ATR-FTIR Temperature Control: Phase Transitions, Kinetics And Spectral Drift

SEP 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

ATR-FTIR Temperature Control Background and Objectives

Attenuated Total Reflection Fourier Transform Infrared Spectroscopy (ATR-FTIR) has evolved significantly since its inception in the mid-20th century, becoming an indispensable analytical technique across various scientific and industrial domains. The integration of temperature control capabilities with ATR-FTIR represents a critical advancement that has expanded the technique's utility for investigating temperature-dependent molecular phenomena.

The evolution of ATR-FTIR temperature control systems has progressed from rudimentary heating elements to sophisticated, precisely controlled environments capable of maintaining stable temperatures within ±0.1°C. Early systems in the 1980s offered limited temperature ranges and poor stability, while contemporary setups can operate from cryogenic temperatures to several hundred degrees Celsius with remarkable precision.

This technological progression has been driven by the growing need to understand molecular behavior under varying thermal conditions, particularly in materials science, pharmaceutical development, and polymer research. The ability to observe phase transitions in real-time has proven invaluable for characterizing novel materials and optimizing manufacturing processes.

Current research objectives in ATR-FTIR temperature control focus on addressing three interconnected challenges: accurate monitoring of phase transitions, quantitative analysis of reaction kinetics, and compensation for spectral drift. Phase transition monitoring requires precise temperature control to capture subtle structural changes during melting, crystallization, or glass transitions. Kinetic studies demand stable temperature environments to accurately measure reaction rates and activation energies.

Spectral drift, perhaps the most persistent technical challenge, manifests as baseline shifts and peak position changes that occur due to thermal expansion of optical components and sample matrices. This phenomenon can significantly compromise data quality and interpretability, particularly in long-duration experiments or those requiring precise quantitative analysis.

The primary technical objective is to develop ATR-FTIR temperature control systems that maintain exceptional thermal stability while simultaneously implementing real-time computational methods to correct for unavoidable spectral artifacts. This includes advanced algorithms for baseline correction, peak position normalization, and signal enhancement that can adapt to changing experimental conditions.

Looking forward, the field is trending toward fully automated systems that integrate machine learning approaches for spectral correction and interpretation. These systems aim to provide researchers with more reliable data for investigating complex phenomena such as protein folding dynamics, polymer crystallization kinetics, and pharmaceutical stability under varying environmental conditions.

The evolution of ATR-FTIR temperature control systems has progressed from rudimentary heating elements to sophisticated, precisely controlled environments capable of maintaining stable temperatures within ±0.1°C. Early systems in the 1980s offered limited temperature ranges and poor stability, while contemporary setups can operate from cryogenic temperatures to several hundred degrees Celsius with remarkable precision.

This technological progression has been driven by the growing need to understand molecular behavior under varying thermal conditions, particularly in materials science, pharmaceutical development, and polymer research. The ability to observe phase transitions in real-time has proven invaluable for characterizing novel materials and optimizing manufacturing processes.

Current research objectives in ATR-FTIR temperature control focus on addressing three interconnected challenges: accurate monitoring of phase transitions, quantitative analysis of reaction kinetics, and compensation for spectral drift. Phase transition monitoring requires precise temperature control to capture subtle structural changes during melting, crystallization, or glass transitions. Kinetic studies demand stable temperature environments to accurately measure reaction rates and activation energies.

Spectral drift, perhaps the most persistent technical challenge, manifests as baseline shifts and peak position changes that occur due to thermal expansion of optical components and sample matrices. This phenomenon can significantly compromise data quality and interpretability, particularly in long-duration experiments or those requiring precise quantitative analysis.

The primary technical objective is to develop ATR-FTIR temperature control systems that maintain exceptional thermal stability while simultaneously implementing real-time computational methods to correct for unavoidable spectral artifacts. This includes advanced algorithms for baseline correction, peak position normalization, and signal enhancement that can adapt to changing experimental conditions.

Looking forward, the field is trending toward fully automated systems that integrate machine learning approaches for spectral correction and interpretation. These systems aim to provide researchers with more reliable data for investigating complex phenomena such as protein folding dynamics, polymer crystallization kinetics, and pharmaceutical stability under varying environmental conditions.

Market Applications and Demand Analysis for Temperature-Controlled Spectroscopy

Temperature-controlled spectroscopy, particularly ATR-FTIR with temperature control capabilities, has witnessed significant market growth across multiple industries. The pharmaceutical sector represents one of the largest market segments, where temperature-controlled spectroscopy is essential for drug formulation studies, polymorphism analysis, and stability testing. The ability to monitor phase transitions and reaction kinetics in real-time provides critical data for drug development and quality control processes.

The polymer and materials science industry constitutes another substantial market, with researchers and manufacturers utilizing temperature-controlled ATR-FTIR to study crystallization behavior, glass transitions, and thermal degradation pathways. This application has seen approximately 15% annual growth as advanced materials development accelerates across automotive, aerospace, and consumer electronics sectors.

Food science and agriculture industries have emerged as rapidly expanding markets for temperature-controlled spectroscopy. Applications include monitoring lipid crystallization, protein denaturation, and starch gelatinization processes. The increasing focus on food quality, authenticity, and processing optimization has driven adoption in these sectors.

Academic and research institutions represent a stable and consistent market segment, with temperature-controlled spectroscopy being fundamental to various research projects spanning chemistry, physics, biology, and materials science. The demand for higher precision temperature control and faster heating/cooling rates continues to grow within this segment.

The petrochemical industry utilizes temperature-controlled ATR-FTIR for analyzing crude oil compositions, monitoring catalytic processes, and studying phase behavior of complex hydrocarbon mixtures. This sector values instruments capable of operating under extreme temperature conditions while maintaining spectral stability.

Market analysis indicates that the global temperature-controlled spectroscopy market was valued at approximately $1.2 billion in 2022, with projected growth to reach $1.8 billion by 2027. North America and Europe currently dominate market share, though Asia-Pacific regions, particularly China and India, are experiencing the fastest growth rates due to expanding pharmaceutical and materials research sectors.

Key market drivers include increasing demand for real-time process monitoring, growing emphasis on quality control in manufacturing, and rising research activities in thermal behavior of materials. The trend toward miniaturization and automation of temperature-controlled spectroscopic systems is reshaping market dynamics, with portable and integrated systems gaining significant traction across various industries.

The polymer and materials science industry constitutes another substantial market, with researchers and manufacturers utilizing temperature-controlled ATR-FTIR to study crystallization behavior, glass transitions, and thermal degradation pathways. This application has seen approximately 15% annual growth as advanced materials development accelerates across automotive, aerospace, and consumer electronics sectors.

Food science and agriculture industries have emerged as rapidly expanding markets for temperature-controlled spectroscopy. Applications include monitoring lipid crystallization, protein denaturation, and starch gelatinization processes. The increasing focus on food quality, authenticity, and processing optimization has driven adoption in these sectors.

Academic and research institutions represent a stable and consistent market segment, with temperature-controlled spectroscopy being fundamental to various research projects spanning chemistry, physics, biology, and materials science. The demand for higher precision temperature control and faster heating/cooling rates continues to grow within this segment.

The petrochemical industry utilizes temperature-controlled ATR-FTIR for analyzing crude oil compositions, monitoring catalytic processes, and studying phase behavior of complex hydrocarbon mixtures. This sector values instruments capable of operating under extreme temperature conditions while maintaining spectral stability.

Market analysis indicates that the global temperature-controlled spectroscopy market was valued at approximately $1.2 billion in 2022, with projected growth to reach $1.8 billion by 2027. North America and Europe currently dominate market share, though Asia-Pacific regions, particularly China and India, are experiencing the fastest growth rates due to expanding pharmaceutical and materials research sectors.

Key market drivers include increasing demand for real-time process monitoring, growing emphasis on quality control in manufacturing, and rising research activities in thermal behavior of materials. The trend toward miniaturization and automation of temperature-controlled spectroscopic systems is reshaping market dynamics, with portable and integrated systems gaining significant traction across various industries.

Current Challenges in ATR-FTIR Temperature Control Systems

Despite significant advancements in ATR-FTIR spectroscopy, temperature control systems continue to face several critical challenges that limit their effectiveness in studying phase transitions, reaction kinetics, and spectral stability. One of the primary obstacles is achieving precise temperature uniformity across the entire sampling interface. Current systems often exhibit temperature gradients between the ATR crystal and the sample, leading to inconsistent phase transition observations and unreliable kinetic measurements.

Temperature stability represents another significant hurdle, with many systems struggling to maintain constant temperatures over extended experimental periods. Even minor fluctuations of ±0.5°C can dramatically affect phase transition studies, particularly for materials with narrow transition ranges or complex polymorphic behaviors. These fluctuations introduce experimental artifacts that complicate data interpretation and reduce reproducibility.

The thermal lag between the temperature controller reading and the actual sample temperature remains problematic, especially during rapid heating or cooling cycles. This discrepancy creates systematic errors in kinetic studies where reaction rates are highly temperature-dependent. Most commercial systems lack adequate compensation mechanisms for this thermal lag, forcing researchers to develop custom calibration protocols that vary between instrument configurations.

Material compatibility issues further compound these challenges. The ATR crystal materials (commonly ZnSe, Ge, or diamond) exhibit different thermal expansion coefficients compared to sample holders and heating elements. These mismatches can cause mechanical stress during temperature cycling, potentially damaging expensive optical components or creating micro-gaps that affect spectral quality and reproducibility.

Spectral drift during temperature changes presents a particularly vexing problem for long-duration experiments. Current systems struggle to distinguish between genuine sample changes and artifacts introduced by thermal expansion of optical components. This limitation severely impacts studies of slow crystallization processes, polymer curing reactions, and other time-dependent phenomena requiring stable baselines over hours or days.

Calibration and validation protocols for temperature-controlled ATR-FTIR systems lack standardization across the industry. Different manufacturers employ proprietary approaches to temperature sensing and control, making cross-platform comparisons challenging. The absence of universally accepted reference materials for temperature calibration further complicates efforts to establish reliable methodologies for thermal studies.

Integration with complementary analytical techniques remains limited in current systems. While multi-modal analysis combining ATR-FTIR with techniques like DSC or XRD would provide more comprehensive insights into material behavior during thermal transitions, practical implementation faces significant engineering challenges related to temperature synchronization and spatial alignment between different measurement modalities.

Temperature stability represents another significant hurdle, with many systems struggling to maintain constant temperatures over extended experimental periods. Even minor fluctuations of ±0.5°C can dramatically affect phase transition studies, particularly for materials with narrow transition ranges or complex polymorphic behaviors. These fluctuations introduce experimental artifacts that complicate data interpretation and reduce reproducibility.

The thermal lag between the temperature controller reading and the actual sample temperature remains problematic, especially during rapid heating or cooling cycles. This discrepancy creates systematic errors in kinetic studies where reaction rates are highly temperature-dependent. Most commercial systems lack adequate compensation mechanisms for this thermal lag, forcing researchers to develop custom calibration protocols that vary between instrument configurations.

Material compatibility issues further compound these challenges. The ATR crystal materials (commonly ZnSe, Ge, or diamond) exhibit different thermal expansion coefficients compared to sample holders and heating elements. These mismatches can cause mechanical stress during temperature cycling, potentially damaging expensive optical components or creating micro-gaps that affect spectral quality and reproducibility.

Spectral drift during temperature changes presents a particularly vexing problem for long-duration experiments. Current systems struggle to distinguish between genuine sample changes and artifacts introduced by thermal expansion of optical components. This limitation severely impacts studies of slow crystallization processes, polymer curing reactions, and other time-dependent phenomena requiring stable baselines over hours or days.

Calibration and validation protocols for temperature-controlled ATR-FTIR systems lack standardization across the industry. Different manufacturers employ proprietary approaches to temperature sensing and control, making cross-platform comparisons challenging. The absence of universally accepted reference materials for temperature calibration further complicates efforts to establish reliable methodologies for thermal studies.

Integration with complementary analytical techniques remains limited in current systems. While multi-modal analysis combining ATR-FTIR with techniques like DSC or XRD would provide more comprehensive insights into material behavior during thermal transitions, practical implementation faces significant engineering challenges related to temperature synchronization and spatial alignment between different measurement modalities.

Existing Temperature Control Solutions for Phase Transition Studies

01 Temperature-controlled ATR-FTIR systems for phase transition analysis

Temperature-controlled ATR-FTIR systems are designed to monitor phase transitions in materials by precisely controlling sample temperature during spectroscopic analysis. These systems integrate heating and cooling elements with FTIR spectroscopy to observe structural changes in real-time. The temperature control mechanisms allow researchers to study phase transitions at specific temperature points, providing insights into material behavior under varying thermal conditions.- Temperature-controlled ATR-FTIR systems for phase transition analysis: Temperature-controlled ATR-FTIR systems enable precise monitoring of phase transitions in materials. These systems incorporate heating and cooling elements that allow researchers to observe spectral changes as materials undergo transitions between solid, liquid, and gaseous states. The controlled temperature environment helps in accurately determining transition points and characterizing material behavior under different thermal conditions.

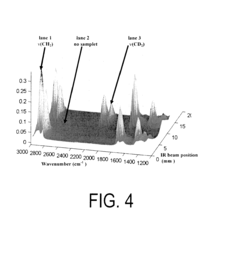

- Kinetic analysis of chemical reactions using time-resolved ATR-FTIR: Time-resolved ATR-FTIR spectroscopy enables the study of reaction kinetics by monitoring spectral changes over time at controlled temperatures. This technique allows researchers to determine reaction rates, activation energies, and reaction mechanisms by analyzing the appearance and disappearance of spectral features. Temperature control is crucial for maintaining consistent reaction conditions and for studying temperature-dependent kinetic parameters.

- Compensation methods for spectral drift in temperature-variable ATR-FTIR: Spectral drift compensation techniques are essential for accurate ATR-FTIR measurements during temperature changes. These methods include algorithmic corrections, reference calibration, and hardware solutions that minimize baseline shifts and peak distortions caused by thermal expansion of optical components. Advanced systems incorporate real-time drift correction to ensure data reliability during temperature-dependent studies.

- In-situ ATR-FTIR monitoring of material transformations at variable temperatures: In-situ ATR-FTIR monitoring allows real-time observation of material transformations at different temperatures. This approach is particularly valuable for studying crystallization processes, polymer curing, protein denaturation, and other temperature-induced structural changes. The technique provides insights into transformation mechanisms by capturing spectral signatures associated with intermediate states that might be missed in ex-situ analysis.

- Advanced temperature control accessories for precision ATR-FTIR measurements: Specialized temperature control accessories enhance the precision of ATR-FTIR measurements across wide temperature ranges. These include Peltier-controlled sample stages, liquid nitrogen cooling systems, and programmable heating elements that enable precise temperature ramping and stability. Advanced designs incorporate thermal isolation to prevent interference with the optical path and temperature sensors for accurate feedback control.

02 Kinetic analysis of chemical reactions using time-resolved ATR-FTIR

Time-resolved ATR-FTIR spectroscopy enables the study of reaction kinetics by monitoring spectral changes over time at controlled temperatures. This approach allows researchers to determine reaction rates, activation energies, and reaction mechanisms by analyzing the appearance and disappearance of spectral features. Temperature control is crucial for maintaining consistent reaction conditions and for studying temperature-dependent kinetic parameters.Expand Specific Solutions03 Compensation techniques for spectral drift in temperature-variable ATR-FTIR

Spectral drift compensation techniques are essential for accurate ATR-FTIR measurements during temperature variation. These methods include algorithmic corrections, reference standards, and hardware solutions that minimize baseline shifts and peak distortions caused by thermal expansion of optical components. Advanced calibration procedures and computational methods help maintain spectral integrity across temperature ranges, ensuring reliable data for phase transition and kinetic studies.Expand Specific Solutions04 In-situ ATR-FTIR monitoring of material transformations

In-situ ATR-FTIR monitoring systems enable real-time observation of material transformations during temperature changes. These setups allow researchers to directly observe crystallization, melting, glass transitions, and other phase changes while simultaneously collecting spectroscopic data. The integration of temperature control with ATR-FTIR provides insights into structural reorganization, intermolecular interactions, and conformational changes during thermal processing.Expand Specific Solutions05 Advanced temperature control accessories for ATR-FTIR instrumentation

Specialized temperature control accessories enhance the capabilities of ATR-FTIR instruments for studying phase transitions. These include heating stages, cooling systems, temperature ramps, and precise temperature sensors that can be integrated with existing FTIR spectrometers. Advanced designs feature uniform heating, rapid temperature changes, and stability over extended measurement periods, enabling detailed characterization of temperature-dependent material properties.Expand Specific Solutions

Leading Manufacturers and Research Institutions in ATR-FTIR Technology

ATR-FTIR temperature control technology is currently in a growth phase, with increasing market adoption across pharmaceutical, chemical, and materials science industries. The global market for advanced spectroscopic analysis equipment is expanding steadily, estimated at approximately $5-7 billion with ATR-FTIR systems representing a significant segment. Technologically, the field shows moderate maturity with ongoing innovations in temperature control precision and stability. Leading companies like Haldor Topsøe, Battelle Memorial Institute, and Fraunhofer-Gesellschaft demonstrate advanced capabilities in spectral drift compensation and phase transition analysis, while academic institutions such as Xi'an Jiaotong University and University of Palermo contribute fundamental research. Industrial players including Toyota, Honda, and Samsung are applying this technology for materials characterization and quality control applications, indicating growing cross-sector implementation.

Centre National de la Recherche Scientifique

Technical Solution: Centre National de la Recherche Scientifique (CNRS) has developed advanced ATR-FTIR temperature control systems that enable precise monitoring of phase transitions and kinetics in materials. Their technology incorporates a specialized temperature-controlled ATR crystal assembly with stability within ±0.1°C across a wide temperature range (-100°C to 300°C). The system utilizes a closed-loop feedback mechanism with platinum resistance thermometers embedded near the sample-crystal interface for real-time temperature monitoring and adjustment. CNRS has also developed proprietary algorithms to compensate for spectral drift caused by thermal expansion of the ATR crystal, implementing mathematical correction models that account for temperature-dependent refractive index changes. Their system includes specialized software for kinetic analysis that can track spectral changes during phase transitions with temporal resolution down to 0.5 seconds, allowing researchers to calculate activation energies and reaction mechanisms with high precision.

Strengths: Superior temperature stability and precision; advanced drift compensation algorithms; excellent temporal resolution for kinetic studies. Weaknesses: Complex system requiring specialized expertise to operate; relatively high cost compared to standard ATR-FTIR setups; limited commercial availability outside research collaborations.

Fraunhofer-Gesellschaft eV

Technical Solution: Fraunhofer-Gesellschaft has engineered a comprehensive ATR-FTIR temperature control solution specifically designed for industrial applications requiring high-throughput analysis of phase transitions and reaction kinetics. Their system features a patented multi-zone temperature control unit that maintains uniform temperature distribution across the ATR crystal with precision of ±0.05°C. The technology incorporates a rapid heating/cooling mechanism capable of temperature ramp rates up to 50°C/minute without compromising stability, enabling detailed study of fast phase transitions. Fraunhofer's approach includes an integrated calibration system that automatically corrects for spectral drift using reference materials with known temperature-dependent spectral features. Their solution also features machine learning algorithms that can identify and isolate spectral changes due to genuine chemical/physical transitions from those caused by instrumental artifacts, significantly improving data reliability. The system is designed with modular components allowing customization for different sample types and experimental conditions.

Strengths: Exceptional temperature uniformity and stability; rapid heating/cooling capabilities; advanced automated drift correction; industrial-grade robustness. Weaknesses: Substantial initial investment cost; requires periodic recalibration for optimal performance; higher power consumption compared to simpler systems.

Key Innovations in Spectral Drift Compensation Techniques

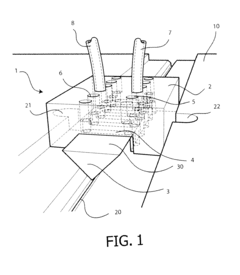

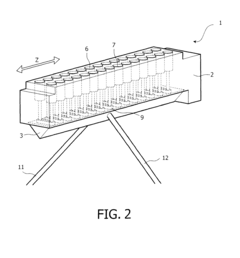

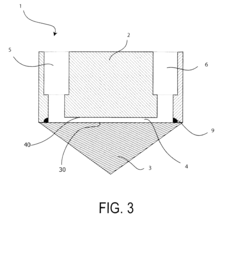

Device for multiple ATR analysis

PatentInactiveEP2116839A1

Innovation

- A device with an ATR element featuring a sample compartment with multiple chambers, allowing for the analysis of multiple samples, and an organic compound for grafting the ATR element to stabilize it against hydrolysis, enabling simultaneous analysis of multiple samples and improving surface stability.

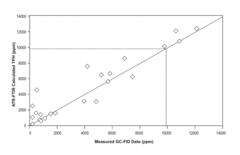

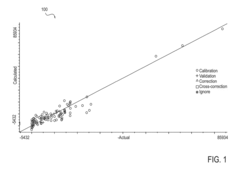

Method for predicting total petroleum hydrocarbon concentration in soils

PatentActiveUS20180017540A1

Innovation

- A method using attenuated total reflectance (ATR) spectroscopy combined with Fourier transform infrared (FTIR) spectroscopy and partial least squares regression analysis to generate a site-specific predictive model for TPH concentration, allowing for rapid field measurements without the need for solvent extraction or sample drying, utilizing a handheld FTIR spectrometer with ATR window and correlating data with GC-FID results.

Calibration Standards and Validation Protocols

Calibration standards and validation protocols are essential components in ensuring the reliability and accuracy of ATR-FTIR temperature control systems. Establishing robust calibration procedures is critical for meaningful interpretation of spectral data, particularly when studying phase transitions and kinetics where temperature precision directly impacts results.

Primary calibration standards for ATR-FTIR temperature control systems typically include certified reference materials with well-documented phase transition temperatures. These materials, such as indium (156.6°C), tin (231.9°C), and gallium (29.8°C), provide fixed temperature points against which the system can be calibrated. For lower temperature ranges, organic compounds with precise melting points such as naphthalene (80.2°C) and benzoic acid (122.4°C) serve as effective calibration standards.

Validation protocols must address both temperature accuracy and spectral stability. A comprehensive validation approach includes temperature mapping across the ATR crystal surface to identify potential thermal gradients that could affect spectral interpretation. This mapping should be performed at multiple setpoints spanning the operational temperature range of the instrument. Documentation of thermal response times and stabilization periods is crucial for kinetic studies where time-resolved measurements are essential.

Spectral validation requires the collection of reference spectra from standard materials at defined temperatures. These spectra serve as benchmarks for system performance and should be regularly compared to detect any instrumental drift. Polymorphic materials like potassium nitrate, which exhibits distinct spectral features at different crystal phases, are particularly valuable for validating both temperature accuracy and spectral response simultaneously.

Interlaboratory comparison studies represent an advanced validation approach, where identical samples are analyzed under standardized conditions across multiple instruments. These studies help establish reproducibility limits and identify instrument-specific biases that might affect data interpretation. The results from such comparisons should be statistically analyzed to determine confidence intervals for temperature measurements.

Automated validation routines integrated into instrument software provide efficient quality control mechanisms. These routines can perform regular checks of temperature calibration and spectral response, alerting users to potential issues before they impact experimental results. Implementation of such systems is particularly valuable in industrial settings where continuous monitoring is required.

Documentation standards for calibration and validation procedures should include detailed records of reference materials, calibration curves, uncertainty calculations, and verification results. These records form an essential part of the quality assurance framework and support regulatory compliance in regulated industries where ATR-FTIR is employed for material characterization or process monitoring.

Primary calibration standards for ATR-FTIR temperature control systems typically include certified reference materials with well-documented phase transition temperatures. These materials, such as indium (156.6°C), tin (231.9°C), and gallium (29.8°C), provide fixed temperature points against which the system can be calibrated. For lower temperature ranges, organic compounds with precise melting points such as naphthalene (80.2°C) and benzoic acid (122.4°C) serve as effective calibration standards.

Validation protocols must address both temperature accuracy and spectral stability. A comprehensive validation approach includes temperature mapping across the ATR crystal surface to identify potential thermal gradients that could affect spectral interpretation. This mapping should be performed at multiple setpoints spanning the operational temperature range of the instrument. Documentation of thermal response times and stabilization periods is crucial for kinetic studies where time-resolved measurements are essential.

Spectral validation requires the collection of reference spectra from standard materials at defined temperatures. These spectra serve as benchmarks for system performance and should be regularly compared to detect any instrumental drift. Polymorphic materials like potassium nitrate, which exhibits distinct spectral features at different crystal phases, are particularly valuable for validating both temperature accuracy and spectral response simultaneously.

Interlaboratory comparison studies represent an advanced validation approach, where identical samples are analyzed under standardized conditions across multiple instruments. These studies help establish reproducibility limits and identify instrument-specific biases that might affect data interpretation. The results from such comparisons should be statistically analyzed to determine confidence intervals for temperature measurements.

Automated validation routines integrated into instrument software provide efficient quality control mechanisms. These routines can perform regular checks of temperature calibration and spectral response, alerting users to potential issues before they impact experimental results. Implementation of such systems is particularly valuable in industrial settings where continuous monitoring is required.

Documentation standards for calibration and validation procedures should include detailed records of reference materials, calibration curves, uncertainty calculations, and verification results. These records form an essential part of the quality assurance framework and support regulatory compliance in regulated industries where ATR-FTIR is employed for material characterization or process monitoring.

Environmental Impact and Energy Efficiency Considerations

The environmental footprint of ATR-FTIR temperature control systems represents a significant consideration in modern analytical laboratories. Traditional temperature control mechanisms often consume substantial electrical power, particularly when maintaining extreme temperatures or when rapid heating and cooling cycles are required for kinetic studies. Recent advancements have focused on developing more energy-efficient systems that reduce power consumption while maintaining precise temperature control necessary for accurate phase transition analysis.

Cooling systems in ATR-FTIR setups present particular environmental challenges, with many conventional systems still relying on refrigerants with high global warming potential (GWP). The transition toward natural refrigerants and closed-loop cooling systems has begun to address this concern, reducing both direct emissions from refrigerant leakage and indirect emissions from energy consumption. Laboratory managers increasingly factor these environmental considerations into procurement decisions, with energy efficiency ratings becoming a key specification parameter.

Heat dissipation represents another environmental consideration, particularly in temperature-controlled laboratory environments. Inefficient ATR-FTIR temperature control systems can increase the cooling load on laboratory HVAC systems, creating a cascading energy consumption effect. Modern designs incorporate improved insulation materials and more efficient heat exchange mechanisms to minimize this thermal leakage, reducing the overall environmental impact of continuous operation.

The materials used in temperature control components also merit environmental scrutiny. Traditional Peltier elements contain bismuth telluride and other materials with significant environmental extraction costs. Research into alternative thermoelectric materials with lower environmental impact is progressing, though commercial implementation remains limited. Similarly, the durability and end-of-life considerations for temperature control components affect the overall lifecycle assessment of ATR-FTIR systems.

Energy management software has emerged as a promising approach to reducing the environmental impact of laboratory instrumentation. Intelligent temperature ramping algorithms can optimize heating and cooling cycles to minimize energy consumption while maintaining experimental integrity. These systems can reduce power consumption by 15-30% compared to conventional constant-power approaches, particularly beneficial during long-duration experiments monitoring slow phase transitions or extended kinetic studies.

Water consumption in liquid-cooled systems presents another environmental consideration, particularly in water-scarce regions. Closed-loop water cooling systems have become standard in modern installations, but their efficiency and maintenance requirements vary considerably. Advanced systems incorporate water quality monitoring to optimize cooling efficiency and reduce both water and energy consumption over the operational lifetime of the instrument.

Cooling systems in ATR-FTIR setups present particular environmental challenges, with many conventional systems still relying on refrigerants with high global warming potential (GWP). The transition toward natural refrigerants and closed-loop cooling systems has begun to address this concern, reducing both direct emissions from refrigerant leakage and indirect emissions from energy consumption. Laboratory managers increasingly factor these environmental considerations into procurement decisions, with energy efficiency ratings becoming a key specification parameter.

Heat dissipation represents another environmental consideration, particularly in temperature-controlled laboratory environments. Inefficient ATR-FTIR temperature control systems can increase the cooling load on laboratory HVAC systems, creating a cascading energy consumption effect. Modern designs incorporate improved insulation materials and more efficient heat exchange mechanisms to minimize this thermal leakage, reducing the overall environmental impact of continuous operation.

The materials used in temperature control components also merit environmental scrutiny. Traditional Peltier elements contain bismuth telluride and other materials with significant environmental extraction costs. Research into alternative thermoelectric materials with lower environmental impact is progressing, though commercial implementation remains limited. Similarly, the durability and end-of-life considerations for temperature control components affect the overall lifecycle assessment of ATR-FTIR systems.

Energy management software has emerged as a promising approach to reducing the environmental impact of laboratory instrumentation. Intelligent temperature ramping algorithms can optimize heating and cooling cycles to minimize energy consumption while maintaining experimental integrity. These systems can reduce power consumption by 15-30% compared to conventional constant-power approaches, particularly beneficial during long-duration experiments monitoring slow phase transitions or extended kinetic studies.

Water consumption in liquid-cooled systems presents another environmental consideration, particularly in water-scarce regions. Closed-loop water cooling systems have become standard in modern installations, but their efficiency and maintenance requirements vary considerably. Advanced systems incorporate water quality monitoring to optimize cooling efficiency and reduce both water and energy consumption over the operational lifetime of the instrument.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!