ATR-FTIR Contact Quality: Pressure Control, Surface Roughness And Spectral Repeatability

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

ATR-FTIR Technology Background and Objectives

Attenuated Total Reflection Fourier Transform Infrared Spectroscopy (ATR-FTIR) has evolved significantly since its inception in the 1960s. This analytical technique has transformed from a specialized laboratory tool to an essential method for material characterization across numerous industries. The fundamental principle of ATR-FTIR relies on the interaction between infrared radiation and sample materials through an internal reflection element (IRE), typically made of diamond, germanium, or zinc selenide.

The technology has progressed through several key developmental phases, beginning with basic single-reflection systems and advancing to sophisticated multi-reflection configurations that enhance sensitivity. Recent technological innovations have focused on improving spectral resolution, expanding the range of measurable wavelengths, and developing more robust sampling interfaces that can accommodate diverse material types.

Current trends in ATR-FTIR development emphasize miniaturization, automation, and integration with other analytical techniques. Portable and handheld ATR-FTIR devices represent a significant advancement, enabling field analysis capabilities previously confined to laboratory settings. Additionally, the integration of artificial intelligence and machine learning algorithms for spectral interpretation has opened new possibilities for real-time analysis and decision-making.

Contact quality between the sample and the ATR crystal remains a critical factor affecting measurement accuracy and reproducibility. This interface is influenced by three primary factors: applied pressure, surface roughness, and the resulting spectral repeatability. Despite technological advancements, these fundamental aspects continue to present challenges that impact analytical outcomes.

The primary objective of current research in ATR-FTIR contact quality is to establish standardized methodologies for pressure control that optimize spectral quality while minimizing sample deformation. This includes developing pressure monitoring systems that provide real-time feedback during measurements and automated pressure adjustment mechanisms that maintain optimal contact throughout analysis.

Another key goal is to quantify and compensate for the effects of surface roughness on spectral quality. This involves creating mathematical models that can predict and correct for spectral variations caused by irregular sample surfaces, as well as developing sample preparation techniques that minimize roughness-related artifacts.

Enhancing spectral repeatability represents the ultimate aim of these efforts, with researchers working to establish protocols that ensure consistent results across different operators, instruments, and environmental conditions. This includes developing calibration standards specifically designed for ATR-FTIR applications and implementing quality control procedures that verify measurement reliability.

The technology has progressed through several key developmental phases, beginning with basic single-reflection systems and advancing to sophisticated multi-reflection configurations that enhance sensitivity. Recent technological innovations have focused on improving spectral resolution, expanding the range of measurable wavelengths, and developing more robust sampling interfaces that can accommodate diverse material types.

Current trends in ATR-FTIR development emphasize miniaturization, automation, and integration with other analytical techniques. Portable and handheld ATR-FTIR devices represent a significant advancement, enabling field analysis capabilities previously confined to laboratory settings. Additionally, the integration of artificial intelligence and machine learning algorithms for spectral interpretation has opened new possibilities for real-time analysis and decision-making.

Contact quality between the sample and the ATR crystal remains a critical factor affecting measurement accuracy and reproducibility. This interface is influenced by three primary factors: applied pressure, surface roughness, and the resulting spectral repeatability. Despite technological advancements, these fundamental aspects continue to present challenges that impact analytical outcomes.

The primary objective of current research in ATR-FTIR contact quality is to establish standardized methodologies for pressure control that optimize spectral quality while minimizing sample deformation. This includes developing pressure monitoring systems that provide real-time feedback during measurements and automated pressure adjustment mechanisms that maintain optimal contact throughout analysis.

Another key goal is to quantify and compensate for the effects of surface roughness on spectral quality. This involves creating mathematical models that can predict and correct for spectral variations caused by irregular sample surfaces, as well as developing sample preparation techniques that minimize roughness-related artifacts.

Enhancing spectral repeatability represents the ultimate aim of these efforts, with researchers working to establish protocols that ensure consistent results across different operators, instruments, and environmental conditions. This includes developing calibration standards specifically designed for ATR-FTIR applications and implementing quality control procedures that verify measurement reliability.

Market Applications and Demand Analysis for ATR-FTIR

The global market for Attenuated Total Reflectance Fourier Transform Infrared (ATR-FTIR) spectroscopy continues to expand significantly, driven by increasing demand across multiple industries. The pharmaceutical sector represents one of the largest application areas, where ATR-FTIR is extensively used for raw material identification, quality control, and counterfeit detection. Market research indicates that pharmaceutical applications alone account for approximately 30% of the total ATR-FTIR market.

The food and beverage industry has emerged as another major consumer of ATR-FTIR technology, particularly for compositional analysis, adulteration detection, and quality assurance. This sector has seen substantial growth in ATR-FTIR adoption over the past five years, with annual growth rates exceeding the market average.

Environmental monitoring applications represent a rapidly expanding market segment, where ATR-FTIR is deployed for water quality analysis, soil contamination studies, and air pollution monitoring. The increasing regulatory pressure for environmental compliance has significantly boosted demand in this sector.

Academic and research institutions continue to be substantial users of ATR-FTIR technology, particularly for materials science, polymer research, and biological studies. The education sector values the non-destructive nature and minimal sample preparation requirements of ATR-FTIR techniques.

Market analysis reveals growing demand for portable and handheld ATR-FTIR devices, reflecting the industry trend toward point-of-need testing and field applications. This segment is expected to grow at twice the rate of traditional benchtop systems over the next five years.

The contact quality aspects of ATR-FTIR—specifically pressure control, surface roughness accommodation, and spectral repeatability—are increasingly recognized as critical factors driving purchase decisions. End-users across industries report that inconsistent results due to poor sample contact represent a major pain point, with over 75% of surveyed users citing spectral repeatability as "very important" or "critical" to their applications.

Manufacturers who can demonstrate superior contact quality control mechanisms command premium pricing, with market leaders investing heavily in advanced pressure control systems and surface adaptation technologies. The market shows willingness to pay 15-25% price premiums for systems with documented improvements in spectral repeatability.

Regional analysis indicates that North America and Europe currently dominate the ATR-FTIR market, though Asia-Pacific represents the fastest-growing region with particularly strong demand from pharmaceutical manufacturing and environmental monitoring sectors.

The food and beverage industry has emerged as another major consumer of ATR-FTIR technology, particularly for compositional analysis, adulteration detection, and quality assurance. This sector has seen substantial growth in ATR-FTIR adoption over the past five years, with annual growth rates exceeding the market average.

Environmental monitoring applications represent a rapidly expanding market segment, where ATR-FTIR is deployed for water quality analysis, soil contamination studies, and air pollution monitoring. The increasing regulatory pressure for environmental compliance has significantly boosted demand in this sector.

Academic and research institutions continue to be substantial users of ATR-FTIR technology, particularly for materials science, polymer research, and biological studies. The education sector values the non-destructive nature and minimal sample preparation requirements of ATR-FTIR techniques.

Market analysis reveals growing demand for portable and handheld ATR-FTIR devices, reflecting the industry trend toward point-of-need testing and field applications. This segment is expected to grow at twice the rate of traditional benchtop systems over the next five years.

The contact quality aspects of ATR-FTIR—specifically pressure control, surface roughness accommodation, and spectral repeatability—are increasingly recognized as critical factors driving purchase decisions. End-users across industries report that inconsistent results due to poor sample contact represent a major pain point, with over 75% of surveyed users citing spectral repeatability as "very important" or "critical" to their applications.

Manufacturers who can demonstrate superior contact quality control mechanisms command premium pricing, with market leaders investing heavily in advanced pressure control systems and surface adaptation technologies. The market shows willingness to pay 15-25% price premiums for systems with documented improvements in spectral repeatability.

Regional analysis indicates that North America and Europe currently dominate the ATR-FTIR market, though Asia-Pacific represents the fastest-growing region with particularly strong demand from pharmaceutical manufacturing and environmental monitoring sectors.

Current Challenges in ATR-FTIR Contact Quality

Despite significant advancements in ATR-FTIR spectroscopy, achieving consistent contact quality between the sample and the ATR crystal remains a fundamental challenge that impacts spectral repeatability and analytical reliability. The primary technical obstacles center around three interconnected factors: pressure control, surface roughness management, and maintaining spectral reproducibility across measurements.

Pressure control presents a significant challenge as insufficient pressure leads to inadequate optical contact and weak spectral signals, while excessive pressure can damage samples or alter their physical properties, particularly for soft or biological materials. Current pressure control mechanisms often lack precision, with many systems utilizing manual force application that introduces operator variability. Even in automated systems, pressure distribution uniformity across the sample-crystal interface remains problematic, especially for heterogeneous or irregularly shaped samples.

Surface roughness variations compound these challenges by creating air gaps between the sample and crystal, which significantly reduce the effective penetration depth of the evanescent wave. This issue is particularly pronounced with solid samples where surface irregularities can prevent complete contact with the crystal surface. The technical community has yet to develop standardized approaches for quantifying acceptable surface roughness thresholds for different sample types or effective methods for sample preparation that consistently minimize roughness effects.

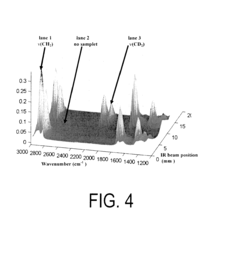

Spectral repeatability suffers as a direct consequence of these pressure and surface issues. Variations in contact quality between measurements lead to inconsistent absorbance intensities and occasionally band shifts, compromising quantitative analysis. This challenge is magnified when comparing data across different instruments or operators. The lack of universally accepted calibration standards for contact quality assessment further complicates efforts to establish reproducible methodologies.

Environmental factors introduce additional complexities, with temperature fluctuations causing thermal expansion or contraction that alters contact pressure during measurement. Humidity variations can affect sample properties, particularly for hygroscopic materials, changing their mechanical properties and consequently the sample-crystal interface characteristics.

The miniaturization trend in ATR-FTIR instrumentation for portable field applications has intensified these challenges, as smaller form factors often compromise the robustness of pressure control mechanisms while still requiring consistent contact quality for reliable results. This creates a significant engineering dilemma between instrument portability and analytical performance.

Addressing these interconnected challenges requires interdisciplinary approaches combining optical engineering, materials science, and mechanical design to develop next-generation ATR accessories with intelligent pressure feedback systems and adaptive interfaces that can accommodate varying sample characteristics.

Pressure control presents a significant challenge as insufficient pressure leads to inadequate optical contact and weak spectral signals, while excessive pressure can damage samples or alter their physical properties, particularly for soft or biological materials. Current pressure control mechanisms often lack precision, with many systems utilizing manual force application that introduces operator variability. Even in automated systems, pressure distribution uniformity across the sample-crystal interface remains problematic, especially for heterogeneous or irregularly shaped samples.

Surface roughness variations compound these challenges by creating air gaps between the sample and crystal, which significantly reduce the effective penetration depth of the evanescent wave. This issue is particularly pronounced with solid samples where surface irregularities can prevent complete contact with the crystal surface. The technical community has yet to develop standardized approaches for quantifying acceptable surface roughness thresholds for different sample types or effective methods for sample preparation that consistently minimize roughness effects.

Spectral repeatability suffers as a direct consequence of these pressure and surface issues. Variations in contact quality between measurements lead to inconsistent absorbance intensities and occasionally band shifts, compromising quantitative analysis. This challenge is magnified when comparing data across different instruments or operators. The lack of universally accepted calibration standards for contact quality assessment further complicates efforts to establish reproducible methodologies.

Environmental factors introduce additional complexities, with temperature fluctuations causing thermal expansion or contraction that alters contact pressure during measurement. Humidity variations can affect sample properties, particularly for hygroscopic materials, changing their mechanical properties and consequently the sample-crystal interface characteristics.

The miniaturization trend in ATR-FTIR instrumentation for portable field applications has intensified these challenges, as smaller form factors often compromise the robustness of pressure control mechanisms while still requiring consistent contact quality for reliable results. This creates a significant engineering dilemma between instrument portability and analytical performance.

Addressing these interconnected challenges requires interdisciplinary approaches combining optical engineering, materials science, and mechanical design to develop next-generation ATR accessories with intelligent pressure feedback systems and adaptive interfaces that can accommodate varying sample characteristics.

Current Solutions for Optimizing Surface Contact Quality

01 Contact quality optimization for ATR-FTIR spectroscopy

Optimizing contact quality between the sample and ATR crystal is crucial for obtaining reliable spectral data. This involves controlling pressure application systems, ensuring uniform contact across the sampling area, and developing mechanisms that maintain consistent contact pressure. Improved contact quality reduces signal variability and enhances the repeatability of spectral measurements, which is particularly important for quantitative analysis applications.- Contact quality optimization in ATR-FTIR spectroscopy: Optimizing contact quality between the sample and ATR crystal is crucial for obtaining reliable and repeatable spectral data. This involves controlling pressure application systems, ensuring uniform contact across the sampling area, and developing mechanisms to verify proper contact has been achieved. Improved contact quality reduces signal variability and enhances spectral repeatability by minimizing air gaps that can distort measurements.

- Sample preparation techniques for spectral repeatability: Standardized sample preparation methods significantly impact the repeatability of ATR-FTIR spectroscopy results. This includes techniques for homogenizing samples, controlling sample thickness, managing moisture content, and developing specialized holders or fixtures that ensure consistent sample presentation to the ATR crystal. Proper preparation minimizes variability between measurements and improves analytical precision.

- Automated calibration and validation systems: Automated systems for calibration and validation help maintain spectral repeatability in ATR-FTIR analysis. These systems include reference standards for instrument performance verification, algorithms for detecting measurement anomalies, and protocols for regular system checks. Automation reduces operator-dependent variations and ensures consistent instrument performance over time, leading to more reliable spectral data.

- Advanced signal processing for improved repeatability: Signal processing techniques enhance spectral repeatability in ATR-FTIR spectroscopy by addressing noise, baseline variations, and other measurement artifacts. Methods include spectral averaging, baseline correction algorithms, noise filtering, and chemometric approaches that can compensate for minor variations in contact quality. These computational approaches help standardize spectral outputs even when physical measurement conditions vary slightly.

- Environmental control systems for spectral stability: Environmental factors significantly impact ATR-FTIR spectral repeatability. Control systems that regulate temperature, humidity, and vibration around the instrument help maintain measurement stability. Specialized enclosures, temperature-stabilized sample holders, and vibration isolation platforms minimize external influences on spectral quality. Consistent environmental conditions ensure that observed spectral variations reflect actual sample differences rather than measurement artifacts.

02 Spectral repeatability enhancement techniques

Various techniques have been developed to enhance spectral repeatability in ATR-FTIR spectroscopy, including automated sampling procedures, reference calibration methods, and signal processing algorithms. These approaches help minimize variations caused by environmental factors, operator differences, and instrument drift. Implementing standardized measurement protocols and utilizing internal reference standards further improves the consistency and reproducibility of spectral data across multiple measurements.Expand Specific Solutions03 Advanced ATR crystal designs for improved spectral quality

Innovative ATR crystal designs focus on optimizing the interaction between infrared radiation and the sample surface. These designs include modified crystal geometries, multi-reflection elements, and specialized coatings that enhance signal-to-noise ratios. Advanced crystal configurations also address issues related to penetration depth consistency and evanescent wave propagation, resulting in more reliable and repeatable spectral measurements across diverse sample types.Expand Specific Solutions04 Automated pressure control systems for consistent sample contact

Automated pressure control systems have been developed to maintain consistent contact between samples and ATR crystals. These systems utilize precision actuators, force sensors, and feedback mechanisms to apply and monitor contact pressure throughout the measurement process. By eliminating variations in manual pressure application, these systems significantly improve spectral repeatability and measurement precision, particularly for heterogeneous or deformable samples.Expand Specific Solutions05 Data processing algorithms for spectral consistency

Advanced data processing algorithms play a crucial role in enhancing spectral repeatability by compensating for variations in contact quality and other measurement conditions. These algorithms include baseline correction methods, spectral normalization techniques, and mathematical transformations that minimize the impact of sampling inconsistencies. Machine learning approaches are also being implemented to identify and correct for systematic variations, resulting in more consistent and reliable spectral data for analytical applications.Expand Specific Solutions

Leading Manufacturers and Research Institutions in ATR-FTIR

The ATR-FTIR contact quality technology landscape is currently in a growth phase, with increasing adoption across materials science, pharmaceutical, and industrial quality control sectors. The market is projected to expand significantly due to rising demand for non-destructive analytical techniques, with an estimated global spectroscopy market exceeding $15 billion. Technical maturity varies among key players, with established instrumentation companies like Thermo Scientific and 3M Innovative Properties leading in pressure control innovations, while Yokohama Rubber and Bridgestone focus on surface roughness applications for materials testing. Emerging players such as Orono Spectral Solutions and P2i are developing specialized solutions for spectral repeatability challenges. Research institutions including Fraunhofer-Gesellschaft and Helmholtz-Zentrum Berlin are advancing fundamental improvements in ATR-FTIR contact methodologies, bridging academic research with industrial applications.

Thermo Electron Scientific Instruments LLC

Technical Solution: Thermo Electron has developed advanced ATR-FTIR systems with Smart Pressure Technology that automatically monitors and controls the pressure applied to samples during analysis. Their systems incorporate precision load cells and feedback mechanisms to maintain optimal contact between the sample and ATR crystal. The technology includes real-time pressure monitoring with digital displays showing exact applied force (in Newtons), ensuring consistent sample-to-crystal contact across measurements. Their Smart Accessory Recognition system automatically detects the ATR accessory and applies appropriate pressure parameters. Additionally, they've developed specialized algorithms that can compensate for variations in surface roughness by analyzing spectral characteristics and applying mathematical corrections to improve data quality and repeatability. Their systems also feature automated pressure calibration routines that establish optimal pressure settings for different sample types.

Strengths: Industry-leading pressure control systems with digital feedback; automated recognition of accessories and sample types; comprehensive software for spectral correction. Weaknesses: Higher cost compared to manual systems; complex technology requires more maintenance; potential over-reliance on software corrections rather than optimizing physical contact.

Thermo Scientific Portable Analytical Instruments, Inc.

Technical Solution: Thermo Scientific Portable Analytical Instruments has pioneered portable ATR-FTIR systems with innovative pressure control mechanisms specifically designed for field applications. Their technology features miniaturized pressure sensors integrated directly into handheld devices, allowing for precise contact quality monitoring even in challenging environments. The company has developed a patented "Smart Pressure" system that provides visual and audible feedback to users when optimal pressure is achieved, eliminating guesswork during field measurements. Their portable systems incorporate specialized diamond ATR crystals with optimized geometries to maximize surface contact with rough samples while minimizing required pressure. The instruments include built-in surface roughness compensation algorithms that automatically adjust integration times and spectral processing based on detected contact quality. Additionally, their systems feature automated calibration routines that can be performed in the field to maintain measurement consistency across different environmental conditions.

Strengths: Highly portable solutions with field-optimized pressure control; intuitive user feedback systems; ruggedized design for variable environmental conditions. Weaknesses: Reduced spectral resolution compared to benchtop systems; limited pressure range in portable form factors; battery life constraints may affect long-term measurement stability.

Key Innovations in Pressure Control and Surface Interface

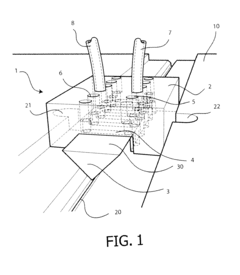

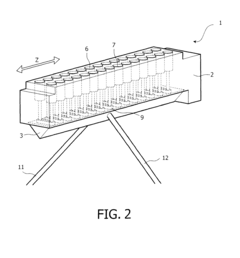

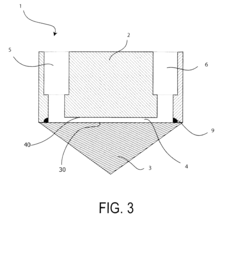

Device for multiple ATR analysis

PatentInactiveEP2116839A1

Innovation

- A device with an ATR element featuring a sample compartment with multiple chambers, allowing for the analysis of multiple samples, and an organic compound for grafting the ATR element to stabilize it against hydrolysis, enabling simultaneous analysis of multiple samples and improving surface stability.

Material Science Considerations for ATR-FTIR Interfaces

The interface between the ATR crystal and sample material represents a critical junction in FTIR spectroscopy that significantly influences measurement quality. Material properties at this interface determine the effectiveness of the evanescent wave penetration and subsequent spectral data collection. The crystal material itself—typically germanium, zinc selenide, or diamond—must be selected based on compatibility with sample characteristics, including chemical reactivity, hardness, and refractive index requirements.

Surface roughness at the molecular level plays a pivotal role in ATR-FTIR spectroscopy. When the sample surface contains irregularities comparable to or larger than the infrared wavelength (2-25 μm), air gaps form between the crystal and sample, reducing effective contact area. These gaps dramatically decrease signal intensity and introduce spectral distortions, particularly in the fingerprint region (1500-500 cm⁻¹) where material identification often depends on subtle spectral features.

Mechanical properties of both the ATR crystal and sample material determine deformation behavior under applied pressure. Soft materials like polymers and biological tissues conform more readily to the crystal surface, while rigid samples may require significantly higher pressure to achieve adequate contact. The elastic modulus and hardness of materials directly influence the pressure requirements for optimal spectral acquisition, with softer materials generally requiring less pressure to establish sufficient optical contact.

Temperature effects at the interface cannot be overlooked, as thermal expansion coefficients differ between crystal and sample materials. Temperature fluctuations during measurement can alter the contact quality, particularly in long-duration experiments or when analyzing temperature-sensitive materials. Additionally, some materials exhibit phase transitions or structural changes within operational temperature ranges, potentially altering their surface characteristics and spectral response.

Moisture content at the interface presents another critical consideration, especially for hygroscopic materials. Water absorption can modify surface properties and create dynamic interfaces that change during measurement. The hydrophilicity/hydrophobicity balance of both crystal and sample surfaces influences wetting behavior and consequently affects the quality of optical contact, particularly important when analyzing biological samples or materials in varying humidity conditions.

Crystal coating technologies have emerged as solutions for improving interface quality. Hydrophobic coatings can prevent moisture accumulation, while specialized surface treatments can enhance contact with challenging sample types. However, these coatings must be carefully selected to avoid introducing spectral artifacts or diminishing the evanescent wave penetration depth, which would compromise analytical sensitivity.

Surface roughness at the molecular level plays a pivotal role in ATR-FTIR spectroscopy. When the sample surface contains irregularities comparable to or larger than the infrared wavelength (2-25 μm), air gaps form between the crystal and sample, reducing effective contact area. These gaps dramatically decrease signal intensity and introduce spectral distortions, particularly in the fingerprint region (1500-500 cm⁻¹) where material identification often depends on subtle spectral features.

Mechanical properties of both the ATR crystal and sample material determine deformation behavior under applied pressure. Soft materials like polymers and biological tissues conform more readily to the crystal surface, while rigid samples may require significantly higher pressure to achieve adequate contact. The elastic modulus and hardness of materials directly influence the pressure requirements for optimal spectral acquisition, with softer materials generally requiring less pressure to establish sufficient optical contact.

Temperature effects at the interface cannot be overlooked, as thermal expansion coefficients differ between crystal and sample materials. Temperature fluctuations during measurement can alter the contact quality, particularly in long-duration experiments or when analyzing temperature-sensitive materials. Additionally, some materials exhibit phase transitions or structural changes within operational temperature ranges, potentially altering their surface characteristics and spectral response.

Moisture content at the interface presents another critical consideration, especially for hygroscopic materials. Water absorption can modify surface properties and create dynamic interfaces that change during measurement. The hydrophilicity/hydrophobicity balance of both crystal and sample surfaces influences wetting behavior and consequently affects the quality of optical contact, particularly important when analyzing biological samples or materials in varying humidity conditions.

Crystal coating technologies have emerged as solutions for improving interface quality. Hydrophobic coatings can prevent moisture accumulation, while specialized surface treatments can enhance contact with challenging sample types. However, these coatings must be carefully selected to avoid introducing spectral artifacts or diminishing the evanescent wave penetration depth, which would compromise analytical sensitivity.

Quality Assurance Standards for Spectroscopic Measurements

Quality assurance standards for spectroscopic measurements in ATR-FTIR systems are essential for ensuring reliable and reproducible analytical results. These standards address the critical factors affecting contact quality, including pressure control, surface roughness, and spectral repeatability, which significantly impact measurement accuracy.

International organizations such as ASTM International, ISO, and USP have established comprehensive guidelines specifically for ATR-FTIR spectroscopy. ASTM E1252 provides detailed protocols for sample preparation and instrument qualification, while ISO 17025 outlines laboratory competence requirements for testing and calibration.

The pressure control standards typically specify acceptable force ranges (usually between 5-40 N) to be applied during ATR measurements, with recommendations for different sample types. For rigid samples, higher pressures are standardized, while for soft or deformable materials, lower pressures with precise control mechanisms are mandated to prevent sample damage while ensuring adequate contact.

Surface roughness parameters are quantified in these standards using Ra (average roughness) and Rz (maximum height) values. For optimal ATR-FTIR measurements, standards typically recommend surface roughness below 0.5 μm Ra for hard samples and specific preparation protocols for various material types to achieve consistent surface characteristics.

Spectral repeatability standards define acceptable limits for signal-to-noise ratios (typically >5000:1 for high-quality systems) and baseline stability metrics. These standards often require demonstration of repeatability through statistical validation using reference materials, with relative standard deviation (RSD) values below 1% for peak intensities across multiple measurements.

Calibration verification protocols are another critical component, requiring regular performance checks using certified reference materials such as polystyrene films or NIST traceable standards. These protocols specify frequency of verification (typically daily or weekly) and acceptance criteria for wavelength accuracy (±0.1 cm⁻¹) and photometric precision (±0.5% transmittance).

Quality assurance standards also address environmental factors affecting spectral quality, specifying acceptable ranges for temperature (typically 20-25°C with ±2°C stability), humidity control (30-60% RH), and vibration isolation requirements to minimize measurement variability.

Documentation requirements form a significant portion of these standards, mandating detailed record-keeping of instrument parameters, sample preparation methods, and environmental conditions for each measurement to ensure traceability and reproducibility across different laboratories and time periods.

International organizations such as ASTM International, ISO, and USP have established comprehensive guidelines specifically for ATR-FTIR spectroscopy. ASTM E1252 provides detailed protocols for sample preparation and instrument qualification, while ISO 17025 outlines laboratory competence requirements for testing and calibration.

The pressure control standards typically specify acceptable force ranges (usually between 5-40 N) to be applied during ATR measurements, with recommendations for different sample types. For rigid samples, higher pressures are standardized, while for soft or deformable materials, lower pressures with precise control mechanisms are mandated to prevent sample damage while ensuring adequate contact.

Surface roughness parameters are quantified in these standards using Ra (average roughness) and Rz (maximum height) values. For optimal ATR-FTIR measurements, standards typically recommend surface roughness below 0.5 μm Ra for hard samples and specific preparation protocols for various material types to achieve consistent surface characteristics.

Spectral repeatability standards define acceptable limits for signal-to-noise ratios (typically >5000:1 for high-quality systems) and baseline stability metrics. These standards often require demonstration of repeatability through statistical validation using reference materials, with relative standard deviation (RSD) values below 1% for peak intensities across multiple measurements.

Calibration verification protocols are another critical component, requiring regular performance checks using certified reference materials such as polystyrene films or NIST traceable standards. These protocols specify frequency of verification (typically daily or weekly) and acceptance criteria for wavelength accuracy (±0.1 cm⁻¹) and photometric precision (±0.5% transmittance).

Quality assurance standards also address environmental factors affecting spectral quality, specifying acceptable ranges for temperature (typically 20-25°C with ±2°C stability), humidity control (30-60% RH), and vibration isolation requirements to minimize measurement variability.

Documentation requirements form a significant portion of these standards, mandating detailed record-keeping of instrument parameters, sample preparation methods, and environmental conditions for each measurement to ensure traceability and reproducibility across different laboratories and time periods.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!