Birefringent Photonic Crystal Fibers for Sensing Applications

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Birefringent PCF Sensing Technology Background and Objectives

Birefringent Photonic Crystal Fibers (PCFs) represent a significant advancement in optical fiber technology that emerged in the late 1990s. These specialized fibers feature a microstructured arrangement of air holes running along their length, creating unique light-guiding properties not achievable with conventional optical fibers. The evolution of this technology has been marked by continuous refinements in fabrication techniques, from the initial stack-and-draw method to more sophisticated approaches enabling precise control of hole geometry and distribution.

The inherent birefringence in these fibers—the difference in refractive indices between two orthogonal polarization states—has opened new avenues for sensing applications. This characteristic has evolved from being an undesired effect in early fiber designs to becoming a deliberately engineered feature for specialized sensing purposes. The technological trajectory shows a clear trend toward higher birefringence values, improved stability, and enhanced sensitivity to external parameters.

The primary technical objective in this field is to develop PCF structures with optimized birefringence properties specifically tailored for sensing applications. This includes achieving high birefringence values (>10^-3) while maintaining low optical losses and ensuring structural stability under varying environmental conditions. Additionally, there is a focus on enhancing sensitivity to specific physical parameters such as temperature, pressure, strain, and biochemical agents.

Current research aims to overcome the trade-off between high birefringence and other desirable fiber characteristics, such as low confinement loss and broad operational wavelength range. The field is moving toward multi-parameter sensing capabilities, where a single fiber can simultaneously detect multiple environmental variables with minimal cross-sensitivity issues.

The integration of novel materials within the PCF structure represents another important trend, with research exploring the incorporation of functional materials like graphene, liquid crystals, and various polymers to enhance sensing performance. This materials-based approach is complemented by innovations in fiber design geometry, including asymmetric core structures, selectively filled air holes, and hybrid guiding mechanisms.

Looking forward, the technical roadmap for birefringent PCFs in sensing applications includes the development of all-fiber sensing systems with improved portability and real-time monitoring capabilities. There is also significant interest in extending the application range to extreme environments, such as high-temperature industrial settings and biomedical implants, which demands further innovations in both fiber design and protective packaging technologies.

The inherent birefringence in these fibers—the difference in refractive indices between two orthogonal polarization states—has opened new avenues for sensing applications. This characteristic has evolved from being an undesired effect in early fiber designs to becoming a deliberately engineered feature for specialized sensing purposes. The technological trajectory shows a clear trend toward higher birefringence values, improved stability, and enhanced sensitivity to external parameters.

The primary technical objective in this field is to develop PCF structures with optimized birefringence properties specifically tailored for sensing applications. This includes achieving high birefringence values (>10^-3) while maintaining low optical losses and ensuring structural stability under varying environmental conditions. Additionally, there is a focus on enhancing sensitivity to specific physical parameters such as temperature, pressure, strain, and biochemical agents.

Current research aims to overcome the trade-off between high birefringence and other desirable fiber characteristics, such as low confinement loss and broad operational wavelength range. The field is moving toward multi-parameter sensing capabilities, where a single fiber can simultaneously detect multiple environmental variables with minimal cross-sensitivity issues.

The integration of novel materials within the PCF structure represents another important trend, with research exploring the incorporation of functional materials like graphene, liquid crystals, and various polymers to enhance sensing performance. This materials-based approach is complemented by innovations in fiber design geometry, including asymmetric core structures, selectively filled air holes, and hybrid guiding mechanisms.

Looking forward, the technical roadmap for birefringent PCFs in sensing applications includes the development of all-fiber sensing systems with improved portability and real-time monitoring capabilities. There is also significant interest in extending the application range to extreme environments, such as high-temperature industrial settings and biomedical implants, which demands further innovations in both fiber design and protective packaging technologies.

Market Analysis for Fiber Optic Sensing Solutions

The global fiber optic sensing market has been experiencing robust growth, with a market value reaching $3.2 billion in 2022 and projected to expand at a compound annual growth rate (CAGR) of 9.8% through 2028. This growth is primarily driven by increasing demand across various industrial sectors including oil and gas, civil engineering, aerospace, and medical applications. Birefringent photonic crystal fibers (PCFs) represent a specialized segment within this market, offering enhanced sensing capabilities through their unique microstructure design.

The oil and gas industry remains the largest consumer of fiber optic sensing solutions, accounting for approximately 32% of the total market share. This sector utilizes these technologies for distributed temperature sensing, pressure monitoring, and structural health monitoring of pipelines and wells. The ability of birefringent PCFs to maintain polarization states while offering high sensitivity to external parameters makes them particularly valuable for these applications.

Civil engineering and structural health monitoring constitute the second-largest application segment, representing 24% of the market. In this sector, fiber optic sensors are deployed for real-time monitoring of bridges, dams, tunnels, and buildings. Birefringent PCFs offer advantages in strain and temperature discrimination, a critical requirement for structural integrity assessment.

Regionally, North America leads the market with 38% share, followed by Europe (27%) and Asia-Pacific (25%). The Asia-Pacific region is expected to witness the fastest growth rate of 12.3% annually, driven by rapid infrastructure development and industrial automation initiatives in China, Japan, and South Korea.

From a competitive landscape perspective, the market features both established players and innovative startups. Major corporations like Honeywell, Schlumberger, and Luna Innovations dominate with comprehensive sensing solution portfolios, while specialized companies such as NKT Photonics and OFS Optics focus on advanced fiber designs including birefringent PCFs.

Customer demand is increasingly shifting toward integrated sensing solutions that offer multi-parameter measurement capabilities. This trend favors birefringent PCF technology, which can simultaneously measure multiple physical parameters with minimal cross-sensitivity. End-users are willing to pay premium prices for sensors that provide higher accuracy, longer service life, and reduced maintenance requirements.

The market also shows growing interest in distributed sensing systems rather than point sensors, particularly for large-scale infrastructure monitoring. Birefringent PCFs, with their ability to maintain signal integrity over longer distances, are well-positioned to capitalize on this trend, especially in applications requiring immunity to electromagnetic interference and operation in harsh environments.

The oil and gas industry remains the largest consumer of fiber optic sensing solutions, accounting for approximately 32% of the total market share. This sector utilizes these technologies for distributed temperature sensing, pressure monitoring, and structural health monitoring of pipelines and wells. The ability of birefringent PCFs to maintain polarization states while offering high sensitivity to external parameters makes them particularly valuable for these applications.

Civil engineering and structural health monitoring constitute the second-largest application segment, representing 24% of the market. In this sector, fiber optic sensors are deployed for real-time monitoring of bridges, dams, tunnels, and buildings. Birefringent PCFs offer advantages in strain and temperature discrimination, a critical requirement for structural integrity assessment.

Regionally, North America leads the market with 38% share, followed by Europe (27%) and Asia-Pacific (25%). The Asia-Pacific region is expected to witness the fastest growth rate of 12.3% annually, driven by rapid infrastructure development and industrial automation initiatives in China, Japan, and South Korea.

From a competitive landscape perspective, the market features both established players and innovative startups. Major corporations like Honeywell, Schlumberger, and Luna Innovations dominate with comprehensive sensing solution portfolios, while specialized companies such as NKT Photonics and OFS Optics focus on advanced fiber designs including birefringent PCFs.

Customer demand is increasingly shifting toward integrated sensing solutions that offer multi-parameter measurement capabilities. This trend favors birefringent PCF technology, which can simultaneously measure multiple physical parameters with minimal cross-sensitivity. End-users are willing to pay premium prices for sensors that provide higher accuracy, longer service life, and reduced maintenance requirements.

The market also shows growing interest in distributed sensing systems rather than point sensors, particularly for large-scale infrastructure monitoring. Birefringent PCFs, with their ability to maintain signal integrity over longer distances, are well-positioned to capitalize on this trend, especially in applications requiring immunity to electromagnetic interference and operation in harsh environments.

Current Challenges in Birefringent PCF Development

Despite significant advancements in birefringent Photonic Crystal Fiber (PCF) technology, several critical challenges continue to impede their widespread adoption in sensing applications. The primary technical obstacle remains the precise control of birefringence during the manufacturing process. Current fabrication methods struggle to maintain consistent air hole geometry and spacing throughout the fiber length, resulting in longitudinal variations that compromise sensing accuracy and reproducibility.

Material selection presents another significant challenge, as the thermal and mechanical properties of materials used in PCF fabrication directly impact birefringence stability under varying environmental conditions. Temperature fluctuations can induce differential thermal expansion between materials, causing unintended birefringence changes that interfere with sensing measurements. This thermal sensitivity becomes particularly problematic in industrial applications where temperature control is limited.

The integration of birefringent PCFs with conventional optical systems poses substantial coupling difficulties. The unique modal characteristics of these specialized fibers often result in high insertion losses at fiber-to-fiber or fiber-to-device interfaces. These coupling inefficiencies reduce signal-to-noise ratios and limit the practical sensing range of PCF-based systems.

Scaling production while maintaining quality represents a major industrial hurdle. Current manufacturing techniques for high-performance birefringent PCFs remain largely laboratory-focused, with limited throughput and high unit costs. The transition from research prototypes to commercially viable products requires significant process engineering to ensure consistency across large production volumes.

Cross-sensitivity issues further complicate birefringent PCF sensing applications. Many PCF designs exhibit simultaneous sensitivity to multiple parameters (temperature, strain, pressure), making it difficult to isolate the specific parameter of interest. While this multi-parameter sensitivity can be advantageous in some applications, it necessitates complex compensation schemes for single-parameter sensing.

Long-term stability and aging effects remain inadequately characterized for many birefringent PCF designs. Microstructural changes over time, particularly in polymer-based or hybrid PCFs, can alter birefringence characteristics and degrade sensing performance. This uncertainty regarding long-term reliability hinders adoption in critical infrastructure monitoring and other applications requiring decades of stable operation.

Finally, computational modeling tools for birefringent PCF design still lack the accuracy needed to fully predict real-world performance. The complex interplay between structural parameters and optical properties often necessitates extensive empirical testing, slowing the development cycle and increasing costs for new PCF designs tailored to specific sensing applications.

Material selection presents another significant challenge, as the thermal and mechanical properties of materials used in PCF fabrication directly impact birefringence stability under varying environmental conditions. Temperature fluctuations can induce differential thermal expansion between materials, causing unintended birefringence changes that interfere with sensing measurements. This thermal sensitivity becomes particularly problematic in industrial applications where temperature control is limited.

The integration of birefringent PCFs with conventional optical systems poses substantial coupling difficulties. The unique modal characteristics of these specialized fibers often result in high insertion losses at fiber-to-fiber or fiber-to-device interfaces. These coupling inefficiencies reduce signal-to-noise ratios and limit the practical sensing range of PCF-based systems.

Scaling production while maintaining quality represents a major industrial hurdle. Current manufacturing techniques for high-performance birefringent PCFs remain largely laboratory-focused, with limited throughput and high unit costs. The transition from research prototypes to commercially viable products requires significant process engineering to ensure consistency across large production volumes.

Cross-sensitivity issues further complicate birefringent PCF sensing applications. Many PCF designs exhibit simultaneous sensitivity to multiple parameters (temperature, strain, pressure), making it difficult to isolate the specific parameter of interest. While this multi-parameter sensitivity can be advantageous in some applications, it necessitates complex compensation schemes for single-parameter sensing.

Long-term stability and aging effects remain inadequately characterized for many birefringent PCF designs. Microstructural changes over time, particularly in polymer-based or hybrid PCFs, can alter birefringence characteristics and degrade sensing performance. This uncertainty regarding long-term reliability hinders adoption in critical infrastructure monitoring and other applications requiring decades of stable operation.

Finally, computational modeling tools for birefringent PCF design still lack the accuracy needed to fully predict real-world performance. The complex interplay between structural parameters and optical properties often necessitates extensive empirical testing, slowing the development cycle and increasing costs for new PCF designs tailored to specific sensing applications.

Current Birefringent PCF Sensing Implementation Methods

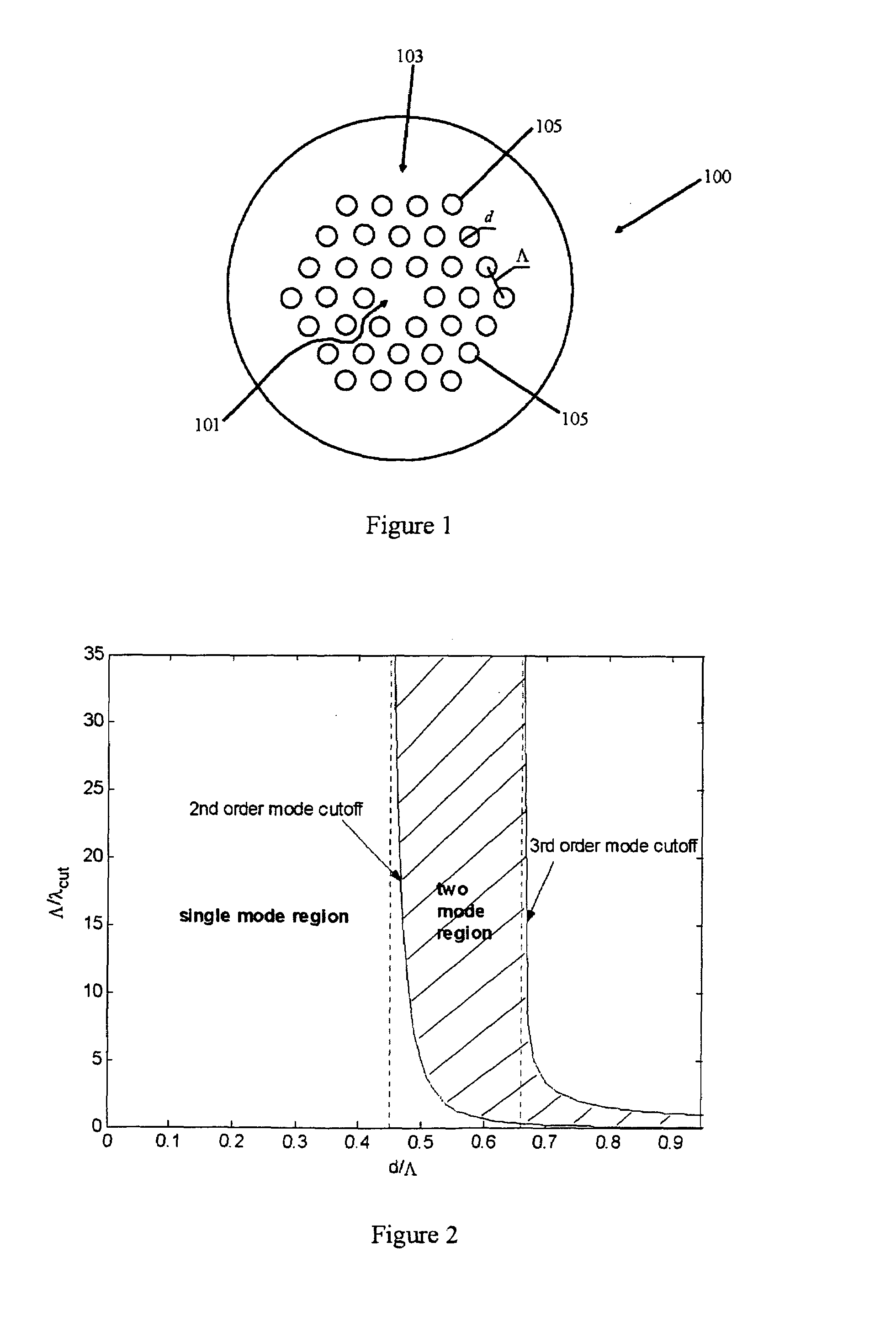

01 Structure and design of birefringent photonic crystal fibers

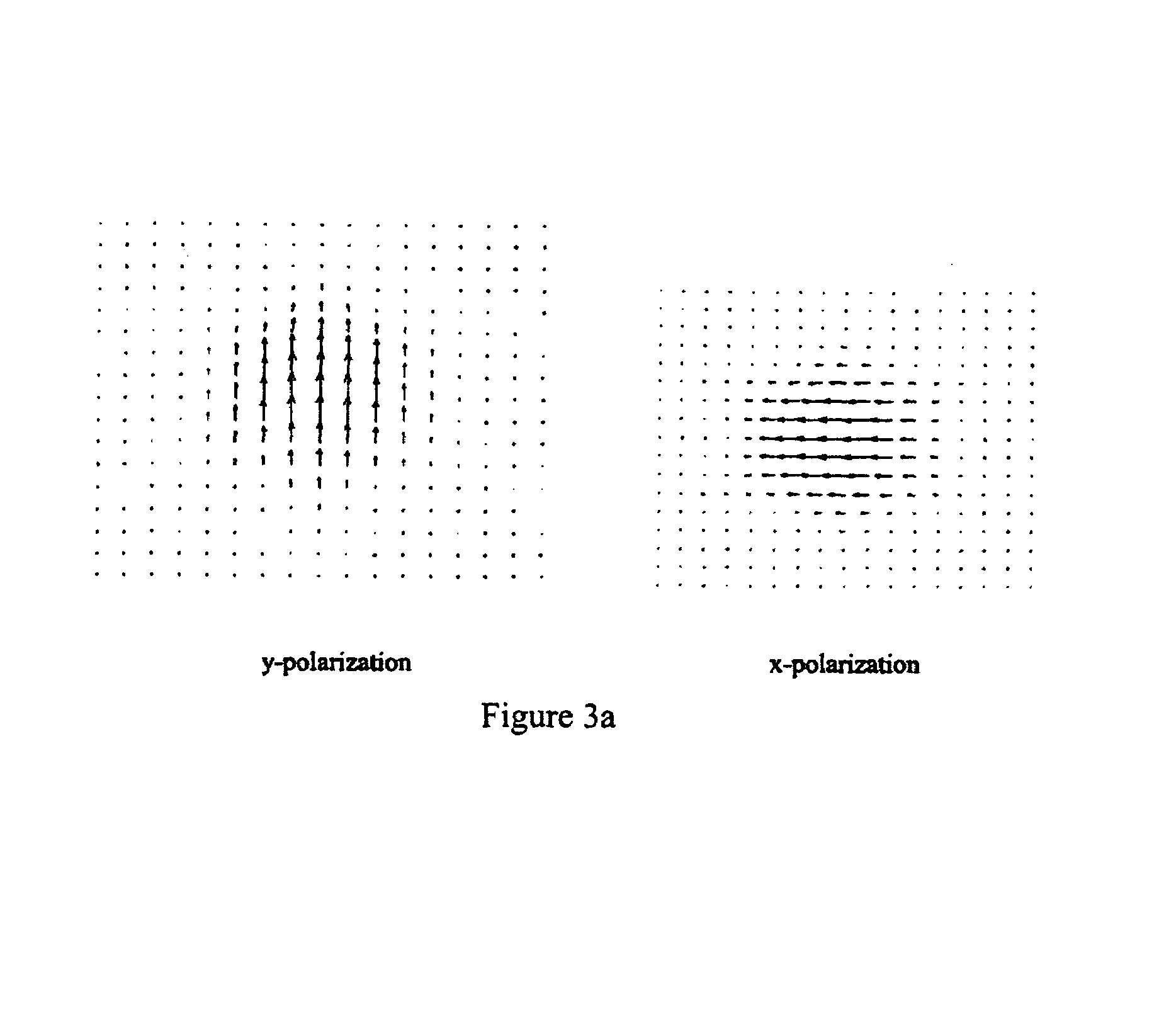

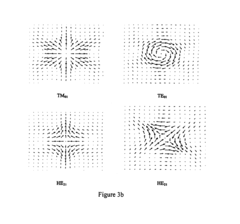

Birefringent photonic crystal fibers (PCFs) feature specialized microstructure designs that create asymmetry in the fiber core or cladding to induce birefringence. These designs typically include asymmetric air hole arrangements, elliptical cores, or stress-applying elements that break the circular symmetry of conventional fibers. The intentional structural asymmetry creates different effective refractive indices for orthogonal polarization modes, resulting in high birefringence that can be maintained over long distances and wide wavelength ranges.- Structure and design of birefringent photonic crystal fibers: Birefringent photonic crystal fibers (PCFs) feature specialized microstructure designs that create intentional asymmetry in the fiber core or cladding. These designs typically involve arrangements of air holes or solid inclusions in specific patterns to induce different refractive indices along orthogonal polarization axes. The structural asymmetry can be achieved through various methods including elliptical cores, asymmetric hole patterns, or stress-inducing elements, resulting in high birefringence that maintains polarization states over long distances.

- Manufacturing techniques for birefringent PCFs: Manufacturing birefringent photonic crystal fibers involves specialized fabrication processes to create precise microstructures. Common techniques include stack-and-draw methods where capillary tubes are arranged in specific patterns before drawing into fiber, extrusion processes for complex geometries, and drilling methods for creating precise hole patterns. Advanced manufacturing approaches may incorporate materials with different thermal expansion coefficients to induce stress-based birefringence or utilize selective filling of air holes with various materials to enhance birefringent properties.

- Applications of birefringent photonic crystal fibers: Birefringent photonic crystal fibers find applications across multiple fields due to their unique polarization-maintaining properties. They are utilized in fiber optic sensing systems for measuring physical parameters like temperature, pressure, and strain with high sensitivity. In telecommunications, these fibers enable polarization-division multiplexing to increase data transmission capacity. They also serve critical roles in fiber lasers, interferometric systems, quantum information processing, and high-precision scientific instruments where polarization control is essential for optimal performance.

- Optical properties and performance characteristics: Birefringent photonic crystal fibers exhibit distinctive optical properties including high birefringence values, customizable dispersion profiles, and controlled mode confinement. These fibers can maintain polarization states with minimal cross-coupling between orthogonal modes, resulting in high polarization extinction ratios. Their wavelength-dependent behavior can be engineered for specific applications, with some designs achieving broadband operation or specialized performance in targeted spectral regions. Advanced birefringent PCFs may also feature enhanced nonlinear effects, tailored modal properties, or specialized light-guiding mechanisms.

- Novel materials and composite structures: Research in birefringent photonic crystal fibers has expanded to incorporate novel materials and composite structures. These innovations include the integration of liquid crystals that allow for tunable birefringence through temperature or electric field control, the incorporation of nanoparticles or quantum dots to enhance specific optical properties, and the development of hybrid structures combining conventional and photonic crystal fiber designs. Some advanced fibers utilize multiple material types or gradient-index structures to achieve unprecedented levels of birefringence or specialized optical functionality.

02 Fabrication methods for birefringent photonic crystal fibers

Various manufacturing techniques are employed to create birefringent photonic crystal fibers with precise microstructures. These include stack-and-draw processes where capillaries are arranged in specific patterns before drawing, extrusion methods for complex preform creation, and drilling techniques for creating asymmetric air hole patterns. Advanced fabrication approaches may incorporate materials with different thermal expansion coefficients or selective filling of air holes with materials to enhance birefringence properties. These methods enable precise control over the geometric parameters that determine the fiber's birefringent characteristics.Expand Specific Solutions03 Applications of birefringent photonic crystal fibers in sensing and measurement

Birefringent photonic crystal fibers are widely used in sensing and measurement applications due to their high sensitivity to external perturbations. They serve as key components in fiber-optic gyroscopes, current sensors, and pressure sensors where polarization maintenance is critical. Their unique properties enable highly sensitive detection of temperature changes, strain, and other physical parameters. The controlled birefringence in these fibers also makes them valuable in interferometric sensing systems and polarimetric sensors where precise polarization control and measurement are required.Expand Specific Solutions04 Polarization control and maintenance in birefringent photonic crystal fibers

Birefringent photonic crystal fibers excel at maintaining polarization states of light over long distances, making them ideal for applications requiring stable polarization. Their high birefringence effectively minimizes cross-coupling between orthogonal polarization modes, reducing polarization mode dispersion. These fibers can be designed with polarization-maintaining properties that surpass conventional PANDA or bow-tie fibers, offering better stability across wider wavelength ranges and under varying environmental conditions. Advanced designs may incorporate additional features to enhance polarization extinction ratios and reduce polarization-dependent losses.Expand Specific Solutions05 Nonlinear optical applications of birefringent photonic crystal fibers

Birefringent photonic crystal fibers enable advanced nonlinear optical applications by combining polarization control with customizable dispersion profiles and enhanced light-matter interactions. These fibers are particularly valuable in supercontinuum generation, where maintaining polarization state throughout the nonlinear processes is critical. They also serve in parametric amplification, four-wave mixing, and other nonlinear optical processes where phase-matching conditions depend on polarization states. The ability to engineer both birefringence and dispersion simultaneously makes these fibers powerful platforms for polarization-dependent nonlinear optics and quantum light generation.Expand Specific Solutions

Leading Manufacturers and Research Institutions in PCF Industry

The birefringent photonic crystal fibers (PCF) sensing market is in a growth phase, characterized by increasing research activities and commercial applications. The global market size for specialty optical fibers, including PCFs, is expanding at approximately 10% CAGR, driven by demand in biomedical, industrial, and environmental monitoring sectors. Technologically, this field shows moderate maturity with ongoing innovations. Key players include NKT Photonics, a leading supplier of photonic crystal fibers, OpSens with expertise in fiber optic sensing solutions, and Crystal Fibre (now part of NKT). Academic institutions like Vrije Universiteit Brussel, University of Rochester, and The Hong Kong Polytechnic University contribute significantly to research advancements, while companies like Weatherford and Mitsubishi Electric are exploring industrial applications.

Weatherford Technology Holdings LLC

Technical Solution: Weatherford has developed specialized birefringent photonic crystal fibers for downhole sensing applications in the oil and gas industry. Their PCF technology features a robust design capable of withstanding extreme temperatures (up to 300°C) and pressures (30,000 psi) encountered in deep well environments. The company's proprietary manufacturing process incorporates high-temperature resistant materials and specialized coatings that maintain optical performance under harsh conditions. Weatherford's birefringent PCFs utilize a hybrid structure combining conventional polarization-maintaining elements with photonic crystal geometry to achieve enhanced sensitivity to pressure and temperature changes while maintaining mechanical integrity. Their sensing systems leverage the differential response of orthogonal polarization modes to discriminate between temperature and strain effects, a critical capability for downhole monitoring. The company has successfully deployed these fibers in distributed temperature sensing (DTS) and distributed acoustic sensing (DAS) systems for well integrity monitoring, production optimization, and reservoir characterization applications. Weatherford's PCF sensors have demonstrated measurement accuracies of ±0.5°C for temperature and ±10 microstrain for strain measurements over distances exceeding 10 km.

Strengths: Exceptional environmental durability for extreme conditions; specialized designs for oil and gas applications; proven field deployment in critical infrastructure. Weaknesses: Higher cost structure compared to conventional sensing technologies; limited application outside energy sector; requires specialized installation and maintenance expertise.

NKT Photonics A/S

Technical Solution: NKT Photonics has developed advanced birefringent photonic crystal fibers (PCFs) specifically designed for sensing applications. Their technology utilizes a microstructured design with asymmetric air hole patterns that create high birefringence (typically >10^-4) while maintaining low optical losses. The company's PCFs feature customizable mode field diameters and numerical apertures, allowing optimization for specific sensing requirements. Their proprietary manufacturing process enables precise control of the fiber geometry, resulting in consistent birefringence properties along the fiber length. NKT's sensing PCFs incorporate specialized coatings that enhance environmental stability while maintaining sensitivity to target parameters. The company has demonstrated successful implementation in distributed temperature and strain sensing systems with resolution capabilities down to 0.1°C and 1μɛ respectively. Their PCFs have been integrated into commercial sensing systems for structural health monitoring, industrial process control, and geophysical applications.

Strengths: Industry-leading manufacturing precision allowing for highly consistent optical properties; extensive customization capabilities to address specific sensing requirements; proven commercial deployment record. Weaknesses: Higher production costs compared to conventional optical fibers; requires specialized connection and handling techniques; limited bend radius compared to some competing technologies.

Key Patents and Innovations in PCF Sensing Technology

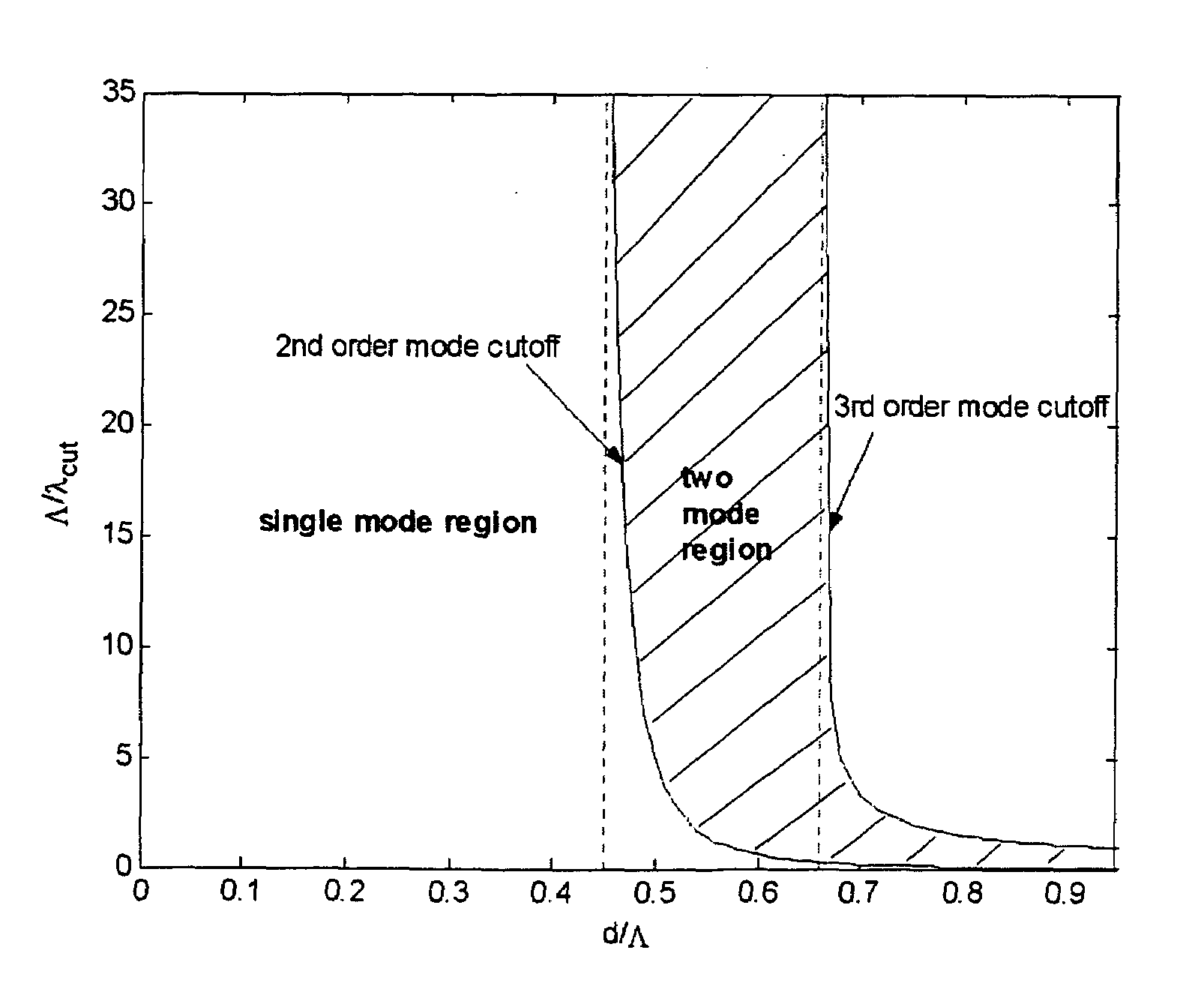

Two-mode photonic crystal fiber and applications thereof

PatentInactiveUS7190869B2

Innovation

- A two-mode photonic crystal fiber with a core and cladding region containing a periodic array of holes, where the hole diameter and pitch dimensions cooperate to enable two-mode propagation independently of the input radiation wavelength for a fixed d/Λ ratio within a specific range, allowing for a wider operating wavelength range.

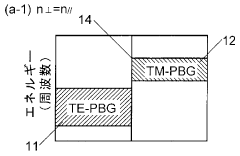

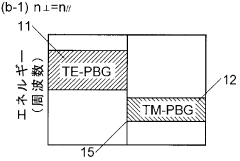

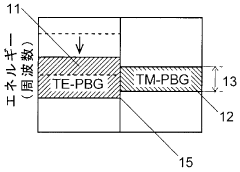

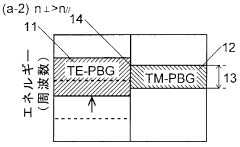

Two-dimensional photonic crystal

PatentWO2006080532A1

Innovation

- A two-dimensional photonic crystal is designed using a birefringent material with different refractive indices for light oscillating perpendicular and parallel to the body, with periodically arranged modified refractive index regions, allowing for independent adjustment of TE-PBG and TM-PBG, and featuring a unique structure such as oriented columnar microcrystals to enhance refractive index anisotropy.

Material Science Advancements for PCF Manufacturing

Recent advancements in material science have revolutionized the manufacturing of Birefringent Photonic Crystal Fibers (PCFs) for sensing applications. Traditional silica-based PCFs, while effective, have faced limitations in extreme environments and specialized sensing scenarios. The evolution of material compositions has significantly enhanced the performance characteristics and application scope of these sophisticated optical structures.

High-purity silica remains the foundation material for most PCFs, but recent innovations have introduced doped variants with germanium, fluorine, and rare-earth elements to manipulate refractive index profiles with unprecedented precision. These dopants enable fine-tuning of birefringence properties critical for sensing applications while maintaining structural integrity under varying environmental conditions.

Polymer-based PCFs represent another significant advancement, offering flexibility and cost-effectiveness compared to their silica counterparts. Materials such as PMMA (polymethyl methacrylate) and CYTOP (cyclic transparent optical polymer) have demonstrated remarkable potential for biosensing applications due to their biocompatibility and ease of surface functionalization. The lower processing temperatures required for polymers also facilitate more complex microstructure designs.

Hybrid material systems combining silica with chalcogenide glasses have emerged as promising candidates for mid-infrared sensing applications. These composites leverage the mechanical stability of silica while exploiting the extended infrared transparency of chalcogenides, enabling novel sensing capabilities in previously inaccessible spectral regions. Such hybrids have demonstrated particular efficacy in environmental monitoring and chemical detection systems.

Nanomaterial incorporation represents the cutting edge of PCF manufacturing. Carbon nanotubes, graphene, and metallic nanoparticles strategically integrated into the fiber structure can dramatically enhance sensing sensitivity through localized surface plasmon resonance effects. These nanomaterial-enhanced PCFs have demonstrated detection limits orders of magnitude better than conventional designs, particularly for biochemical and gas sensing applications.

Manufacturing techniques have evolved in parallel with material innovations. Advanced methods such as stack-and-draw with precision pressure control, direct laser writing, and 3D printing technologies now enable the creation of complex microstructures with sub-micron precision. These fabrication advances have made possible previously unachievable geometries that maximize birefringence effects while maintaining low optical losses.

Surface modification technologies have also progressed significantly, allowing for post-fabrication enhancement of PCF sensing capabilities. Techniques such as atomic layer deposition and chemical vapor deposition enable the creation of functional nanolayers that can interact specifically with target analytes, dramatically improving both sensitivity and selectivity in sensing applications.

High-purity silica remains the foundation material for most PCFs, but recent innovations have introduced doped variants with germanium, fluorine, and rare-earth elements to manipulate refractive index profiles with unprecedented precision. These dopants enable fine-tuning of birefringence properties critical for sensing applications while maintaining structural integrity under varying environmental conditions.

Polymer-based PCFs represent another significant advancement, offering flexibility and cost-effectiveness compared to their silica counterparts. Materials such as PMMA (polymethyl methacrylate) and CYTOP (cyclic transparent optical polymer) have demonstrated remarkable potential for biosensing applications due to their biocompatibility and ease of surface functionalization. The lower processing temperatures required for polymers also facilitate more complex microstructure designs.

Hybrid material systems combining silica with chalcogenide glasses have emerged as promising candidates for mid-infrared sensing applications. These composites leverage the mechanical stability of silica while exploiting the extended infrared transparency of chalcogenides, enabling novel sensing capabilities in previously inaccessible spectral regions. Such hybrids have demonstrated particular efficacy in environmental monitoring and chemical detection systems.

Nanomaterial incorporation represents the cutting edge of PCF manufacturing. Carbon nanotubes, graphene, and metallic nanoparticles strategically integrated into the fiber structure can dramatically enhance sensing sensitivity through localized surface plasmon resonance effects. These nanomaterial-enhanced PCFs have demonstrated detection limits orders of magnitude better than conventional designs, particularly for biochemical and gas sensing applications.

Manufacturing techniques have evolved in parallel with material innovations. Advanced methods such as stack-and-draw with precision pressure control, direct laser writing, and 3D printing technologies now enable the creation of complex microstructures with sub-micron precision. These fabrication advances have made possible previously unachievable geometries that maximize birefringence effects while maintaining low optical losses.

Surface modification technologies have also progressed significantly, allowing for post-fabrication enhancement of PCF sensing capabilities. Techniques such as atomic layer deposition and chemical vapor deposition enable the creation of functional nanolayers that can interact specifically with target analytes, dramatically improving both sensitivity and selectivity in sensing applications.

Standardization and Calibration Protocols for PCF Sensors

The standardization and calibration of Birefringent Photonic Crystal Fiber (PCF) sensors represent critical challenges in transitioning these advanced sensing technologies from laboratory environments to practical field applications. Currently, the lack of universally accepted protocols significantly hampers widespread industrial adoption and reliable performance comparison between different sensor implementations.

Establishing standardized calibration procedures requires addressing the unique optical properties of birefringent PCFs, particularly their sensitivity to external perturbations such as temperature fluctuations, mechanical strain, and ambient humidity. These environmental factors can substantially alter the birefringence characteristics, potentially leading to measurement inaccuracies if not properly accounted for during calibration.

Several research institutions have proposed calibration methodologies specific to birefringent PCF sensors. The National Institute of Standards and Technology (NIST) has developed preliminary guidelines focusing on temperature compensation techniques, which involve simultaneous measurement of environmental parameters to isolate the target measurand signal. Similarly, the International Electrotechnical Commission (IEC) has initiated working groups dedicated to drafting standards for optical fiber sensors, with specific attention to PCF-based implementations.

Cross-sensitivity management represents another crucial aspect of standardization protocols. Birefringent PCF sensors often exhibit responses to multiple physical parameters simultaneously, necessitating sophisticated algorithms for signal deconvolution. Current best practices involve multi-parameter calibration matrices that quantify the sensor's response to each potential influencing factor, enabling more accurate interpretation of measurement data.

Traceability to SI units remains fundamental for any standardization effort. For birefringent PCF sensors, this typically involves establishing calibration chains linking the measured optical parameters (wavelength shifts, polarization changes) to physical quantities such as temperature, pressure, or concentration. Reference materials with well-characterized properties are essential for this purpose, though their development specifically for PCF applications remains limited.

Inter-laboratory comparison studies have emerged as valuable tools for validating calibration protocols. These collaborative efforts involve multiple facilities performing identical measurements on standardized PCF samples, allowing for statistical analysis of measurement uncertainties and identification of procedural inconsistencies. The European Metrology Research Programme has coordinated several such initiatives, contributing valuable data toward consensus-building in standardization efforts.

Long-term stability assessment constitutes another critical component of comprehensive calibration protocols. Birefringent PCF sensors may exhibit drift over extended periods due to material aging, hydrogen diffusion, or structural relaxation. Standardized aging tests and periodic recalibration schedules are being developed to address these concerns, ensuring measurement reliability throughout the sensor's operational lifetime.

Establishing standardized calibration procedures requires addressing the unique optical properties of birefringent PCFs, particularly their sensitivity to external perturbations such as temperature fluctuations, mechanical strain, and ambient humidity. These environmental factors can substantially alter the birefringence characteristics, potentially leading to measurement inaccuracies if not properly accounted for during calibration.

Several research institutions have proposed calibration methodologies specific to birefringent PCF sensors. The National Institute of Standards and Technology (NIST) has developed preliminary guidelines focusing on temperature compensation techniques, which involve simultaneous measurement of environmental parameters to isolate the target measurand signal. Similarly, the International Electrotechnical Commission (IEC) has initiated working groups dedicated to drafting standards for optical fiber sensors, with specific attention to PCF-based implementations.

Cross-sensitivity management represents another crucial aspect of standardization protocols. Birefringent PCF sensors often exhibit responses to multiple physical parameters simultaneously, necessitating sophisticated algorithms for signal deconvolution. Current best practices involve multi-parameter calibration matrices that quantify the sensor's response to each potential influencing factor, enabling more accurate interpretation of measurement data.

Traceability to SI units remains fundamental for any standardization effort. For birefringent PCF sensors, this typically involves establishing calibration chains linking the measured optical parameters (wavelength shifts, polarization changes) to physical quantities such as temperature, pressure, or concentration. Reference materials with well-characterized properties are essential for this purpose, though their development specifically for PCF applications remains limited.

Inter-laboratory comparison studies have emerged as valuable tools for validating calibration protocols. These collaborative efforts involve multiple facilities performing identical measurements on standardized PCF samples, allowing for statistical analysis of measurement uncertainties and identification of procedural inconsistencies. The European Metrology Research Programme has coordinated several such initiatives, contributing valuable data toward consensus-building in standardization efforts.

Long-term stability assessment constitutes another critical component of comprehensive calibration protocols. Birefringent PCF sensors may exhibit drift over extended periods due to material aging, hydrogen diffusion, or structural relaxation. Standardized aging tests and periodic recalibration schedules are being developed to address these concerns, ensuring measurement reliability throughout the sensor's operational lifetime.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!