How ATR-FTIR Avoids Spectral Distortions From Poor Contact Or Crystal Overloading?

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

ATR-FTIR Technology Background and Objectives

Attenuated Total Reflection Fourier Transform Infrared Spectroscopy (ATR-FTIR) has evolved significantly since its inception in the 1960s. Initially developed as a specialized technique for analyzing difficult samples, it has transformed into a mainstream analytical method across numerous scientific and industrial applications. The technology leverages the principle of total internal reflection, where an infrared beam passes through a crystal with high refractive index, creating an evanescent wave that penetrates the sample in contact with the crystal surface.

The evolution of ATR-FTIR technology has been marked by continuous improvements in crystal materials, from early zinc selenide and germanium crystals to modern diamond ATR crystals that offer exceptional durability and chemical resistance. Parallel advancements in computational capabilities have enabled more sophisticated data processing algorithms, enhancing spectral resolution and analysis capabilities.

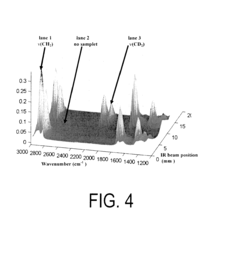

Current technological trends in ATR-FTIR focus on addressing the persistent challenges of spectral distortions caused by poor sample-crystal contact and crystal overloading. These distortions can significantly compromise data quality and analytical accuracy, particularly in quantitative applications. The industry has recognized these issues as critical barriers to broader adoption of ATR-FTIR in quality control and high-throughput screening environments.

The primary technical objective in this field is to develop robust methodologies and instrumental designs that can systematically eliminate or compensate for contact-related spectral artifacts. This includes innovations in pressure application systems, sample preparation protocols, and advanced algorithmic corrections that can identify and mitigate distortions in real-time during data acquisition.

Another key goal is to establish standardized protocols for optimal sample loading that prevent crystal overloading while ensuring sufficient signal-to-noise ratios. This balance is particularly challenging for diverse sample types with varying physical properties and IR absorption characteristics.

The technology aims to evolve toward more automated and user-independent systems that can self-adjust measurement parameters based on sample characteristics, reducing the expertise required for high-quality data collection. This democratization of ATR-FTIR technology would significantly expand its utility across research, quality control, and field applications.

Looking forward, the integration of machine learning approaches for automated spectral correction represents a promising frontier. These systems could potentially learn from vast datasets of distorted and ideal spectra to apply appropriate corrections without human intervention, further enhancing the reliability and accessibility of ATR-FTIR technology across diverse analytical challenges.

The evolution of ATR-FTIR technology has been marked by continuous improvements in crystal materials, from early zinc selenide and germanium crystals to modern diamond ATR crystals that offer exceptional durability and chemical resistance. Parallel advancements in computational capabilities have enabled more sophisticated data processing algorithms, enhancing spectral resolution and analysis capabilities.

Current technological trends in ATR-FTIR focus on addressing the persistent challenges of spectral distortions caused by poor sample-crystal contact and crystal overloading. These distortions can significantly compromise data quality and analytical accuracy, particularly in quantitative applications. The industry has recognized these issues as critical barriers to broader adoption of ATR-FTIR in quality control and high-throughput screening environments.

The primary technical objective in this field is to develop robust methodologies and instrumental designs that can systematically eliminate or compensate for contact-related spectral artifacts. This includes innovations in pressure application systems, sample preparation protocols, and advanced algorithmic corrections that can identify and mitigate distortions in real-time during data acquisition.

Another key goal is to establish standardized protocols for optimal sample loading that prevent crystal overloading while ensuring sufficient signal-to-noise ratios. This balance is particularly challenging for diverse sample types with varying physical properties and IR absorption characteristics.

The technology aims to evolve toward more automated and user-independent systems that can self-adjust measurement parameters based on sample characteristics, reducing the expertise required for high-quality data collection. This democratization of ATR-FTIR technology would significantly expand its utility across research, quality control, and field applications.

Looking forward, the integration of machine learning approaches for automated spectral correction represents a promising frontier. These systems could potentially learn from vast datasets of distorted and ideal spectra to apply appropriate corrections without human intervention, further enhancing the reliability and accessibility of ATR-FTIR technology across diverse analytical challenges.

Market Applications and Demand Analysis for ATR-FTIR

The global market for ATR-FTIR technology has experienced significant growth in recent years, driven by increasing demand for accurate and reliable spectroscopic analysis across multiple industries. The market size for FTIR spectroscopy equipment was valued at approximately $1.2 billion in 2022, with ATR accessories representing a substantial segment of this market. Industry analysts project a compound annual growth rate of 5.8% through 2028, highlighting the expanding applications and adoption of this technology.

Pharmaceutical and biotechnology sectors constitute the largest market segment for ATR-FTIR systems, accounting for nearly 40% of total demand. These industries require precise molecular analysis for drug development, quality control, and regulatory compliance. The ability of ATR-FTIR to avoid spectral distortions from poor contact or crystal overloading is particularly valuable in pharmaceutical manufacturing, where consistent quality assessment of raw materials and finished products is essential.

The food and beverage industry represents another significant market, with growing implementation of ATR-FTIR for compositional analysis, authenticity verification, and contaminant detection. Regulatory requirements for food safety and increasing consumer demand for transparency in food production have accelerated adoption in this sector. The non-destructive nature of ATR-FTIR analysis, combined with minimal sample preparation requirements, makes it particularly attractive for routine quality control applications.

Environmental monitoring applications have shown the fastest growth rate, expanding at approximately 7.2% annually. Government agencies and environmental consulting firms increasingly rely on ATR-FTIR for the identification of microplastics, soil contaminants, and water pollutants. The technology's ability to provide accurate results despite challenging sample conditions has positioned it as a preferred method for field and laboratory environmental analysis.

Academic and research institutions constitute a stable market segment, utilizing ATR-FTIR for a wide range of scientific investigations. The demand in this sector is primarily driven by research funding availability and technological advancements that enhance analytical capabilities while reducing spectral distortion issues.

Geographically, North America leads the market with approximately 35% share, followed by Europe at 30% and Asia-Pacific at 25%. The Asia-Pacific region is expected to show the highest growth rate due to expanding industrial infrastructure, increasing research activities, and growing awareness of advanced analytical techniques.

Market surveys indicate that end-users prioritize reliability and accuracy of results, with 78% of respondents citing spectral quality as a critical factor in purchasing decisions. The ability of modern ATR-FTIR systems to minimize distortions from poor contact or crystal overloading has become a key selling point, with manufacturers increasingly focusing on innovations that address these specific challenges.

Pharmaceutical and biotechnology sectors constitute the largest market segment for ATR-FTIR systems, accounting for nearly 40% of total demand. These industries require precise molecular analysis for drug development, quality control, and regulatory compliance. The ability of ATR-FTIR to avoid spectral distortions from poor contact or crystal overloading is particularly valuable in pharmaceutical manufacturing, where consistent quality assessment of raw materials and finished products is essential.

The food and beverage industry represents another significant market, with growing implementation of ATR-FTIR for compositional analysis, authenticity verification, and contaminant detection. Regulatory requirements for food safety and increasing consumer demand for transparency in food production have accelerated adoption in this sector. The non-destructive nature of ATR-FTIR analysis, combined with minimal sample preparation requirements, makes it particularly attractive for routine quality control applications.

Environmental monitoring applications have shown the fastest growth rate, expanding at approximately 7.2% annually. Government agencies and environmental consulting firms increasingly rely on ATR-FTIR for the identification of microplastics, soil contaminants, and water pollutants. The technology's ability to provide accurate results despite challenging sample conditions has positioned it as a preferred method for field and laboratory environmental analysis.

Academic and research institutions constitute a stable market segment, utilizing ATR-FTIR for a wide range of scientific investigations. The demand in this sector is primarily driven by research funding availability and technological advancements that enhance analytical capabilities while reducing spectral distortion issues.

Geographically, North America leads the market with approximately 35% share, followed by Europe at 30% and Asia-Pacific at 25%. The Asia-Pacific region is expected to show the highest growth rate due to expanding industrial infrastructure, increasing research activities, and growing awareness of advanced analytical techniques.

Market surveys indicate that end-users prioritize reliability and accuracy of results, with 78% of respondents citing spectral quality as a critical factor in purchasing decisions. The ability of modern ATR-FTIR systems to minimize distortions from poor contact or crystal overloading has become a key selling point, with manufacturers increasingly focusing on innovations that address these specific challenges.

Current Challenges in ATR-FTIR Contact and Overloading

Despite significant advancements in ATR-FTIR spectroscopy, several persistent challenges related to sample-crystal contact and crystal overloading continue to impact spectral quality and analytical reliability. The primary challenge stems from the fundamental requirement of intimate contact between the sample and the ATR crystal. When this contact is inadequate, the evanescent wave cannot properly interact with the sample, resulting in reduced absorbance intensity and potentially misleading spectral features.

For solid samples, achieving uniform contact across the entire crystal surface remains problematic. Surface irregularities, sample hardness variations, and insufficient pressure application can create air gaps between the sample and crystal. These gaps cause significant reduction in signal intensity and introduce spectral artifacts that compromise data interpretation. Even with pressure devices, maintaining consistent contact throughout the measurement process presents difficulties, particularly for samples with complex morphologies.

Liquid samples face different contact challenges. Bubble formation at the crystal-sample interface creates localized areas of poor contact, leading to spectral inconsistencies. Additionally, viscous liquids may not distribute evenly across the crystal surface, resulting in concentration gradients that affect spectral reproducibility. Temperature fluctuations can further exacerbate these issues by altering sample viscosity during measurement.

Crystal overloading represents another significant challenge, occurring when sample thickness exceeds the penetration depth of the evanescent wave. This condition leads to deviation from the Beer-Lambert relationship, causing non-linear absorbance responses and band saturation. Particularly problematic for strongly absorbing functional groups, overloading results in distorted band shapes, shifted peak positions, and altered relative intensities between spectral features.

The detection of overloading conditions presents its own challenges. Without careful monitoring, analysts may misinterpret saturated bands as genuine spectral features, leading to incorrect structural assignments or concentration determinations. This is especially problematic in automated high-throughput applications where individual spectrum quality assessment may be limited.

Instrument-specific factors further complicate these challenges. Different ATR accessories employ various crystal materials (diamond, germanium, zinc selenide) with different refractive indices and penetration depths. This diversity creates inconsistencies when comparing spectra across different instruments or when developing standardized methods. Additionally, wear on crystal surfaces over time can create microscopic scratches that affect contact quality and spectral reproducibility.

Environmental factors such as humidity and ambient temperature fluctuations introduce additional variables that can affect sample-crystal interactions, particularly for hygroscopic or thermally sensitive materials. These external influences can be difficult to control consistently in routine laboratory environments, adding another layer of complexity to achieving reliable spectral data.

For solid samples, achieving uniform contact across the entire crystal surface remains problematic. Surface irregularities, sample hardness variations, and insufficient pressure application can create air gaps between the sample and crystal. These gaps cause significant reduction in signal intensity and introduce spectral artifacts that compromise data interpretation. Even with pressure devices, maintaining consistent contact throughout the measurement process presents difficulties, particularly for samples with complex morphologies.

Liquid samples face different contact challenges. Bubble formation at the crystal-sample interface creates localized areas of poor contact, leading to spectral inconsistencies. Additionally, viscous liquids may not distribute evenly across the crystal surface, resulting in concentration gradients that affect spectral reproducibility. Temperature fluctuations can further exacerbate these issues by altering sample viscosity during measurement.

Crystal overloading represents another significant challenge, occurring when sample thickness exceeds the penetration depth of the evanescent wave. This condition leads to deviation from the Beer-Lambert relationship, causing non-linear absorbance responses and band saturation. Particularly problematic for strongly absorbing functional groups, overloading results in distorted band shapes, shifted peak positions, and altered relative intensities between spectral features.

The detection of overloading conditions presents its own challenges. Without careful monitoring, analysts may misinterpret saturated bands as genuine spectral features, leading to incorrect structural assignments or concentration determinations. This is especially problematic in automated high-throughput applications where individual spectrum quality assessment may be limited.

Instrument-specific factors further complicate these challenges. Different ATR accessories employ various crystal materials (diamond, germanium, zinc selenide) with different refractive indices and penetration depths. This diversity creates inconsistencies when comparing spectra across different instruments or when developing standardized methods. Additionally, wear on crystal surfaces over time can create microscopic scratches that affect contact quality and spectral reproducibility.

Environmental factors such as humidity and ambient temperature fluctuations introduce additional variables that can affect sample-crystal interactions, particularly for hygroscopic or thermally sensitive materials. These external influences can be difficult to control consistently in routine laboratory environments, adding another layer of complexity to achieving reliable spectral data.

Current Solutions for Contact and Overloading Issues

01 Correction methods for ATR-FTIR spectral distortions

Various mathematical and computational methods are employed to correct distortions in ATR-FTIR spectra. These include advanced algorithms for baseline correction, noise reduction, and compensation for optical effects. Software solutions implement these correction methods to enhance spectral quality and accuracy, allowing for more reliable analysis of chemical compositions and material properties.- Correction methods for ATR-FTIR spectral distortions: Various mathematical and computational methods are employed to correct distortions in ATR-FTIR spectra. These include advanced algorithms for baseline correction, noise reduction, and compensation for optical effects. Such correction techniques help improve the accuracy and reliability of spectral data by removing artifacts and enhancing signal quality, which is crucial for proper interpretation of molecular structures and compositions.

- Hardware solutions for minimizing ATR-FTIR distortions: Specialized hardware components and configurations are designed to minimize spectral distortions in ATR-FTIR systems. These include improved crystal materials, optimized optical pathways, and enhanced detector systems. Hardware innovations focus on reducing interference, improving signal-to-noise ratios, and ensuring consistent sample-crystal contact, thereby producing more accurate and reproducible spectral measurements.

- Sample preparation techniques to reduce spectral distortions: Proper sample preparation methods are critical for minimizing distortions in ATR-FTIR spectroscopy. These techniques include standardized protocols for sample handling, appropriate drying procedures, and optimal sample positioning on the ATR crystal. Careful attention to sample preparation helps ensure uniform contact with the crystal, reduces water interference, and minimizes artifacts from sample heterogeneity.

- Advanced data processing for ATR-FTIR spectral analysis: Sophisticated data processing techniques are employed to handle distortions in ATR-FTIR spectra. These include multivariate statistical methods, machine learning algorithms, and spectral deconvolution approaches. Such advanced processing enables the extraction of meaningful information from complex or distorted spectra, facilitating accurate identification of chemical components and structural features despite the presence of spectral artifacts.

- Calibration and standardization protocols for ATR-FTIR: Standardized calibration protocols are essential for addressing systematic distortions in ATR-FTIR spectroscopy. These include the use of reference materials, regular instrument validation procedures, and the development of correction factors for known distortion patterns. Proper calibration ensures consistency across measurements, enables comparison between different instruments, and provides a foundation for accurate quantitative analysis.

02 Hardware solutions for minimizing ATR-FTIR distortions

Specialized hardware components and configurations are designed to minimize spectral distortions in ATR-FTIR systems. These include improved crystal materials, optimized optical pathways, and enhanced detector systems. Hardware modifications focus on reducing interference, improving signal-to-noise ratios, and ensuring consistent sample-crystal contact to obtain more accurate and reproducible spectral data.Expand Specific Solutions03 Sample preparation techniques to reduce spectral distortions

Proper sample preparation methods are crucial for minimizing distortions in ATR-FTIR spectroscopy. Techniques include standardized sample handling protocols, surface preparation procedures, and controlled environmental conditions during measurement. These approaches help to ensure uniform sample-crystal contact, reduce contamination effects, and minimize variations in sample thickness or concentration that can lead to spectral distortions.Expand Specific Solutions04 Advanced calibration techniques for ATR-FTIR systems

Calibration methods are developed to address systematic distortions in ATR-FTIR spectroscopy. These include reference material standardization, instrument-specific calibration protocols, and adaptive calibration algorithms. Regular calibration using these techniques helps compensate for instrumental drift, environmental variations, and optical aberrations that can distort spectral data.Expand Specific Solutions05 Machine learning approaches for ATR-FTIR spectral correction

Machine learning and artificial intelligence techniques are increasingly applied to identify and correct distortions in ATR-FTIR spectra. These approaches use pattern recognition, neural networks, and statistical models to automatically detect anomalies, remove artifacts, and enhance spectral quality. Machine learning algorithms can be trained on large datasets to recognize and compensate for various types of distortions, improving both accuracy and efficiency in spectral analysis.Expand Specific Solutions

Leading Manufacturers and Research Institutions in ATR-FTIR

ATR-FTIR spectroscopy market is currently in a growth phase, with an expanding market size driven by increasing applications in pharmaceutical, chemical, and materials science industries. The technology has reached moderate maturity, with ongoing innovations focused on addressing spectral distortion challenges. Key players like Thermo Fisher Scientific lead the market with advanced solutions that optimize crystal-sample contact and prevent overloading issues. Other significant contributors include Spectrolytic GmbH and Si-Ware Systems, who are developing portable and miniaturized ATR-FTIR systems. Academic institutions such as Technical University of Denmark and École Polytechnique Fédérale de Lausanne collaborate with industry partners to advance fundamental understanding of spectral distortion mechanisms and develop improved algorithms for data correction.

Thermo Electron Scientific Instruments LLC

Technical Solution: Thermo Electron has developed advanced ATR-FTIR systems with Smart Accessory Recognition technology that automatically optimizes measurement parameters to prevent spectral distortions. Their patented pressure monitoring systems ensure consistent sample-crystal contact while preventing overloading. The company's Diamond ATR accessories incorporate pressure distribution mechanisms that maintain uniform contact across samples with irregular surfaces. Additionally, their software includes real-time feedback algorithms that detect poor contact or overloading conditions, alerting users to adjust sampling parameters. Thermo's multi-bounce ATR crystals increase sensitivity without risking overloading by distributing the sample across a larger surface area while maintaining optimal penetration depth.

Strengths: Industry-leading automated pressure control systems provide consistent results across different operators and sample types. Their diamond ATR crystals offer exceptional durability while maintaining spectral quality. Weaknesses: Higher cost compared to simpler ATR systems, and some automated features may limit flexibility for specialized research applications requiring manual parameter control.

Spectrolytic GmbH

Technical Solution: Spectrolytic has pioneered adaptive ATR-FTIR technology specifically designed to overcome contact and overloading issues in industrial environments. Their system employs a variable-angle ATR mechanism that automatically adjusts the incident angle based on real-time spectral quality assessment. This approach dynamically modifies the effective penetration depth to maintain optimal signal-to-noise ratios regardless of sample characteristics. For liquid samples, Spectrolytic's flow-cell design incorporates microfluidic channels with precise depth control to prevent crystal overloading. Their proprietary algorithms perform continuous baseline correction and spectral normalization during measurement, compensating for minor contact variations. The company's industrial sensors also feature self-cleaning mechanisms that prevent sample buildup on crystal surfaces, which could otherwise cause progressive overloading during continuous monitoring applications.

Strengths: Highly adaptable to varying sample conditions without operator intervention, making it ideal for process monitoring applications. Robust design suitable for harsh industrial environments with minimal maintenance requirements. Weaknesses: Specialized focus on industrial applications may limit versatility for research purposes, and the adaptive systems may introduce additional complexity in spectral interpretation for novel sample types.

Key Innovations in ATR-FTIR Interface Design

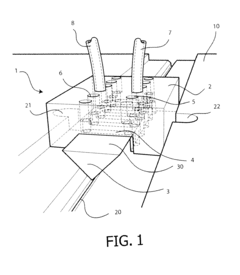

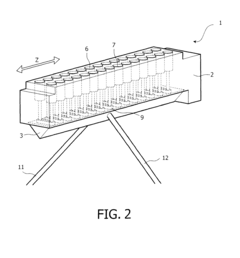

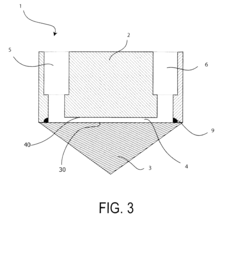

Device for multiple ATR analysis

PatentInactiveEP2116839A1

Innovation

- A device with an ATR element featuring a sample compartment with multiple chambers, allowing for the analysis of multiple samples, and an organic compound for grafting the ATR element to stabilize it against hydrolysis, enabling simultaneous analysis of multiple samples and improving surface stability.

Sample Preparation Protocols for Optimal ATR-FTIR Analysis

Effective sample preparation is critical for obtaining accurate and reproducible results in ATR-FTIR spectroscopy. The quality of contact between the sample and the ATR crystal directly impacts spectral quality, making proper preparation protocols essential to avoid distortions.

For solid samples, particle size reduction through grinding or milling is recommended to ensure uniform contact with the crystal surface. Samples should be ground to a fine powder with particles smaller than the penetration depth of the evanescent wave (typically 0.5-5 μm). This maximizes surface contact and minimizes air gaps that can cause spectral artifacts and reduced signal intensity.

Pressure application is another crucial factor in ATR-FTIR analysis. Most ATR accessories include pressure devices that should be adjusted to provide consistent force across samples. For optimal results, the pressure should be sufficient to ensure good contact without damaging the crystal or deforming the sample structure. Pressure indicators or torque-limited pressure devices help maintain reproducibility between measurements.

Liquid samples require different handling protocols. Small volumes (typically 10-50 μL) should be applied directly to the crystal surface, ensuring complete coverage without overflow. For volatile liquids, sealed or flow-through cells can prevent evaporation during measurement. The crystal should be thoroughly cleaned between samples using appropriate solvents that don't damage the crystal material.

Temperature control during sample preparation and measurement can significantly impact spectral quality. Samples should be equilibrated to ambient or controlled temperature before analysis to prevent thermal gradients that may affect contact quality or cause spectral shifts. For temperature-sensitive materials, specialized ATR accessories with temperature control capabilities are recommended.

Sample homogeneity is essential for representative results. Heterogeneous samples should be thoroughly mixed or measured at multiple points to capture compositional variations. For layered or composite materials, careful positioning is required to ensure the layer of interest contacts the crystal surface within the penetration depth of the evanescent wave.

Cleaning protocols between samples must be rigorous to prevent cross-contamination. This typically involves solvent cleaning followed by verification scans to confirm complete removal of previous samples. Different crystal materials (diamond, germanium, zinc selenide) may require specific cleaning agents that effectively remove residues without damaging the crystal surface.

For solid samples, particle size reduction through grinding or milling is recommended to ensure uniform contact with the crystal surface. Samples should be ground to a fine powder with particles smaller than the penetration depth of the evanescent wave (typically 0.5-5 μm). This maximizes surface contact and minimizes air gaps that can cause spectral artifacts and reduced signal intensity.

Pressure application is another crucial factor in ATR-FTIR analysis. Most ATR accessories include pressure devices that should be adjusted to provide consistent force across samples. For optimal results, the pressure should be sufficient to ensure good contact without damaging the crystal or deforming the sample structure. Pressure indicators or torque-limited pressure devices help maintain reproducibility between measurements.

Liquid samples require different handling protocols. Small volumes (typically 10-50 μL) should be applied directly to the crystal surface, ensuring complete coverage without overflow. For volatile liquids, sealed or flow-through cells can prevent evaporation during measurement. The crystal should be thoroughly cleaned between samples using appropriate solvents that don't damage the crystal material.

Temperature control during sample preparation and measurement can significantly impact spectral quality. Samples should be equilibrated to ambient or controlled temperature before analysis to prevent thermal gradients that may affect contact quality or cause spectral shifts. For temperature-sensitive materials, specialized ATR accessories with temperature control capabilities are recommended.

Sample homogeneity is essential for representative results. Heterogeneous samples should be thoroughly mixed or measured at multiple points to capture compositional variations. For layered or composite materials, careful positioning is required to ensure the layer of interest contacts the crystal surface within the penetration depth of the evanescent wave.

Cleaning protocols between samples must be rigorous to prevent cross-contamination. This typically involves solvent cleaning followed by verification scans to confirm complete removal of previous samples. Different crystal materials (diamond, germanium, zinc selenide) may require specific cleaning agents that effectively remove residues without damaging the crystal surface.

Quality Control Standards for ATR-FTIR Measurements

To ensure reliable and reproducible ATR-FTIR spectroscopic measurements, comprehensive quality control standards must be established and rigorously followed. These standards serve as the foundation for maintaining data integrity and enabling meaningful comparisons across different samples, instruments, and laboratories.

The primary quality control parameters for ATR-FTIR measurements include spectral resolution, signal-to-noise ratio, baseline stability, and reproducibility metrics. Industry standards typically recommend a minimum spectral resolution of 4 cm^-1 for routine analysis, while more detailed molecular fingerprinting may require resolutions of 2 cm^-1 or better. Signal-to-noise ratios should exceed 5000:1 for standard measurements, calculated using peak-to-peak noise in the 2200-2000 cm^-1 region.

Contact quality between the sample and ATR crystal represents a critical control point that directly impacts spectral quality. Standard protocols should specify optimal pressure application methods, with pressure monitoring systems calibrated to maintain consistent force across measurements. For solid samples, pressure indicators should be employed to ensure uniform contact, while liquid samples require standardized volumes and application techniques to prevent air bubble formation.

Crystal cleanliness verification protocols constitute another essential component of quality standards. Established procedures should include regular background scans against reference materials, with acceptance criteria typically requiring absorbance values below 0.002 AU in key diagnostic regions. Automated software validation tools can flag potential contamination issues before sample analysis begins.

Sample preparation standardization is equally important for preventing overloading effects. Protocols should specify optimal sample quantities based on material type, with particular attention to highly absorbing samples. For powdered materials, particle size standardization through controlled grinding and sieving processes helps ensure consistent optical interaction with the evanescent wave.

Calibration verification using certified reference materials should be performed at scheduled intervals, typically daily for routine operations and hourly for high-precision applications. These reference materials must be traceable to recognized standards organizations such as NIST or equivalent international bodies.

Documentation requirements form the final component of comprehensive quality control standards. All ATR-FTIR measurements should be accompanied by metadata recording instrument parameters, environmental conditions, sample preparation details, and operator information. This documentation enables troubleshooting of anomalous results and supports long-term data integrity across multiple users and instruments.

The primary quality control parameters for ATR-FTIR measurements include spectral resolution, signal-to-noise ratio, baseline stability, and reproducibility metrics. Industry standards typically recommend a minimum spectral resolution of 4 cm^-1 for routine analysis, while more detailed molecular fingerprinting may require resolutions of 2 cm^-1 or better. Signal-to-noise ratios should exceed 5000:1 for standard measurements, calculated using peak-to-peak noise in the 2200-2000 cm^-1 region.

Contact quality between the sample and ATR crystal represents a critical control point that directly impacts spectral quality. Standard protocols should specify optimal pressure application methods, with pressure monitoring systems calibrated to maintain consistent force across measurements. For solid samples, pressure indicators should be employed to ensure uniform contact, while liquid samples require standardized volumes and application techniques to prevent air bubble formation.

Crystal cleanliness verification protocols constitute another essential component of quality standards. Established procedures should include regular background scans against reference materials, with acceptance criteria typically requiring absorbance values below 0.002 AU in key diagnostic regions. Automated software validation tools can flag potential contamination issues before sample analysis begins.

Sample preparation standardization is equally important for preventing overloading effects. Protocols should specify optimal sample quantities based on material type, with particular attention to highly absorbing samples. For powdered materials, particle size standardization through controlled grinding and sieving processes helps ensure consistent optical interaction with the evanescent wave.

Calibration verification using certified reference materials should be performed at scheduled intervals, typically daily for routine operations and hourly for high-precision applications. These reference materials must be traceable to recognized standards organizations such as NIST or equivalent international bodies.

Documentation requirements form the final component of comprehensive quality control standards. All ATR-FTIR measurements should be accompanied by metadata recording instrument parameters, environmental conditions, sample preparation details, and operator information. This documentation enables troubleshooting of anomalous results and supports long-term data integrity across multiple users and instruments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!