How ATR-FTIR Maximizes S/N With Strongly Absorbing Liquids Or Highly Scattering Solids?

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

ATR-FTIR Technology Background and Objectives

Attenuated Total Reflection Fourier Transform Infrared Spectroscopy (ATR-FTIR) has evolved significantly since its inception in the 1960s. Initially developed as a specialized technique for analyzing difficult samples, it has grown into one of the most versatile and widely used analytical methods in modern spectroscopy. The fundamental principle of ATR-FTIR relies on the phenomenon of total internal reflection, where an infrared beam is directed through a crystal with high refractive index, creating an evanescent wave that extends beyond the crystal surface into the sample.

The evolution of ATR-FTIR technology has been marked by continuous improvements in crystal materials, optical designs, and detection systems. Early systems utilized thallium bromide-iodide (KRS-5) or zinc selenide crystals, while modern systems predominantly employ diamond, germanium, or silicon crystals depending on the application requirements. This progression has significantly enhanced the robustness, sensitivity, and application range of the technology.

Signal-to-noise ratio (SNR) optimization has been a persistent challenge in FTIR spectroscopy, particularly when analyzing strongly absorbing liquids or highly scattering solids. These challenging sample types often produce weak signals or introduce significant noise, compromising data quality and interpretation reliability. Traditional transmission FTIR methods frequently fail to provide adequate results with such samples due to excessive absorption or scattering effects.

The primary technical objective in ATR-FTIR development has been to maximize the signal-to-noise ratio while maintaining spectral integrity across diverse sample types. This involves optimizing several parameters including the depth of penetration, angle of incidence, crystal-sample contact, and the number of reflections within the ATR crystal. Recent advancements have focused on variable angle ATR accessories, multi-bounce systems, and specialized crystal geometries designed specifically for challenging samples.

Current technological trends in ATR-FTIR include the integration of advanced computational methods for spectral processing, the development of portable and handheld devices for field applications, and the combination with other analytical techniques for comprehensive sample characterization. Machine learning algorithms are increasingly being employed to enhance spectral interpretation and automate the identification of spectral features in complex matrices.

The ultimate goal of modern ATR-FTIR technology development is to achieve reliable, high-quality spectral data from any sample type without extensive preparation, while simultaneously reducing analysis time and simplifying user operation. This includes pushing the boundaries of detection limits, improving spectral resolution, and expanding the range of materials that can be effectively analyzed, particularly those that have historically been challenging due to their physical or chemical properties.

The evolution of ATR-FTIR technology has been marked by continuous improvements in crystal materials, optical designs, and detection systems. Early systems utilized thallium bromide-iodide (KRS-5) or zinc selenide crystals, while modern systems predominantly employ diamond, germanium, or silicon crystals depending on the application requirements. This progression has significantly enhanced the robustness, sensitivity, and application range of the technology.

Signal-to-noise ratio (SNR) optimization has been a persistent challenge in FTIR spectroscopy, particularly when analyzing strongly absorbing liquids or highly scattering solids. These challenging sample types often produce weak signals or introduce significant noise, compromising data quality and interpretation reliability. Traditional transmission FTIR methods frequently fail to provide adequate results with such samples due to excessive absorption or scattering effects.

The primary technical objective in ATR-FTIR development has been to maximize the signal-to-noise ratio while maintaining spectral integrity across diverse sample types. This involves optimizing several parameters including the depth of penetration, angle of incidence, crystal-sample contact, and the number of reflections within the ATR crystal. Recent advancements have focused on variable angle ATR accessories, multi-bounce systems, and specialized crystal geometries designed specifically for challenging samples.

Current technological trends in ATR-FTIR include the integration of advanced computational methods for spectral processing, the development of portable and handheld devices for field applications, and the combination with other analytical techniques for comprehensive sample characterization. Machine learning algorithms are increasingly being employed to enhance spectral interpretation and automate the identification of spectral features in complex matrices.

The ultimate goal of modern ATR-FTIR technology development is to achieve reliable, high-quality spectral data from any sample type without extensive preparation, while simultaneously reducing analysis time and simplifying user operation. This includes pushing the boundaries of detection limits, improving spectral resolution, and expanding the range of materials that can be effectively analyzed, particularly those that have historically been challenging due to their physical or chemical properties.

Market Applications and Demand Analysis

The ATR-FTIR (Attenuated Total Reflection Fourier Transform Infrared) spectroscopy market has experienced significant growth in recent years, driven by increasing demand for advanced analytical techniques across multiple industries. The technology's ability to maximize signal-to-noise ratio when analyzing challenging samples such as strongly absorbing liquids and highly scattering solids has positioned it as a critical tool in various sectors.

In the pharmaceutical industry, ATR-FTIR has become indispensable for quality control and formulation development. Pharmaceutical manufacturers require precise molecular characterization of compounds that are often difficult to analyze using traditional methods. The enhanced signal-to-noise capabilities of ATR-FTIR allow for accurate identification of active pharmaceutical ingredients and excipients, even in complex formulations.

The polymer and materials science sector represents another substantial market for ATR-FTIR technology. Researchers and manufacturers in this field frequently work with highly scattering solid materials where traditional transmission FTIR techniques fail to provide adequate results. The demand for non-destructive, rapid analysis of polymer compositions, curing processes, and material degradation has driven adoption of advanced ATR-FTIR systems.

Environmental monitoring applications have created a growing market segment for ATR-FTIR technology. Water quality analysis, particularly for detecting trace organic contaminants in strongly absorbing aqueous samples, benefits significantly from the enhanced signal-to-noise ratio capabilities. Regulatory requirements for more sensitive and accurate environmental testing continue to drive demand in this sector.

The food and beverage industry has increasingly adopted ATR-FTIR for quality control and authentication purposes. The ability to analyze viscous liquids, emulsions, and heterogeneous solid food samples without extensive preparation has made this technology particularly valuable for detecting adulterants and verifying product composition.

Academic and research institutions constitute a stable market base for ATR-FTIR instruments, particularly those with enhanced signal-to-noise capabilities. The versatility of the technology for analyzing challenging samples makes it essential equipment in analytical chemistry laboratories and materials research facilities.

Market trends indicate growing demand for portable and field-deployable ATR-FTIR systems that maintain high signal-to-noise performance. This reflects the broader industry shift toward point-of-need testing across multiple sectors. Additionally, integration with artificial intelligence and machine learning for automated spectral interpretation represents an emerging market opportunity, particularly for applications involving complex sample matrices where signal optimization is critical.

In the pharmaceutical industry, ATR-FTIR has become indispensable for quality control and formulation development. Pharmaceutical manufacturers require precise molecular characterization of compounds that are often difficult to analyze using traditional methods. The enhanced signal-to-noise capabilities of ATR-FTIR allow for accurate identification of active pharmaceutical ingredients and excipients, even in complex formulations.

The polymer and materials science sector represents another substantial market for ATR-FTIR technology. Researchers and manufacturers in this field frequently work with highly scattering solid materials where traditional transmission FTIR techniques fail to provide adequate results. The demand for non-destructive, rapid analysis of polymer compositions, curing processes, and material degradation has driven adoption of advanced ATR-FTIR systems.

Environmental monitoring applications have created a growing market segment for ATR-FTIR technology. Water quality analysis, particularly for detecting trace organic contaminants in strongly absorbing aqueous samples, benefits significantly from the enhanced signal-to-noise ratio capabilities. Regulatory requirements for more sensitive and accurate environmental testing continue to drive demand in this sector.

The food and beverage industry has increasingly adopted ATR-FTIR for quality control and authentication purposes. The ability to analyze viscous liquids, emulsions, and heterogeneous solid food samples without extensive preparation has made this technology particularly valuable for detecting adulterants and verifying product composition.

Academic and research institutions constitute a stable market base for ATR-FTIR instruments, particularly those with enhanced signal-to-noise capabilities. The versatility of the technology for analyzing challenging samples makes it essential equipment in analytical chemistry laboratories and materials research facilities.

Market trends indicate growing demand for portable and field-deployable ATR-FTIR systems that maintain high signal-to-noise performance. This reflects the broader industry shift toward point-of-need testing across multiple sectors. Additionally, integration with artificial intelligence and machine learning for automated spectral interpretation represents an emerging market opportunity, particularly for applications involving complex sample matrices where signal optimization is critical.

Current Challenges in Analyzing Strong Absorbers and Scatterers

Despite significant advancements in ATR-FTIR spectroscopy, analyzing strongly absorbing liquids and highly scattering solids remains problematic for researchers and industry professionals. The fundamental challenge lies in the physical limitations of infrared light interaction with these materials, resulting in poor signal quality and reduced analytical accuracy.

For strongly absorbing liquids, the primary issue is excessive absorption of the infrared radiation, which drastically reduces the penetration depth of the evanescent wave. When the absorption coefficient exceeds certain thresholds, typically above 10^4 cm^-1, the effective path length becomes extremely short, often less than 0.5 μm. This results in significantly attenuated signals and compromised spectral quality, particularly in the fingerprint region where critical molecular information resides.

Highly scattering solids present a different set of challenges. The irregular surfaces and heterogeneous compositions cause unpredictable scattering of the incident infrared beam, leading to reduced optical throughput and increased noise levels. The scattering effects are particularly pronounced for materials with particle sizes comparable to the infrared wavelengths (2-25 μm), creating interference patterns that distort spectral features and complicate interpretation.

Current ATR-FTIR systems struggle with achieving consistent optical contact between the crystal and these challenging samples. For liquids with high viscosity or solids with irregular surfaces, air gaps frequently form at the interface, causing significant signal loss and spectral artifacts. Even minor variations in contact pressure can lead to substantial changes in spectral intensity and band shapes, compromising reproducibility and quantitative analysis.

Temperature fluctuations further exacerbate these challenges, particularly for strongly absorbing liquids. Small temperature changes can alter absorption coefficients and refractive indices, leading to unpredictable variations in spectral features. This thermal sensitivity necessitates precise temperature control systems that many standard instruments lack.

The limitations of conventional ATR crystals represent another significant hurdle. Traditional materials like zinc selenide (ZnSe) and germanium (Ge) offer inadequate performance for these challenging samples. ZnSe provides insufficient penetration depth control for strongly absorbing liquids, while Ge, despite its higher refractive index, suffers from poor transmission in certain spectral regions and is susceptible to surface oxidation.

Data processing algorithms in current systems are often inadequate for handling the complex spectral artifacts produced by these challenging samples. Standard baseline correction and noise reduction techniques frequently fail to properly compensate for the distortions caused by strong absorption or scattering effects, leading to misinterpretation of spectral features and inaccurate quantitative analysis.

For strongly absorbing liquids, the primary issue is excessive absorption of the infrared radiation, which drastically reduces the penetration depth of the evanescent wave. When the absorption coefficient exceeds certain thresholds, typically above 10^4 cm^-1, the effective path length becomes extremely short, often less than 0.5 μm. This results in significantly attenuated signals and compromised spectral quality, particularly in the fingerprint region where critical molecular information resides.

Highly scattering solids present a different set of challenges. The irregular surfaces and heterogeneous compositions cause unpredictable scattering of the incident infrared beam, leading to reduced optical throughput and increased noise levels. The scattering effects are particularly pronounced for materials with particle sizes comparable to the infrared wavelengths (2-25 μm), creating interference patterns that distort spectral features and complicate interpretation.

Current ATR-FTIR systems struggle with achieving consistent optical contact between the crystal and these challenging samples. For liquids with high viscosity or solids with irregular surfaces, air gaps frequently form at the interface, causing significant signal loss and spectral artifacts. Even minor variations in contact pressure can lead to substantial changes in spectral intensity and band shapes, compromising reproducibility and quantitative analysis.

Temperature fluctuations further exacerbate these challenges, particularly for strongly absorbing liquids. Small temperature changes can alter absorption coefficients and refractive indices, leading to unpredictable variations in spectral features. This thermal sensitivity necessitates precise temperature control systems that many standard instruments lack.

The limitations of conventional ATR crystals represent another significant hurdle. Traditional materials like zinc selenide (ZnSe) and germanium (Ge) offer inadequate performance for these challenging samples. ZnSe provides insufficient penetration depth control for strongly absorbing liquids, while Ge, despite its higher refractive index, suffers from poor transmission in certain spectral regions and is susceptible to surface oxidation.

Data processing algorithms in current systems are often inadequate for handling the complex spectral artifacts produced by these challenging samples. Standard baseline correction and noise reduction techniques frequently fail to properly compensate for the distortions caused by strong absorption or scattering effects, leading to misinterpretation of spectral features and inaccurate quantitative analysis.

Current Signal-to-Noise Optimization Methods

01 Signal processing techniques for improving ATR-FTIR SNR

Various signal processing algorithms and techniques can be applied to enhance the signal-to-noise ratio in ATR-FTIR spectroscopy. These include digital filtering, wavelet transforms, and advanced mathematical models that can separate signal from noise components. By implementing these processing techniques, researchers can significantly improve the quality of spectral data, enabling more accurate analysis of samples with low concentration analytes or complex matrices.- Signal processing techniques for improving ATR-FTIR signal-to-noise ratio: Various signal processing algorithms and techniques can be applied to enhance the signal-to-noise ratio in ATR-FTIR spectroscopy. These include digital filtering, wavelet transforms, and advanced mathematical models that help separate the actual signal from background noise. By implementing these computational methods, researchers can significantly improve the quality of spectral data, enabling more accurate analysis of samples with low concentration analytes or complex matrices.

- Hardware modifications for enhancing ATR-FTIR sensitivity: Specific hardware configurations and modifications can substantially improve the signal-to-noise ratio in ATR-FTIR systems. These include optimized detector designs, improved optical components, and specialized sampling accessories. Enhanced cooling systems for detectors, high-efficiency beam splitters, and precision-engineered ATR crystals with optimal geometry contribute to reducing noise while maximizing signal strength, resulting in clearer spectral data even from challenging samples.

- Calibration methods for optimizing ATR-FTIR measurements: Proper calibration protocols are essential for maximizing signal-to-noise ratio in ATR-FTIR spectroscopy. These methods include reference standardization, background correction algorithms, and instrument response function optimization. Regular calibration using known standards helps compensate for instrumental drift and environmental variations, ensuring consistent high-quality spectra with improved signal-to-noise characteristics across different measurement sessions.

- Sample preparation techniques affecting ATR-FTIR signal quality: The quality of ATR-FTIR spectra is significantly influenced by sample preparation methods. Techniques such as proper sample drying, homogenization, and surface treatment can dramatically improve signal-to-noise ratio. Ensuring optimal contact between the sample and ATR crystal, controlling sample thickness, and removing interfering substances are critical factors that enhance spectral quality by maximizing signal strength while minimizing background noise and interference.

- Integration of ATR-FTIR with other analytical techniques for enhanced performance: Combining ATR-FTIR with complementary analytical methods creates synergistic systems with improved signal-to-noise characteristics. These hybrid approaches include coupling with Raman spectroscopy, mass spectrometry, or chemometric analysis tools. The integration allows for cross-validation of results, noise reduction through data fusion, and enhanced analytical sensitivity, providing more comprehensive and reliable spectral information than standalone ATR-FTIR measurements.

02 Hardware modifications for ATR-FTIR SNR enhancement

Hardware improvements in ATR-FTIR systems can substantially increase signal-to-noise ratio. These modifications include optimized detector designs, improved optical components, enhanced cooling systems, and specialized sampling accessories. By reducing system noise at the hardware level, these innovations allow for more sensitive measurements and better spectral resolution, particularly important when analyzing trace components or when working with challenging sample types.Expand Specific Solutions03 Sample preparation methods affecting ATR-FTIR SNR

Sample preparation techniques play a crucial role in achieving optimal signal-to-noise ratios in ATR-FTIR analysis. Methods such as concentration enhancement, removal of interfering substances, proper sample positioning, and ensuring good contact between the sample and ATR crystal can significantly improve spectral quality. These preparation strategies are particularly important for complex biological samples, environmental specimens, or dilute solutions where signal strength may be inherently low.Expand Specific Solutions04 Integration of machine learning for ATR-FTIR SNR improvement

Machine learning and artificial intelligence approaches are increasingly being applied to enhance signal-to-noise ratios in ATR-FTIR spectroscopy. These computational methods can identify patterns in noisy data, perform automated baseline corrections, and distinguish between signal and noise components more effectively than traditional algorithms. By leveraging neural networks and other AI techniques, researchers can extract meaningful information from spectra that would otherwise be obscured by noise.Expand Specific Solutions05 Communication systems for remote ATR-FTIR data transmission

Advanced communication technologies enable the transmission of ATR-FTIR spectral data with minimal degradation of signal-to-noise ratio. These systems incorporate error correction protocols, data compression algorithms optimized for spectroscopic information, and robust transmission methods that preserve spectral integrity. Such technologies are particularly valuable for remote sensing applications, field-deployable instruments, and situations requiring real-time analysis of samples at locations distant from the main analytical facility.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The ATR-FTIR technology market for maximizing signal-to-noise ratio in challenging samples is currently in a growth phase, with increasing adoption across pharmaceutical, chemical, and materials science industries. The global spectroscopy market, which includes ATR-FTIR, is projected to reach approximately $20 billion by 2025, driven by demand for advanced analytical techniques. Key players in this competitive landscape include established instrumentation companies like Siemens AG and Horiba Ltd, alongside specialized firms such as Daylight Solutions and Irubis GmbH. Academic institutions including TU Wien and École Polytechnique Fédérale de Lausanne are advancing fundamental research, while industrial giants like LG Chem and Saudi Aramco are implementing these technologies in production environments. The technology has reached commercial maturity but continues to evolve with innovations in crystal materials, signal processing algorithms, and application-specific optimizations.

IR Medtek LLC

Technical Solution: IR Medtek has developed specialized ATR-FTIR technology focused on maximizing signal-to-noise ratio for challenging biomedical and pharmaceutical applications. Their approach utilizes germanium and silicon ATR crystals with optimized refractive indices specifically selected to enhance performance with strongly absorbing aqueous solutions and biological samples. For highly scattering solid samples, they've implemented proprietary sample preparation protocols combined with specialized crystal geometries that minimize scattering effects while maximizing useful signal. Their systems incorporate advanced interferometer designs with high-throughput optics that significantly increase energy throughput compared to conventional systems. IR Medtek's technology also features sophisticated digital filtering algorithms that adaptively process spectral data based on sample characteristics, effectively separating signal from noise in real-time. Additionally, their instruments employ automated optical alignment systems that continuously optimize beam focus and energy throughput during measurement sessions.

Strengths: Specialized crystal materials optimized for biomedical applications; advanced interferometer design with superior energy throughput; sophisticated adaptive filtering algorithms. Weaknesses: More limited application range compared to general-purpose systems; higher specialization requirements for operators; potentially higher costs for specialized components and maintenance.

Irubis GmbH

Technical Solution: Irubis has developed innovative ATR-FTIR solutions specifically designed for challenging industrial process monitoring applications. Their technology centers on proprietary waveguide-enhanced ATR elements that significantly increase light-sample interaction without the penetration depth issues that typically plague strongly absorbing liquid analysis. For highly scattering solids, Irubis implements specialized surface treatments on their ATR crystals that enhance contact while minimizing scatter-induced signal loss. Their systems feature advanced optical designs with optimized beam paths that maximize energy throughput while minimizing stray light contributions to noise. Irubis' technology incorporates real-time reference correction algorithms that continuously compensate for environmental fluctuations, particularly important in industrial settings where conditions vary significantly. Additionally, their instruments employ specialized detector arrays with enhanced sensitivity in specific spectral regions most relevant to target applications, further improving signal-to-noise ratio for specific compound detection in complex matrices.

Strengths: Waveguide-enhanced ATR technology providing superior sensitivity for specific applications; robust designs optimized for industrial environments; specialized detector systems for application-specific performance enhancement. Weaknesses: More limited spectral range compared to general-purpose systems; higher specialization requirements for system integration; potentially higher initial investment costs.

Key Patents and Innovations in ATR-FTIR Technology

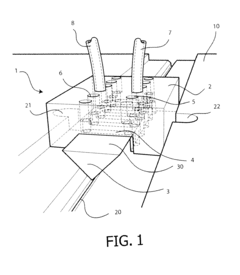

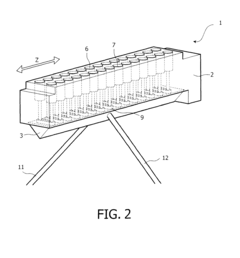

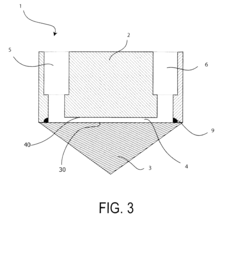

Device for multiple ATR analysis

PatentInactiveEP2116839A1

Innovation

- A device with an ATR element featuring a sample compartment with multiple chambers, allowing for the analysis of multiple samples, and an organic compound for grafting the ATR element to stabilize it against hydrolysis, enabling simultaneous analysis of multiple samples and improving surface stability.

Material Compatibility and Sample Preparation Considerations

Material compatibility is a critical factor when utilizing ATR-FTIR for maximizing signal-to-noise ratio with challenging samples. The ATR crystal material selection directly impacts measurement quality and must be carefully matched to sample characteristics. Diamond crystals offer exceptional durability and chemical resistance, making them ideal for strongly acidic or alkaline solutions that would damage other crystal materials. However, their limited spectral range (particularly the absorption region around 2000-2400 cm⁻¹) may compromise data quality for certain applications.

Germanium crystals provide an excellent alternative for highly absorbing samples due to their shallow penetration depth, which prevents signal saturation. This property makes germanium particularly valuable when analyzing carbon-black filled polymers or dark-colored liquids where excessive absorption would otherwise diminish spectral quality. ZnSe crystals offer broader spectral ranges but exhibit limited chemical compatibility with acidic samples and may deteriorate when exposed to certain solvents.

Sample preparation techniques significantly influence ATR-FTIR measurement quality, especially for challenging materials. For strongly absorbing liquids, dilution protocols must be carefully optimized to maintain representative composition while reducing absorption intensity to measurable levels. The dilution medium must be spectroscopically transparent in regions of interest and chemically compatible with both the sample and crystal material.

Highly scattering solids require specialized preparation approaches to ensure optimal crystal contact. Particle size reduction through controlled grinding or milling improves surface contact and reduces scattering effects. However, excessive mechanical processing may induce structural changes or crystallinity alterations that affect spectral characteristics. Applying consistent pressure during measurement is essential, with pressure monitoring systems recommended for quantitative applications to ensure reproducible crystal-sample interface conditions.

Temperature control during sample preparation and measurement represents another critical consideration. Many strongly absorbing liquids exhibit temperature-dependent spectral features, necessitating precise thermal regulation to maintain measurement consistency. For volatile samples, sealed sample chambers or controlled evaporation protocols help prevent concentration changes during analysis that would otherwise compromise signal quality.

Pre-measurement sample conditioning, such as controlled drying for moisture-sensitive materials or degassing for bubble-prone liquids, significantly enhances measurement reproducibility. For heterogeneous samples, multiple sampling points with statistical averaging helps overcome spatial variability challenges while maintaining acceptable signal-to-noise ratios. These preparation considerations, when properly implemented, substantially improve ATR-FTIR performance with challenging sample types.

Germanium crystals provide an excellent alternative for highly absorbing samples due to their shallow penetration depth, which prevents signal saturation. This property makes germanium particularly valuable when analyzing carbon-black filled polymers or dark-colored liquids where excessive absorption would otherwise diminish spectral quality. ZnSe crystals offer broader spectral ranges but exhibit limited chemical compatibility with acidic samples and may deteriorate when exposed to certain solvents.

Sample preparation techniques significantly influence ATR-FTIR measurement quality, especially for challenging materials. For strongly absorbing liquids, dilution protocols must be carefully optimized to maintain representative composition while reducing absorption intensity to measurable levels. The dilution medium must be spectroscopically transparent in regions of interest and chemically compatible with both the sample and crystal material.

Highly scattering solids require specialized preparation approaches to ensure optimal crystal contact. Particle size reduction through controlled grinding or milling improves surface contact and reduces scattering effects. However, excessive mechanical processing may induce structural changes or crystallinity alterations that affect spectral characteristics. Applying consistent pressure during measurement is essential, with pressure monitoring systems recommended for quantitative applications to ensure reproducible crystal-sample interface conditions.

Temperature control during sample preparation and measurement represents another critical consideration. Many strongly absorbing liquids exhibit temperature-dependent spectral features, necessitating precise thermal regulation to maintain measurement consistency. For volatile samples, sealed sample chambers or controlled evaporation protocols help prevent concentration changes during analysis that would otherwise compromise signal quality.

Pre-measurement sample conditioning, such as controlled drying for moisture-sensitive materials or degassing for bubble-prone liquids, significantly enhances measurement reproducibility. For heterogeneous samples, multiple sampling points with statistical averaging helps overcome spatial variability challenges while maintaining acceptable signal-to-noise ratios. These preparation considerations, when properly implemented, substantially improve ATR-FTIR performance with challenging sample types.

Quantitative Performance Metrics and Validation Methods

To effectively evaluate the performance of ATR-FTIR systems when analyzing strongly absorbing liquids or highly scattering solids, standardized quantitative metrics and validation methodologies are essential. These metrics provide objective benchmarks for comparing different instrumental configurations and methodologies.

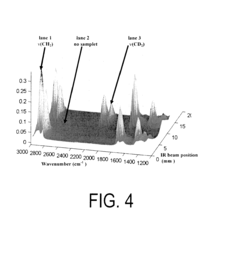

Signal-to-Noise Ratio (SNR) serves as the primary performance indicator, typically calculated as the ratio of peak signal intensity to the standard deviation of background noise. For ATR-FTIR applications with challenging samples, industry standards recommend minimum SNR values of 5000:1 for routine analysis and 10000:1 for trace component detection. These thresholds ensure reliable spectral interpretation even with highly absorptive or scattering materials.

Spectral resolution represents another critical metric, measured by the system's ability to distinguish between closely spaced absorption bands. Current high-performance ATR-FTIR systems achieve resolutions of 0.5-2 cm⁻¹, with validation performed using standard reference materials such as polystyrene films or gas-phase spectra with well-characterized rotational-vibrational transitions.

Penetration depth consistency must be rigorously assessed, particularly for strongly absorbing samples. This validation involves measuring the effective path length using reference standards with known absorption coefficients across multiple replicates. Acceptable variation should remain below 2% to ensure quantitative reliability.

Dynamic range evaluation becomes particularly important when analyzing samples with both strong and weak absorption bands. Modern ATR-FTIR systems should demonstrate linear response across at least three orders of magnitude, validated through serial dilutions of reference compounds with well-characterized absorption properties.

Reproducibility testing protocols require multiple measurements of the same sample under identical conditions, with statistical analysis of spectral variations. For challenging samples, the relative standard deviation of peak intensities should not exceed 1.5% across repeated measurements to ensure reliable quantitative analysis.

Accuracy validation employs certified reference materials with compositions similar to target analytes. Performance is assessed by comparing measured concentrations against certified values, with acceptance criteria typically set at ±5% for major components and ±10% for minor components in complex matrices.

Robustness testing evaluates system performance under varying environmental conditions, including temperature fluctuations (±5°C), humidity changes (±15%), and mechanical vibrations. ATR-FTIR systems optimized for challenging samples should maintain performance metrics within 90% of baseline values under these stress conditions.

Signal-to-Noise Ratio (SNR) serves as the primary performance indicator, typically calculated as the ratio of peak signal intensity to the standard deviation of background noise. For ATR-FTIR applications with challenging samples, industry standards recommend minimum SNR values of 5000:1 for routine analysis and 10000:1 for trace component detection. These thresholds ensure reliable spectral interpretation even with highly absorptive or scattering materials.

Spectral resolution represents another critical metric, measured by the system's ability to distinguish between closely spaced absorption bands. Current high-performance ATR-FTIR systems achieve resolutions of 0.5-2 cm⁻¹, with validation performed using standard reference materials such as polystyrene films or gas-phase spectra with well-characterized rotational-vibrational transitions.

Penetration depth consistency must be rigorously assessed, particularly for strongly absorbing samples. This validation involves measuring the effective path length using reference standards with known absorption coefficients across multiple replicates. Acceptable variation should remain below 2% to ensure quantitative reliability.

Dynamic range evaluation becomes particularly important when analyzing samples with both strong and weak absorption bands. Modern ATR-FTIR systems should demonstrate linear response across at least three orders of magnitude, validated through serial dilutions of reference compounds with well-characterized absorption properties.

Reproducibility testing protocols require multiple measurements of the same sample under identical conditions, with statistical analysis of spectral variations. For challenging samples, the relative standard deviation of peak intensities should not exceed 1.5% across repeated measurements to ensure reliable quantitative analysis.

Accuracy validation employs certified reference materials with compositions similar to target analytes. Performance is assessed by comparing measured concentrations against certified values, with acceptance criteria typically set at ±5% for major components and ±10% for minor components in complex matrices.

Robustness testing evaluates system performance under varying environmental conditions, including temperature fluctuations (±5°C), humidity changes (±15%), and mechanical vibrations. ATR-FTIR systems optimized for challenging samples should maintain performance metrics within 90% of baseline values under these stress conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!