Enzymatic Pre-Treatments To Enhance Natural Dye Affinity On Cellulosics

SEP 2, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Enzymatic Pretreatment Technology Background and Objectives

Enzymatic pretreatment technologies for enhancing natural dye affinity on cellulosic materials have evolved significantly over the past decades. Initially, traditional dyeing processes relied heavily on chemical mordants and harsh conditions to achieve acceptable color fastness on cellulosic fibers. The environmental concerns associated with these conventional methods have driven research toward more sustainable alternatives, with enzymatic pretreatments emerging as a promising approach since the early 1990s.

The evolution of this technology has been marked by several key milestones, including the initial application of cellulases for denim washing in the 1980s, followed by the discovery that certain enzymes could modify fiber surfaces to enhance dye uptake in the 1990s. The 2000s witnessed significant advancements in enzyme engineering and the development of specialized enzyme cocktails specifically designed for textile pretreatment applications.

Current technological trends indicate a shift toward multi-enzyme systems that can simultaneously address multiple aspects of fiber modification, including surface roughening, removal of non-cellulosic impurities, and creation of new binding sites for natural dyes. Recent developments in protein engineering have also enabled the creation of enzymes with enhanced stability under industrial processing conditions, making enzymatic pretreatments increasingly viable for commercial applications.

The primary objective of enzymatic pretreatment technology is to enhance the affinity of natural dyes for cellulosic fibers without compromising fiber integrity or requiring additional chemical inputs. This involves modifying the fiber surface to increase accessibility to dye molecules, creating new functional groups that can form stable bonds with natural colorants, and removing hydrophobic substances that might interfere with dye penetration.

Secondary objectives include reducing water and energy consumption in the dyeing process, minimizing effluent load, and enabling the replacement of synthetic dyes with natural alternatives across a broader range of textile applications. The technology also aims to achieve these improvements while maintaining or enhancing fabric properties such as strength, drape, and comfort.

From a sustainability perspective, enzymatic pretreatments align with growing industry commitments to reduce chemical usage and environmental impact. The technology seeks to enable a circular approach to textile dyeing by facilitating the use of biodegradable natural dyes derived from renewable resources, including agricultural waste streams and traditional plant sources.

Looking forward, the field is moving toward the development of highly specific enzyme systems tailored to particular fiber types and dye classes, potentially enabling unprecedented levels of color fastness and shade reproducibility with natural colorants. Integration with other green technologies, such as ultrasonic or plasma treatments, represents another frontier in the evolution of this technology.

The evolution of this technology has been marked by several key milestones, including the initial application of cellulases for denim washing in the 1980s, followed by the discovery that certain enzymes could modify fiber surfaces to enhance dye uptake in the 1990s. The 2000s witnessed significant advancements in enzyme engineering and the development of specialized enzyme cocktails specifically designed for textile pretreatment applications.

Current technological trends indicate a shift toward multi-enzyme systems that can simultaneously address multiple aspects of fiber modification, including surface roughening, removal of non-cellulosic impurities, and creation of new binding sites for natural dyes. Recent developments in protein engineering have also enabled the creation of enzymes with enhanced stability under industrial processing conditions, making enzymatic pretreatments increasingly viable for commercial applications.

The primary objective of enzymatic pretreatment technology is to enhance the affinity of natural dyes for cellulosic fibers without compromising fiber integrity or requiring additional chemical inputs. This involves modifying the fiber surface to increase accessibility to dye molecules, creating new functional groups that can form stable bonds with natural colorants, and removing hydrophobic substances that might interfere with dye penetration.

Secondary objectives include reducing water and energy consumption in the dyeing process, minimizing effluent load, and enabling the replacement of synthetic dyes with natural alternatives across a broader range of textile applications. The technology also aims to achieve these improvements while maintaining or enhancing fabric properties such as strength, drape, and comfort.

From a sustainability perspective, enzymatic pretreatments align with growing industry commitments to reduce chemical usage and environmental impact. The technology seeks to enable a circular approach to textile dyeing by facilitating the use of biodegradable natural dyes derived from renewable resources, including agricultural waste streams and traditional plant sources.

Looking forward, the field is moving toward the development of highly specific enzyme systems tailored to particular fiber types and dye classes, potentially enabling unprecedented levels of color fastness and shade reproducibility with natural colorants. Integration with other green technologies, such as ultrasonic or plasma treatments, represents another frontier in the evolution of this technology.

Market Analysis for Natural Dye Cellulosic Textiles

The global market for natural dye cellulosic textiles has experienced significant growth in recent years, driven primarily by increasing consumer awareness about environmental sustainability and health concerns associated with synthetic dyes. The market size for natural dyed textiles was valued at approximately $1.5 billion in 2022, with cellulosic fabrics representing about 40% of this segment. Industry analysts project a compound annual growth rate of 8.7% through 2028, significantly outpacing the conventional textile market's growth rate of 4.2%.

Consumer demand patterns indicate a clear shift toward eco-friendly textile products, with surveys showing that 67% of consumers in developed markets are willing to pay a premium of 15-30% for naturally dyed garments. This trend is particularly pronounced among millennials and Gen Z consumers, who prioritize sustainability in their purchasing decisions. The fashion industry has responded to this demand shift, with major brands incorporating naturally dyed cellulosic textiles into their sustainable product lines.

Geographically, Europe leads the market for natural dyed cellulosic textiles, accounting for 38% of global consumption, followed by North America (27%) and Asia-Pacific (24%). However, the fastest growth is occurring in emerging economies, particularly India, where traditional natural dyeing techniques are being revitalized and commercialized at scale. The Indian market for natural dyed textiles has grown by 12.3% annually over the past five years.

Supply chain analysis reveals significant challenges in scaling natural dye production to meet growing demand. The inconsistency in color outcomes and lower color fastness compared to synthetic alternatives remain key barriers to wider market adoption. These technical limitations directly relate to the affinity between natural dyes and cellulosic fibers, highlighting the market relevance of enzymatic pre-treatment technologies.

Price sensitivity analysis indicates that production cost remains a critical factor, with naturally dyed cellulosic textiles typically costing 30-45% more to produce than their synthetic counterparts. Enzymatic pre-treatments that can improve dye uptake efficiency could potentially reduce this cost differential by 15-20%, making naturally dyed products more competitive in mainstream markets.

The B2B segment currently dominates the market, with textile manufacturers and fashion brands being the primary purchasers of natural dye technologies. However, the direct-to-consumer segment is growing rapidly, with small-scale artisanal producers leveraging e-commerce platforms to reach environmentally conscious consumers willing to pay premium prices for sustainable textiles.

Consumer demand patterns indicate a clear shift toward eco-friendly textile products, with surveys showing that 67% of consumers in developed markets are willing to pay a premium of 15-30% for naturally dyed garments. This trend is particularly pronounced among millennials and Gen Z consumers, who prioritize sustainability in their purchasing decisions. The fashion industry has responded to this demand shift, with major brands incorporating naturally dyed cellulosic textiles into their sustainable product lines.

Geographically, Europe leads the market for natural dyed cellulosic textiles, accounting for 38% of global consumption, followed by North America (27%) and Asia-Pacific (24%). However, the fastest growth is occurring in emerging economies, particularly India, where traditional natural dyeing techniques are being revitalized and commercialized at scale. The Indian market for natural dyed textiles has grown by 12.3% annually over the past five years.

Supply chain analysis reveals significant challenges in scaling natural dye production to meet growing demand. The inconsistency in color outcomes and lower color fastness compared to synthetic alternatives remain key barriers to wider market adoption. These technical limitations directly relate to the affinity between natural dyes and cellulosic fibers, highlighting the market relevance of enzymatic pre-treatment technologies.

Price sensitivity analysis indicates that production cost remains a critical factor, with naturally dyed cellulosic textiles typically costing 30-45% more to produce than their synthetic counterparts. Enzymatic pre-treatments that can improve dye uptake efficiency could potentially reduce this cost differential by 15-20%, making naturally dyed products more competitive in mainstream markets.

The B2B segment currently dominates the market, with textile manufacturers and fashion brands being the primary purchasers of natural dye technologies. However, the direct-to-consumer segment is growing rapidly, with small-scale artisanal producers leveraging e-commerce platforms to reach environmentally conscious consumers willing to pay premium prices for sustainable textiles.

Current Challenges in Enzymatic Pretreatment Technologies

Despite the promising potential of enzymatic pretreatments for enhancing natural dye affinity on cellulosic materials, several significant challenges continue to impede widespread industrial adoption. One primary obstacle is the high cost of enzyme production and purification, which substantially increases the overall processing expenses compared to conventional chemical pretreatments. This economic barrier is particularly problematic for small and medium-sized textile enterprises operating with limited financial resources.

Enzyme stability presents another critical challenge, as many enzymes demonstrate reduced activity or complete denaturation under industrial processing conditions. The textile industry typically requires treatments that can withstand high temperatures, extreme pH levels, and the presence of various chemicals. Most commercially available enzymes exhibit optimal performance within narrow parameter ranges, limiting their practical application in diverse manufacturing environments.

Process standardization remains elusive due to the inherent variability in enzyme activity across different batches and sources. This inconsistency leads to unpredictable treatment outcomes, making quality control exceptionally difficult in production settings. Furthermore, the complex interaction between specific enzymes and different cellulosic substrates introduces additional variables that complicate the development of universal treatment protocols.

The time-intensive nature of enzymatic reactions poses a significant hurdle for integration into existing high-speed textile production lines. While chemical processes often complete within minutes, enzymatic treatments typically require extended periods—sometimes hours—to achieve comparable results. This temporal inefficiency creates bottlenecks in production workflows and reduces overall manufacturing throughput.

Environmental considerations, though generally favorable for enzymatic approaches, still present challenges. While enzymes themselves are biodegradable, their production processes may involve substantial resource consumption and carbon emissions. Additionally, the disposal of spent enzyme solutions requires proper waste management protocols to prevent potential ecological impacts.

Technical knowledge gaps further complicate implementation efforts. Many textile manufacturers lack specialized expertise in enzyme technology, creating barriers to proper selection, application, and optimization of enzymatic pretreatments. This knowledge deficit extends to understanding the complex mechanisms by which different enzymes modify cellulosic surfaces to enhance dye affinity.

Scalability issues emerge when transitioning from laboratory success to industrial application. Processes that demonstrate excellent results at small scales often encounter unforeseen complications when implemented in large-scale production environments. These scaling challenges frequently relate to mixing efficiency, temperature control, and uniform enzyme distribution across larger substrate volumes.

Enzyme stability presents another critical challenge, as many enzymes demonstrate reduced activity or complete denaturation under industrial processing conditions. The textile industry typically requires treatments that can withstand high temperatures, extreme pH levels, and the presence of various chemicals. Most commercially available enzymes exhibit optimal performance within narrow parameter ranges, limiting their practical application in diverse manufacturing environments.

Process standardization remains elusive due to the inherent variability in enzyme activity across different batches and sources. This inconsistency leads to unpredictable treatment outcomes, making quality control exceptionally difficult in production settings. Furthermore, the complex interaction between specific enzymes and different cellulosic substrates introduces additional variables that complicate the development of universal treatment protocols.

The time-intensive nature of enzymatic reactions poses a significant hurdle for integration into existing high-speed textile production lines. While chemical processes often complete within minutes, enzymatic treatments typically require extended periods—sometimes hours—to achieve comparable results. This temporal inefficiency creates bottlenecks in production workflows and reduces overall manufacturing throughput.

Environmental considerations, though generally favorable for enzymatic approaches, still present challenges. While enzymes themselves are biodegradable, their production processes may involve substantial resource consumption and carbon emissions. Additionally, the disposal of spent enzyme solutions requires proper waste management protocols to prevent potential ecological impacts.

Technical knowledge gaps further complicate implementation efforts. Many textile manufacturers lack specialized expertise in enzyme technology, creating barriers to proper selection, application, and optimization of enzymatic pretreatments. This knowledge deficit extends to understanding the complex mechanisms by which different enzymes modify cellulosic surfaces to enhance dye affinity.

Scalability issues emerge when transitioning from laboratory success to industrial application. Processes that demonstrate excellent results at small scales often encounter unforeseen complications when implemented in large-scale production environments. These scaling challenges frequently relate to mixing efficiency, temperature control, and uniform enzyme distribution across larger substrate volumes.

Existing Enzymatic Solutions for Natural Dye Affinity

01 Cellulase enzyme treatments for improved dye affinity

Cellulase enzymes can be used as pre-treatments for cellulosic textiles to improve dye affinity. These enzymes work by partially hydrolyzing the surface fibers, removing protruding fibrils and creating a smoother surface with more accessible binding sites. This enzymatic treatment increases the uptake of dyes, resulting in deeper colors, more uniform dyeing, and reduced dye consumption. The process also improves the fabric's softness and appearance while being environmentally friendly compared to conventional chemical treatments.- Cellulase enzyme treatments for improved dye affinity: Cellulase enzymes are used as pre-treatments for textile materials to improve dye affinity. These enzymes modify the fiber surface by removing protruding fibers and microfibrils, creating a smoother surface that allows for better dye penetration and more uniform coloration. This enzymatic treatment also reduces pilling and improves the hand feel of the fabric while enhancing the brightness and depth of colors achieved during dyeing processes.

- Laccase and peroxidase treatments for synthetic fibers: Laccase and peroxidase enzymes are utilized in pre-treatments for synthetic fibers to enhance dye affinity. These oxidative enzymes modify the surface properties of synthetic polymers by introducing functional groups that increase the fiber's ability to bind with dyes. This enzymatic modification creates additional binding sites for dyes, resulting in improved color fastness, reduced dye consumption, and more environmentally friendly dyeing processes for materials like polyester and nylon.

- Amylase treatments for natural fibers: Amylase enzymes are employed as pre-treatments for natural fibers, particularly cotton and other cellulosic materials, to remove starch-based sizing agents and improve dye affinity. By hydrolyzing starch molecules that might interfere with dyeing processes, amylases ensure better dye penetration and more uniform color distribution. This enzymatic desizing process is more environmentally friendly than traditional chemical methods and results in improved color yield, reduced water consumption, and enhanced fabric quality.

- Protease treatments for protein fibers: Protease enzymes are used as pre-treatments for protein-based fibers such as wool and silk to enhance dye affinity. These enzymes partially hydrolyze the protein structure on the fiber surface, removing scales in wool or sericin in silk, which creates better access for dyes to penetrate the fiber core. The controlled enzymatic modification results in improved dye uptake, more uniform coloration, reduced dyeing temperature requirements, and enhanced color fastness properties while maintaining the integrity of the fiber.

- Multi-enzyme sequential treatments: Multi-enzyme sequential treatments involve the application of different enzymes in a specific order to optimize dye affinity for various textile materials. This approach combines the benefits of different enzymatic actions, such as using cellulases followed by pectinases for cotton, or proteases followed by lipases for wool. The sequential treatment creates synergistic effects that enhance fiber surface modification, improve dye penetration, increase color yield, and reduce the environmental impact of the dyeing process by lowering chemical, water, and energy consumption.

02 Laccase and peroxidase treatments for enhanced dye binding

Laccase and peroxidase enzymes can be used in pre-treatments to enhance dye affinity, particularly for natural fibers. These oxidative enzymes modify the surface properties of fibers by creating reactive sites that can form covalent bonds with dye molecules. This treatment leads to improved color fastness, reduced dye runoff, and enhanced dye uptake efficiency. The enzymatic process operates under mild conditions, reducing energy consumption and environmental impact compared to traditional dyeing methods.Expand Specific Solutions03 Amylase pre-treatments for starch removal and improved dyeing

Amylase enzymes can be used as pre-treatments to remove starch-based sizing agents from textiles before dyeing. The removal of these sizing agents improves dye penetration and affinity by eliminating barriers that would otherwise prevent dye molecules from reaching fiber binding sites. This enzymatic desizing process results in more uniform dyeing, better color yield, and improved fabric quality. The treatment is particularly effective for cotton and cotton-blend fabrics that have been sized during manufacturing.Expand Specific Solutions04 Protease treatments for protein fibers and dye uptake

Protease enzymes can be used as pre-treatments for protein-based fibers such as wool and silk to enhance dye affinity. These enzymes partially hydrolyze the surface proteins, removing scales in wool fibers and creating additional binding sites for dyes. The treatment results in improved dye uptake, more uniform coloration, and reduced damage compared to chemical treatments. Additionally, protease pre-treatments can reduce the felting tendency of wool while improving its softness and luster.Expand Specific Solutions05 Combined enzymatic treatments and process optimization

Combining multiple enzyme types in pre-treatment processes can synergistically enhance dye affinity across various fiber types. These multi-enzyme systems typically include cellulases, pectinases, and hemicellulases for cellulosic fibers, or combinations of proteases and lipases for protein fibers. Process parameters such as temperature, pH, treatment time, and enzyme concentration can be optimized to maximize dye affinity while minimizing fiber damage. Advanced enzyme formulations may also include stabilizers and activators to enhance performance under industrial dyeing conditions.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The enzymatic pre-treatment for enhancing natural dye affinity on cellulosics is in an emerging growth phase, with the global natural dye market expected to reach $5 billion by 2025. This technology sits at the intersection of sustainable textiles and biotechnology, currently at mid-level maturity. Leading players include Novozymes, a pioneer in industrial enzymes, and Danisco, which brings significant bioinnovation expertise. Companies like DyStar and Huntsman Advanced Materials are integrating these technologies into their textile chemical portfolios, while academic institutions such as Jiangnan University and Donghua University contribute valuable research. L'Oréal and Henkel represent potential applications in consumer products. The technology is advancing from experimental to commercial applications, with increasing focus on scalability and cost-effectiveness.

Danisco US, Inc.

Technical Solution: Danisco has developed the Primagreen® enzymatic pre-treatment system specifically for enhancing natural dye affinity on cellulosic materials. Their approach utilizes a multi-enzyme cascade system that sequentially modifies fiber surfaces to maximize dye binding sites. The technology begins with specialized pectinases that remove pectin and waxy substances from cotton and other cellulosic fibers, improving water absorption by up to 40% compared to conventional methods. This is followed by their proprietary cellulase complex that creates controlled surface modifications without compromising fiber strength. Their research has shown that this two-step enzymatic treatment increases the number of accessible hydroxyl groups on cellulose by approximately 25-30%, providing additional binding sites for natural dyes. Danisco has also developed enzyme stabilizers that extend the active life of enzymes during processing, allowing for lower enzyme dosages while maintaining effectiveness. Their system operates at neutral to slightly acidic pH ranges (5.0-7.0), which is particularly beneficial for subsequent natural dyeing processes that often perform optimally in similar pH environments.

Strengths: Highly efficient at low enzyme concentrations (0.5-1.5% owf); operates at moderate temperatures (40-55°C) reducing energy consumption; creates uniform surface modification for consistent dyeing results. Weaknesses: Requires precise process control parameters; some formulations show reduced effectiveness with certain plant-based natural dyes; initial implementation requires modification of existing processing protocols.

Novozymes A/S

Technical Solution: Novozymes has developed advanced enzymatic pre-treatment solutions specifically for enhancing natural dye affinity on cellulosic materials. Their technology utilizes specialized cellulases, pectinases, and laccases that modify cellulose fiber surfaces by creating micro-roughness and increasing the number of binding sites for natural dyes. Their BioPrep® system employs alkaline pectinases that remove non-cellulosic impurities and waxy substances from cotton fibers, increasing dye penetration by up to 25% compared to conventional methods. Additionally, their Cellusoft® enzymes selectively hydrolyze cellulose microfibrils on the surface, creating additional hydroxyl groups that serve as binding sites for natural dyes. Novozymes has also pioneered the use of laccase-mediator systems (LMS) that can activate lignin components in some natural dyes, creating reactive quinones that form covalent bonds with cellulose, significantly improving colorfastness properties without metal mordants.

Strengths: Highly specific enzyme formulations that target precise fiber modifications without damaging core structure; environmentally friendly processes that reduce water and energy consumption by up to 30% compared to conventional methods. Weaknesses: Higher initial cost compared to chemical treatments; requires precise pH and temperature control during application; some enzyme formulations have limited shelf life requiring special storage conditions.

Key Enzymatic Mechanisms for Cellulose Modification

Enzymatic treatment of textiles using a pectate lyase from bacillus subtilis

PatentWO2008039353A2

Innovation

- A pectate lyase enzyme from Bacillus subtilis with a molecular weight of 43 kD and a pH of 7.3, suitable for use in a one-step treatment composition that includes bleaching agents and desizing enzymes, operating optimally between 10-50°C and pH 5-8.5, without the need for divalent cations, to facilitate bioscouring, bleaching, and desizing of cellulosic fibers.

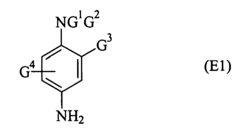

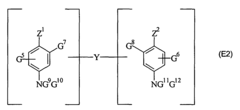

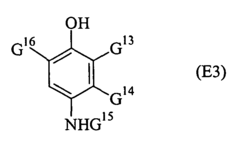

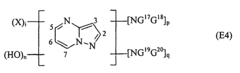

Composition for the enzymatic pre-colouration treatment of keratin fibres.

PatentInactiveEP1634577A1

Innovation

- An enzymatic pretreatment using carboxyl ester hydrolases and proteases is applied to keratin fibers before dyeing, which enlarges hair pores, degreases the surface, and exposes reactive groups, enhancing dye penetration and stability.

Sustainability Impact and Life Cycle Assessment

The implementation of enzymatic pre-treatments for enhancing natural dye affinity on cellulosic materials represents a significant advancement in sustainable textile processing. When evaluating the sustainability impact of these enzymatic approaches, life cycle assessment (LCA) reveals substantial environmental benefits compared to conventional chemical pre-treatment methods.

Enzymatic pre-treatments significantly reduce water consumption by operating effectively at lower temperatures and requiring fewer rinse cycles. Studies indicate a potential reduction of 30-40% in water usage compared to traditional alkaline scouring processes. This water conservation aspect is particularly crucial considering the textile industry's position as one of the most water-intensive manufacturing sectors globally.

Energy consumption metrics similarly demonstrate favorable outcomes, with enzymatic processes typically requiring temperatures between 40-60°C versus 90-100°C for conventional treatments. This temperature differential translates to approximately 25-35% energy savings, contributing to reduced carbon footprints across textile manufacturing operations.

Chemical load reduction represents another critical sustainability advantage. Enzymatic pre-treatments eliminate or significantly reduce the need for harsh chemicals like sodium hydroxide, hydrogen peroxide, and various surfactants. This reduction minimizes harmful effluent discharge, decreasing the biological oxygen demand (BOD) and chemical oxygen demand (COD) of wastewater by up to 60% in some applications.

From a biodegradability perspective, enzymes offer inherent advantages as naturally occurring proteins that decompose into harmless components. Unlike persistent chemical agents, enzymes leave minimal environmental residues and pose negligible ecotoxicity concerns. This characteristic aligns perfectly with circular economy principles increasingly adopted by the textile industry.

Worker health and safety metrics also favor enzymatic approaches, as these biological catalysts eliminate exposure to caustic chemicals and reduce workplace hazards associated with high-temperature operations. This human-centered sustainability benefit often receives less attention but remains crucial for holistic sustainability assessment.

Economic sustainability analysis reveals that while enzyme costs may initially exceed those of bulk chemicals, the total process economics frequently favor enzymatic routes when accounting for reduced energy, water, effluent treatment, and regulatory compliance costs. Several studies indicate potential overall process cost reductions of 15-20% when implementing optimized enzymatic pre-treatment protocols.

Carbon footprint calculations across the complete life cycle demonstrate that enzymatic pre-treatments for natural dyeing of cellulosics can reduce greenhouse gas emissions by 20-30% compared to conventional approaches, primarily through energy savings and reduced chemical manufacturing impacts. This climate benefit becomes increasingly valuable as textile manufacturers face growing pressure to decarbonize their operations.

Enzymatic pre-treatments significantly reduce water consumption by operating effectively at lower temperatures and requiring fewer rinse cycles. Studies indicate a potential reduction of 30-40% in water usage compared to traditional alkaline scouring processes. This water conservation aspect is particularly crucial considering the textile industry's position as one of the most water-intensive manufacturing sectors globally.

Energy consumption metrics similarly demonstrate favorable outcomes, with enzymatic processes typically requiring temperatures between 40-60°C versus 90-100°C for conventional treatments. This temperature differential translates to approximately 25-35% energy savings, contributing to reduced carbon footprints across textile manufacturing operations.

Chemical load reduction represents another critical sustainability advantage. Enzymatic pre-treatments eliminate or significantly reduce the need for harsh chemicals like sodium hydroxide, hydrogen peroxide, and various surfactants. This reduction minimizes harmful effluent discharge, decreasing the biological oxygen demand (BOD) and chemical oxygen demand (COD) of wastewater by up to 60% in some applications.

From a biodegradability perspective, enzymes offer inherent advantages as naturally occurring proteins that decompose into harmless components. Unlike persistent chemical agents, enzymes leave minimal environmental residues and pose negligible ecotoxicity concerns. This characteristic aligns perfectly with circular economy principles increasingly adopted by the textile industry.

Worker health and safety metrics also favor enzymatic approaches, as these biological catalysts eliminate exposure to caustic chemicals and reduce workplace hazards associated with high-temperature operations. This human-centered sustainability benefit often receives less attention but remains crucial for holistic sustainability assessment.

Economic sustainability analysis reveals that while enzyme costs may initially exceed those of bulk chemicals, the total process economics frequently favor enzymatic routes when accounting for reduced energy, water, effluent treatment, and regulatory compliance costs. Several studies indicate potential overall process cost reductions of 15-20% when implementing optimized enzymatic pre-treatment protocols.

Carbon footprint calculations across the complete life cycle demonstrate that enzymatic pre-treatments for natural dyeing of cellulosics can reduce greenhouse gas emissions by 20-30% compared to conventional approaches, primarily through energy savings and reduced chemical manufacturing impacts. This climate benefit becomes increasingly valuable as textile manufacturers face growing pressure to decarbonize their operations.

Scalability and Industrial Implementation Considerations

The scalability of enzymatic pre-treatments for enhancing natural dye affinity on cellulosic materials represents a critical consideration for industrial adoption. Current laboratory-scale processes demonstrate promising results, but significant challenges emerge when transitioning to commercial production volumes. Primary scaling considerations include enzyme stability under industrial processing conditions, consistency of treatment results across large batches, and the economic feasibility of enzyme recovery and reuse systems.

Equipment modification requirements constitute another important aspect of industrial implementation. Existing textile processing machinery requires adaptation to accommodate enzymatic treatment parameters, including temperature control systems capable of maintaining optimal enzyme activity ranges (typically 40-60°C) and pH regulation mechanisms. The capital investment for these modifications varies significantly based on facility size and current technological infrastructure, with estimates ranging from $50,000 for small operations to several million dollars for large-scale manufacturing plants.

Process integration within established production workflows presents both challenges and opportunities. The enzymatic pre-treatment step must be seamlessly incorporated into existing manufacturing sequences without creating bottlenecks or significantly extending production timelines. Optimally positioned between scouring and dyeing processes, the enzymatic treatment requires careful synchronization with subsequent operations to prevent fiber degradation from prolonged exposure to enzymatic activity.

Economic viability analysis reveals a complex cost-benefit relationship. While enzyme costs remain relatively high compared to conventional chemical treatments (approximately 2-3 times higher per unit of treated material), these expenses may be offset by reduced dyeing temperatures, shorter processing times, and decreased wastewater treatment requirements. Return on investment calculations suggest payback periods of 18-36 months for most implementations, contingent upon production volume and market positioning of the finished products.

Environmental impact assessments strongly favor enzymatic approaches when evaluating complete life cycle metrics. The biodegradability of enzymes, reduced energy consumption during dyeing (15-30% reduction), and significantly lower chemical oxygen demand (COD) in effluent streams (40-60% reduction) contribute to a substantially improved ecological footprint compared to conventional methods. These environmental benefits increasingly translate to tangible market advantages as sustainability becomes a key purchasing criterion in textile markets.

Regulatory compliance frameworks vary significantly by region but generally favor enzymatic processes due to their alignment with green chemistry principles. Implementation strategies must account for worker safety protocols, enzyme handling procedures, and appropriate documentation to satisfy regulatory requirements across different markets.

Equipment modification requirements constitute another important aspect of industrial implementation. Existing textile processing machinery requires adaptation to accommodate enzymatic treatment parameters, including temperature control systems capable of maintaining optimal enzyme activity ranges (typically 40-60°C) and pH regulation mechanisms. The capital investment for these modifications varies significantly based on facility size and current technological infrastructure, with estimates ranging from $50,000 for small operations to several million dollars for large-scale manufacturing plants.

Process integration within established production workflows presents both challenges and opportunities. The enzymatic pre-treatment step must be seamlessly incorporated into existing manufacturing sequences without creating bottlenecks or significantly extending production timelines. Optimally positioned between scouring and dyeing processes, the enzymatic treatment requires careful synchronization with subsequent operations to prevent fiber degradation from prolonged exposure to enzymatic activity.

Economic viability analysis reveals a complex cost-benefit relationship. While enzyme costs remain relatively high compared to conventional chemical treatments (approximately 2-3 times higher per unit of treated material), these expenses may be offset by reduced dyeing temperatures, shorter processing times, and decreased wastewater treatment requirements. Return on investment calculations suggest payback periods of 18-36 months for most implementations, contingent upon production volume and market positioning of the finished products.

Environmental impact assessments strongly favor enzymatic approaches when evaluating complete life cycle metrics. The biodegradability of enzymes, reduced energy consumption during dyeing (15-30% reduction), and significantly lower chemical oxygen demand (COD) in effluent streams (40-60% reduction) contribute to a substantially improved ecological footprint compared to conventional methods. These environmental benefits increasingly translate to tangible market advantages as sustainability becomes a key purchasing criterion in textile markets.

Regulatory compliance frameworks vary significantly by region but generally favor enzymatic processes due to their alignment with green chemistry principles. Implementation strategies must account for worker safety protocols, enzyme handling procedures, and appropriate documentation to satisfy regulatory requirements across different markets.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!