrates without requiring water. These techniques modify the surface properties of fibers to improve dye uptake and bonding with natural colorants. The treatments can be applied before or after the application of natural dyes to increase color fastness and reduce the need for chemical mordants. These environmentally friendly approaches minimize resource consumption while achieving good coloration results.

- Microencapsulation of natural colorants: Microencapsulation technology enables the effective application of natural colorants to textiles without conventional water-based dyeing processes. Natural dyes are encapsulated in biodegradable polymers or carriers that can be applied to fabrics through various dry application methods. Upon activation by heat, pressure, or other triggers, the capsules release the colorants directly onto the fiber surface. This technique provides improved color stability for sensitive natural dyes while eliminating wastewater generation.

- Vapor and sublimation techniques for natural dyes: These innovative methods utilize the principles of sublimation or vapor deposition to apply natural colorants to textiles without water. The natural dyes are converted to vapor form through heating or other processes and then deposited onto the fiber surface where they form stable bonds. These techniques are particularly suitable for heat-resistant natural colorants and certain fiber types. The processes offer precise color application with minimal environmental impact and can be optimized for various natural dye sources.

02 Solvent-based natural dyeing techniques

Organic solvents can replace water in dyeing processes compatible with natural colorants. These methods use environmentally acceptable solvents like alcohols, ketones, or modified vegetable oils to dissolve and carry natural dyes into textile fibers. The solvent-based approach reduces water consumption, energy usage, and wastewater generation while maintaining compatibility with a wide range of natural dye sources. These techniques often result in improved color uniformity and reduced processing time compared to traditional aqueous dyeing.Expand Specific Solutions03 Plasma and UV treatment for natural colorant fixation

Advanced physical treatment methods using plasma technology or ultraviolet radiation can enhance the fixation of natural colorants to textiles without water. These techniques modify the fiber surface to improve dye uptake and bonding with natural colorants. The process creates reactive sites on the fiber surface that form stronger bonds with natural dye molecules, resulting in better color fastness and reduced need for chemical mordants. This environmentally friendly approach minimizes resource consumption while achieving high-quality coloration with natural dyes.Expand Specific Solutions04 Microencapsulation of natural colorants for dry application

Microencapsulation technology enables the application of natural colorants to textiles through dry processes. Natural dyes are encapsulated in biodegradable polymers or carriers that can be applied to fabrics using heat, pressure, or minimal moisture activation. This technique protects sensitive natural colorants from degradation while allowing precise application and controlled release during the coloration process. The method significantly reduces water consumption and effluent generation while maintaining the ecological benefits of natural dye sources.Expand Specific Solutions05 Vapor phase dyeing with natural colorant derivatives

Vapor phase dyeing techniques involve converting natural colorants into sublimable derivatives that can transfer to textiles in gaseous form. This process uses heat to vaporize the modified natural dyes, which then penetrate and bond with fibers without requiring water as a medium. The method is particularly suitable for cellulosic and protein fibers, offering excellent color uniformity and penetration. This waterless approach significantly reduces environmental impact while preserving the beneficial properties of natural colorants through careful modification processes.Expand Specific Solutions

Key Industry Players in Sustainable Textile Coloration

Waterless dyeing with natural colorants is in an emerging growth phase, with increasing market interest driven by sustainability demands. The global market is expanding as textile industries seek eco-friendly alternatives to traditional water-intensive dyeing processes. Technologically, the field remains in early-to-mid development stages with varying maturity levels across different approaches. Academic institutions like Dalian Polytechnic University, Jiangnan University, and Soochow University are leading fundamental research, while companies including DyStar, Zhejiang Luyu Textile Technology, and Make In Italy are developing commercial applications. Established corporations such as L'Oréal, FUJIFILM, and Chr. Hansen are leveraging their expertise in natural colorants to enter this space, indicating growing cross-industry interest in sustainable textile processing technologies.

Zhejiang Luyu Textile Technology Co., Ltd.

Technical Solution: Zhejiang Luyu has developed an innovative plasma-assisted natural dyeing technology that significantly reduces water consumption. Their system utilizes low-temperature plasma treatment as a pre-processing step to increase fiber reactivity and dye uptake for natural colorants. The plasma creates microscopic surface modifications on textile fibers, enhancing their ability to bond with natural dye molecules without water as a medium. Following plasma treatment, their process employs a minimal-water spray application system that precisely delivers concentrated natural dye solutions directly to fabrics. The company has also engineered specialized natural dye formulations derived from traditional Chinese herbal sources, optimized for their waterless application method. Their integrated system includes ultrasonic energy to enhance dye penetration and fixation, further reducing water and energy requirements. Recent innovations include a closed-loop solvent recovery system that captures and reuses the small amounts of organic solvents used in their process.

Strengths: Reduces water consumption by approximately 80% compared to conventional natural dyeing, achieves superior color penetration and fastness properties, and works effectively with a wide range of plant-based colorants including indigo, madder, and safflower. Weaknesses: The plasma equipment represents a significant capital investment, the technology requires specialized technical expertise to operate effectively, and the process is currently optimized primarily for cellulosic fibers rather than synthetics or protein fibers.

DyStar Textilfarben GmbH & Co. Deutschland KG

Technical Solution: DyStar has developed advanced supercritical CO2 (scCO2) dyeing technology for natural colorants, which uses pressurized carbon dioxide as a solvent instead of water. Their process involves dissolving natural dyes in supercritical CO2 at specific temperature and pressure conditions (typically 31°C and 73 atmospheres), allowing the dye to penetrate textile fibers. The company has also created specialized natural dye formulations that are compatible with this waterless process, focusing on improving the solubility of natural colorants in the scCO2 medium. DyStar's technology includes proprietary dye carriers and modifiers that enhance the affinity between natural dyes and various fiber types, particularly focusing on cotton, wool, and silk applications. Their system achieves color fixation through pressure modulation rather than chemical fixatives, significantly reducing chemical usage while maintaining colorfastness comparable to traditional water-based methods.

Strengths: Eliminates water consumption entirely, reduces energy usage by approximately 60% compared to conventional dyeing, and produces no wastewater. The closed-loop system allows for CO2 recycling, making it highly sustainable. Weaknesses: Requires significant capital investment for high-pressure equipment, has limitations with certain natural dye molecules that are poorly soluble in scCO2, and currently faces scalability challenges for mass production.

Technical Analysis of Breakthrough Natural Dyeing Patents

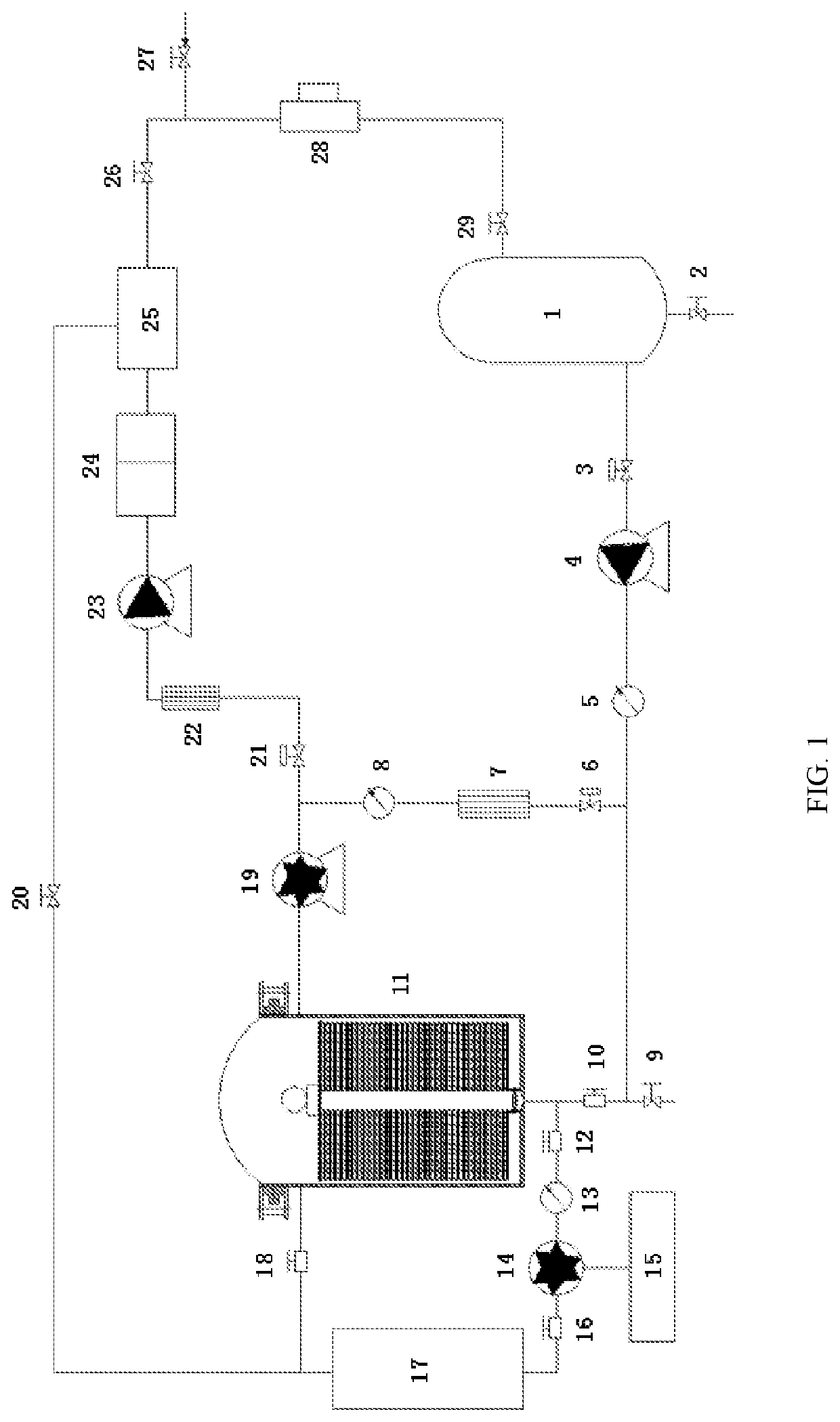

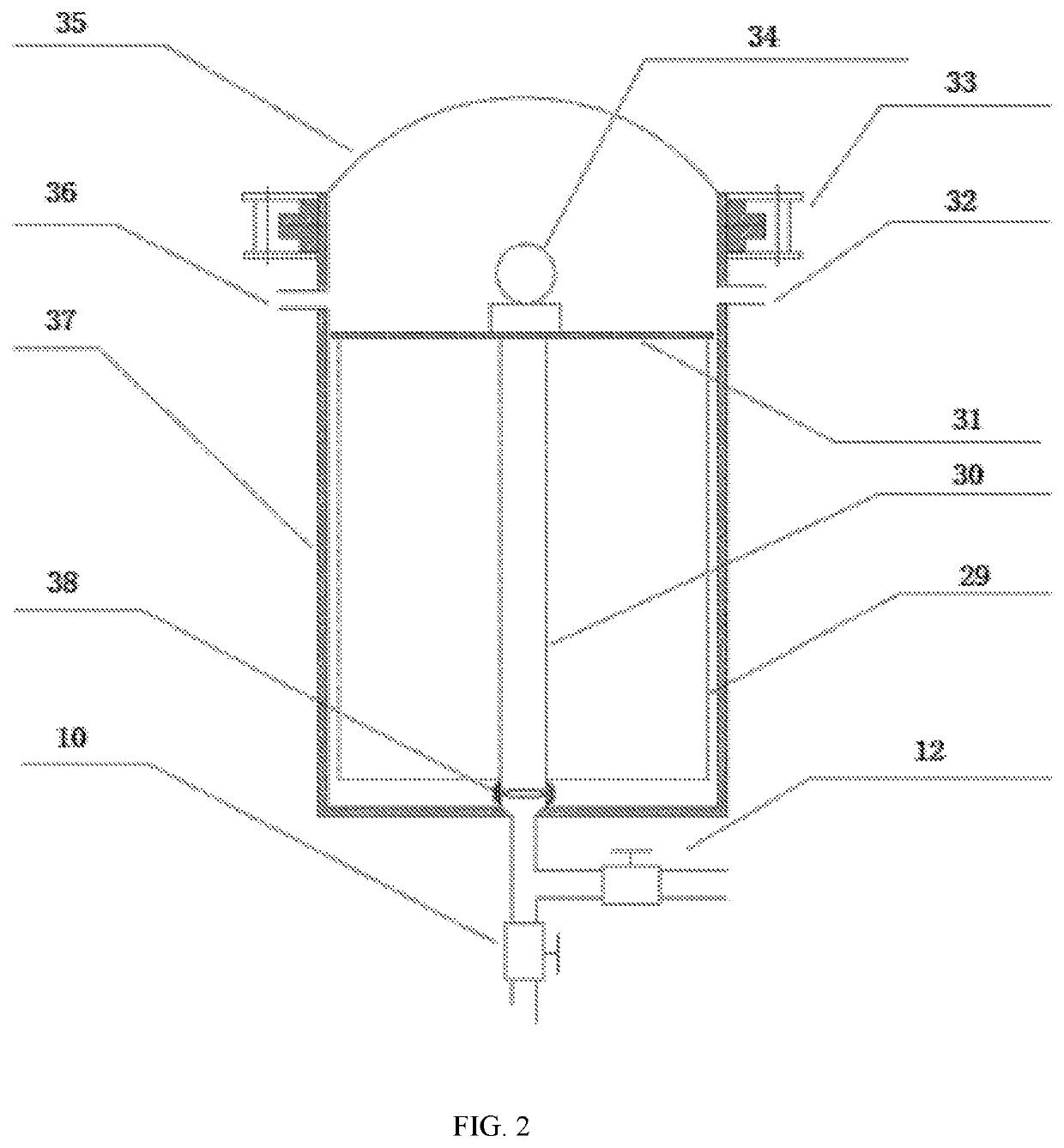

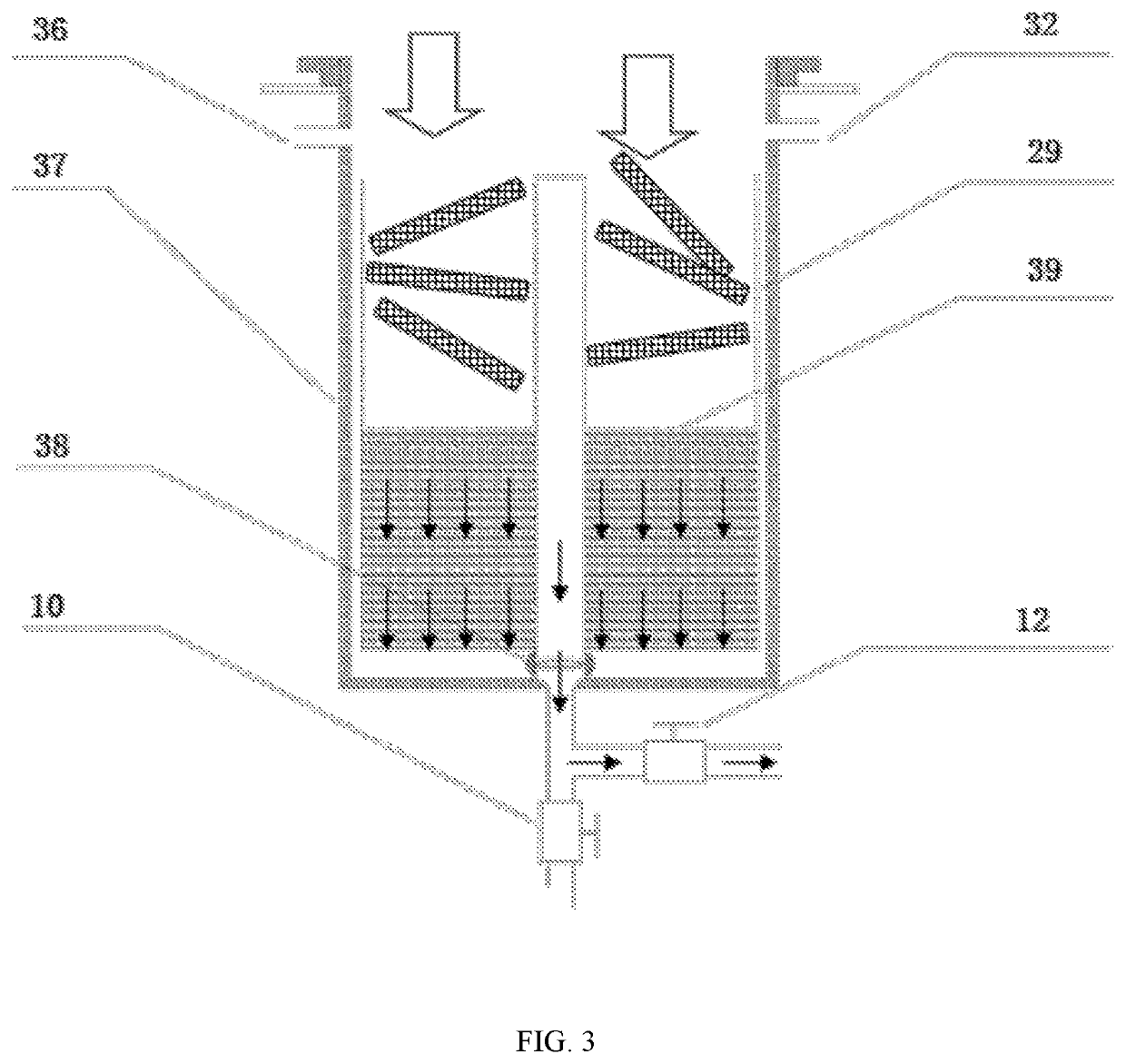

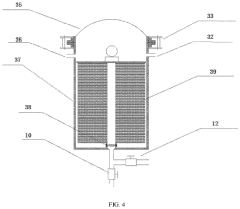

Waterless dyeing machine suitable for mixed fluid medium

PatentActiveUS20200115836A1

Innovation

- A waterless dyeing machine using a mixed fluid medium system with separate pressurizing and recycling systems for carbon dioxide and polar media, which modifies the hydrophobic medium to improve fiber swelling and dye solubility, combined with an automated fiber loading and unloading system for enhanced processing efficiency.

Dyeing method of water insoluble natural pigment on silk fabric

PatentActiveCN102899924A

Innovation

- Dissolve the water-insoluble pigment in an organic solvent, add an emulsifier and stir to form an oil-in-water pigment microemulsion. Then put the silk fabric into the liquid for dyeing, and use the molecular state of the pigment in the emulsion to make it uniform and firm. Ground fiber binding.

Environmental Impact Assessment of Waterless Dyeing Methods

The environmental impact assessment of waterless dyeing methods reveals significant advantages over conventional water-intensive processes. Traditional textile dyeing consumes approximately 100-150 liters of water per kilogram of fabric, making it one of the most water-intensive industrial processes. Additionally, it generates substantial volumes of wastewater containing harmful chemicals, dyes, and auxiliaries that require extensive treatment before discharge.

Waterless dyeing technologies, particularly those compatible with natural colorants, demonstrate remarkable environmental benefits. Carbon dioxide-based supercritical fluid dyeing reduces water consumption by nearly 100% while eliminating wastewater discharge entirely. This technology operates in closed-loop systems that recycle up to 95% of the CO2 used, significantly reducing the carbon footprint compared to conventional methods.

Digital printing technologies compatible with natural dyes show a 60-80% reduction in water usage and a 40% decrease in energy consumption. These systems produce minimal waste as they apply colorants precisely where needed, eliminating the need for extensive rinsing processes that characterize traditional dyeing.

Plasma treatment methods, when optimized for natural colorants, demonstrate a 90% reduction in water usage while improving dye fixation rates by 15-25%. This enhanced efficiency translates to fewer resources consumed per unit of dyed fabric and reduced environmental impact throughout the product lifecycle.

Life cycle assessments indicate that waterless dyeing methods using natural colorants reduce the overall environmental impact by 35-45% compared to conventional processes. The elimination of synthetic auxiliaries and harmful mordants typically required in traditional dyeing further enhances the ecological profile of these technologies.

Regulatory compliance analyses show that waterless dyeing facilities face fewer environmental compliance challenges and reduced costs associated with wastewater treatment. This advantage becomes increasingly significant as global environmental regulations become more stringent, particularly in textile manufacturing hubs across Asia and Latin America.

The biodegradability of effluents from waterless processes using natural colorants is substantially higher than conventional methods, with tests showing 75-85% biodegradation within 28 days compared to 30-40% for conventional synthetic dye processes. This characteristic significantly reduces the long-term environmental burden of textile manufacturing operations.

Waterless dyeing technologies, particularly those compatible with natural colorants, demonstrate remarkable environmental benefits. Carbon dioxide-based supercritical fluid dyeing reduces water consumption by nearly 100% while eliminating wastewater discharge entirely. This technology operates in closed-loop systems that recycle up to 95% of the CO2 used, significantly reducing the carbon footprint compared to conventional methods.

Digital printing technologies compatible with natural dyes show a 60-80% reduction in water usage and a 40% decrease in energy consumption. These systems produce minimal waste as they apply colorants precisely where needed, eliminating the need for extensive rinsing processes that characterize traditional dyeing.

Plasma treatment methods, when optimized for natural colorants, demonstrate a 90% reduction in water usage while improving dye fixation rates by 15-25%. This enhanced efficiency translates to fewer resources consumed per unit of dyed fabric and reduced environmental impact throughout the product lifecycle.

Life cycle assessments indicate that waterless dyeing methods using natural colorants reduce the overall environmental impact by 35-45% compared to conventional processes. The elimination of synthetic auxiliaries and harmful mordants typically required in traditional dyeing further enhances the ecological profile of these technologies.

Regulatory compliance analyses show that waterless dyeing facilities face fewer environmental compliance challenges and reduced costs associated with wastewater treatment. This advantage becomes increasingly significant as global environmental regulations become more stringent, particularly in textile manufacturing hubs across Asia and Latin America.

The biodegradability of effluents from waterless processes using natural colorants is substantially higher than conventional methods, with tests showing 75-85% biodegradation within 28 days compared to 30-40% for conventional synthetic dye processes. This characteristic significantly reduces the long-term environmental burden of textile manufacturing operations.

Supply Chain Considerations for Natural Colorant Adoption

The adoption of natural colorants in waterless dyeing processes requires a comprehensive supply chain strategy that differs significantly from conventional synthetic dye supply chains. Natural colorants are typically derived from plant sources such as indigo, madder, and turmeric, or from insect sources like cochineal. These raw materials are often seasonal and geographically specific, creating unique procurement challenges.

Sourcing natural colorants involves establishing relationships with agricultural producers or wild harvesters, which introduces variability in supply availability and quality. Unlike synthetic dyes that can be manufactured year-round with consistent specifications, natural colorants are subject to harvest fluctuations, climate impacts, and regional growing conditions. This necessitates robust inventory management systems and potentially multiple sourcing regions to ensure continuity.

Processing infrastructure represents another critical supply chain consideration. Natural colorants typically require specialized extraction facilities located near harvesting areas to minimize degradation of color compounds. These facilities must be equipped with appropriate technology for extraction methods compatible with waterless dyeing processes, such as supercritical CO2 extraction or ultrasonic-assisted extraction.

Transportation and storage of natural colorants present additional challenges. Many natural colorant compounds are sensitive to light, temperature, and oxidation, requiring specialized packaging and controlled transportation conditions. The shelf life of natural colorants is generally shorter than synthetic alternatives, necessitating more frequent replenishment cycles and potentially cold chain logistics.

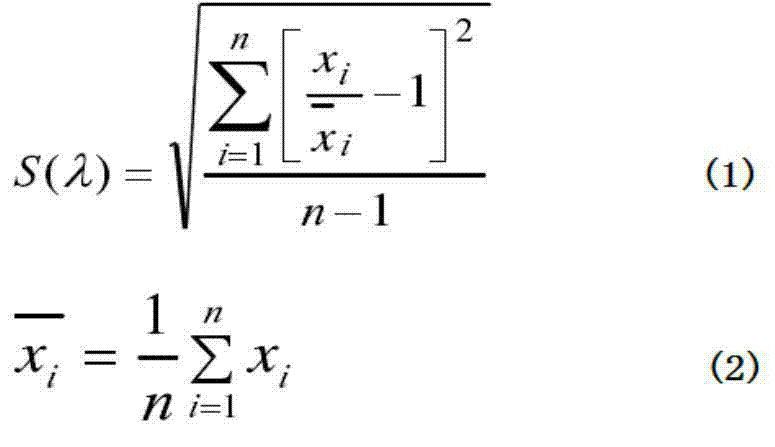

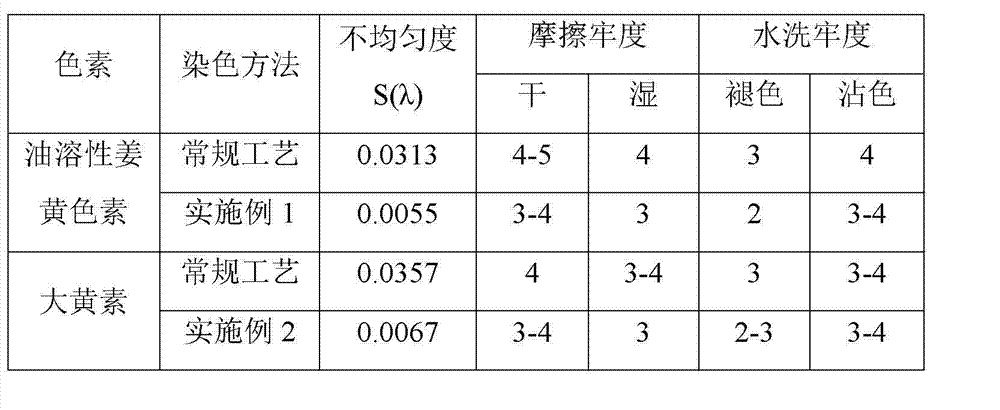

Quality control systems throughout the supply chain must be adapted for natural colorants. Standardization is more complex due to inherent variability in natural materials, requiring sophisticated analytical methods to ensure color consistency across batches. This may include spectrophotometric analysis, HPLC testing, and other quality assurance protocols specific to natural compounds.

Cost structures for natural colorant supply chains typically include premium pricing for sustainable and ethical sourcing practices. Companies adopting natural colorants must consider fair trade certification, organic cultivation standards, and sustainable harvesting practices as integral components of their supply chain strategy. These factors contribute to higher raw material costs compared to synthetic alternatives.

Traceability systems are increasingly important for natural colorant supply chains, allowing manufacturers to verify sustainability claims and provide transparency to consumers. Blockchain technology and digital tracking systems are emerging as valuable tools for documenting the journey of natural colorants from field to finished product, supporting authenticity verification and sustainability reporting requirements.

Sourcing natural colorants involves establishing relationships with agricultural producers or wild harvesters, which introduces variability in supply availability and quality. Unlike synthetic dyes that can be manufactured year-round with consistent specifications, natural colorants are subject to harvest fluctuations, climate impacts, and regional growing conditions. This necessitates robust inventory management systems and potentially multiple sourcing regions to ensure continuity.

Processing infrastructure represents another critical supply chain consideration. Natural colorants typically require specialized extraction facilities located near harvesting areas to minimize degradation of color compounds. These facilities must be equipped with appropriate technology for extraction methods compatible with waterless dyeing processes, such as supercritical CO2 extraction or ultrasonic-assisted extraction.

Transportation and storage of natural colorants present additional challenges. Many natural colorant compounds are sensitive to light, temperature, and oxidation, requiring specialized packaging and controlled transportation conditions. The shelf life of natural colorants is generally shorter than synthetic alternatives, necessitating more frequent replenishment cycles and potentially cold chain logistics.

Quality control systems throughout the supply chain must be adapted for natural colorants. Standardization is more complex due to inherent variability in natural materials, requiring sophisticated analytical methods to ensure color consistency across batches. This may include spectrophotometric analysis, HPLC testing, and other quality assurance protocols specific to natural compounds.

Cost structures for natural colorant supply chains typically include premium pricing for sustainable and ethical sourcing practices. Companies adopting natural colorants must consider fair trade certification, organic cultivation standards, and sustainable harvesting practices as integral components of their supply chain strategy. These factors contribute to higher raw material costs compared to synthetic alternatives.

Traceability systems are increasingly important for natural colorant supply chains, allowing manufacturers to verify sustainability claims and provide transparency to consumers. Blockchain technology and digital tracking systems are emerging as valuable tools for documenting the journey of natural colorants from field to finished product, supporting authenticity verification and sustainability reporting requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!