ATR-FTIR Penetration Depth: Refractive Index, Angle Of Incidence And Wavelength Dependence

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

ATR-FTIR Technology Background and Objectives

Attenuated Total Reflection Fourier Transform Infrared Spectroscopy (ATR-FTIR) has evolved significantly since its inception in the 1960s, becoming an indispensable analytical technique across multiple industries. The technology leverages the principle of total internal reflection, where an infrared beam passes through a crystal with high refractive index, creating an evanescent wave that penetrates the sample in contact with the crystal surface.

The evolution of ATR-FTIR technology has been marked by continuous improvements in instrumentation, including more sensitive detectors, higher resolution capabilities, and advanced data processing algorithms. These developments have expanded its application from basic chemical identification to sophisticated material characterization, biological sample analysis, and quality control processes in manufacturing.

Understanding penetration depth in ATR-FTIR is crucial as it directly impacts the quality and interpretation of spectral data. The penetration depth—typically ranging from 0.5 to 5 micrometers—determines how deeply the evanescent wave interacts with the sample, affecting the resulting spectral information. This parameter is fundamentally influenced by three key factors: the refractive indices of both the ATR crystal and the sample, the angle of incidence of the infrared beam, and the wavelength of the infrared radiation.

Recent technological trends show increasing interest in variable angle ATR-FTIR systems that allow researchers to manipulate penetration depth for layer-specific analysis. Additionally, there is growing development in specialized ATR crystals with tailored refractive indices for specific applications, particularly in the fields of polymer science, pharmaceutical research, and biological sample analysis.

The primary objective of this technical research is to establish a comprehensive understanding of how refractive index, angle of incidence, and wavelength interdependently affect ATR-FTIR penetration depth. This understanding will enable the optimization of experimental parameters for specific analytical challenges, particularly in complex multi-layered samples or when analyzing trace components.

Secondary objectives include developing predictive models for penetration depth under varying conditions, establishing standardized protocols for different sample types, and exploring novel applications where controlled penetration depth can provide unique analytical advantages. These might include depth profiling in polymer laminates, analyzing concentration gradients in diffusion studies, or characterizing thin films in semiconductor manufacturing.

By advancing our understanding of these fundamental relationships, we aim to enhance the precision, reliability, and application scope of ATR-FTIR spectroscopy, ultimately supporting innovation across multiple industries that rely on this analytical technique.

The evolution of ATR-FTIR technology has been marked by continuous improvements in instrumentation, including more sensitive detectors, higher resolution capabilities, and advanced data processing algorithms. These developments have expanded its application from basic chemical identification to sophisticated material characterization, biological sample analysis, and quality control processes in manufacturing.

Understanding penetration depth in ATR-FTIR is crucial as it directly impacts the quality and interpretation of spectral data. The penetration depth—typically ranging from 0.5 to 5 micrometers—determines how deeply the evanescent wave interacts with the sample, affecting the resulting spectral information. This parameter is fundamentally influenced by three key factors: the refractive indices of both the ATR crystal and the sample, the angle of incidence of the infrared beam, and the wavelength of the infrared radiation.

Recent technological trends show increasing interest in variable angle ATR-FTIR systems that allow researchers to manipulate penetration depth for layer-specific analysis. Additionally, there is growing development in specialized ATR crystals with tailored refractive indices for specific applications, particularly in the fields of polymer science, pharmaceutical research, and biological sample analysis.

The primary objective of this technical research is to establish a comprehensive understanding of how refractive index, angle of incidence, and wavelength interdependently affect ATR-FTIR penetration depth. This understanding will enable the optimization of experimental parameters for specific analytical challenges, particularly in complex multi-layered samples or when analyzing trace components.

Secondary objectives include developing predictive models for penetration depth under varying conditions, establishing standardized protocols for different sample types, and exploring novel applications where controlled penetration depth can provide unique analytical advantages. These might include depth profiling in polymer laminates, analyzing concentration gradients in diffusion studies, or characterizing thin films in semiconductor manufacturing.

By advancing our understanding of these fundamental relationships, we aim to enhance the precision, reliability, and application scope of ATR-FTIR spectroscopy, ultimately supporting innovation across multiple industries that rely on this analytical technique.

Market Applications and Demand Analysis

The ATR-FTIR (Attenuated Total Reflection-Fourier Transform Infrared) spectroscopy market has experienced significant growth in recent years, driven by increasing demand for advanced analytical techniques across multiple industries. The global spectroscopy market, of which ATR-FTIR is a crucial component, was valued at approximately $16.3 billion in 2022 and is projected to grow at a CAGR of 7.2% through 2030.

The pharmaceutical and biotechnology sectors represent the largest market segments for ATR-FTIR technology, accounting for nearly 35% of the total market share. These industries leverage the penetration depth characteristics of ATR-FTIR for drug formulation analysis, quality control, and research applications. The ability to adjust penetration depth through refractive index manipulation and angle of incidence optimization provides pharmaceutical researchers with versatile analytical capabilities for both solid and liquid samples.

Material science and polymer industries constitute the second-largest market segment, with approximately 28% market share. These sectors utilize ATR-FTIR's variable penetration depth capabilities for surface analysis, coating thickness determination, and material composition studies. The wavelength dependence aspect is particularly valuable for identifying specific chemical bonds and functional groups within complex polymer matrices.

Environmental monitoring applications have emerged as the fastest-growing segment, with a projected CAGR of 9.5% through 2030. This growth is driven by increasing regulatory requirements for water quality assessment, soil contamination analysis, and atmospheric pollutant detection. The non-destructive nature of ATR-FTIR and its ability to analyze samples with minimal preparation make it ideal for field-deployable environmental monitoring systems.

The food and beverage industry has also shown increasing adoption of ATR-FTIR technology for quality control, authenticity verification, and contaminant detection. The market in this sector is expected to grow at a CAGR of 8.3% through 2030, driven by stringent food safety regulations and consumer demand for product transparency.

Geographically, North America dominates the ATR-FTIR market with approximately 38% share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is experiencing the fastest growth rate due to expanding pharmaceutical manufacturing, increasing R&D investments, and growing environmental concerns in countries like China, India, and South Korea.

The demand for portable and miniaturized ATR-FTIR systems has increased significantly, with this segment growing at a CAGR of 10.2%. This trend reflects the industry's movement toward point-of-need testing and real-time analysis capabilities, particularly in pharmaceutical manufacturing, environmental monitoring, and food safety applications.

The pharmaceutical and biotechnology sectors represent the largest market segments for ATR-FTIR technology, accounting for nearly 35% of the total market share. These industries leverage the penetration depth characteristics of ATR-FTIR for drug formulation analysis, quality control, and research applications. The ability to adjust penetration depth through refractive index manipulation and angle of incidence optimization provides pharmaceutical researchers with versatile analytical capabilities for both solid and liquid samples.

Material science and polymer industries constitute the second-largest market segment, with approximately 28% market share. These sectors utilize ATR-FTIR's variable penetration depth capabilities for surface analysis, coating thickness determination, and material composition studies. The wavelength dependence aspect is particularly valuable for identifying specific chemical bonds and functional groups within complex polymer matrices.

Environmental monitoring applications have emerged as the fastest-growing segment, with a projected CAGR of 9.5% through 2030. This growth is driven by increasing regulatory requirements for water quality assessment, soil contamination analysis, and atmospheric pollutant detection. The non-destructive nature of ATR-FTIR and its ability to analyze samples with minimal preparation make it ideal for field-deployable environmental monitoring systems.

The food and beverage industry has also shown increasing adoption of ATR-FTIR technology for quality control, authenticity verification, and contaminant detection. The market in this sector is expected to grow at a CAGR of 8.3% through 2030, driven by stringent food safety regulations and consumer demand for product transparency.

Geographically, North America dominates the ATR-FTIR market with approximately 38% share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is experiencing the fastest growth rate due to expanding pharmaceutical manufacturing, increasing R&D investments, and growing environmental concerns in countries like China, India, and South Korea.

The demand for portable and miniaturized ATR-FTIR systems has increased significantly, with this segment growing at a CAGR of 10.2%. This trend reflects the industry's movement toward point-of-need testing and real-time analysis capabilities, particularly in pharmaceutical manufacturing, environmental monitoring, and food safety applications.

Current Challenges in Penetration Depth Control

Despite significant advancements in ATR-FTIR spectroscopy, controlling penetration depth remains a complex challenge that impacts measurement accuracy and reproducibility. The primary difficulty stems from the multivariable nature of penetration depth, which depends simultaneously on refractive indices, angle of incidence, and wavelength parameters. These interdependencies create a complex system where adjusting one variable inevitably affects the others.

A fundamental challenge is the accurate determination of sample refractive indices, which vary significantly across different materials and can change with temperature, pressure, and chemical composition. For heterogeneous or multi-layered samples, the effective refractive index becomes even more difficult to determine precisely, leading to uncertainties in penetration depth calculations.

The angle of incidence presents another significant control challenge. While theoretical models suggest precise angular requirements, practical implementation often suffers from mechanical limitations in commercial ATR accessories. Even minor angular deviations of 0.1-0.2 degrees can result in measurable changes to penetration depth, particularly at angles close to the critical angle. Current instrumentation typically lacks the precision mechanisms needed for fine angular adjustments.

Wavelength dependence adds another layer of complexity, as penetration depth varies across the spectral range. This creates differential sampling depths across a single spectrum, complicating quantitative analysis. For broadband measurements spanning several thousand wavenumbers, the penetration depth can vary by factors of 3-5 across the spectrum, leading to distorted band intensities and peak ratios.

Contact quality between the ATR crystal and sample surface represents a persistent practical challenge. Incomplete or inconsistent contact creates air gaps that dramatically alter the effective penetration depth. For solid samples, applied pressure variations can change the contact area and effective penetration, while liquid samples may experience evaporation or concentration gradients at the interface.

Current mathematical models for penetration depth correction remain inadequate for complex real-world samples. Most models assume homogeneous, isotropic materials with well-defined optical properties, which rarely applies to biological samples, polymer blends, or multi-component mixtures. The lack of robust algorithms that can account for sample heterogeneity and anisotropy limits the accuracy of depth corrections.

Finally, there exists a significant instrumentation gap between research-grade equipment used in academic studies and commercially available systems. Many commercial ATR accessories offer limited control over critical parameters affecting penetration depth, making it difficult to implement theoretical advances in routine analytical settings.

A fundamental challenge is the accurate determination of sample refractive indices, which vary significantly across different materials and can change with temperature, pressure, and chemical composition. For heterogeneous or multi-layered samples, the effective refractive index becomes even more difficult to determine precisely, leading to uncertainties in penetration depth calculations.

The angle of incidence presents another significant control challenge. While theoretical models suggest precise angular requirements, practical implementation often suffers from mechanical limitations in commercial ATR accessories. Even minor angular deviations of 0.1-0.2 degrees can result in measurable changes to penetration depth, particularly at angles close to the critical angle. Current instrumentation typically lacks the precision mechanisms needed for fine angular adjustments.

Wavelength dependence adds another layer of complexity, as penetration depth varies across the spectral range. This creates differential sampling depths across a single spectrum, complicating quantitative analysis. For broadband measurements spanning several thousand wavenumbers, the penetration depth can vary by factors of 3-5 across the spectrum, leading to distorted band intensities and peak ratios.

Contact quality between the ATR crystal and sample surface represents a persistent practical challenge. Incomplete or inconsistent contact creates air gaps that dramatically alter the effective penetration depth. For solid samples, applied pressure variations can change the contact area and effective penetration, while liquid samples may experience evaporation or concentration gradients at the interface.

Current mathematical models for penetration depth correction remain inadequate for complex real-world samples. Most models assume homogeneous, isotropic materials with well-defined optical properties, which rarely applies to biological samples, polymer blends, or multi-component mixtures. The lack of robust algorithms that can account for sample heterogeneity and anisotropy limits the accuracy of depth corrections.

Finally, there exists a significant instrumentation gap between research-grade equipment used in academic studies and commercially available systems. Many commercial ATR accessories offer limited control over critical parameters affecting penetration depth, making it difficult to implement theoretical advances in routine analytical settings.

Existing Methods for Optimizing Penetration Depth

01 Fundamentals of ATR-FTIR penetration depth

Attenuated Total Reflection Fourier Transform Infrared (ATR-FTIR) spectroscopy has a characteristic penetration depth that depends on several factors including the refractive indices of the sample and crystal, the angle of incidence, and the wavelength of the infrared radiation. The penetration depth typically ranges from 0.5 to 5 micrometers, making it suitable for surface analysis. This shallow penetration allows for analysis of thin films, coatings, and surface modifications without extensive sample preparation.- Fundamentals of ATR-FTIR penetration depth: ATR-FTIR spectroscopy operates on the principle of attenuated total reflection, where the penetration depth is determined by several factors including the wavelength of infrared radiation, the refractive indices of the ATR crystal and sample, and the angle of incidence. The penetration depth typically ranges from 0.5 to 5 micrometers, making it suitable for surface analysis. This shallow penetration allows for the examination of thin films, coatings, and surface modifications without extensive sample preparation.

- Advanced ATR crystal materials for controlled penetration depth: Different ATR crystal materials offer varying penetration depths and spectral ranges. Materials such as diamond, germanium, zinc selenide, and silicon provide different refractive indices, affecting the depth of penetration into the sample. Diamond offers durability and a wide spectral range, while germanium provides shallower penetration suitable for strongly absorbing samples. Selection of appropriate crystal material allows researchers to optimize the penetration depth according to specific analytical requirements and sample characteristics.

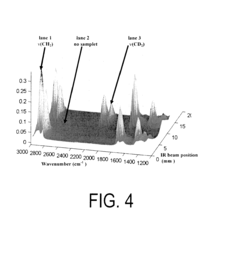

- Variable angle ATR-FTIR for depth profiling: Variable angle ATR-FTIR techniques enable controlled modification of penetration depth by adjusting the incident angle of the infrared beam. This approach allows for non-destructive depth profiling of layered materials and gradient structures. By systematically varying the angle of incidence, different depths within the sample can be probed, providing information about composition changes as a function of depth. This technique is particularly valuable for analyzing multilayer films, coatings, and diffusion processes at interfaces.

- Mathematical models for penetration depth calculation: Mathematical models have been developed to accurately calculate and predict the penetration depth in ATR-FTIR spectroscopy. These models incorporate parameters such as wavelength, refractive indices, incident angle, and polarization state of the infrared radiation. Advanced algorithms allow for the correction of spectral distortions caused by wavelength-dependent penetration depth variations. These computational approaches enable more precise interpretation of ATR-FTIR data, particularly for quantitative analysis and depth profiling applications.

- Applications leveraging controlled penetration depth: The controlled penetration depth of ATR-FTIR spectroscopy has enabled numerous specialized applications across various fields. In biomedical research, it allows for analysis of tissue samples, drug delivery systems, and biofilm formation. In materials science, it facilitates characterization of polymer surfaces, nanocoatings, and interface phenomena. Environmental applications include monitoring of contaminants on surfaces and in thin films. The pharmaceutical industry utilizes this capability for quality control of drug formulations and packaging materials. The shallow and controllable penetration depth makes ATR-FTIR particularly valuable for non-destructive analysis of precious or sensitive samples.

02 Variable penetration depth techniques in ATR-FTIR

Various techniques have been developed to control and modify the penetration depth in ATR-FTIR spectroscopy. These include adjusting the angle of incidence, using different crystal materials with varying refractive indices, and employing multiple reflection elements. Variable angle ATR-FTIR allows researchers to probe different depths within a sample, providing depth-profiling capabilities. These techniques enable more comprehensive analysis of layered materials and gradient compositions in samples.Expand Specific Solutions03 Applications of controlled penetration depth in material analysis

Controlled penetration depth in ATR-FTIR spectroscopy has significant applications in material analysis across various industries. It allows for non-destructive characterization of thin films, coatings, and surface treatments. The technique is particularly valuable for analyzing diffusion processes, chemical gradients, and interfacial phenomena. By manipulating the penetration depth, researchers can obtain spatial information about sample composition and structure, enabling more detailed characterization of complex materials and interfaces.Expand Specific Solutions04 Penetration depth enhancement and measurement techniques

Various methods have been developed to enhance and accurately measure the penetration depth in ATR-FTIR spectroscopy. These include the use of specialized optical configurations, computational algorithms for depth profiling, and calibration techniques using reference materials. Advanced signal processing methods can extract depth-dependent information from spectral data. Some innovations involve combining ATR-FTIR with other analytical techniques to correlate spectral information with physical depth measurements.Expand Specific Solutions05 Biological and pharmaceutical applications of ATR-FTIR penetration depth

The controlled penetration depth of ATR-FTIR spectroscopy makes it particularly valuable for biological and pharmaceutical applications. It allows for analysis of biological membranes, tissue samples, and drug delivery systems without extensive sample preparation. The technique can monitor diffusion of active ingredients through membranes, analyze skin penetration of topical formulations, and characterize biological interfaces. The non-destructive nature and ability to analyze samples in their native state make it ideal for studying biological systems and pharmaceutical formulations.Expand Specific Solutions

Leading Manufacturers and Research Institutions

ATR-FTIR penetration depth technology is currently in a growth phase, with the market expanding due to increasing applications in materials science, pharmaceuticals, and biomedical research. The global spectroscopy market, which includes ATR-FTIR, is projected to reach significant value as demand for advanced analytical techniques grows. Technologically, the field shows varying maturity levels across applications. Leading players include Thermo Fisher Scientific, which dominates with comprehensive instrumentation solutions, while specialized innovators like Photothermal Spectroscopy Corp. focus on novel techniques such as Optical Photothermal IR spectroscopy. Academic institutions (University of Strathclyde, Université Catholique de Louvain) contribute fundamental research, while industrial players (AGC Inc., FUJIFILM) apply these technologies in materials development. Companies like Irubis GmbH and Si-Ware Systems are advancing portable and real-time monitoring applications, indicating a trend toward more accessible and versatile ATR-FTIR solutions.

Thermo Electron Scientific Instruments LLC

Technical Solution: Thermo Electron has developed advanced ATR-FTIR systems that precisely control penetration depth through variable angle of incidence capabilities. Their technology incorporates sophisticated algorithms that account for the relationship between refractive indices of samples and ATR crystals across different wavelengths. Their Smart ATR™ technology automatically adjusts measurement parameters based on sample characteristics, optimizing penetration depth for various applications. The company has pioneered multi-bounce ATR accessories that enhance sensitivity while maintaining precise control over penetration depth. Their systems incorporate real-time penetration depth calculation based on the Harrick equation, accounting for wavelength-dependent refractive index changes to provide more accurate quantitative analysis. Thermo's instruments feature interchangeable crystal options (ZnSe, Ge, Diamond) to accommodate different sample types and desired penetration depths.

Strengths: Industry-leading expertise in ATR-FTIR instrumentation with highly accurate penetration depth control; extensive range of crystal options for different applications; sophisticated software for real-time penetration depth calculations. Weaknesses: Higher cost compared to simpler systems; complex systems may require specialized training; some configurations may have limitations for extremely high refractive index samples.

Photothermal Spectroscopy Corp.

Technical Solution: Photothermal Spectroscopy Corp. has developed innovative O-PTIR (Optical Photothermal Infrared) technology that addresses traditional ATR-FTIR penetration depth limitations. Their approach combines the benefits of FTIR with photothermal detection to achieve submicron spatial resolution while maintaining precise control over penetration depth. The technology uses a tunable quantum cascade laser to excite samples and a probe laser to detect the resulting photothermal response, effectively decoupling the wavelength dependence from the penetration depth. Their mIRage® system incorporates proprietary algorithms that account for refractive index variations across different materials and wavelengths, providing more consistent penetration depth regardless of sample composition. The company has also developed specialized accessories that allow for variable angle measurements, enabling researchers to experimentally validate theoretical penetration depth calculations across different incident angles and wavelengths.

Strengths: Revolutionary approach combining FTIR with photothermal detection; submicron spatial resolution capabilities; reduced wavelength dependence of penetration depth; compatible with a wide range of sample types. Weaknesses: Higher initial investment compared to conventional ATR-FTIR systems; requires specialized training for optimal operation; technology is relatively new with evolving application protocols.

Key Parameters Affecting ATR-FTIR Performance

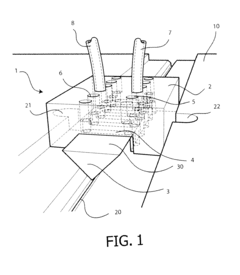

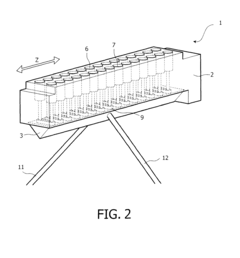

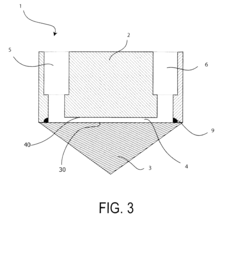

Device for multiple ATR analysis

PatentInactiveEP2116839A1

Innovation

- A device with an ATR element featuring a sample compartment with multiple chambers, allowing for the analysis of multiple samples, and an organic compound for grafting the ATR element to stabilize it against hydrolysis, enabling simultaneous analysis of multiple samples and improving surface stability.

Material Science Implications of ATR-FTIR Analysis

ATR-FTIR analysis has profound implications for material science, extending far beyond its analytical capabilities. The penetration depth characteristics of ATR-FTIR, influenced by refractive index, angle of incidence, and wavelength, directly impact how materials can be characterized and understood at their interfaces and surfaces.

The variable penetration depth of ATR-FTIR enables depth profiling of materials, allowing scientists to examine compositional changes from surface to subsurface regions without destructive sampling. This capability is particularly valuable for studying gradient materials, coatings, and layered structures where properties change with depth.

For polymer science, ATR-FTIR penetration characteristics facilitate the study of crystallization, cross-linking, and degradation processes at different depths. The technique's sensitivity to refractive index makes it especially useful for monitoring phase transitions and structural reorganizations within polymeric materials, providing insights into processing-structure-property relationships.

In thin film technology, precise control of penetration depth through manipulation of incident angle and wavelength selection allows researchers to characterize films with thicknesses ranging from nanometers to micrometers. This has accelerated development in fields such as semiconductor manufacturing, optical coatings, and barrier films where precise thickness control and interfacial properties are critical.

The dependence of penetration depth on refractive index differences has enabled new approaches to studying material interfaces. By selecting appropriate experimental parameters, scientists can enhance sensitivity to interfacial phenomena such as adsorption, diffusion, and chemical reactions occurring at material boundaries, which are crucial for adhesion, catalysis, and sensor applications.

For composite materials, the wavelength dependence of ATR-FTIR penetration provides opportunities to selectively probe different components based on their spectral characteristics. This selective analysis helps in understanding component distribution, interfacial bonding, and failure mechanisms in complex material systems.

The technique's non-destructive nature, combined with controlled penetration depth, has revolutionized in-situ monitoring of material processes including curing, aging, and environmental degradation. This real-time analytical capability has accelerated material development cycles and improved quality control procedures across industries ranging from pharmaceuticals to advanced manufacturing.

As material science increasingly focuses on nanoscale phenomena and surface-dominated properties, the ability to precisely control ATR-FTIR penetration depth through adjustment of refractive index matching, incident angle optimization, and wavelength selection has become an essential tool in the development of next-generation materials with tailored surface and interfacial properties.

The variable penetration depth of ATR-FTIR enables depth profiling of materials, allowing scientists to examine compositional changes from surface to subsurface regions without destructive sampling. This capability is particularly valuable for studying gradient materials, coatings, and layered structures where properties change with depth.

For polymer science, ATR-FTIR penetration characteristics facilitate the study of crystallization, cross-linking, and degradation processes at different depths. The technique's sensitivity to refractive index makes it especially useful for monitoring phase transitions and structural reorganizations within polymeric materials, providing insights into processing-structure-property relationships.

In thin film technology, precise control of penetration depth through manipulation of incident angle and wavelength selection allows researchers to characterize films with thicknesses ranging from nanometers to micrometers. This has accelerated development in fields such as semiconductor manufacturing, optical coatings, and barrier films where precise thickness control and interfacial properties are critical.

The dependence of penetration depth on refractive index differences has enabled new approaches to studying material interfaces. By selecting appropriate experimental parameters, scientists can enhance sensitivity to interfacial phenomena such as adsorption, diffusion, and chemical reactions occurring at material boundaries, which are crucial for adhesion, catalysis, and sensor applications.

For composite materials, the wavelength dependence of ATR-FTIR penetration provides opportunities to selectively probe different components based on their spectral characteristics. This selective analysis helps in understanding component distribution, interfacial bonding, and failure mechanisms in complex material systems.

The technique's non-destructive nature, combined with controlled penetration depth, has revolutionized in-situ monitoring of material processes including curing, aging, and environmental degradation. This real-time analytical capability has accelerated material development cycles and improved quality control procedures across industries ranging from pharmaceuticals to advanced manufacturing.

As material science increasingly focuses on nanoscale phenomena and surface-dominated properties, the ability to precisely control ATR-FTIR penetration depth through adjustment of refractive index matching, incident angle optimization, and wavelength selection has become an essential tool in the development of next-generation materials with tailored surface and interfacial properties.

Standardization and Calibration Protocols

The standardization and calibration of ATR-FTIR measurements are critical for ensuring reproducible and comparable results across different instruments and experimental setups. Current protocols exhibit significant variations, leading to inconsistencies in penetration depth calculations and subsequent data interpretation.

Establishing universal reference materials is essential for calibration purposes. Silicon, germanium, and zinc selenide are commonly used as ATR crystal materials, each requiring specific calibration approaches due to their unique refractive indices. A comprehensive calibration protocol should include verification using these materials across multiple wavelengths to account for dispersion effects.

Angle of incidence standardization represents another critical aspect, as even minor deviations can significantly alter penetration depth calculations. Current best practices recommend calibration at standard angles (typically 45°, 60°, and sometimes 30°) with verification using reference samples of known optical properties. Documentation of the exact angle used is paramount for result reproducibility.

Wavelength-dependent calibration procedures must address the variable penetration depth across the infrared spectrum. Calibration curves should be established using reference materials with well-characterized absorption bands at different wavelengths. This approach enables the development of correction factors that can be applied to compensate for wavelength-dependent variations in penetration depth.

Temperature control during calibration has emerged as a significant factor affecting measurement accuracy. Recent studies indicate that temperature fluctuations can alter refractive indices of both the ATR crystal and sample materials. Standardized protocols increasingly recommend temperature stabilization at 25°C ± 0.5°C during calibration procedures and subsequent measurements.

Interlaboratory validation studies have highlighted the need for round-robin testing to establish reproducibility limits for penetration depth measurements. Such collaborative efforts have led to the development of statistical confidence intervals for measurements at various combinations of refractive indices, angles, and wavelengths.

Digital calibration tools and software solutions are gaining prominence in standardization efforts. These tools incorporate theoretical models with empirical correction factors to provide real-time adjustments for penetration depth calculations based on input parameters. The integration of machine learning algorithms for automated calibration represents an emerging trend in this field.

Establishing universal reference materials is essential for calibration purposes. Silicon, germanium, and zinc selenide are commonly used as ATR crystal materials, each requiring specific calibration approaches due to their unique refractive indices. A comprehensive calibration protocol should include verification using these materials across multiple wavelengths to account for dispersion effects.

Angle of incidence standardization represents another critical aspect, as even minor deviations can significantly alter penetration depth calculations. Current best practices recommend calibration at standard angles (typically 45°, 60°, and sometimes 30°) with verification using reference samples of known optical properties. Documentation of the exact angle used is paramount for result reproducibility.

Wavelength-dependent calibration procedures must address the variable penetration depth across the infrared spectrum. Calibration curves should be established using reference materials with well-characterized absorption bands at different wavelengths. This approach enables the development of correction factors that can be applied to compensate for wavelength-dependent variations in penetration depth.

Temperature control during calibration has emerged as a significant factor affecting measurement accuracy. Recent studies indicate that temperature fluctuations can alter refractive indices of both the ATR crystal and sample materials. Standardized protocols increasingly recommend temperature stabilization at 25°C ± 0.5°C during calibration procedures and subsequent measurements.

Interlaboratory validation studies have highlighted the need for round-robin testing to establish reproducibility limits for penetration depth measurements. Such collaborative efforts have led to the development of statistical confidence intervals for measurements at various combinations of refractive indices, angles, and wavelengths.

Digital calibration tools and software solutions are gaining prominence in standardization efforts. These tools incorporate theoretical models with empirical correction factors to provide real-time adjustments for penetration depth calculations based on input parameters. The integration of machine learning algorithms for automated calibration represents an emerging trend in this field.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!