ATR-FTIR Thin Films: Evanescent Field Overlap, Film Thickness And Orientation

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

ATR-FTIR Spectroscopy Background and Objectives

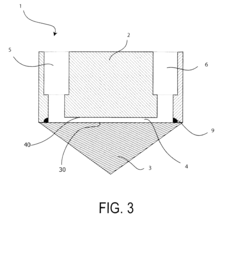

Attenuated Total Reflection Fourier Transform Infrared (ATR-FTIR) spectroscopy has evolved significantly since its inception in the 1960s, becoming an indispensable analytical technique for surface and thin film characterization. The technique leverages the principle of total internal reflection, where an infrared beam passes through a high refractive index crystal, creating an evanescent wave that penetrates the sample in contact with the crystal surface. This non-destructive method has revolutionized material analysis by eliminating the need for extensive sample preparation.

The historical development of ATR-FTIR technology has seen remarkable advancements in instrumentation, from early dispersive spectrometers to modern Fourier transform systems with enhanced sensitivity and resolution. These improvements have expanded its application across diverse fields including polymer science, biochemistry, pharmaceutical research, and semiconductor manufacturing, particularly for thin film analysis.

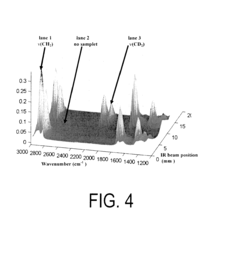

Recent technological trends in ATR-FTIR spectroscopy focus on enhancing spatial resolution, improving signal-to-noise ratios, and developing specialized accessories for specific applications. The integration of ATR-FTIR with imaging capabilities has enabled spatial mapping of chemical compositions across sample surfaces, while advances in computational methods have improved data processing and interpretation.

For thin film analysis, understanding the relationship between the evanescent field penetration depth and film thickness is crucial. The evanescent wave typically penetrates between 0.5-5 micrometers into the sample, depending on factors such as wavelength, angle of incidence, and the refractive indices of the materials involved. This characteristic makes ATR-FTIR particularly suitable for analyzing thin films where traditional transmission methods may be challenging.

The primary objectives of current ATR-FTIR thin film research include optimizing the overlap between the evanescent field and the film to maximize signal quality, developing methodologies for accurate thickness determination across various material types, and establishing reliable techniques for molecular orientation analysis within films. These objectives address critical needs in quality control for industrial coatings, functional materials development, and fundamental research in surface science.

Additionally, researchers aim to overcome existing limitations such as the variability in penetration depth across the spectral range, which complicates quantitative analysis, and the challenges associated with analyzing ultra-thin films below 100 nanometers where the evanescent field may extend well beyond the film thickness. Enhancing the sensitivity for detecting subtle orientation changes in molecular structures within thin films represents another frontier in the field.

The convergence of these technological advancements and research objectives is expected to further expand ATR-FTIR capabilities, enabling more precise characterization of increasingly complex thin film systems and supporting innovation across multiple industries and scientific disciplines.

The historical development of ATR-FTIR technology has seen remarkable advancements in instrumentation, from early dispersive spectrometers to modern Fourier transform systems with enhanced sensitivity and resolution. These improvements have expanded its application across diverse fields including polymer science, biochemistry, pharmaceutical research, and semiconductor manufacturing, particularly for thin film analysis.

Recent technological trends in ATR-FTIR spectroscopy focus on enhancing spatial resolution, improving signal-to-noise ratios, and developing specialized accessories for specific applications. The integration of ATR-FTIR with imaging capabilities has enabled spatial mapping of chemical compositions across sample surfaces, while advances in computational methods have improved data processing and interpretation.

For thin film analysis, understanding the relationship between the evanescent field penetration depth and film thickness is crucial. The evanescent wave typically penetrates between 0.5-5 micrometers into the sample, depending on factors such as wavelength, angle of incidence, and the refractive indices of the materials involved. This characteristic makes ATR-FTIR particularly suitable for analyzing thin films where traditional transmission methods may be challenging.

The primary objectives of current ATR-FTIR thin film research include optimizing the overlap between the evanescent field and the film to maximize signal quality, developing methodologies for accurate thickness determination across various material types, and establishing reliable techniques for molecular orientation analysis within films. These objectives address critical needs in quality control for industrial coatings, functional materials development, and fundamental research in surface science.

Additionally, researchers aim to overcome existing limitations such as the variability in penetration depth across the spectral range, which complicates quantitative analysis, and the challenges associated with analyzing ultra-thin films below 100 nanometers where the evanescent field may extend well beyond the film thickness. Enhancing the sensitivity for detecting subtle orientation changes in molecular structures within thin films represents another frontier in the field.

The convergence of these technological advancements and research objectives is expected to further expand ATR-FTIR capabilities, enabling more precise characterization of increasingly complex thin film systems and supporting innovation across multiple industries and scientific disciplines.

Market Applications of ATR-FTIR for Thin Film Analysis

The market for ATR-FTIR thin film analysis spans multiple high-value industries, with semiconductor manufacturing representing the largest segment. The global semiconductor industry, valued at over $500 billion, relies heavily on ATR-FTIR for quality control and process optimization in thin film deposition. This analytical technique enables manufacturers to verify film composition, thickness, and uniformity—critical parameters that directly impact device performance and yield rates.

Pharmaceutical companies constitute another significant market, utilizing ATR-FTIR for drug delivery system development and quality assurance. The controlled-release coating industry particularly benefits from the non-destructive nature of ATR-FTIR analysis, allowing manufacturers to verify coating integrity without compromising product quality. This application segment has shown consistent growth as pharmaceutical companies increasingly develop complex drug delivery mechanisms requiring precise thin film characterization.

The polymer and advanced materials sector represents a rapidly expanding market for ATR-FTIR thin film analysis. With the global advanced materials market growing at approximately 10% annually, manufacturers require sophisticated analytical tools to characterize novel thin film materials. ATR-FTIR provides crucial data on molecular orientation, crystallinity, and chemical composition—information essential for developing materials with tailored properties for specific applications.

In the optics and photonics industry, ATR-FTIR has become indispensable for analyzing anti-reflective coatings, optical filters, and specialized thin films. This market segment values the technique's ability to provide detailed information about film thickness and uniformity without damaging delicate optical components. The growing demand for advanced optical systems in telecommunications, consumer electronics, and scientific instrumentation drives continued growth in this application area.

The biomedical device industry represents an emerging high-growth market for ATR-FTIR thin film analysis. Manufacturers of implantable devices, biosensors, and diagnostic equipment utilize the technique to verify biocompatible coatings and functional surface modifications. The ability to analyze samples in aqueous environments makes ATR-FTIR particularly valuable for characterizing biomaterials under physiologically relevant conditions.

Energy sector applications, particularly in photovoltaics and battery technology, constitute a rapidly expanding market segment. Manufacturers of thin-film solar cells and advanced battery components rely on ATR-FTIR to optimize material properties and manufacturing processes. As renewable energy adoption accelerates globally, demand for sophisticated thin film analysis capabilities continues to grow substantially in this sector.

Pharmaceutical companies constitute another significant market, utilizing ATR-FTIR for drug delivery system development and quality assurance. The controlled-release coating industry particularly benefits from the non-destructive nature of ATR-FTIR analysis, allowing manufacturers to verify coating integrity without compromising product quality. This application segment has shown consistent growth as pharmaceutical companies increasingly develop complex drug delivery mechanisms requiring precise thin film characterization.

The polymer and advanced materials sector represents a rapidly expanding market for ATR-FTIR thin film analysis. With the global advanced materials market growing at approximately 10% annually, manufacturers require sophisticated analytical tools to characterize novel thin film materials. ATR-FTIR provides crucial data on molecular orientation, crystallinity, and chemical composition—information essential for developing materials with tailored properties for specific applications.

In the optics and photonics industry, ATR-FTIR has become indispensable for analyzing anti-reflective coatings, optical filters, and specialized thin films. This market segment values the technique's ability to provide detailed information about film thickness and uniformity without damaging delicate optical components. The growing demand for advanced optical systems in telecommunications, consumer electronics, and scientific instrumentation drives continued growth in this application area.

The biomedical device industry represents an emerging high-growth market for ATR-FTIR thin film analysis. Manufacturers of implantable devices, biosensors, and diagnostic equipment utilize the technique to verify biocompatible coatings and functional surface modifications. The ability to analyze samples in aqueous environments makes ATR-FTIR particularly valuable for characterizing biomaterials under physiologically relevant conditions.

Energy sector applications, particularly in photovoltaics and battery technology, constitute a rapidly expanding market segment. Manufacturers of thin-film solar cells and advanced battery components rely on ATR-FTIR to optimize material properties and manufacturing processes. As renewable energy adoption accelerates globally, demand for sophisticated thin film analysis capabilities continues to grow substantially in this sector.

Technical Challenges in Evanescent Field Measurements

Attenuated Total Reflection Fourier Transform Infrared Spectroscopy (ATR-FTIR) for thin film analysis presents several significant technical challenges related to evanescent field measurements. The evanescent wave, which forms the basis of this analytical technique, penetrates only a few micrometers into the sample, creating complex measurement dynamics that must be carefully managed.

One primary challenge is achieving optimal evanescent field overlap with thin film samples. The penetration depth of the evanescent wave varies with wavelength, angle of incidence, and the refractive indices of both the ATR crystal and sample. For ultrathin films (below 100 nm), ensuring sufficient interaction between the evanescent field and the entire film volume becomes problematic, often resulting in weak signal intensity and poor signal-to-noise ratios.

Film thickness determination presents another substantial hurdle. Unlike bulk materials, thin films exhibit thickness-dependent spectral features due to varying degrees of evanescent field interaction. Quantitative analysis requires complex mathematical models that account for the exponential decay of the evanescent field intensity with distance from the crystal surface. Current algorithms struggle to accurately determine thickness below certain thresholds, particularly when dealing with multilayer systems.

Molecular orientation effects further complicate measurements. The evanescent field has a non-uniform polarization profile, which interacts differently with molecules depending on their orientation relative to the substrate. This creates anisotropic absorption patterns that can be misinterpreted without proper reference standards and calibration protocols. Distinguishing between thickness variations and orientation effects remains particularly challenging.

Interface phenomena between the ATR crystal and sample introduce additional complexities. Surface roughness, air gaps, and interfacial water layers can significantly alter the evanescent field profile. These effects become increasingly dominant as film thickness decreases, often leading to systematic measurement errors that are difficult to identify and correct.

Temperature and pressure dependencies further impact measurement reliability. Thermal expansion or contraction of the sample can change the effective film thickness during measurement, while pressure variations may alter the contact quality between the sample and ATR crystal, affecting the evanescent field coupling efficiency.

Advanced technical solutions are being developed to address these challenges, including multi-angle ATR-FTIR systems that provide depth-profiling capabilities, machine learning algorithms for spectral deconvolution, and specialized sample preparation techniques. However, standardization across different instrument configurations remains elusive, hampering direct comparison of results between research groups and limiting the broader adoption of quantitative thin film analysis using ATR-FTIR.

One primary challenge is achieving optimal evanescent field overlap with thin film samples. The penetration depth of the evanescent wave varies with wavelength, angle of incidence, and the refractive indices of both the ATR crystal and sample. For ultrathin films (below 100 nm), ensuring sufficient interaction between the evanescent field and the entire film volume becomes problematic, often resulting in weak signal intensity and poor signal-to-noise ratios.

Film thickness determination presents another substantial hurdle. Unlike bulk materials, thin films exhibit thickness-dependent spectral features due to varying degrees of evanescent field interaction. Quantitative analysis requires complex mathematical models that account for the exponential decay of the evanescent field intensity with distance from the crystal surface. Current algorithms struggle to accurately determine thickness below certain thresholds, particularly when dealing with multilayer systems.

Molecular orientation effects further complicate measurements. The evanescent field has a non-uniform polarization profile, which interacts differently with molecules depending on their orientation relative to the substrate. This creates anisotropic absorption patterns that can be misinterpreted without proper reference standards and calibration protocols. Distinguishing between thickness variations and orientation effects remains particularly challenging.

Interface phenomena between the ATR crystal and sample introduce additional complexities. Surface roughness, air gaps, and interfacial water layers can significantly alter the evanescent field profile. These effects become increasingly dominant as film thickness decreases, often leading to systematic measurement errors that are difficult to identify and correct.

Temperature and pressure dependencies further impact measurement reliability. Thermal expansion or contraction of the sample can change the effective film thickness during measurement, while pressure variations may alter the contact quality between the sample and ATR crystal, affecting the evanescent field coupling efficiency.

Advanced technical solutions are being developed to address these challenges, including multi-angle ATR-FTIR systems that provide depth-profiling capabilities, machine learning algorithms for spectral deconvolution, and specialized sample preparation techniques. However, standardization across different instrument configurations remains elusive, hampering direct comparison of results between research groups and limiting the broader adoption of quantitative thin film analysis using ATR-FTIR.

Current Methodologies for Optimizing Field-Film Overlap

01 Principles of ATR-FTIR for thin film analysis

Attenuated Total Reflection Fourier Transform Infrared (ATR-FTIR) spectroscopy utilizes the evanescent field phenomenon to analyze thin films. When infrared radiation passes through an ATR crystal at a specific angle, the evanescent wave penetrates a short distance into the sample in contact with the crystal. For thin films, the depth of penetration and the evanescent field overlap with the sample are critical parameters that determine the quality of spectral data. The technique allows for non-destructive surface analysis with enhanced sensitivity for films in the nanometer to micrometer range.- Principles of ATR-FTIR for thin film analysis: Attenuated Total Reflection Fourier Transform Infrared (ATR-FTIR) spectroscopy utilizes the evanescent field phenomenon to analyze thin films. When infrared radiation passes through an ATR crystal at an angle exceeding the critical angle, an evanescent wave forms that penetrates the sample in contact with the crystal. The depth of penetration depends on wavelength, refractive indices, and incident angle. This technique is particularly effective for thin films as the evanescent field overlap with the sample provides surface-sensitive measurements without sample preparation requirements.

- Optimization of evanescent field penetration depth: The effectiveness of ATR-FTIR for thin film analysis depends on optimizing the evanescent field penetration depth to match the film thickness. This can be achieved by selecting appropriate ATR crystal materials with specific refractive indices, adjusting the angle of incidence, and controlling the wavelength range. Enhanced sensitivity is possible when the evanescent field depth closely matches the thin film dimensions, maximizing the signal-to-noise ratio and providing more accurate compositional information about the sample surface layers.

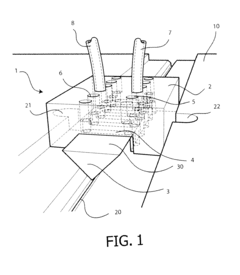

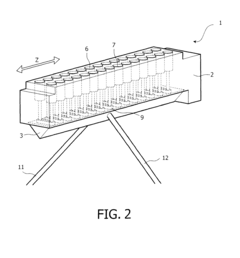

- Multi-reflection ATR systems for enhanced sensitivity: Multi-reflection ATR systems improve sensitivity for thin film analysis by increasing the interaction between the evanescent field and the sample. These systems utilize multiple internal reflections within the ATR crystal, effectively multiplying the evanescent field overlap with the thin film. This approach enhances the detection of weak spectral features and improves the signal-to-noise ratio, making it particularly valuable for ultra-thin films or samples with low concentrations of analytes where conventional single-reflection systems might provide insufficient signal strength.

- Advanced ATR crystal materials and geometries: The choice of ATR crystal material and geometry significantly impacts the evanescent field characteristics and thus the analysis of thin films. Materials such as germanium, zinc selenide, silicon, and diamond offer different refractive indices and spectral ranges. Specialized crystal geometries, including hemispherical, trapezoidal, and parallelogram designs, can optimize the angle of incidence and number of reflections. These advancements in crystal design enable tailored evanescent field overlap with specific thin film types, improving measurement accuracy and expanding the range of analyzable materials.

- Real-time monitoring and in-situ analysis applications: ATR-FTIR with optimized evanescent field overlap enables real-time monitoring and in-situ analysis of thin film processes. This capability is valuable for studying dynamic changes during film deposition, curing, degradation, or chemical reactions. The non-destructive nature of the technique allows continuous measurement without disturbing the sample. Applications include monitoring polymer film formation, surface functionalization processes, biomolecular interactions at interfaces, and quality control in semiconductor manufacturing where precise thin film characteristics are critical.

02 Optimization of evanescent field overlap in thin film measurements

Maximizing the overlap between the evanescent field and the thin film sample is essential for obtaining high-quality spectral data. This can be achieved by selecting appropriate ATR crystal materials with optimal refractive indices, controlling the angle of incidence, and ensuring good contact between the sample and crystal. Enhanced evanescent field overlap increases the signal-to-noise ratio and improves detection limits for ultra-thin films. Various techniques have been developed to optimize this overlap, including pressure application systems and specialized sample holders designed for specific film geometries.Expand Specific Solutions03 Advanced ATR-FTIR configurations for enhanced thin film sensitivity

Specialized ATR-FTIR configurations have been developed to enhance sensitivity for thin film analysis. These include multiple-reflection ATR systems, variable-angle ATR setups, and polarization-dependent measurements that can provide additional information about molecular orientation within films. Micro and nano-ATR techniques utilize focused infrared beams to analyze extremely small sample areas. These advanced configurations allow for better characterization of film thickness, uniformity, and chemical composition by maximizing the interaction between the evanescent field and the thin film sample.Expand Specific Solutions04 In-situ and real-time monitoring of thin films using ATR-FTIR

ATR-FTIR spectroscopy can be adapted for in-situ and real-time monitoring of thin film processes such as deposition, growth, and chemical reactions. By integrating ATR-FTIR with deposition chambers or reaction cells, researchers can observe changes in film composition and structure as they occur. The evanescent field overlap with the growing film provides valuable information about reaction kinetics, intermediate species formation, and film quality during processing. This approach is particularly valuable for optimizing thin film manufacturing processes and understanding dynamic surface phenomena.Expand Specific Solutions05 Quantitative analysis and modeling of evanescent field interactions

Quantitative analysis of thin films using ATR-FTIR requires sophisticated modeling of evanescent field interactions with layered materials. Mathematical models have been developed to relate spectral features to film thickness, composition, and structure based on the extent of evanescent field overlap. These models account for factors such as penetration depth variations across the infrared spectrum, optical properties of the film and substrate, and interface effects. Advanced algorithms and software tools enable researchers to extract precise information about film properties from ATR-FTIR spectra, making it a powerful technique for thin film characterization.Expand Specific Solutions

Leading Manufacturers and Research Institutions

ATR-FTIR thin film technology is currently in a growth phase, with an expanding market driven by increasing applications in materials science, semiconductor, and optical industries. The global market for this technology is estimated to be around $500 million, with projected annual growth of 7-9%. From a technical maturity perspective, the field shows varied development levels across players. Leading organizations like Georgia Tech Research Corp., Koninklijke Philips, and 3M Innovative Properties demonstrate advanced capabilities in evanescent field manipulation and orientation analysis, while academic institutions such as Zhejiang University and Yale University contribute significant fundamental research. Japanese corporations including Seiko Epson, Sharp, and Japan Display have established strong positions in thin film characterization for display technologies, creating a competitive landscape balanced between established industrial players and emerging research-focused entities.

The Georgia Tech Research Corp.

Technical Solution: Georgia Tech has developed advanced ATR-FTIR methodologies specifically for thin film characterization across multiple research domains. Their technical approach combines traditional ATR-FTIR with novel optical configurations to enhance sensitivity for ultra-thin films. Georgia Tech researchers have pioneered the use of plasmonic substrates that amplify the evanescent field intensity at the ATR crystal interface, enabling detection of monolayer and sub-monolayer films that would be undetectable with conventional ATR-FTIR. Their systems incorporate variable angle capabilities with precise angular resolution (±0.01°) to systematically map the evanescent field penetration depth as a function of incident angle. This allows accurate determination of film thickness and refractive index simultaneously. Georgia Tech has also developed advanced polarization modulation techniques that enable real-time measurement of molecular orientation dynamics in thin films during various stimuli (electrical, thermal, mechanical), providing insights into structure-property relationships at the molecular level.

Strengths: Cutting-edge research capabilities beyond commercial systems; exceptional sensitivity for ultra-thin films; advanced capabilities for dynamic measurements; interdisciplinary approach combining optical physics and materials science. Weaknesses: Systems typically custom-built for specific research applications; less user-friendly than commercial alternatives; requires significant expertise to implement and interpret results.

Koninklijke Philips NV

Technical Solution: Philips has developed specialized ATR-FTIR technology focused on thin film characterization for their display, semiconductor, and healthcare product lines. Their technical approach emphasizes in-line monitoring capabilities, with ATR-FTIR systems designed for real-time quality control during thin film deposition processes. Philips' systems utilize custom-designed ATR crystals with optimized geometries to maximize evanescent field interaction with films of specific thickness ranges relevant to their product manufacturing. Their technology incorporates automated multi-angle measurement capabilities that systematically vary the incident angle to create depth profiles through thin films. This allows determination of both thickness gradients and molecular orientation changes throughout the film structure. Philips has also developed proprietary chemometric algorithms that can detect subtle orientation changes in organic semiconductor films that correlate with device performance parameters, enabling predictive quality control during manufacturing.

Strengths: Highly optimized for specific industrial applications; excellent integration with manufacturing processes; sophisticated chemometric analysis capabilities; robust design for production environments. Weaknesses: Less flexible than research-oriented systems; may have limitations for novel materials outside established parameters; typically requires integration with other Philips systems for maximum functionality.

Key Innovations in Thin Film Orientation Detection

Device for multiple ATR analysis

PatentInactiveEP2116839A1

Innovation

- A device with an ATR element featuring a sample compartment with multiple chambers, allowing for the analysis of multiple samples, and an organic compound for grafting the ATR element to stabilize it against hydrolysis, enabling simultaneous analysis of multiple samples and improving surface stability.

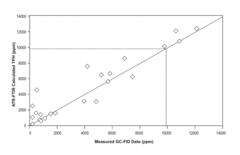

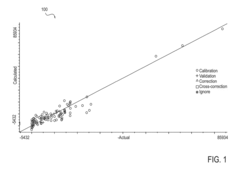

Method for predicting total petroleum hydrocarbon concentration in soils

PatentActiveUS20180017540A1

Innovation

- A method using attenuated total reflectance (ATR) spectroscopy combined with Fourier transform infrared (FTIR) spectroscopy and partial least squares regression analysis to generate a site-specific predictive model for TPH concentration, allowing for rapid field measurements without the need for solvent extraction or sample drying, utilizing a handheld FTIR spectrometer with ATR window and correlating data with GC-FID results.

Material Science Implications of ATR-FTIR Advancements

The advancements in ATR-FTIR technology have revolutionized material science by enabling unprecedented characterization capabilities for thin films. These developments have significantly impacted our understanding of material properties at the molecular level, particularly in relation to surface chemistry, interfacial phenomena, and structural orientation.

The enhanced sensitivity of modern ATR-FTIR systems allows for detection of molecular vibrations in films as thin as a few nanometers, providing critical insights into material composition and behavior that were previously unattainable. This capability has proven invaluable for industries ranging from semiconductor manufacturing to biomedical implant development, where surface properties often dictate functionality.

Material scientists have leveraged the evanescent field characteristics of ATR-FTIR to develop new methodologies for quantifying film thickness with remarkable precision. The depth of penetration of the infrared radiation, which varies with wavelength, angle of incidence, and refractive indices, provides a non-destructive means to analyze films at different depths, enabling comprehensive characterization of multilayer systems.

The ability to determine molecular orientation within thin films represents perhaps the most significant materials science implication. By analyzing the dichroic ratio of specific absorption bands under polarized infrared radiation, researchers can now quantify the degree of molecular alignment in polymeric films, liquid crystals, and self-assembled monolayers. This information is crucial for optimizing material properties in applications where anisotropic behavior is desired.

Surface modification techniques have been revolutionized through ATR-FTIR analysis, as the technology enables real-time monitoring of chemical reactions at interfaces. This has led to the development of more efficient functionalization protocols and surface engineering approaches, particularly in the creation of biocompatible materials and specialized coatings with tailored surface energies.

The correlation between processing conditions and molecular orientation in thin films, as revealed by ATR-FTIR studies, has established new structure-property relationships that guide material design. For instance, the degree of crystallinity in polymer films, which significantly affects mechanical and barrier properties, can now be precisely controlled through processing parameters informed by spectroscopic analysis.

Furthermore, ATR-FTIR advancements have enabled in-situ characterization of dynamic processes such as solvent evaporation, curing reactions, and phase transitions in thin films. This temporal dimension of analysis provides unprecedented insights into kinetic aspects of material formation and transformation, leading to more sophisticated material design strategies and processing techniques.

The enhanced sensitivity of modern ATR-FTIR systems allows for detection of molecular vibrations in films as thin as a few nanometers, providing critical insights into material composition and behavior that were previously unattainable. This capability has proven invaluable for industries ranging from semiconductor manufacturing to biomedical implant development, where surface properties often dictate functionality.

Material scientists have leveraged the evanescent field characteristics of ATR-FTIR to develop new methodologies for quantifying film thickness with remarkable precision. The depth of penetration of the infrared radiation, which varies with wavelength, angle of incidence, and refractive indices, provides a non-destructive means to analyze films at different depths, enabling comprehensive characterization of multilayer systems.

The ability to determine molecular orientation within thin films represents perhaps the most significant materials science implication. By analyzing the dichroic ratio of specific absorption bands under polarized infrared radiation, researchers can now quantify the degree of molecular alignment in polymeric films, liquid crystals, and self-assembled monolayers. This information is crucial for optimizing material properties in applications where anisotropic behavior is desired.

Surface modification techniques have been revolutionized through ATR-FTIR analysis, as the technology enables real-time monitoring of chemical reactions at interfaces. This has led to the development of more efficient functionalization protocols and surface engineering approaches, particularly in the creation of biocompatible materials and specialized coatings with tailored surface energies.

The correlation between processing conditions and molecular orientation in thin films, as revealed by ATR-FTIR studies, has established new structure-property relationships that guide material design. For instance, the degree of crystallinity in polymer films, which significantly affects mechanical and barrier properties, can now be precisely controlled through processing parameters informed by spectroscopic analysis.

Furthermore, ATR-FTIR advancements have enabled in-situ characterization of dynamic processes such as solvent evaporation, curing reactions, and phase transitions in thin films. This temporal dimension of analysis provides unprecedented insights into kinetic aspects of material formation and transformation, leading to more sophisticated material design strategies and processing techniques.

Standardization Efforts for ATR-FTIR Thin Film Measurements

Despite the growing importance of ATR-FTIR spectroscopy for thin film analysis, the field has suffered from a lack of standardized protocols, leading to inconsistent results across laboratories and instrumentation. Recognizing this challenge, several international organizations have initiated standardization efforts to establish uniform methodologies for ATR-FTIR thin film measurements.

The International Organization for Standardization (ISO) has developed ISO 10810, which provides guidelines for sample preparation and measurement parameters specifically for polymer thin films using ATR-FTIR. This standard addresses critical variables including angle of incidence, crystal material selection, and pressure application during measurement.

ASTM International has contributed through its E1252 standard, which outlines general practices for infrared spectroscopy including ATR techniques. More recently, ASTM has formed a specialized working group focused on developing standards specifically for quantitative ATR-FTIR analysis of thin films, with particular attention to evanescent field penetration depth calculations.

The National Institute of Standards and Technology (NIST) has established reference materials with certified thicknesses and optical properties, enabling laboratories to calibrate their ATR-FTIR systems. These materials include polymer films of varying thicknesses deposited on standardized substrates, providing crucial benchmarks for method validation.

European efforts have been coordinated through the European Committee for Standardization (CEN), which has published technical specifications for ATR-FTIR analysis of surface coatings and thin films. Their guidelines emphasize the importance of controlling the evanescent field overlap with sample thickness to ensure measurement reproducibility.

Industry consortia have also emerged to address application-specific standardization needs. The Semiconductor Equipment and Materials International (SEMI) organization has developed standards for ATR-FTIR characterization of thin dielectric films used in microelectronics, including protocols for orientation analysis.

Academic-industrial partnerships have contributed to standardization through round-robin testing programs, where identical samples are analyzed across multiple laboratories to identify variables affecting measurement consistency. These initiatives have led to best practice recommendations for controlling film thickness measurement uncertainty and quantifying molecular orientation effects.

Recent standardization efforts have increasingly focused on digital protocols, including standardized data formats and processing algorithms. This includes the development of reference spectral libraries specifically for thin films of varying thicknesses, enabling more accurate interpretation of spectral features affected by evanescent field interactions.

The International Organization for Standardization (ISO) has developed ISO 10810, which provides guidelines for sample preparation and measurement parameters specifically for polymer thin films using ATR-FTIR. This standard addresses critical variables including angle of incidence, crystal material selection, and pressure application during measurement.

ASTM International has contributed through its E1252 standard, which outlines general practices for infrared spectroscopy including ATR techniques. More recently, ASTM has formed a specialized working group focused on developing standards specifically for quantitative ATR-FTIR analysis of thin films, with particular attention to evanescent field penetration depth calculations.

The National Institute of Standards and Technology (NIST) has established reference materials with certified thicknesses and optical properties, enabling laboratories to calibrate their ATR-FTIR systems. These materials include polymer films of varying thicknesses deposited on standardized substrates, providing crucial benchmarks for method validation.

European efforts have been coordinated through the European Committee for Standardization (CEN), which has published technical specifications for ATR-FTIR analysis of surface coatings and thin films. Their guidelines emphasize the importance of controlling the evanescent field overlap with sample thickness to ensure measurement reproducibility.

Industry consortia have also emerged to address application-specific standardization needs. The Semiconductor Equipment and Materials International (SEMI) organization has developed standards for ATR-FTIR characterization of thin dielectric films used in microelectronics, including protocols for orientation analysis.

Academic-industrial partnerships have contributed to standardization through round-robin testing programs, where identical samples are analyzed across multiple laboratories to identify variables affecting measurement consistency. These initiatives have led to best practice recommendations for controlling film thickness measurement uncertainty and quantifying molecular orientation effects.

Recent standardization efforts have increasingly focused on digital protocols, including standardized data formats and processing algorithms. This includes the development of reference spectral libraries specifically for thin films of varying thicknesses, enabling more accurate interpretation of spectral features affected by evanescent field interactions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!