ATR-FTIR Reaction Monitoring: Real-Time Spectra, Time Resolution And Flow Cells

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

ATR-FTIR Technology Evolution and Objectives

Attenuated Total Reflection Fourier Transform Infrared (ATR-FTIR) spectroscopy has evolved significantly since its inception in the mid-20th century. Initially developed as a surface analysis technique, ATR-FTIR has transformed into a powerful tool for real-time reaction monitoring across various industries. The technology leverages the principle of total internal reflection, where an infrared beam reflects within a crystal medium in contact with a sample, creating an evanescent wave that penetrates the sample surface.

The evolution of ATR-FTIR technology can be traced through several key developmental phases. In the 1960s, the basic principles of ATR were established, primarily focusing on qualitative analysis of solid and liquid samples. The 1980s witnessed the integration of FTIR with ATR accessories, significantly enhancing spectral quality and acquisition speed. By the 1990s, advancements in computing power and algorithm development enabled more sophisticated data processing capabilities.

The early 2000s marked a pivotal shift toward in-situ and real-time applications, particularly in reaction monitoring. This period saw the emergence of specialized flow cells and time-resolved spectroscopy techniques that allowed chemists and process engineers to observe chemical transformations as they occurred. The miniaturization of components and improvements in detector sensitivity further expanded the technology's applicability.

Recent technological advancements have focused on enhancing time resolution capabilities, with modern systems capable of collecting spectra at sub-second intervals. This temporal precision is crucial for monitoring fast reactions and capturing transient intermediates. Parallel developments in flow cell design have improved sample handling, temperature control, and pressure resistance, enabling applications under diverse reaction conditions.

The primary objectives of current ATR-FTIR reaction monitoring technology development are multifaceted. First, there is a push toward higher spectral resolution and sensitivity to detect minor components and subtle chemical changes during reactions. Second, researchers aim to further improve time resolution to capture increasingly rapid reaction dynamics. Third, there is significant interest in developing more robust and versatile flow cell designs that can withstand extreme conditions while maintaining spectral quality.

Another key objective is the integration of ATR-FTIR systems with other analytical techniques and process control systems, creating comprehensive reaction monitoring platforms. Additionally, there is growing emphasis on developing advanced chemometric methods and machine learning algorithms to extract meaningful information from complex spectral datasets in real-time, enabling automated decision-making in industrial processes.

The technology continues to evolve toward more user-friendly interfaces, reduced instrument footprint, and lower operational costs, making ATR-FTIR reaction monitoring more accessible across various research and industrial settings. These developments collectively aim to establish ATR-FTIR as an indispensable tool for reaction optimization, quality control, and process understanding.

The evolution of ATR-FTIR technology can be traced through several key developmental phases. In the 1960s, the basic principles of ATR were established, primarily focusing on qualitative analysis of solid and liquid samples. The 1980s witnessed the integration of FTIR with ATR accessories, significantly enhancing spectral quality and acquisition speed. By the 1990s, advancements in computing power and algorithm development enabled more sophisticated data processing capabilities.

The early 2000s marked a pivotal shift toward in-situ and real-time applications, particularly in reaction monitoring. This period saw the emergence of specialized flow cells and time-resolved spectroscopy techniques that allowed chemists and process engineers to observe chemical transformations as they occurred. The miniaturization of components and improvements in detector sensitivity further expanded the technology's applicability.

Recent technological advancements have focused on enhancing time resolution capabilities, with modern systems capable of collecting spectra at sub-second intervals. This temporal precision is crucial for monitoring fast reactions and capturing transient intermediates. Parallel developments in flow cell design have improved sample handling, temperature control, and pressure resistance, enabling applications under diverse reaction conditions.

The primary objectives of current ATR-FTIR reaction monitoring technology development are multifaceted. First, there is a push toward higher spectral resolution and sensitivity to detect minor components and subtle chemical changes during reactions. Second, researchers aim to further improve time resolution to capture increasingly rapid reaction dynamics. Third, there is significant interest in developing more robust and versatile flow cell designs that can withstand extreme conditions while maintaining spectral quality.

Another key objective is the integration of ATR-FTIR systems with other analytical techniques and process control systems, creating comprehensive reaction monitoring platforms. Additionally, there is growing emphasis on developing advanced chemometric methods and machine learning algorithms to extract meaningful information from complex spectral datasets in real-time, enabling automated decision-making in industrial processes.

The technology continues to evolve toward more user-friendly interfaces, reduced instrument footprint, and lower operational costs, making ATR-FTIR reaction monitoring more accessible across various research and industrial settings. These developments collectively aim to establish ATR-FTIR as an indispensable tool for reaction optimization, quality control, and process understanding.

Market Demand for Real-Time Reaction Monitoring

The global market for real-time reaction monitoring technologies has experienced significant growth in recent years, driven by increasing demands for process optimization and quality control across various industries. The pharmaceutical sector represents the largest market segment, accounting for approximately 40% of the total demand, followed by chemical manufacturing at 25% and academic research at 20%.

Real-time monitoring solutions like ATR-FTIR (Attenuated Total Reflection-Fourier Transform Infrared) spectroscopy are becoming essential tools in modern laboratories and production facilities. Market research indicates that the global market for spectroscopic reaction monitoring systems reached $1.2 billion in 2022 and is projected to grow at a compound annual growth rate of 8.7% through 2028.

The primary market drivers include stringent regulatory requirements for product quality and safety, particularly in pharmaceutical manufacturing where the FDA's Process Analytical Technology (PAT) initiative continues to influence adoption. Additionally, the push toward continuous manufacturing processes across industries has created substantial demand for inline monitoring capabilities that ATR-FTIR systems provide.

Cost reduction pressures represent another significant market force. Real-time monitoring enables immediate detection of process deviations, reducing waste and improving resource efficiency. Studies have shown that implementation of real-time monitoring technologies can reduce production costs by 15-20% through optimization of reaction conditions and minimization of failed batches.

The COVID-19 pandemic has accelerated market growth by highlighting vulnerabilities in global supply chains and increasing emphasis on domestic manufacturing capabilities, particularly for pharmaceuticals and specialty chemicals. This has led to increased investment in advanced manufacturing technologies, including real-time monitoring systems.

Regional analysis reveals North America as the largest market for reaction monitoring technologies, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is experiencing the fastest growth rate, driven by rapid industrialization in China and India, along with increasing adoption of quality control standards.

Customer requirements are evolving toward more integrated solutions that combine hardware, software, and data analytics capabilities. End-users increasingly demand systems that not only provide spectroscopic data but also offer automated interpretation, predictive capabilities, and integration with manufacturing execution systems. Time resolution capabilities and miniaturization of flow cells are becoming key differentiating factors in purchasing decisions.

Real-time monitoring solutions like ATR-FTIR (Attenuated Total Reflection-Fourier Transform Infrared) spectroscopy are becoming essential tools in modern laboratories and production facilities. Market research indicates that the global market for spectroscopic reaction monitoring systems reached $1.2 billion in 2022 and is projected to grow at a compound annual growth rate of 8.7% through 2028.

The primary market drivers include stringent regulatory requirements for product quality and safety, particularly in pharmaceutical manufacturing where the FDA's Process Analytical Technology (PAT) initiative continues to influence adoption. Additionally, the push toward continuous manufacturing processes across industries has created substantial demand for inline monitoring capabilities that ATR-FTIR systems provide.

Cost reduction pressures represent another significant market force. Real-time monitoring enables immediate detection of process deviations, reducing waste and improving resource efficiency. Studies have shown that implementation of real-time monitoring technologies can reduce production costs by 15-20% through optimization of reaction conditions and minimization of failed batches.

The COVID-19 pandemic has accelerated market growth by highlighting vulnerabilities in global supply chains and increasing emphasis on domestic manufacturing capabilities, particularly for pharmaceuticals and specialty chemicals. This has led to increased investment in advanced manufacturing technologies, including real-time monitoring systems.

Regional analysis reveals North America as the largest market for reaction monitoring technologies, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is experiencing the fastest growth rate, driven by rapid industrialization in China and India, along with increasing adoption of quality control standards.

Customer requirements are evolving toward more integrated solutions that combine hardware, software, and data analytics capabilities. End-users increasingly demand systems that not only provide spectroscopic data but also offer automated interpretation, predictive capabilities, and integration with manufacturing execution systems. Time resolution capabilities and miniaturization of flow cells are becoming key differentiating factors in purchasing decisions.

Current Capabilities and Limitations of ATR-FTIR

ATR-FTIR technology currently offers significant capabilities for reaction monitoring in both laboratory and industrial settings. The technique provides real-time spectroscopic data with minimal sample preparation, allowing researchers to observe chemical transformations as they occur. Modern ATR-FTIR systems can achieve spectral acquisition rates of up to 100 scans per second, enabling the monitoring of reactions with half-lives in the range of seconds to minutes with reasonable temporal resolution.

The sensitivity of current ATR-FTIR systems allows for detection of components at concentrations as low as 0.1% in many reaction mixtures, though this varies significantly depending on the specific molecular structures and their IR absorption characteristics. Most commercial systems operate in the mid-IR range (4000-400 cm⁻¹), providing detailed structural information about functional groups and their transformations during reactions.

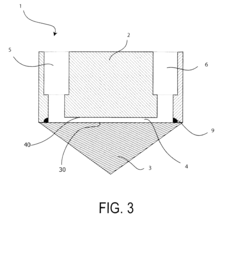

Flow cell designs have substantially improved in recent years, with materials resistant to a wide range of solvents and reaction conditions. Diamond ATR elements, in particular, offer exceptional chemical resistance and durability, withstanding harsh reaction environments including strong acids, bases, and temperatures up to 200°C in some configurations. Modern flow cells can operate at pressures up to 200 bar, making them suitable for monitoring reactions under supercritical conditions.

Despite these advances, ATR-FTIR technology faces several limitations. The penetration depth of the evanescent wave is typically limited to 0.5-2 μm, restricting analysis to the interface region and potentially missing information from the bulk reaction mixture. This becomes particularly problematic in heterogeneous reactions or those involving precipitation.

Time resolution remains a challenge for extremely fast reactions, as the need to collect multiple scans to improve signal-to-noise ratios inherently limits temporal resolution. Even with rapid scanning capabilities, reactions with half-lives below one second are difficult to monitor effectively with current ATR-FTIR systems.

Water presents a significant challenge due to its strong IR absorption, which can mask signals from other components in aqueous reactions. This limitation is particularly relevant for biochemical reactions and green chemistry applications where water is the preferred solvent.

Quantitative analysis can be complex, as the ATR effect depends on refractive indices that may change during reactions, affecting the effective path length. This introduces uncertainties in concentration measurements, especially in systems with varying composition or temperature.

Integration with other analytical techniques remains limited, with few commercial systems offering seamless combination of ATR-FTIR with complementary methods like Raman spectroscopy or mass spectrometry, which would provide more comprehensive reaction monitoring capabilities.

The sensitivity of current ATR-FTIR systems allows for detection of components at concentrations as low as 0.1% in many reaction mixtures, though this varies significantly depending on the specific molecular structures and their IR absorption characteristics. Most commercial systems operate in the mid-IR range (4000-400 cm⁻¹), providing detailed structural information about functional groups and their transformations during reactions.

Flow cell designs have substantially improved in recent years, with materials resistant to a wide range of solvents and reaction conditions. Diamond ATR elements, in particular, offer exceptional chemical resistance and durability, withstanding harsh reaction environments including strong acids, bases, and temperatures up to 200°C in some configurations. Modern flow cells can operate at pressures up to 200 bar, making them suitable for monitoring reactions under supercritical conditions.

Despite these advances, ATR-FTIR technology faces several limitations. The penetration depth of the evanescent wave is typically limited to 0.5-2 μm, restricting analysis to the interface region and potentially missing information from the bulk reaction mixture. This becomes particularly problematic in heterogeneous reactions or those involving precipitation.

Time resolution remains a challenge for extremely fast reactions, as the need to collect multiple scans to improve signal-to-noise ratios inherently limits temporal resolution. Even with rapid scanning capabilities, reactions with half-lives below one second are difficult to monitor effectively with current ATR-FTIR systems.

Water presents a significant challenge due to its strong IR absorption, which can mask signals from other components in aqueous reactions. This limitation is particularly relevant for biochemical reactions and green chemistry applications where water is the preferred solvent.

Quantitative analysis can be complex, as the ATR effect depends on refractive indices that may change during reactions, affecting the effective path length. This introduces uncertainties in concentration measurements, especially in systems with varying composition or temperature.

Integration with other analytical techniques remains limited, with few commercial systems offering seamless combination of ATR-FTIR with complementary methods like Raman spectroscopy or mass spectrometry, which would provide more comprehensive reaction monitoring capabilities.

Contemporary ATR-FTIR Flow Cell Designs

01 Real-time ATR-FTIR monitoring systems for chemical reactions

Advanced ATR-FTIR systems designed specifically for real-time monitoring of chemical reactions, allowing researchers to track reaction progress with high temporal resolution. These systems integrate attenuated total reflection infrared spectroscopy with specialized reaction vessels or flow cells to provide continuous data acquisition during chemical transformations, enabling detection of intermediates and determination of reaction kinetics.- Real-time ATR-FTIR monitoring systems for chemical reactions: Advanced ATR-FTIR systems designed specifically for real-time monitoring of chemical reactions, allowing researchers to track reaction progress with high temporal resolution. These systems integrate attenuated total reflection (ATR) technology with Fourier transform infrared spectroscopy to provide continuous data collection during reaction processes, enabling detection of transient species and reaction intermediates.

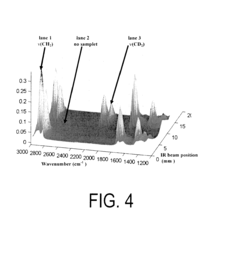

- Time resolution enhancement techniques for ATR-FTIR monitoring: Methods to improve the time resolution of ATR-FTIR reaction monitoring, including rapid-scan techniques, step-scan methodologies, and advanced data processing algorithms. These approaches enable millisecond or even microsecond time resolution for capturing fast reaction kinetics and transient species, significantly enhancing the analytical capabilities of ATR-FTIR for dynamic chemical processes.

- Integrated microfluidic ATR-FTIR systems: Miniaturized ATR-FTIR systems integrated with microfluidic platforms for high-throughput reaction monitoring with improved time resolution. These systems combine the advantages of microfluidic technology (small sample volumes, precise control of reaction conditions) with the analytical power of ATR-FTIR spectroscopy, enabling continuous monitoring of reactions in flow with enhanced temporal resolution.

- Data processing algorithms for ATR-FTIR temporal analysis: Specialized software and algorithms developed for processing time-resolved ATR-FTIR spectral data, including chemometric methods, machine learning approaches, and multivariate analysis techniques. These computational tools enable extraction of kinetic information from complex spectral datasets, automatic identification of reaction endpoints, and enhanced signal-to-noise ratios for improved time resolution.

- Industrial applications of time-resolved ATR-FTIR monitoring: Implementation of time-resolved ATR-FTIR monitoring systems in industrial settings for quality control, process optimization, and continuous manufacturing. These applications demonstrate how high temporal resolution ATR-FTIR techniques can be scaled up from laboratory to production environments, providing real-time feedback for process control and ensuring consistent product quality in pharmaceutical, chemical, and materials manufacturing.

02 Time resolution enhancement techniques for ATR-FTIR monitoring

Methods to improve the temporal resolution of ATR-FTIR reaction monitoring, including advanced data acquisition protocols, specialized hardware configurations, and signal processing algorithms. These techniques enable faster sampling rates and improved signal-to-noise ratios, allowing for the detection of rapid reaction events and transient species that might otherwise be missed with conventional FTIR monitoring approaches.Expand Specific Solutions03 Integrated microfluidic ATR-FTIR systems for reaction monitoring

Miniaturized ATR-FTIR systems incorporating microfluidic technology for high-resolution reaction monitoring in small volumes. These systems combine the advantages of microfluidic reactors (precise control of reaction conditions, minimal reagent consumption) with the analytical capabilities of ATR-FTIR spectroscopy, enabling detailed chemical analysis with improved time resolution due to reduced diffusion distances and optimized flow dynamics.Expand Specific Solutions04 Data processing algorithms for ATR-FTIR temporal resolution

Specialized software and algorithms developed to enhance the temporal resolution of ATR-FTIR reaction monitoring data. These computational approaches include chemometric methods, machine learning techniques, and advanced signal processing to extract maximum information from spectral data, reduce noise, resolve overlapping peaks, and identify subtle spectral changes that indicate reaction progress or formation of intermediates.Expand Specific Solutions05 In-situ ATR-FTIR probes with enhanced time resolution

Specialized ATR-FTIR probe designs that can be inserted directly into reaction vessels to provide enhanced temporal resolution for reaction monitoring. These probes feature optimized optical configurations, robust materials resistant to various reaction conditions, and designs that minimize interference with the reaction while maximizing signal quality, enabling researchers to obtain high-quality spectral data with improved time resolution.Expand Specific Solutions

Leading Manufacturers and Research Institutions

ATR-FTIR reaction monitoring technology is currently in a growth phase, with increasing adoption across pharmaceutical and chemical industries. The market size is expanding steadily, driven by demand for real-time analytical solutions in process development and manufacturing. Technologically, the field shows moderate maturity with ongoing innovations in time resolution capabilities and flow cell designs. Key players include Agilent Technologies and Bruker BioSpin MRI, who lead commercial instrumentation development, while Daylight Solutions specializes in tunable laser technology enhancing spectral acquisition. Academic institutions like Heriot-Watt University and Technical University of Denmark are advancing fundamental research, while pharmaceutical companies such as Sunshine Lake Pharma are implementing these technologies in drug development workflows. Research organizations including Battelle Memorial Institute and Fraunhofer-Gesellschaft are bridging the gap between academic innovation and industrial application.

Daylight Solutions, Inc.

Technical Solution: Daylight Solutions has developed innovative quantum cascade laser (QCL) based mid-IR spectroscopy systems for reaction monitoring that complement traditional FTIR approaches. Their technology combines tunable QCL sources with ATR sampling interfaces to achieve unprecedented time resolution (down to milliseconds) for reaction monitoring. The company's MIRcat™ platform integrates with specialized flow cells featuring diamond ATR elements optimized for both aqueous and organic reaction systems. Their proprietary software enables real-time spectral acquisition and processing, with capabilities for multivariate analysis and reaction kinetics modeling. The system's high spectral brightness allows for enhanced sensitivity in detecting low-concentration intermediates and monitoring reactions in challenging media including heterogeneous mixtures.

Strengths: Superior time resolution compared to conventional FTIR systems; exceptional sensitivity for trace component detection; compact form factor enabling integration with various reaction setups. Weaknesses: More limited spectral range compared to traditional FTIR; higher cost for QCL technology; requires specialized knowledge for system optimization.

Agilent Technologies, Inc.

Technical Solution: Agilent has developed advanced ATR-FTIR reaction monitoring systems featuring their proprietary ReactIR technology. Their solution integrates diamond ATR probes with high-performance FTIR spectrometers to enable real-time chemical reaction monitoring with sub-second time resolution. The system employs sophisticated chemometric algorithms for multivariate data analysis, allowing researchers to track reaction progress, identify intermediates, and determine endpoints with exceptional precision. Agilent's platform includes specialized flow cells designed for both batch and continuous flow chemistry applications, with temperature control capabilities ranging from -80°C to 300°C. Their software suite provides automated background correction and spectral processing to enhance data quality and interpretation efficiency.

Strengths: Industry-leading spectral resolution (up to 0.5 cm⁻¹) and time resolution (as fast as 0.1s); robust diamond ATR probes resistant to harsh chemical environments; comprehensive software for data analysis. Weaknesses: Higher cost compared to competitors; requires specialized training for optimal operation; limited compatibility with some solvent systems.

Critical Innovations in Time-Resolved Spectroscopy

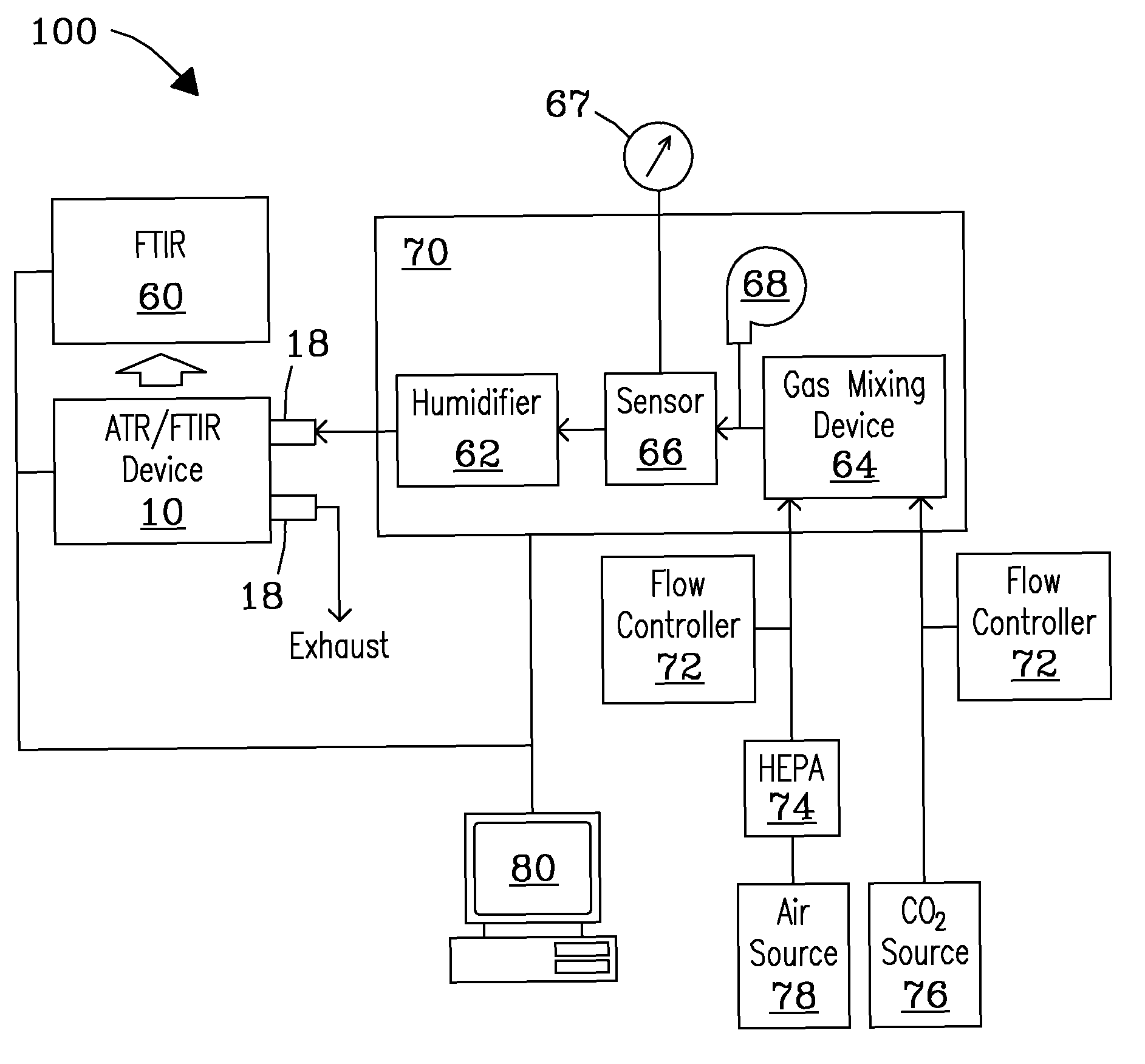

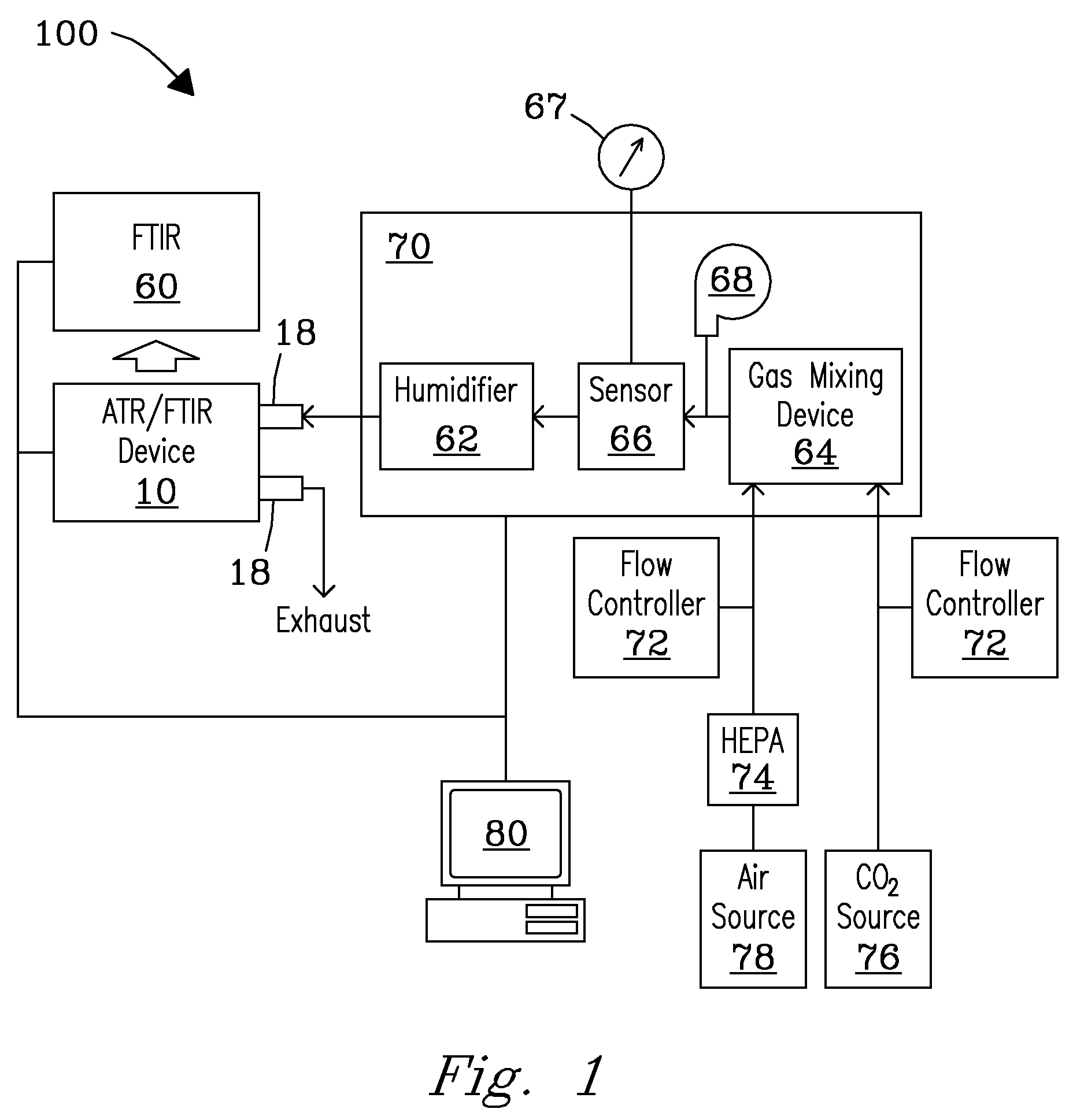

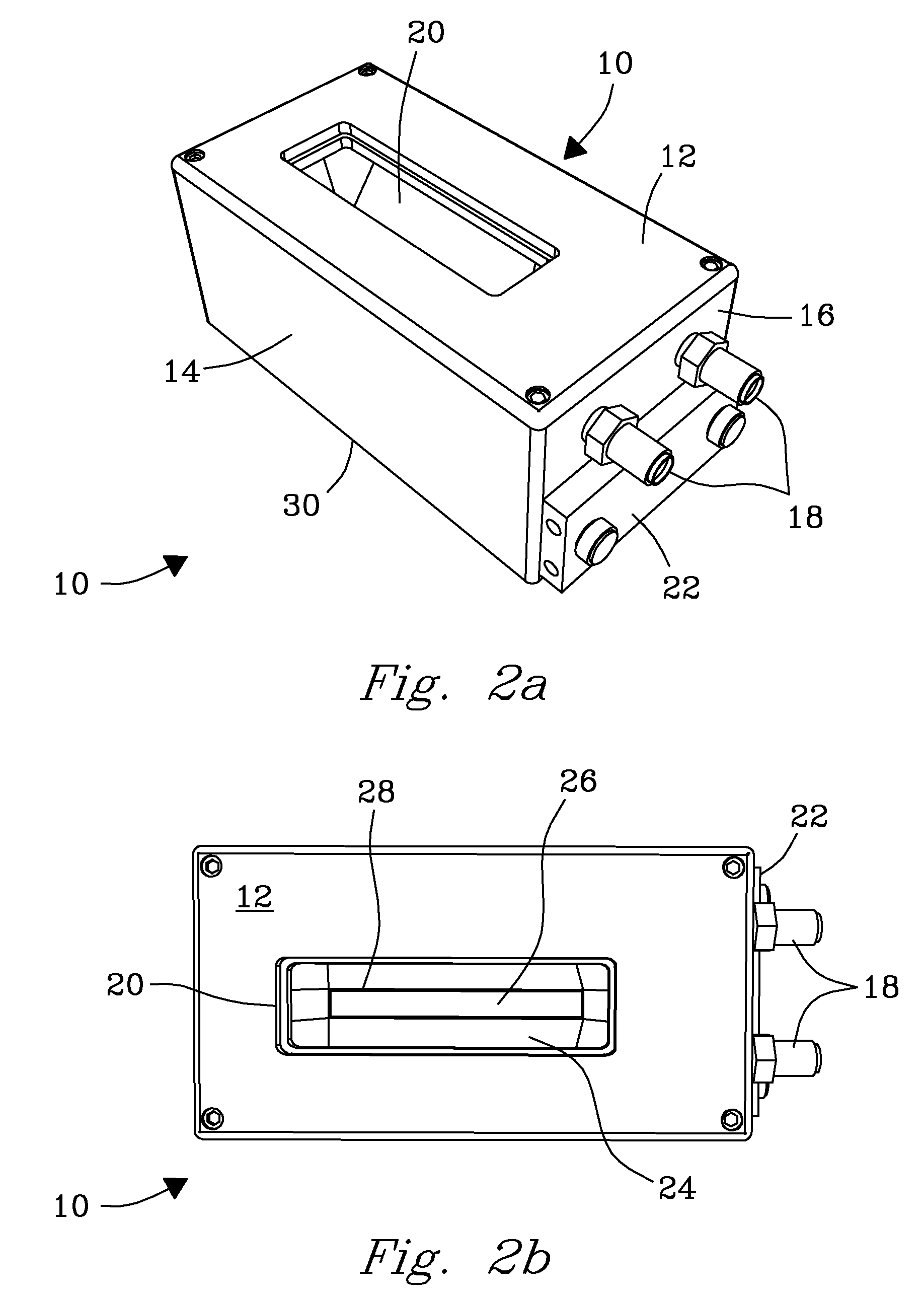

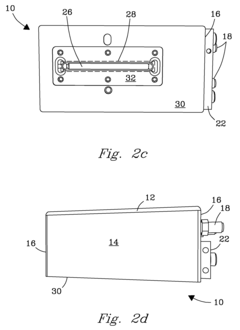

System, device, and methods for real-time screening of live cells, biomarkers, and chemical signatures

PatentInactiveUS7956328B2

Innovation

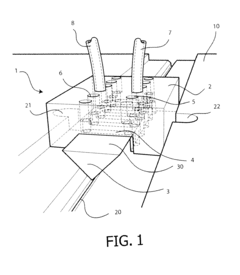

- A device and system that includes a structured growth material on an ATR substrate within a growth-supporting environment, allowing live cells to be affixed and monitored for extended periods, coupled with an FTIR instrument, featuring a customizable substrate material, functionalization layers for cell adhesion, and environmental controls for temperature, humidity, and gas levels, enabling continuous real-time data collection.

Device for multiple ATR analysis

PatentInactiveEP2116839A1

Innovation

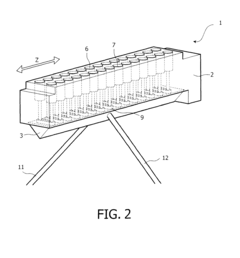

- A device with an ATR element featuring a sample compartment with multiple chambers, allowing for the analysis of multiple samples, and an organic compound for grafting the ATR element to stabilize it against hydrolysis, enabling simultaneous analysis of multiple samples and improving surface stability.

Integration with Process Analytical Technology (PAT)

The integration of ATR-FTIR reaction monitoring systems with Process Analytical Technology (PAT) frameworks represents a significant advancement in pharmaceutical and chemical manufacturing processes. PAT, as defined by regulatory bodies like the FDA, encompasses systems that design, analyze, and control manufacturing through timely measurements of critical quality attributes and performance attributes of raw and in-process materials.

ATR-FTIR technology serves as a cornerstone analytical tool within the PAT ecosystem, providing real-time molecular-level insights during chemical reactions. This integration enables continuous quality verification rather than relying solely on end-product testing, aligning perfectly with Quality by Design (QbD) principles that emphasize building quality into products from the development stage.

The implementation of ATR-FTIR within PAT frameworks typically involves strategic placement of probes at critical control points throughout the manufacturing process. These probes continuously collect spectral data that is fed into chemometric models and multivariate data analysis systems. The resulting information allows for real-time process understanding and control, facilitating immediate intervention when deviations occur.

Modern PAT implementations featuring ATR-FTIR technology increasingly incorporate advanced data management systems that handle the substantial volume of spectral information generated during continuous monitoring. These systems often employ machine learning algorithms to identify patterns and predict process outcomes, transforming raw spectral data into actionable intelligence for process engineers and operators.

The regulatory landscape strongly supports this integration, with initiatives like the FDA's PAT Framework and ICH Q8-Q12 guidelines encouraging adoption of innovative analytical technologies. Companies implementing ATR-FTIR within their PAT strategy often report significant benefits, including reduced batch failures, decreased cycle times, and improved process understanding.

Flow cell designs for ATR-FTIR have evolved specifically to meet PAT requirements, featuring robust construction materials compatible with GMP environments, CIP/SIP capabilities, and integration with distributed control systems. These specialized flow cells enable seamless incorporation into existing manufacturing equipment while maintaining the analytical precision required for regulatory compliance.

Time resolution capabilities of modern ATR-FTIR systems align well with PAT needs, allowing for detection of transient species and rapid reaction events that might otherwise go unnoticed in traditional quality control approaches. This temporal advantage enables more sophisticated process control strategies, including feedback and feedforward control loops based on spectral information.

ATR-FTIR technology serves as a cornerstone analytical tool within the PAT ecosystem, providing real-time molecular-level insights during chemical reactions. This integration enables continuous quality verification rather than relying solely on end-product testing, aligning perfectly with Quality by Design (QbD) principles that emphasize building quality into products from the development stage.

The implementation of ATR-FTIR within PAT frameworks typically involves strategic placement of probes at critical control points throughout the manufacturing process. These probes continuously collect spectral data that is fed into chemometric models and multivariate data analysis systems. The resulting information allows for real-time process understanding and control, facilitating immediate intervention when deviations occur.

Modern PAT implementations featuring ATR-FTIR technology increasingly incorporate advanced data management systems that handle the substantial volume of spectral information generated during continuous monitoring. These systems often employ machine learning algorithms to identify patterns and predict process outcomes, transforming raw spectral data into actionable intelligence for process engineers and operators.

The regulatory landscape strongly supports this integration, with initiatives like the FDA's PAT Framework and ICH Q8-Q12 guidelines encouraging adoption of innovative analytical technologies. Companies implementing ATR-FTIR within their PAT strategy often report significant benefits, including reduced batch failures, decreased cycle times, and improved process understanding.

Flow cell designs for ATR-FTIR have evolved specifically to meet PAT requirements, featuring robust construction materials compatible with GMP environments, CIP/SIP capabilities, and integration with distributed control systems. These specialized flow cells enable seamless incorporation into existing manufacturing equipment while maintaining the analytical precision required for regulatory compliance.

Time resolution capabilities of modern ATR-FTIR systems align well with PAT needs, allowing for detection of transient species and rapid reaction events that might otherwise go unnoticed in traditional quality control approaches. This temporal advantage enables more sophisticated process control strategies, including feedback and feedforward control loops based on spectral information.

Data Processing Algorithms for Spectral Analysis

In the realm of ATR-FTIR reaction monitoring, data processing algorithms play a pivotal role in transforming raw spectral data into meaningful chemical insights. These algorithms encompass a range of mathematical and computational techniques designed to enhance signal quality, extract relevant information, and facilitate interpretation of complex spectral datasets.

Preprocessing algorithms form the foundation of spectral analysis, addressing common challenges such as baseline correction, noise reduction, and spectral normalization. Advanced techniques like Savitzky-Golay filtering have proven particularly effective for smoothing ATR-FTIR spectra while preserving peak shapes and intensities, which is crucial for accurate quantitative analysis in reaction monitoring applications.

Multivariate statistical methods have revolutionized the analysis of time-resolved spectral data. Principal Component Analysis (PCA) enables dimensionality reduction by identifying the most significant variations in spectral datasets, while Partial Least Squares (PLS) regression establishes correlations between spectral features and reaction parameters. These techniques are especially valuable when monitoring complex reactions where multiple species evolve simultaneously.

Chemometric approaches such as Multivariate Curve Resolution (MCR) and Classical Least Squares (CLS) modeling allow for the deconvolution of overlapping spectral bands, enabling the extraction of concentration profiles for individual chemical species throughout the reaction process. This capability is particularly important in flow cell applications where rapid changes in composition must be accurately tracked.

Machine learning algorithms represent the cutting edge of spectral data processing. Artificial Neural Networks (ANNs) and Support Vector Machines (SVMs) have demonstrated remarkable capabilities in pattern recognition and classification of spectral features, while deep learning approaches show promise for automated interpretation of complex reaction pathways.

Time-series analysis algorithms address the temporal dimension of reaction monitoring data. Dynamic Time Warping (DTW) enables comparison of reaction profiles with different time scales, while Fourier and wavelet transforms facilitate the identification of periodic behaviors and transient events in reaction systems.

Integration of these algorithms into automated workflows has significantly enhanced the real-time monitoring capabilities of ATR-FTIR systems. Modern software platforms now offer comprehensive suites of data processing tools that enable rapid analysis of spectral data streams, supporting immediate decision-making in research and industrial settings.

Preprocessing algorithms form the foundation of spectral analysis, addressing common challenges such as baseline correction, noise reduction, and spectral normalization. Advanced techniques like Savitzky-Golay filtering have proven particularly effective for smoothing ATR-FTIR spectra while preserving peak shapes and intensities, which is crucial for accurate quantitative analysis in reaction monitoring applications.

Multivariate statistical methods have revolutionized the analysis of time-resolved spectral data. Principal Component Analysis (PCA) enables dimensionality reduction by identifying the most significant variations in spectral datasets, while Partial Least Squares (PLS) regression establishes correlations between spectral features and reaction parameters. These techniques are especially valuable when monitoring complex reactions where multiple species evolve simultaneously.

Chemometric approaches such as Multivariate Curve Resolution (MCR) and Classical Least Squares (CLS) modeling allow for the deconvolution of overlapping spectral bands, enabling the extraction of concentration profiles for individual chemical species throughout the reaction process. This capability is particularly important in flow cell applications where rapid changes in composition must be accurately tracked.

Machine learning algorithms represent the cutting edge of spectral data processing. Artificial Neural Networks (ANNs) and Support Vector Machines (SVMs) have demonstrated remarkable capabilities in pattern recognition and classification of spectral features, while deep learning approaches show promise for automated interpretation of complex reaction pathways.

Time-series analysis algorithms address the temporal dimension of reaction monitoring data. Dynamic Time Warping (DTW) enables comparison of reaction profiles with different time scales, while Fourier and wavelet transforms facilitate the identification of periodic behaviors and transient events in reaction systems.

Integration of these algorithms into automated workflows has significantly enhanced the real-time monitoring capabilities of ATR-FTIR systems. Modern software platforms now offer comprehensive suites of data processing tools that enable rapid analysis of spectral data streams, supporting immediate decision-making in research and industrial settings.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!