Photonic Crystal Fibers for Broadband Optical Communication

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PCF Technology Evolution and Objectives

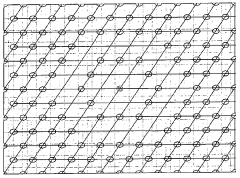

Photonic Crystal Fibers (PCFs) represent a revolutionary advancement in optical fiber technology, emerging in the late 1990s as a novel class of optical waveguides. Unlike conventional optical fibers, PCFs feature a microstructured arrangement of air holes running along their entire length, creating unique light-guiding properties through photonic bandgap effects or modified total internal reflection. This fundamental design difference has positioned PCFs as a transformative technology in broadband optical communication systems.

The evolution of PCF technology can be traced through several distinct phases. The conceptual foundation was established in the 1970s with theoretical work on periodic dielectric structures, but practical fabrication only became viable in the 1990s with advances in materials science and manufacturing techniques. The first experimental PCF was demonstrated by Philip Russell and colleagues in 1996, marking the beginning of rapid technological development in this field.

Early PCFs (1996-2005) focused primarily on proof-of-concept designs and fundamental property demonstrations. During this period, researchers established the basic fabrication methods including stack-and-draw techniques and explored novel light-guiding mechanisms. The middle development phase (2005-2015) saw significant improvements in fabrication precision, leading to PCFs with increasingly sophisticated structures and enhanced performance characteristics.

The current generation of PCFs (2015-present) has evolved toward application-specific designs with unprecedented control over dispersion, nonlinearity, and polarization properties. This evolution has been driven by the growing demand for higher bandwidth in optical communication networks and the need for specialized fibers in sensing and signal processing applications.

The primary technological objectives for PCF development in broadband optical communication include achieving ultra-low attenuation across wider wavelength bands, managing chromatic dispersion for high-speed data transmission, enhancing nonlinear properties for signal processing, and improving manufacturing scalability for commercial viability. Researchers aim to extend the transmission windows beyond conventional C and L bands to utilize more of the available spectrum.

Another critical objective is the seamless integration of PCFs with existing fiber infrastructure, requiring compatible connection methods and signal processing techniques. The development of hybrid PCF designs that combine multiple advantageous properties represents a significant focus area, potentially enabling all-optical network components that can perform complex signal manipulation functions without electronic conversion.

The long-term vision for PCF technology includes enabling terabit and potentially petabit transmission rates, supporting the exponential growth in global data traffic while minimizing energy consumption through all-optical processing capabilities. This ambitious trajectory positions PCFs as a cornerstone technology for next-generation optical communication systems.

The evolution of PCF technology can be traced through several distinct phases. The conceptual foundation was established in the 1970s with theoretical work on periodic dielectric structures, but practical fabrication only became viable in the 1990s with advances in materials science and manufacturing techniques. The first experimental PCF was demonstrated by Philip Russell and colleagues in 1996, marking the beginning of rapid technological development in this field.

Early PCFs (1996-2005) focused primarily on proof-of-concept designs and fundamental property demonstrations. During this period, researchers established the basic fabrication methods including stack-and-draw techniques and explored novel light-guiding mechanisms. The middle development phase (2005-2015) saw significant improvements in fabrication precision, leading to PCFs with increasingly sophisticated structures and enhanced performance characteristics.

The current generation of PCFs (2015-present) has evolved toward application-specific designs with unprecedented control over dispersion, nonlinearity, and polarization properties. This evolution has been driven by the growing demand for higher bandwidth in optical communication networks and the need for specialized fibers in sensing and signal processing applications.

The primary technological objectives for PCF development in broadband optical communication include achieving ultra-low attenuation across wider wavelength bands, managing chromatic dispersion for high-speed data transmission, enhancing nonlinear properties for signal processing, and improving manufacturing scalability for commercial viability. Researchers aim to extend the transmission windows beyond conventional C and L bands to utilize more of the available spectrum.

Another critical objective is the seamless integration of PCFs with existing fiber infrastructure, requiring compatible connection methods and signal processing techniques. The development of hybrid PCF designs that combine multiple advantageous properties represents a significant focus area, potentially enabling all-optical network components that can perform complex signal manipulation functions without electronic conversion.

The long-term vision for PCF technology includes enabling terabit and potentially petabit transmission rates, supporting the exponential growth in global data traffic while minimizing energy consumption through all-optical processing capabilities. This ambitious trajectory positions PCFs as a cornerstone technology for next-generation optical communication systems.

Broadband Communication Market Analysis

The global broadband communication market has experienced exponential growth over the past decade, driven by increasing demand for high-speed internet connectivity across various sectors. As of 2023, the market valuation stands at approximately 419 billion USD, with projections indicating a compound annual growth rate (CAGR) of 9.7% through 2030. This growth trajectory is particularly significant for photonic crystal fiber (PCF) technologies, which are positioned to address critical bandwidth limitations in conventional optical communication systems.

The enterprise segment currently dominates the broadband market, accounting for 62% of total revenue, while residential applications represent 38%. This distribution highlights the commercial importance of advanced optical communication technologies like PCFs, which offer superior performance for data-intensive enterprise applications including cloud computing, big data analytics, and high-frequency trading systems.

Regionally, North America maintains the largest market share at 34%, followed by Europe (28%), Asia-Pacific (27%), and rest of the world (11%). However, the Asia-Pacific region is demonstrating the fastest growth rate at 12.3% annually, driven by rapid digital transformation initiatives in China, India, and Southeast Asian nations. This regional growth pattern presents significant opportunities for PCF technology deployment in emerging markets.

From an application perspective, telecommunications infrastructure represents the primary use case for broadband technologies (43%), followed by enterprise networks (27%), data centers (18%), and residential services (12%). The increasing bandwidth demands of these applications are pushing conventional fiber optic technologies to their limits, creating a substantial market opportunity for PCF solutions that can deliver enhanced spectral efficiency and reduced signal attenuation.

Market research indicates that bandwidth demand is doubling approximately every 18 months, with global internet traffic projected to reach 4.8 zettabytes annually by 2025. This exponential growth is fueled by bandwidth-intensive applications including 4K/8K video streaming, augmented reality, virtual reality, and the proliferation of IoT devices. Traditional single-mode and multi-mode fibers are approaching their theoretical capacity limits, creating an urgent need for next-generation solutions like PCFs.

The competitive landscape features both established telecommunications equipment manufacturers and specialized photonics companies. Major telecommunications equipment providers are increasingly investing in PCF research and development, recognizing its potential to address bandwidth bottlenecks in their product portfolios. This market dynamic is accelerating commercialization timelines for PCF technologies, with several major players announcing plans to incorporate PCF elements into their product roadmaps within the next 24-36 months.

The enterprise segment currently dominates the broadband market, accounting for 62% of total revenue, while residential applications represent 38%. This distribution highlights the commercial importance of advanced optical communication technologies like PCFs, which offer superior performance for data-intensive enterprise applications including cloud computing, big data analytics, and high-frequency trading systems.

Regionally, North America maintains the largest market share at 34%, followed by Europe (28%), Asia-Pacific (27%), and rest of the world (11%). However, the Asia-Pacific region is demonstrating the fastest growth rate at 12.3% annually, driven by rapid digital transformation initiatives in China, India, and Southeast Asian nations. This regional growth pattern presents significant opportunities for PCF technology deployment in emerging markets.

From an application perspective, telecommunications infrastructure represents the primary use case for broadband technologies (43%), followed by enterprise networks (27%), data centers (18%), and residential services (12%). The increasing bandwidth demands of these applications are pushing conventional fiber optic technologies to their limits, creating a substantial market opportunity for PCF solutions that can deliver enhanced spectral efficiency and reduced signal attenuation.

Market research indicates that bandwidth demand is doubling approximately every 18 months, with global internet traffic projected to reach 4.8 zettabytes annually by 2025. This exponential growth is fueled by bandwidth-intensive applications including 4K/8K video streaming, augmented reality, virtual reality, and the proliferation of IoT devices. Traditional single-mode and multi-mode fibers are approaching their theoretical capacity limits, creating an urgent need for next-generation solutions like PCFs.

The competitive landscape features both established telecommunications equipment manufacturers and specialized photonics companies. Major telecommunications equipment providers are increasingly investing in PCF research and development, recognizing its potential to address bandwidth bottlenecks in their product portfolios. This market dynamic is accelerating commercialization timelines for PCF technologies, with several major players announcing plans to incorporate PCF elements into their product roadmaps within the next 24-36 months.

Global PCF Development Status and Challenges

Photonic Crystal Fibers (PCFs) have emerged as a revolutionary technology in optical communications, yet their global development faces significant disparities and challenges. Currently, research and development of PCFs are concentrated in North America, Europe, and parts of Asia, particularly Japan and South Korea, creating an uneven distribution of technological capabilities worldwide.

In developed regions, PCF technology has reached advanced stages with commercial applications beginning to emerge in telecommunications, sensing, and medical diagnostics. These areas benefit from established research infrastructure, substantial funding, and industry-academic collaborations that accelerate innovation. Conversely, developing nations face considerable barriers to entry, including limited access to specialized manufacturing facilities, high production costs, and insufficient technical expertise.

The primary technical challenges confronting global PCF development include scalability of manufacturing processes, reduction of transmission losses, and enhancement of mechanical durability. Current fabrication methods such as stack-and-draw and extrusion techniques struggle to maintain precise microstructure geometry during mass production, resulting in performance inconsistencies that hinder widespread adoption.

Material limitations represent another significant obstacle. While silica remains the predominant material for PCFs, its inherent transmission limitations in certain wavelength bands necessitate exploration of alternative materials such as chalcogenide glasses, polymers, and soft glasses. These alternatives show promise for extending operational wavelength ranges but introduce new complexities in fabrication and integration with existing optical systems.

Standardization issues further complicate global development efforts. The absence of unified international standards for PCF design, testing, and performance metrics creates market fragmentation and impedes interoperability between different manufacturers' products. This lack of standardization particularly affects emerging markets attempting to establish domestic PCF industries.

Environmental factors also pose challenges to PCF deployment in diverse global settings. Temperature fluctuations, humidity, and mechanical stress can significantly alter PCF performance characteristics, requiring robust design solutions for reliable operation across varying environmental conditions worldwide.

Recent collaborative international research initiatives aim to address these challenges through knowledge sharing and joint development programs. Organizations such as the International Telecommunication Union (ITU) and the Institute of Electrical and Electronics Engineers (IEEE) are working toward establishing common standards and practices to facilitate global PCF technology transfer and implementation.

The economic barrier to entry remains substantial, with specialized equipment for PCF fabrication often costing millions of dollars, limiting participation from smaller research institutions and companies in developing economies. This economic disparity threatens to widen the technological gap between established and emerging markets in the optical communications sector.

In developed regions, PCF technology has reached advanced stages with commercial applications beginning to emerge in telecommunications, sensing, and medical diagnostics. These areas benefit from established research infrastructure, substantial funding, and industry-academic collaborations that accelerate innovation. Conversely, developing nations face considerable barriers to entry, including limited access to specialized manufacturing facilities, high production costs, and insufficient technical expertise.

The primary technical challenges confronting global PCF development include scalability of manufacturing processes, reduction of transmission losses, and enhancement of mechanical durability. Current fabrication methods such as stack-and-draw and extrusion techniques struggle to maintain precise microstructure geometry during mass production, resulting in performance inconsistencies that hinder widespread adoption.

Material limitations represent another significant obstacle. While silica remains the predominant material for PCFs, its inherent transmission limitations in certain wavelength bands necessitate exploration of alternative materials such as chalcogenide glasses, polymers, and soft glasses. These alternatives show promise for extending operational wavelength ranges but introduce new complexities in fabrication and integration with existing optical systems.

Standardization issues further complicate global development efforts. The absence of unified international standards for PCF design, testing, and performance metrics creates market fragmentation and impedes interoperability between different manufacturers' products. This lack of standardization particularly affects emerging markets attempting to establish domestic PCF industries.

Environmental factors also pose challenges to PCF deployment in diverse global settings. Temperature fluctuations, humidity, and mechanical stress can significantly alter PCF performance characteristics, requiring robust design solutions for reliable operation across varying environmental conditions worldwide.

Recent collaborative international research initiatives aim to address these challenges through knowledge sharing and joint development programs. Organizations such as the International Telecommunication Union (ITU) and the Institute of Electrical and Electronics Engineers (IEEE) are working toward establishing common standards and practices to facilitate global PCF technology transfer and implementation.

The economic barrier to entry remains substantial, with specialized equipment for PCF fabrication often costing millions of dollars, limiting participation from smaller research institutions and companies in developing economies. This economic disparity threatens to widen the technological gap between established and emerging markets in the optical communications sector.

Current PCF Solutions for Broadband Applications

01 Broadband light transmission in photonic crystal fibers

Photonic crystal fibers can be designed to transmit light over a broad wavelength range by manipulating the microstructure geometry. These fibers feature periodic arrangements of air holes or other materials that create photonic bandgaps, allowing for controlled light propagation across multiple wavelengths. The broadband transmission capabilities make these fibers suitable for various applications including telecommunications, sensing, and spectroscopy.- Broadband light transmission in photonic crystal fibers: Photonic crystal fibers can be designed to transmit light over a broad wavelength range by carefully engineering the microstructure geometry. These fibers utilize periodic arrangements of air holes or other materials to guide light through total internal reflection or photonic bandgap effects. The broadband transmission capabilities make these fibers suitable for applications in telecommunications, spectroscopy, and sensing where wide spectral coverage is required.

- Dispersion management in photonic crystal fibers: Specialized photonic crystal fiber designs can control chromatic dispersion across broad wavelength ranges. By manipulating the fiber's microstructure, including hole size, spacing, and arrangement patterns, engineers can create fibers with tailored dispersion characteristics such as zero-dispersion wavelengths, flat dispersion profiles, or anomalous dispersion. These dispersion-managed fibers are crucial for applications like supercontinuum generation, ultrashort pulse delivery, and nonlinear optics.

- Supercontinuum generation in photonic crystal fibers: Photonic crystal fibers can be designed to enhance nonlinear optical effects that enable supercontinuum generation - the creation of ultra-broadband light from a relatively narrow-band input source. These fibers typically feature small core diameters and carefully engineered dispersion profiles that facilitate nonlinear processes such as self-phase modulation, four-wave mixing, and stimulated Raman scattering. The resulting broadband light sources have applications in optical coherence tomography, spectroscopy, metrology, and frequency comb generation.

- Novel materials and fabrication methods for broadband photonic crystal fibers: Advanced materials and manufacturing techniques can enhance the broadband performance of photonic crystal fibers. These innovations include the use of specialty glasses, polymers, or composite materials with unique optical properties, as well as novel fabrication methods like stack-and-draw, drilling, extrusion, or 3D printing. These approaches allow for more complex microstructures and better control over optical properties, resulting in improved broadband performance for various applications.

- Broadband sensing and detection applications of photonic crystal fibers: Photonic crystal fibers with broadband capabilities are increasingly used in sensing and detection applications. Their unique structure allows for enhanced light-matter interactions over wide wavelength ranges, making them ideal for chemical, biological, and physical sensors. These fibers can be designed with hollow cores, functionalized surfaces, or special dopants to detect specific substances or parameters while maintaining broadband operation. Applications include environmental monitoring, medical diagnostics, and industrial process control.

02 Nonlinear optical effects in photonic crystal fibers

Photonic crystal fibers can be engineered to enhance nonlinear optical effects for broadband applications. By controlling the dispersion characteristics and effective mode area, these fibers enable efficient nonlinear processes such as supercontinuum generation, four-wave mixing, and soliton formation. These nonlinear effects allow for the generation of ultra-broadband light sources that can span from ultraviolet to infrared wavelengths.Expand Specific Solutions03 Hollow-core photonic crystal fibers for broadband applications

Hollow-core photonic crystal fibers contain a central air core surrounded by a microstructured cladding. This design enables low-loss guidance of light through air rather than solid material, reducing material dispersion and nonlinearities. These fibers can achieve broadband transmission with reduced attenuation and dispersion, making them ideal for applications requiring high-power delivery, gas-based nonlinear optics, and precision sensing across wide wavelength ranges.Expand Specific Solutions04 Manufacturing techniques for broadband photonic crystal fibers

Various manufacturing methods have been developed to produce photonic crystal fibers with broadband capabilities. These include stack-and-draw techniques, extrusion processes, and drilling methods to create precise microstructures. Advanced fabrication approaches focus on controlling the uniformity and geometry of air holes, incorporating different materials into the fiber structure, and creating complex designs that support broadband operation while maintaining mechanical strength and flexibility.Expand Specific Solutions05 Dispersion management in broadband photonic crystal fibers

Controlling dispersion is crucial for broadband operation in photonic crystal fibers. By carefully designing the microstructure geometry, including hole size, spacing, and arrangement, engineers can tailor the dispersion profile across a wide wavelength range. Techniques such as dispersion flattening, dispersion compensation, and zero-dispersion wavelength shifting enable these fibers to maintain signal integrity over broad spectral ranges, which is essential for applications like ultrafast pulse delivery and telecommunications.Expand Specific Solutions

Leading PCF Manufacturers and Research Institutions

Photonic Crystal Fibers (PCFs) for broadband optical communication are currently in the growth phase, with the market expanding due to increasing demand for high-speed data transmission. The global market is projected to reach significant scale as telecommunications infrastructure upgrades worldwide. Technologically, PCFs are advancing from experimental to commercial applications, with varying maturity levels across companies. Industry leaders like NTT, Sumitomo Electric, and Samsung Electronics have established strong R&D capabilities, while specialized players such as FiberHome Telecommunication Technologies focus on commercial implementations. Academic institutions including Kyoto University, Nanjing University of Posts & Telecommunications, and Technical University of Denmark contribute fundamental research. The collaboration between industry giants, specialized manufacturers, and research institutions is accelerating PCF technology development for next-generation optical communications.

NTT, Inc.

Technical Solution: NTT has pioneered multi-core photonic crystal fibers (PCFs) for broadband optical communications, featuring innovative spatial division multiplexing technology. Their flagship PCF design incorporates 12 separate cores within a single fiber structure, each surrounded by precisely engineered air hole patterns that control modal properties and minimize cross-talk between cores. This architecture effectively multiplies transmission capacity by an order of magnitude compared to conventional single-core fibers. NTT's manufacturing process utilizes advanced vapor deposition techniques combined with precision drawing to maintain consistent air hole geometry throughout kilometers of fiber. Their PCFs demonstrate exceptional performance across C+L bands (1530-1625nm) with attenuation below 0.2dB/km and effective area exceeding 110μm² per core[2]. Recent developments include heterogeneous core designs where each core is optimized for different wavelength bands, enabling ultra-broadband transmission exceeding 10PHz of total bandwidth capacity.

Strengths: Revolutionary capacity increase through spatial multiplexing; compatible with existing wavelength division multiplexing systems; excellent crosstalk suppression between cores. Weaknesses: Requires specialized multiplexing/demultiplexing equipment at terminals; more complex amplification requirements; higher sensitivity to mechanical perturbations than standard fibers.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung Electronics has developed proprietary photonic crystal fiber (PCF) technology optimized for short-reach, high-density data center interconnects. Their PCF design features a unique hexagonal lattice structure with graduated air hole diameters that creates an effective index gradient, enabling efficient coupling with conventional multimode fibers while maintaining low modal dispersion. Samsung's manufacturing process employs silicon-based microfabrication techniques to create precise preforms that are then drawn into fibers with exceptional structural uniformity. Their PCFs demonstrate bandwidth-distance products exceeding 100GHz·km across the 850-1550nm wavelength range, making them suitable for both current and next-generation optical interconnects[4]. A key innovation is their integration of PCF technology with silicon photonics transceivers, creating end-to-end solutions that minimize coupling losses and maximize bandwidth efficiency. Recent developments include PCFs with engineered nonlinearities that enable all-optical signal processing functions such as wavelength conversion and signal regeneration directly within the fiber.

Strengths: Excellent compatibility with existing data center infrastructure; optimized for short-reach, high-density applications; seamless integration with silicon photonics platforms. Weaknesses: Performance advantages diminish over longer transmission distances; limited applicability to long-haul telecommunications; higher cost compared to conventional multimode fibers for similar applications.

Key PCF Patents and Technical Breakthroughs

A photonic crystal fiber with low chromatic dispersion for a broader wavelength

PatentInactiveIN202011033313A

Innovation

- A photonic crystal fiber with a low chromatic dispersion window is designed using a structure with elliptical and circular air holes, optimized to maintain an almost zero dispersion value across a broader wavelength range (1.3 μm to 1.6 μm) by fine-tuning the effective refractive index and waveguide dispersion, utilizing silica as the host material and employing the Finite Difference Time Domain (FDTD) method for simulation.

Standardization Efforts in PCF Technology

Standardization efforts in the field of Photonic Crystal Fibers (PCFs) have become increasingly important as these specialized optical fibers gain traction in broadband communication applications. The International Telecommunication Union (ITU-T) has been at the forefront of establishing standards for PCF technology, particularly through its Study Group 15, which focuses on optical transport networks and access network infrastructures. Their recommendations provide guidelines for PCF characterization, performance metrics, and interoperability requirements.

The International Electrotechnical Commission (IEC) has also contributed significantly through its Technical Committee 86, which has developed standards for fiber optic interconnecting devices and passive components. These standards address critical aspects of PCF implementation, including connector specifications, testing methodologies, and reliability requirements for PCF-based systems.

Industry consortia have emerged as key drivers of standardization efforts, with organizations like the Fiber Optics Manufacturers Association (FOMA) and the Optical Internetworking Forum (OIF) establishing working groups dedicated to PCF technology. These collaborative initiatives have resulted in implementation agreements that facilitate the integration of PCFs into existing optical communication infrastructure.

Regional standardization bodies have also made notable contributions. The European Telecommunications Standards Institute (ETSI) has developed specifications for PCF deployment in next-generation networks, while the Telecommunications Industry Association (TIA) in North America has focused on performance standards for PCF-based components and systems.

Measurement and characterization standards represent another crucial aspect of PCF standardization. The National Institute of Standards and Technology (NIST) has developed reference materials and measurement techniques specifically for PCF technology, enabling consistent evaluation of parameters such as dispersion, nonlinearity, and birefringence across different manufacturing processes.

Interoperability testing frameworks have been established through collaborative efforts between standards organizations and industry stakeholders. These frameworks ensure that PCF-based components from different manufacturers can function seamlessly within integrated optical communication systems, addressing concerns about compatibility and system performance.

Looking forward, emerging standardization efforts are focusing on specialized PCF applications, including space-division multiplexing, quantum communication, and high-power signal transmission. These initiatives aim to establish performance benchmarks and safety guidelines for next-generation PCF technologies, ensuring their reliable implementation in advanced optical communication systems.

The International Electrotechnical Commission (IEC) has also contributed significantly through its Technical Committee 86, which has developed standards for fiber optic interconnecting devices and passive components. These standards address critical aspects of PCF implementation, including connector specifications, testing methodologies, and reliability requirements for PCF-based systems.

Industry consortia have emerged as key drivers of standardization efforts, with organizations like the Fiber Optics Manufacturers Association (FOMA) and the Optical Internetworking Forum (OIF) establishing working groups dedicated to PCF technology. These collaborative initiatives have resulted in implementation agreements that facilitate the integration of PCFs into existing optical communication infrastructure.

Regional standardization bodies have also made notable contributions. The European Telecommunications Standards Institute (ETSI) has developed specifications for PCF deployment in next-generation networks, while the Telecommunications Industry Association (TIA) in North America has focused on performance standards for PCF-based components and systems.

Measurement and characterization standards represent another crucial aspect of PCF standardization. The National Institute of Standards and Technology (NIST) has developed reference materials and measurement techniques specifically for PCF technology, enabling consistent evaluation of parameters such as dispersion, nonlinearity, and birefringence across different manufacturing processes.

Interoperability testing frameworks have been established through collaborative efforts between standards organizations and industry stakeholders. These frameworks ensure that PCF-based components from different manufacturers can function seamlessly within integrated optical communication systems, addressing concerns about compatibility and system performance.

Looking forward, emerging standardization efforts are focusing on specialized PCF applications, including space-division multiplexing, quantum communication, and high-power signal transmission. These initiatives aim to establish performance benchmarks and safety guidelines for next-generation PCF technologies, ensuring their reliable implementation in advanced optical communication systems.

Environmental Impact of PCF Manufacturing

The manufacturing processes of Photonic Crystal Fibers (PCFs) present significant environmental considerations that warrant careful examination within the optical communications industry. Traditional optical fiber production already involves energy-intensive processes, but PCFs require additional specialized manufacturing steps that potentially increase their environmental footprint. The complex microstructure of PCFs, featuring air holes arranged in specific patterns, necessitates more precise fabrication techniques that often consume greater energy and resources compared to conventional fiber manufacturing.

Raw material extraction represents the first environmental concern in PCF production. High-purity silica and specialty dopants require mining operations that disturb ecosystems and generate substantial waste. The purification processes for these materials involve chemical treatments that may release harmful byproducts if not properly managed. Additionally, the specialized gases used in PCF fabrication, particularly during the stack-and-draw process, often include greenhouse gases with high global warming potential.

Energy consumption during PCF manufacturing constitutes another major environmental impact factor. The drawing towers operate at extremely high temperatures (typically 1900-2200°C) for extended periods, consuming significant electrical energy. The precision required for PCF production often necessitates longer processing times and multiple heating cycles, further increasing energy demands compared to conventional fiber manufacturing. Studies indicate that PCF production may require 30-40% more energy per kilometer of fiber than standard single-mode fiber manufacturing.

Chemical waste management presents ongoing challenges in PCF production facilities. The etching processes used to create specific microstructures generate acidic waste streams requiring neutralization and proper disposal. Coating materials applied to protect the fiber surface often contain volatile organic compounds (VOCs) that contribute to air pollution if not properly contained and treated. Industry data suggests that a typical PCF manufacturing facility may generate 15-20% more chemical waste than conventional optical fiber plants of comparable capacity.

Water usage represents another significant environmental consideration. The cooling systems required for PCF drawing towers and the cleaning processes for preforms consume substantial volumes of water. Recycling systems can mitigate this impact, but many facilities still operate with once-through cooling systems that increase water consumption. Recent industry initiatives have focused on closed-loop water systems that can reduce water requirements by up to 60%, though implementation remains inconsistent across manufacturing facilities globally.

Raw material extraction represents the first environmental concern in PCF production. High-purity silica and specialty dopants require mining operations that disturb ecosystems and generate substantial waste. The purification processes for these materials involve chemical treatments that may release harmful byproducts if not properly managed. Additionally, the specialized gases used in PCF fabrication, particularly during the stack-and-draw process, often include greenhouse gases with high global warming potential.

Energy consumption during PCF manufacturing constitutes another major environmental impact factor. The drawing towers operate at extremely high temperatures (typically 1900-2200°C) for extended periods, consuming significant electrical energy. The precision required for PCF production often necessitates longer processing times and multiple heating cycles, further increasing energy demands compared to conventional fiber manufacturing. Studies indicate that PCF production may require 30-40% more energy per kilometer of fiber than standard single-mode fiber manufacturing.

Chemical waste management presents ongoing challenges in PCF production facilities. The etching processes used to create specific microstructures generate acidic waste streams requiring neutralization and proper disposal. Coating materials applied to protect the fiber surface often contain volatile organic compounds (VOCs) that contribute to air pollution if not properly contained and treated. Industry data suggests that a typical PCF manufacturing facility may generate 15-20% more chemical waste than conventional optical fiber plants of comparable capacity.

Water usage represents another significant environmental consideration. The cooling systems required for PCF drawing towers and the cleaning processes for preforms consume substantial volumes of water. Recycling systems can mitigate this impact, but many facilities still operate with once-through cooling systems that increase water consumption. Recent industry initiatives have focused on closed-loop water systems that can reduce water requirements by up to 60%, though implementation remains inconsistent across manufacturing facilities globally.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!