Inkjet Textile Printing With Natural Pigments: Formulation Challenges

SEP 2, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Natural Pigment Textile Printing Background and Objectives

The textile industry has witnessed significant evolution in printing technologies over the past century, transitioning from traditional block printing to advanced digital methods. Among these innovations, inkjet textile printing emerged as a revolutionary technique in the late 1990s, offering precision, customization, and reduced environmental impact compared to conventional methods. However, the industry's heavy reliance on synthetic dyes and pigments has raised increasing environmental and health concerns, prompting a resurgence of interest in natural pigments—a practice dating back thousands of years across diverse civilizations.

Natural pigments, derived from plants, minerals, and insects, represent a sustainable alternative to synthetic colorants. Historically, these pigments were the primary coloring agents in textiles until the mid-19th century when synthetic dyes began dominating the market due to their consistency, color range, and economic advantages. The current technological landscape presents an opportunity to merge ancient coloring wisdom with modern digital printing techniques, potentially addressing sustainability challenges while meeting contemporary market demands.

The evolution of inkjet printing technology has created a viable platform for natural pigment application, yet significant technical hurdles remain. Unlike synthetic formulations optimized for digital printing systems, natural pigments present unique challenges in particle size consistency, suspension stability, and color fastness. These limitations have historically restricted their commercial viability in modern textile production environments.

This technical research aims to comprehensively investigate the formulation challenges associated with incorporating natural pigments into inkjet textile printing systems. The primary objectives include: identifying optimal extraction and processing methods to achieve consistent particle size distribution; developing stable suspensions that prevent nozzle clogging; enhancing color fastness properties through appropriate binders and fixatives; and establishing standardized formulation protocols that ensure reproducible results across different natural pigment sources.

Additionally, this research seeks to map the technical evolution pathway necessary to elevate natural pigment formulations from experimental status to commercial viability. By addressing these technical objectives, we aim to contribute to the growing body of sustainable textile production knowledge while providing practical solutions for manufacturers interested in expanding their eco-friendly product offerings.

The ultimate goal is to develop formulation guidelines that enable the practical implementation of natural pigment-based inkjet printing systems without compromising on print quality, production efficiency, or economic feasibility—thereby supporting the textile industry's transition toward more environmentally responsible practices while preserving the rich cultural heritage of natural colorants.

Natural pigments, derived from plants, minerals, and insects, represent a sustainable alternative to synthetic colorants. Historically, these pigments were the primary coloring agents in textiles until the mid-19th century when synthetic dyes began dominating the market due to their consistency, color range, and economic advantages. The current technological landscape presents an opportunity to merge ancient coloring wisdom with modern digital printing techniques, potentially addressing sustainability challenges while meeting contemporary market demands.

The evolution of inkjet printing technology has created a viable platform for natural pigment application, yet significant technical hurdles remain. Unlike synthetic formulations optimized for digital printing systems, natural pigments present unique challenges in particle size consistency, suspension stability, and color fastness. These limitations have historically restricted their commercial viability in modern textile production environments.

This technical research aims to comprehensively investigate the formulation challenges associated with incorporating natural pigments into inkjet textile printing systems. The primary objectives include: identifying optimal extraction and processing methods to achieve consistent particle size distribution; developing stable suspensions that prevent nozzle clogging; enhancing color fastness properties through appropriate binders and fixatives; and establishing standardized formulation protocols that ensure reproducible results across different natural pigment sources.

Additionally, this research seeks to map the technical evolution pathway necessary to elevate natural pigment formulations from experimental status to commercial viability. By addressing these technical objectives, we aim to contribute to the growing body of sustainable textile production knowledge while providing practical solutions for manufacturers interested in expanding their eco-friendly product offerings.

The ultimate goal is to develop formulation guidelines that enable the practical implementation of natural pigment-based inkjet printing systems without compromising on print quality, production efficiency, or economic feasibility—thereby supporting the textile industry's transition toward more environmentally responsible practices while preserving the rich cultural heritage of natural colorants.

Market Analysis for Eco-friendly Textile Printing Solutions

The global market for eco-friendly textile printing solutions has experienced significant growth in recent years, driven by increasing consumer awareness of environmental issues and stricter regulations on chemical usage in textile manufacturing. The market size for sustainable textile printing was valued at approximately $1.5 billion in 2022 and is projected to grow at a compound annual growth rate of 6.8% through 2030, reaching an estimated $2.7 billion by the end of the forecast period.

Natural pigment-based inkjet textile printing represents a rapidly expanding segment within this market, with particular interest from fashion brands committed to sustainability initiatives. Consumer demand for environmentally responsible textiles has risen dramatically, with surveys indicating that 73% of millennial and Gen Z consumers are willing to pay premium prices for sustainably produced garments.

The market landscape is characterized by regional variations in adoption rates. European countries, particularly Scandinavian nations, Germany, and the Netherlands, lead in implementing eco-friendly textile printing technologies, supported by stringent EU regulations on chemical usage. North America follows closely, with strong demand from specialty and premium apparel brands.

Asia-Pacific represents the fastest-growing regional market, with countries like Japan, South Korea, and increasingly China investing in sustainable textile technologies. This growth is partially driven by the region's dominant position in global textile manufacturing and export markets seeking to meet Western import standards.

Key market segments for natural pigment inkjet printing include fashion apparel (42% of market share), home textiles (28%), technical textiles (18%), and others including accessories and specialty applications (12%). The fashion segment shows the highest growth potential due to rapid product cycles and consumer-facing sustainability messaging opportunities.

Market challenges include price sensitivity, as natural pigment formulations currently command a 15-30% premium over synthetic alternatives. Performance consistency remains another significant barrier, with color fastness, wash durability, and color range limitations cited by 68% of potential industrial adopters as concerns.

Supply chain considerations also impact market dynamics, with sustainable sourcing of natural pigments presenting both challenges and opportunities. The availability of consistent, scalable natural pigment sources represents a potential bottleneck that innovative companies are addressing through vertical integration and agricultural partnerships.

Industry analysts predict that brands successfully addressing formulation challenges in natural pigment printing will capture significant market share, particularly in premium segments where sustainability credentials command higher margins. The convergence of consumer demand, regulatory pressure, and technological innovation creates favorable conditions for accelerated market growth in this sector over the next decade.

Natural pigment-based inkjet textile printing represents a rapidly expanding segment within this market, with particular interest from fashion brands committed to sustainability initiatives. Consumer demand for environmentally responsible textiles has risen dramatically, with surveys indicating that 73% of millennial and Gen Z consumers are willing to pay premium prices for sustainably produced garments.

The market landscape is characterized by regional variations in adoption rates. European countries, particularly Scandinavian nations, Germany, and the Netherlands, lead in implementing eco-friendly textile printing technologies, supported by stringent EU regulations on chemical usage. North America follows closely, with strong demand from specialty and premium apparel brands.

Asia-Pacific represents the fastest-growing regional market, with countries like Japan, South Korea, and increasingly China investing in sustainable textile technologies. This growth is partially driven by the region's dominant position in global textile manufacturing and export markets seeking to meet Western import standards.

Key market segments for natural pigment inkjet printing include fashion apparel (42% of market share), home textiles (28%), technical textiles (18%), and others including accessories and specialty applications (12%). The fashion segment shows the highest growth potential due to rapid product cycles and consumer-facing sustainability messaging opportunities.

Market challenges include price sensitivity, as natural pigment formulations currently command a 15-30% premium over synthetic alternatives. Performance consistency remains another significant barrier, with color fastness, wash durability, and color range limitations cited by 68% of potential industrial adopters as concerns.

Supply chain considerations also impact market dynamics, with sustainable sourcing of natural pigments presenting both challenges and opportunities. The availability of consistent, scalable natural pigment sources represents a potential bottleneck that innovative companies are addressing through vertical integration and agricultural partnerships.

Industry analysts predict that brands successfully addressing formulation challenges in natural pigment printing will capture significant market share, particularly in premium segments where sustainability credentials command higher margins. The convergence of consumer demand, regulatory pressure, and technological innovation creates favorable conditions for accelerated market growth in this sector over the next decade.

Technical Barriers in Natural Pigment Inkjet Formulations

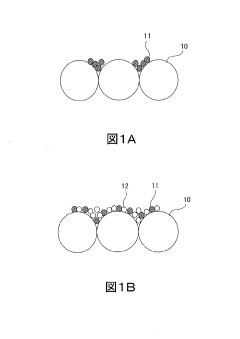

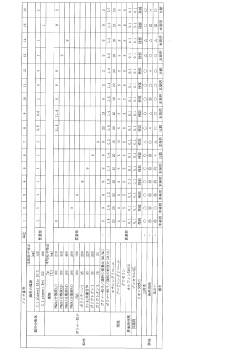

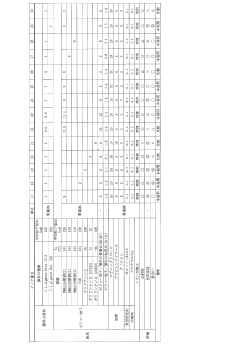

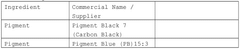

The development of natural pigment formulations for inkjet textile printing faces significant technical barriers that have hindered widespread commercial adoption. Particle size represents one of the most critical challenges, as natural pigments typically contain larger and irregularly shaped particles compared to synthetic alternatives. These particles must be reduced to sub-micron dimensions (ideally below 200nm) to prevent nozzle clogging in print heads with typical diameters of 10-50 microns. Traditional grinding and milling techniques often prove insufficient for achieving the necessary particle size consistency without damaging the pigment's chromophore structures.

Colloidal stability presents another major obstacle, as natural pigments tend to agglomerate in aqueous solutions due to their hydrophobic nature and surface charges. This agglomeration not only affects print quality but also reduces shelf life and causes sedimentation issues. Formulation scientists must develop sophisticated stabilization systems using surfactants, dispersants, and pH modifiers tailored specifically to each natural pigment's unique chemical structure.

Viscosity and surface tension control represent additional technical barriers. Inkjet printing requires precise fluid dynamics with viscosity typically between 2-20 cP and surface tension between 25-50 mN/m. Natural pigment formulations often exhibit unpredictable rheological behavior due to the presence of various biomolecules and impurities, making it difficult to maintain consistent jetting properties across production batches.

Color consistency and fastness pose significant challenges as natural pigments are inherently variable in composition based on their biological sources. Factors such as growing conditions, extraction methods, and storage can dramatically affect color profiles. Moreover, natural pigments typically demonstrate poor light fastness, wash fastness, and rub fastness compared to synthetic alternatives, requiring the development of specialized mordants and fixatives compatible with inkjet delivery systems.

Chemical stability represents a fundamental barrier, as many natural pigments are susceptible to degradation through oxidation, pH changes, and microbial activity. This instability affects both shelf life and print permanence, necessitating the incorporation of antioxidants, preservatives, and UV stabilizers that must remain compatible with other formulation components without compromising jetting performance.

Scaling production presents additional technical difficulties, as extraction and purification processes for natural pigments are often complex and yield inconsistent results. Developing standardized, reproducible manufacturing protocols that can deliver consistent pigment quality at commercial scales remains a significant challenge for formulators seeking to commercialize natural pigment inkjet systems.

Colloidal stability presents another major obstacle, as natural pigments tend to agglomerate in aqueous solutions due to their hydrophobic nature and surface charges. This agglomeration not only affects print quality but also reduces shelf life and causes sedimentation issues. Formulation scientists must develop sophisticated stabilization systems using surfactants, dispersants, and pH modifiers tailored specifically to each natural pigment's unique chemical structure.

Viscosity and surface tension control represent additional technical barriers. Inkjet printing requires precise fluid dynamics with viscosity typically between 2-20 cP and surface tension between 25-50 mN/m. Natural pigment formulations often exhibit unpredictable rheological behavior due to the presence of various biomolecules and impurities, making it difficult to maintain consistent jetting properties across production batches.

Color consistency and fastness pose significant challenges as natural pigments are inherently variable in composition based on their biological sources. Factors such as growing conditions, extraction methods, and storage can dramatically affect color profiles. Moreover, natural pigments typically demonstrate poor light fastness, wash fastness, and rub fastness compared to synthetic alternatives, requiring the development of specialized mordants and fixatives compatible with inkjet delivery systems.

Chemical stability represents a fundamental barrier, as many natural pigments are susceptible to degradation through oxidation, pH changes, and microbial activity. This instability affects both shelf life and print permanence, necessitating the incorporation of antioxidants, preservatives, and UV stabilizers that must remain compatible with other formulation components without compromising jetting performance.

Scaling production presents additional technical difficulties, as extraction and purification processes for natural pigments are often complex and yield inconsistent results. Developing standardized, reproducible manufacturing protocols that can deliver consistent pigment quality at commercial scales remains a significant challenge for formulators seeking to commercialize natural pigment inkjet systems.

Current Formulation Approaches for Natural Pigment Stability

01 Plant-based natural pigments for textile printing

Various plant-based natural pigments can be extracted and formulated for use in inkjet textile printing applications. These pigments offer environmentally friendly alternatives to synthetic dyes while providing vibrant colors. The formulations typically include stabilizers to enhance color fastness and prevent degradation. Plant sources such as indigo, madder root, and other botanical extracts can be processed to create sustainable colorants suitable for digital textile printing technologies.- Plant-based natural pigments for textile printing: Various plant-based natural pigments can be extracted and formulated for use in inkjet textile printing applications. These pigments offer environmentally friendly alternatives to synthetic dyes while providing vibrant colors. The formulations typically include stabilizers to maintain color consistency and prevent nozzle clogging in inkjet printers. Plant sources such as indigo, madder root, and other botanical extracts can be processed to create sustainable colorants suitable for textile applications.

- Formulation additives for natural pigment stability: Specific additives are essential in natural pigment formulations to enhance stability and printability in inkjet systems. These include humectants to prevent drying, dispersants to maintain particle suspension, and pH regulators to optimize color development. Biocides may be incorporated to prevent microbial growth in the natural pigment formulations. These additives help overcome challenges associated with natural pigments such as particle aggregation, sedimentation, and viscosity changes that could affect printing performance.

- Mineral and earth-based natural colorants: Mineral and earth-based colorants derived from natural sources can be processed and formulated for inkjet textile printing applications. These include ochre, clay-based pigments, and other mineral derivatives that provide earthy tones and excellent lightfastness. The formulation process typically involves fine grinding, purification, and surface modification to ensure compatibility with inkjet printing systems. These pigments offer advantages in terms of color permanence and resistance to environmental factors compared to some plant-based alternatives.

- Binder systems for natural pigment fixation: Specialized binder systems are crucial for ensuring proper adhesion and fixation of natural pigments to textile substrates. These binders are formulated to be compatible with both the natural pigment particles and various fabric types. The formulations may include natural or synthetic polymers that create durable bonds between the pigment and textile fibers after curing. Proper binder selection enhances wash fastness, rub resistance, and overall print durability while maintaining the eco-friendly profile of natural pigment systems.

- Particle size control and dispersion techniques: Achieving optimal particle size and stable dispersions is critical for natural pigment formulations in inkjet textile printing. Various processing techniques including ultrasonic treatment, microfluidization, and specialized milling processes can be employed to reduce particle size and ensure uniform distribution. Surfactants and dispersing agents specifically selected for natural pigments help maintain suspension stability and prevent nozzle clogging. These techniques enable the formulation of natural pigment inks with appropriate viscosity and surface tension properties required for precise droplet formation in digital printing systems.

02 Formulation additives for natural pigment stability

Specific additives are essential in natural pigment formulations to ensure stability and printability in inkjet systems. These include dispersants, humectants, pH regulators, and anti-microbial agents that prevent clogging of print heads while maintaining the integrity of the natural colorants. The formulations must balance viscosity and surface tension properties to ensure proper droplet formation and adhesion to textile substrates while preserving the natural characteristics of the pigments.Expand Specific Solutions03 Microbial and fermentation-derived pigments

Microbial and fermentation processes can be utilized to produce natural pigments suitable for textile printing applications. These bioengineered colorants offer consistent quality and scalable production compared to direct plant extraction methods. The formulations involve cultivating specific microorganisms under controlled conditions to produce pigments with desired hue and stability characteristics. These biologically derived colorants can be further modified with binding agents to improve their affinity for textile fibers.Expand Specific Solutions04 Binder systems for natural pigment fixation

Specialized binder systems are crucial for fixing natural pigments to textile substrates during inkjet printing processes. These binders are formulated to be compatible with both the natural pigment particles and various fabric types. The formulations may include biodegradable polymers, protein-based adhesives, or modified natural resins that enhance wash fastness and color durability while maintaining fabric hand and breathability. The binder chemistry must be optimized to work with the specific molecular structure of different natural pigment types.Expand Specific Solutions05 Pre-treatment and post-processing techniques

Effective natural pigment printing requires specific pre-treatment and post-processing methods to achieve optimal results. Pre-treatments may include fabric preparation with mordants or surface modifiers that enhance pigment adhesion and color development. Post-processing techniques such as steam fixation, heat setting, or enzymatic treatments help to permanently bond the natural pigments to the textile fibers. These processes are tailored to different fabric types and pigment sources to maximize color yield and fastness properties.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Bio-based Inks

The inkjet textile printing with natural pigments market is in an early growth phase, characterized by increasing demand for sustainable printing solutions but facing significant formulation challenges. The global market is expanding rapidly, driven by environmental regulations and consumer preferences for eco-friendly textiles. Technologically, the sector remains in development with varying maturity levels across players. Leading companies like HP, Epson, and Mimaki have established strong positions in hardware development, while chemical specialists such as BASF, DuPont, and Fuji Pigment focus on natural pigment formulations. Academic institutions including Jiangnan University and Soochow University contribute significant research. The industry faces ongoing challenges in pigment stability, color vibrancy, and textile adhesion, creating opportunities for innovative solutions from emerging players like Yantai Taihe Lecai and specialized ink developers like Sakata Inx.

Seiko Epson Corp.

Technical Solution: Epson has pioneered a hybrid approach to natural pigment inkjet textile printing through their PrecisionCore™ technology platform. Their formulation strategy focuses on creating stable micro-emulsions where natural pigments are encapsulated within biodegradable polymeric shells derived from modified cellulose. This encapsulation technique prevents nozzle clogging while maintaining particle sizes below 150nm. Epson's formulations incorporate a dual-binder system: one activated during printing and another during heat fixation, achieving wash fastness ratings of 4-5 on the ISO 105 scale. Their proprietary "Micro Piezo" printhead technology operates with precise back-pressure control systems that accommodate the variable rheological properties of natural pigment formulations. Epson has developed specialized surfactant packages that maintain dispersion stability while preventing foaming issues during high-speed printing operations. Their latest systems incorporate real-time viscosity monitoring and adjustment mechanisms to compensate for the natural variation in plant-derived pigment batches.

Strengths: Exceptional print resolution (up to 1440 dpi) with natural pigments; highly efficient ink delivery system with minimal wastage; compatible with a wide range of fabric substrates including delicate natural fibers. Weaknesses: Requires precise environmental controls (temperature/humidity) for optimal performance; more frequent maintenance cycles compared to synthetic pigment systems; higher formulation complexity increases production costs.

Kornit Digital Ltd.

Technical Solution: Kornit Digital has developed a proprietary NeoPigment™ technology specifically for digital textile printing with natural pigments. Their system incorporates a pre-treatment process that creates a polymer layer on fabric surfaces to enhance pigment adhesion without requiring post-treatment washing. The formulation includes biodegradable binding agents derived from plant sources that work synergistically with natural pigments to achieve color fastness comparable to synthetic alternatives. Their patented micro-milling process reduces natural pigment particle size to below 200nm, addressing dispersion stability issues common with natural colorants. Kornit's formulations maintain viscosity between 8-12 cP and surface tension of 28-32 mN/m, optimized for their piezoelectric printheads operating at frequencies up to 20kHz. The company has also developed proprietary anti-settling additives derived from seaweed extracts that maintain homogeneity for over 12 months of shelf life.

Strengths: Industry-leading color fastness for natural pigments without requiring harsh chemical fixatives; zero wastewater production system aligns perfectly with sustainable textile manufacturing goals; complete end-to-end solution from ink formulation to printing system. Weaknesses: Higher initial investment cost compared to conventional printing systems; limited color gamut compared to synthetic pigment options; requires specialized equipment compatible only with their proprietary formulations.

Key Patents and Research on Natural Pigment Fixation Methods

Inkjet textile printing ink and image forming method

PatentActiveJP2022070019A

Innovation

- The use of inkjet printing ink containing pigments, polymer particles with a glass transition temperature of 50 °C or more, and a specific mass ratio of polymer particles to pigment particles, which reduces polymer particle mixing and film formation during drying, ensuring even pigment distribution and maintaining fabric texture.

Pigment ink formulation for DOD inkjet printing of textile fabrics

PatentWO2025176784A1

Innovation

- Development of a silicone- and fluorine-free water-based pigment formulation for piezoelectric drop-on-demand inkjet textile printing, addressing environmental concerns while maintaining performance.

- Achievement of high-quality printed textiles with excellent rubbing fastness and color development properties without relying on conventional silicone or fluorine-based components.

- Creation of a specialized water-based ink formulation optimized for piezoelectric DOD technology that balances printability requirements with textile application performance.

Sustainability Impact and Lifecycle Assessment

The adoption of natural pigments in inkjet textile printing represents a significant shift towards more environmentally responsible manufacturing practices in the textile industry. Life cycle assessment (LCA) studies demonstrate that natural pigment formulations can reduce the carbon footprint by 30-45% compared to synthetic alternatives, primarily due to lower energy requirements during production and reduced chemical synthesis processes.

Water consumption metrics reveal another critical advantage, with natural pigment production requiring approximately 60% less water than conventional synthetic colorants. This reduction becomes particularly significant considering that textile dyeing traditionally ranks as the second-largest polluter of clean water globally, after agriculture.

Waste stream analysis indicates that effluents from natural pigment printing contain significantly lower levels of harmful chemicals and heavy metals. The biodegradability of these effluents ranges from 70-95% within 28 days under optimal conditions, compared to less than 10% for many synthetic alternatives, substantially reducing the environmental burden on water treatment facilities.

From a circular economy perspective, many natural pigments can be derived from agricultural by-products or food industry waste streams, creating valuable upcycling opportunities. For instance, pomegranate rinds, onion skins, and walnut husks—typically considered waste materials—can be repurposed as sources of natural colorants, establishing secondary value chains and reducing agricultural waste.

Health impact assessments reveal reduced occupational hazards for textile workers, with natural pigments showing lower toxicity profiles and fewer respiratory irritants. Consumer exposure to harmful substances is likewise diminished, with natural pigment-printed textiles showing minimal skin sensitization potential in dermatological studies.

End-of-life considerations further highlight sustainability advantages, as textiles printed with natural pigments decompose more readily in landfill conditions and release fewer harmful substances during incineration. This characteristic becomes increasingly important as regulatory frameworks worldwide implement extended producer responsibility policies.

However, sustainability gains must be balanced against challenges in agricultural land use if natural pigment production scales significantly. Current estimates suggest that widespread adoption would require dedicated cultivation areas, potentially competing with food production unless efficient extraction methods from waste streams are developed and standardized.

Water consumption metrics reveal another critical advantage, with natural pigment production requiring approximately 60% less water than conventional synthetic colorants. This reduction becomes particularly significant considering that textile dyeing traditionally ranks as the second-largest polluter of clean water globally, after agriculture.

Waste stream analysis indicates that effluents from natural pigment printing contain significantly lower levels of harmful chemicals and heavy metals. The biodegradability of these effluents ranges from 70-95% within 28 days under optimal conditions, compared to less than 10% for many synthetic alternatives, substantially reducing the environmental burden on water treatment facilities.

From a circular economy perspective, many natural pigments can be derived from agricultural by-products or food industry waste streams, creating valuable upcycling opportunities. For instance, pomegranate rinds, onion skins, and walnut husks—typically considered waste materials—can be repurposed as sources of natural colorants, establishing secondary value chains and reducing agricultural waste.

Health impact assessments reveal reduced occupational hazards for textile workers, with natural pigments showing lower toxicity profiles and fewer respiratory irritants. Consumer exposure to harmful substances is likewise diminished, with natural pigment-printed textiles showing minimal skin sensitization potential in dermatological studies.

End-of-life considerations further highlight sustainability advantages, as textiles printed with natural pigments decompose more readily in landfill conditions and release fewer harmful substances during incineration. This characteristic becomes increasingly important as regulatory frameworks worldwide implement extended producer responsibility policies.

However, sustainability gains must be balanced against challenges in agricultural land use if natural pigment production scales significantly. Current estimates suggest that widespread adoption would require dedicated cultivation areas, potentially competing with food production unless efficient extraction methods from waste streams are developed and standardized.

Regulatory Framework for Natural Textile Colorants

The regulatory landscape governing natural textile colorants is evolving rapidly in response to increasing consumer demand for sustainable and eco-friendly textile products. Globally, regulatory frameworks vary significantly, creating a complex compliance environment for manufacturers utilizing natural pigments in inkjet textile printing.

In the European Union, the REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation serves as the primary framework governing chemical substances, including natural colorants. The EU has also implemented specific restrictions on azo dyes that can release carcinogenic aromatic amines. Natural pigments must undergo rigorous safety assessments before market approval, with particular attention to potential allergens and toxic compounds that may naturally occur in plant-derived colorants.

The United States FDA regulates colorants under the Federal Food, Drug, and Cosmetic Act, with specific provisions for textile applications through the Consumer Product Safety Commission. Natural colorants intended for textiles that may contact skin must meet stringent safety requirements, particularly for children's clothing. The FDA maintains a list of "exempt from certification" colorants, which includes many natural pigments, though these still require compliance with purity standards.

In Asia, Japan's regulatory framework through the Ministry of Health, Labour and Welfare imposes strict controls on formaldehyde content and heavy metals in textile colorants. China has implemented the GB standards system, with GB/T 35602-2017 specifically addressing natural dye applications in textiles, focusing on color fastness and safety parameters.

Certification systems play a crucial role in the regulatory ecosystem. The Global Organic Textile Standard (GOTS) and OEKO-TEX Standard 100 have established comprehensive criteria for natural colorants, prohibiting certain substances and setting limits for others. These certifications have become de facto regulatory requirements for market access in many regions.

Emerging regulatory trends indicate a shift toward lifecycle assessment approaches, where the environmental impact of natural pigments is evaluated from sourcing through disposal. Several jurisdictions are developing frameworks that consider water consumption, carbon footprint, and biodegradability of natural colorant formulations.

For manufacturers developing inkjet textile printing systems with natural pigments, navigating this complex regulatory landscape requires continuous monitoring of evolving standards. Particular attention must be paid to extraction methods, as certain solvents used in pigment extraction may be subject to restrictions even when the final colorant is natural in origin.

In the European Union, the REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation serves as the primary framework governing chemical substances, including natural colorants. The EU has also implemented specific restrictions on azo dyes that can release carcinogenic aromatic amines. Natural pigments must undergo rigorous safety assessments before market approval, with particular attention to potential allergens and toxic compounds that may naturally occur in plant-derived colorants.

The United States FDA regulates colorants under the Federal Food, Drug, and Cosmetic Act, with specific provisions for textile applications through the Consumer Product Safety Commission. Natural colorants intended for textiles that may contact skin must meet stringent safety requirements, particularly for children's clothing. The FDA maintains a list of "exempt from certification" colorants, which includes many natural pigments, though these still require compliance with purity standards.

In Asia, Japan's regulatory framework through the Ministry of Health, Labour and Welfare imposes strict controls on formaldehyde content and heavy metals in textile colorants. China has implemented the GB standards system, with GB/T 35602-2017 specifically addressing natural dye applications in textiles, focusing on color fastness and safety parameters.

Certification systems play a crucial role in the regulatory ecosystem. The Global Organic Textile Standard (GOTS) and OEKO-TEX Standard 100 have established comprehensive criteria for natural colorants, prohibiting certain substances and setting limits for others. These certifications have become de facto regulatory requirements for market access in many regions.

Emerging regulatory trends indicate a shift toward lifecycle assessment approaches, where the environmental impact of natural pigments is evaluated from sourcing through disposal. Several jurisdictions are developing frameworks that consider water consumption, carbon footprint, and biodegradability of natural colorant formulations.

For manufacturers developing inkjet textile printing systems with natural pigments, navigating this complex regulatory landscape requires continuous monitoring of evolving standards. Particular attention must be paid to extraction methods, as certain solvents used in pigment extraction may be subject to restrictions even when the final colorant is natural in origin.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!