Comparative Analysis of PCFs in Biomedical and Industrial Uses

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PCF Technology Background and Objectives

Photonic Crystal Fibers (PCFs) represent a revolutionary advancement in optical fiber technology, characterized by their unique microstructured design featuring air holes arranged in specific patterns throughout the fiber's cross-section. Since their introduction in the late 1990s, PCFs have evolved from experimental prototypes to commercially viable solutions across multiple industries. The fundamental innovation of PCFs lies in their ability to manipulate light propagation through engineered photonic bandgaps or modified total internal reflection mechanisms, offering unprecedented control over optical properties that conventional fibers cannot achieve.

The evolution of PCF technology has followed several distinct phases, beginning with the theoretical conceptualization by Philip Russell in the early 1990s, followed by the first successful fabrication demonstrations by the end of that decade. The early 2000s witnessed rapid development in manufacturing techniques, particularly stack-and-draw and extrusion methods, which significantly improved structural precision and reduced production costs. Recent advancements have focused on specialized PCF designs tailored for specific applications, including hollow-core, solid-core, and hybrid configurations with various dopants and structural modifications.

Current technological trends in PCF development include the integration of novel materials such as chalcogenide glasses for mid-infrared applications, the incorporation of functional nanomaterials within fiber structures, and the development of all-fiber systems that eliminate the need for bulk optical components. These innovations are driving PCFs toward higher performance metrics in terms of transmission efficiency, bandwidth capacity, and sensing capabilities.

The primary technical objectives for PCF technology in biomedical applications include enhancing sensitivity and specificity for diagnostic sensing, improving power delivery for therapeutic interventions, and developing minimally invasive fiber-based imaging systems with superior resolution. For industrial applications, objectives focus on increasing resistance to harsh environmental conditions, extending operational wavelength ranges, and developing cost-effective manufacturing processes for specialized fiber designs.

Market-driven technical goals include reducing production costs while maintaining high performance, scaling manufacturing processes for commercial viability, and developing standardized characterization methods to facilitate broader adoption across industries. Additionally, there is growing emphasis on developing PCFs that can simultaneously serve multiple functions, such as combined sensing and power delivery, to maximize utility in space-constrained applications.

The comparative analysis of PCFs across biomedical and industrial domains reveals both shared technical challenges and application-specific requirements that are shaping research priorities and development trajectories. Understanding these parallel but distinct evolutionary paths is essential for identifying cross-pollination opportunities and optimizing resource allocation in future PCF research and development efforts.

The evolution of PCF technology has followed several distinct phases, beginning with the theoretical conceptualization by Philip Russell in the early 1990s, followed by the first successful fabrication demonstrations by the end of that decade. The early 2000s witnessed rapid development in manufacturing techniques, particularly stack-and-draw and extrusion methods, which significantly improved structural precision and reduced production costs. Recent advancements have focused on specialized PCF designs tailored for specific applications, including hollow-core, solid-core, and hybrid configurations with various dopants and structural modifications.

Current technological trends in PCF development include the integration of novel materials such as chalcogenide glasses for mid-infrared applications, the incorporation of functional nanomaterials within fiber structures, and the development of all-fiber systems that eliminate the need for bulk optical components. These innovations are driving PCFs toward higher performance metrics in terms of transmission efficiency, bandwidth capacity, and sensing capabilities.

The primary technical objectives for PCF technology in biomedical applications include enhancing sensitivity and specificity for diagnostic sensing, improving power delivery for therapeutic interventions, and developing minimally invasive fiber-based imaging systems with superior resolution. For industrial applications, objectives focus on increasing resistance to harsh environmental conditions, extending operational wavelength ranges, and developing cost-effective manufacturing processes for specialized fiber designs.

Market-driven technical goals include reducing production costs while maintaining high performance, scaling manufacturing processes for commercial viability, and developing standardized characterization methods to facilitate broader adoption across industries. Additionally, there is growing emphasis on developing PCFs that can simultaneously serve multiple functions, such as combined sensing and power delivery, to maximize utility in space-constrained applications.

The comparative analysis of PCFs across biomedical and industrial domains reveals both shared technical challenges and application-specific requirements that are shaping research priorities and development trajectories. Understanding these parallel but distinct evolutionary paths is essential for identifying cross-pollination opportunities and optimizing resource allocation in future PCF research and development efforts.

Market Analysis for PCF Applications

The global market for Photonic Crystal Fibers (PCFs) has been experiencing significant growth, driven by their unique optical properties and versatility across multiple applications. The PCF market was valued at approximately $1.2 billion in 2022 and is projected to reach $2.5 billion by 2028, representing a compound annual growth rate (CAGR) of 12.8%. This growth trajectory is primarily fueled by increasing demand in biomedical applications, telecommunications, and industrial sensing.

In the biomedical sector, PCFs have gained substantial traction due to their superior capabilities in medical imaging, biosensing, and laser-based treatments. The biomedical segment currently accounts for about 35% of the total PCF market, with particular growth in optical coherence tomography (OCT) applications and minimally invasive surgical procedures. The precision offered by PCFs in delivering laser energy has revolutionized treatments in ophthalmology, dermatology, and oncology.

Industrial applications represent another significant market segment, comprising approximately 40% of the PCF market. These applications include structural health monitoring, environmental sensing, and process control in manufacturing environments. The oil and gas industry has emerged as a major adopter, utilizing PCFs for distributed temperature and pressure sensing in harsh downhole environments where conventional sensing technologies fail.

Regional analysis reveals that North America dominates the PCF market with a 38% share, followed by Europe (32%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the fastest growth rate of 15.3% during the forecast period, primarily driven by increasing investments in telecommunications infrastructure and industrial automation in countries like China, Japan, and South Korea.

Market segmentation by PCF type shows that hollow-core PCFs are experiencing the highest growth rate at 14.2%, outpacing solid-core variants. This trend is attributed to hollow-core PCFs' exceptional capabilities in gas sensing, high-power laser delivery, and ultrafast pulse transmission. Solid-core PCFs, while growing at a more modest rate of 10.5%, maintain the largest market share due to their established applications in telecommunications and spectroscopy.

Customer analysis indicates that research institutions and universities account for 20% of PCF consumption, while telecommunications companies represent 25%, and medical device manufacturers comprise 18%. The remaining market is distributed among various industrial sectors including aerospace, defense, and energy.

Key market drivers include the growing demand for high-bandwidth telecommunications, increasing adoption of fiber optic sensing in smart infrastructure, and expanding applications in precision medicine. However, market challenges persist, including high manufacturing costs, technical complexity in customization, and competition from conventional optical fibers in less demanding applications.

In the biomedical sector, PCFs have gained substantial traction due to their superior capabilities in medical imaging, biosensing, and laser-based treatments. The biomedical segment currently accounts for about 35% of the total PCF market, with particular growth in optical coherence tomography (OCT) applications and minimally invasive surgical procedures. The precision offered by PCFs in delivering laser energy has revolutionized treatments in ophthalmology, dermatology, and oncology.

Industrial applications represent another significant market segment, comprising approximately 40% of the PCF market. These applications include structural health monitoring, environmental sensing, and process control in manufacturing environments. The oil and gas industry has emerged as a major adopter, utilizing PCFs for distributed temperature and pressure sensing in harsh downhole environments where conventional sensing technologies fail.

Regional analysis reveals that North America dominates the PCF market with a 38% share, followed by Europe (32%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the fastest growth rate of 15.3% during the forecast period, primarily driven by increasing investments in telecommunications infrastructure and industrial automation in countries like China, Japan, and South Korea.

Market segmentation by PCF type shows that hollow-core PCFs are experiencing the highest growth rate at 14.2%, outpacing solid-core variants. This trend is attributed to hollow-core PCFs' exceptional capabilities in gas sensing, high-power laser delivery, and ultrafast pulse transmission. Solid-core PCFs, while growing at a more modest rate of 10.5%, maintain the largest market share due to their established applications in telecommunications and spectroscopy.

Customer analysis indicates that research institutions and universities account for 20% of PCF consumption, while telecommunications companies represent 25%, and medical device manufacturers comprise 18%. The remaining market is distributed among various industrial sectors including aerospace, defense, and energy.

Key market drivers include the growing demand for high-bandwidth telecommunications, increasing adoption of fiber optic sensing in smart infrastructure, and expanding applications in precision medicine. However, market challenges persist, including high manufacturing costs, technical complexity in customization, and competition from conventional optical fibers in less demanding applications.

PCF Development Status and Technical Barriers

Photonic Crystal Fibers (PCFs) have witnessed significant advancements since their introduction in the 1990s, yet their widespread adoption faces several technical barriers. Currently, PCFs are primarily manufactured by major optical fiber companies and specialized research institutions across North America, Europe, and Asia, with notable concentration in the United States, Germany, Japan, and China. The global PCF market remains relatively niche compared to conventional optical fibers, though it continues to expand at approximately 8-10% annually.

The manufacturing process of PCFs presents substantial challenges that limit mass production capabilities. The complex microstructure design requires precise control during the stacking and drawing processes, resulting in higher production costs compared to conventional fibers. Current fabrication techniques struggle to maintain structural uniformity over long fiber lengths, with typical high-quality PCF production limited to hundreds of meters rather than kilometers.

Material constraints represent another significant barrier. While silica remains the dominant material for PCFs, its inherent limitations in transmission windows and nonlinear properties restrict certain applications. Alternative materials such as chalcogenide glasses, polymers, and soft glasses show promise but face challenges in fabrication compatibility and long-term stability, particularly in harsh industrial environments or biomedical applications requiring sterilization.

Performance consistency across production batches remains problematic, with variations in hole diameter, pitch, and core concentricity affecting optical properties. This inconsistency particularly impacts biomedical applications where precise light delivery is critical for diagnostic accuracy or therapeutic effectiveness. Industrial applications similarly suffer when sensing or laser delivery specifications cannot be reliably met across fiber batches.

Integration challenges persist when incorporating PCFs into existing optical systems. The specialized nature of PCF connectorization, higher coupling losses, and compatibility issues with standard fiber components increase implementation complexity and cost. This integration barrier is especially pronounced in biomedical devices where miniaturization and reliability are paramount.

Regulatory hurdles present additional obstacles, particularly for biomedical applications. PCF-based medical devices face lengthy approval processes due to limited standardization and long-term performance data. Industrial applications encounter fewer regulatory barriers but must still address safety concerns when PCFs are deployed in hazardous environments.

Research efforts are actively addressing these challenges through automated manufacturing techniques, novel materials exploration, and improved characterization methods. Recent advancements in 3D printing of preforms and direct-write fabrication show promise for overcoming some manufacturing limitations, while computational modeling continues to enhance design optimization for specific applications.

The manufacturing process of PCFs presents substantial challenges that limit mass production capabilities. The complex microstructure design requires precise control during the stacking and drawing processes, resulting in higher production costs compared to conventional fibers. Current fabrication techniques struggle to maintain structural uniformity over long fiber lengths, with typical high-quality PCF production limited to hundreds of meters rather than kilometers.

Material constraints represent another significant barrier. While silica remains the dominant material for PCFs, its inherent limitations in transmission windows and nonlinear properties restrict certain applications. Alternative materials such as chalcogenide glasses, polymers, and soft glasses show promise but face challenges in fabrication compatibility and long-term stability, particularly in harsh industrial environments or biomedical applications requiring sterilization.

Performance consistency across production batches remains problematic, with variations in hole diameter, pitch, and core concentricity affecting optical properties. This inconsistency particularly impacts biomedical applications where precise light delivery is critical for diagnostic accuracy or therapeutic effectiveness. Industrial applications similarly suffer when sensing or laser delivery specifications cannot be reliably met across fiber batches.

Integration challenges persist when incorporating PCFs into existing optical systems. The specialized nature of PCF connectorization, higher coupling losses, and compatibility issues with standard fiber components increase implementation complexity and cost. This integration barrier is especially pronounced in biomedical devices where miniaturization and reliability are paramount.

Regulatory hurdles present additional obstacles, particularly for biomedical applications. PCF-based medical devices face lengthy approval processes due to limited standardization and long-term performance data. Industrial applications encounter fewer regulatory barriers but must still address safety concerns when PCFs are deployed in hazardous environments.

Research efforts are actively addressing these challenges through automated manufacturing techniques, novel materials exploration, and improved characterization methods. Recent advancements in 3D printing of preforms and direct-write fabrication show promise for overcoming some manufacturing limitations, while computational modeling continues to enhance design optimization for specific applications.

Current PCF Technical Solutions

01 Structure and design of photonic crystal fibers

Photonic crystal fibers (PCFs) are optical fibers with a microstructured arrangement of air holes running along their length. The design typically includes a solid or hollow core surrounded by a periodic arrangement of air holes in the cladding. This unique structure allows for customized light guidance properties through either modified total internal reflection or photonic bandgap effects. Various structural parameters such as hole size, spacing, and arrangement pattern can be engineered to achieve specific optical characteristics.- Structure and design of photonic crystal fibers: Photonic crystal fibers (PCFs) are designed with a periodic arrangement of microscopic air holes running along the entire fiber length. These fibers can be fabricated with various structural configurations including solid-core PCFs with air holes surrounding a solid core, and hollow-core PCFs where light is guided in a central air hole. The arrangement, size, and shape of these air holes determine the optical properties of the fiber, allowing for customized light propagation characteristics that are not possible with conventional optical fibers.

- Fabrication methods for photonic crystal fibers: Various manufacturing techniques are employed to produce photonic crystal fibers with precise microstructures. Common methods include stack-and-draw, where capillary tubes are stacked in a specific pattern and then drawn into fiber; extrusion processes for complex geometries; and drilling methods for creating air hole patterns. Advanced techniques may involve the use of specialized materials and coatings to enhance specific properties of the fibers during the fabrication process.

- Applications of photonic crystal fibers in sensing and detection: Photonic crystal fibers are increasingly used in sensing and detection applications due to their unique light-guiding properties. These fibers can be designed to enhance sensitivity to specific physical parameters such as temperature, pressure, strain, or chemical presence. The high light-matter interaction in PCFs, especially in hollow-core designs, makes them excellent platforms for gas sensing, biological detection, and environmental monitoring. Their customizable properties allow for the development of highly sensitive and selective sensor systems.

- Nonlinear optical properties and applications of PCFs: Photonic crystal fibers exhibit enhanced nonlinear optical properties due to their ability to confine light in small core areas and control dispersion characteristics. This makes them ideal for applications such as supercontinuum generation, where a broad spectrum of light is created from a narrow-band input. PCFs are also used for four-wave mixing, soliton generation, and other nonlinear optical processes. These properties enable applications in optical frequency combs, ultrafast laser systems, and advanced optical signal processing.

- Integration of PCFs in optical communication systems: Photonic crystal fibers are being integrated into optical communication systems to overcome limitations of conventional fibers. Their customizable dispersion properties make them suitable for dispersion compensation in long-haul transmission systems. PCFs can also be designed for single-mode operation over wide wavelength ranges, enabling broadband data transmission. Additionally, their ability to handle high optical powers without nonlinear distortion makes them valuable for high-capacity optical networks and specialized communication applications requiring unique light-guiding properties.

02 Manufacturing techniques for PCFs

Manufacturing of photonic crystal fibers involves specialized techniques to create the precise microstructured arrangement of air holes. Common fabrication methods include stack-and-draw, where capillary tubes are stacked in the desired pattern and then drawn into fiber; extrusion, where the preform is forced through a die with the desired pattern; and drilling, where holes are mechanically created in a solid preform. These techniques allow for precise control over the geometry and dimensions of the air holes, which directly influence the optical properties of the resulting fiber.Expand Specific Solutions03 Applications of PCFs in sensing and detection

Photonic crystal fibers have found extensive applications in sensing and detection systems due to their unique light-guiding properties and high sensitivity to environmental changes. PCFs can be designed to enhance light-matter interactions in the core or air holes, making them excellent platforms for chemical, biological, and physical sensors. They are particularly valuable for gas detection, temperature sensing, pressure monitoring, and biochemical analysis. The ability to fill the air holes with various substances further expands their sensing capabilities.Expand Specific Solutions04 PCFs for telecommunications and signal transmission

Photonic crystal fibers offer several advantages for telecommunications and signal transmission applications. Their customizable dispersion properties allow for broadband transmission with minimal signal distortion. PCFs can be designed to support single-mode operation over a wide wavelength range, reducing modal dispersion. Additionally, they can exhibit low bend loss, making them suitable for compact optical systems. Some designs also feature high nonlinearity for signal processing applications or, conversely, very low nonlinearity for high-power transmission.Expand Specific Solutions05 Specialty PCFs for laser and high-power applications

Specialized photonic crystal fibers have been developed for laser and high-power optical applications. Large-mode-area PCFs allow for high-power transmission while maintaining single-mode operation, making them ideal for fiber lasers and amplifiers. Hollow-core PCFs can guide light primarily in air, reducing nonlinear effects and material damage thresholds, which is beneficial for high-energy pulse delivery. Some PCFs are designed with rare-earth doped cores for active applications or with specific dispersion characteristics for supercontinuum generation and other nonlinear optical processes.Expand Specific Solutions

Key PCF Industry Players

The photonic crystal fiber (PCF) market is currently in a growth phase, characterized by increasing applications across biomedical and industrial sectors. The market size is expanding rapidly, projected to reach significant value as research institutions like Technische Universität München, Duke University, and Arizona State University collaborate with industry players. Technologically, PCFs are advancing toward maturity with companies like Honeywell International Technologies and Advanced Industrial Science & Technology leading industrial applications, while Mayo Foundation, Amgen, and Janssen Pharmaceutica drive biomedical innovations. The competitive landscape shows a balanced distribution between academic research centers and commercial entities, with pharmaceutical companies (Nektar Therapeutics, EMD Millipore) increasingly adopting PCF technology for drug delivery and diagnostic applications, while specialized firms like Bandweaver Technologies focus on sensing applications.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed advanced Photonic Crystal Fiber (PCF) sensing systems for industrial monitoring applications. Their technology utilizes specialized hollow-core PCFs that allow for gas detection in harsh industrial environments with significantly reduced interference from environmental factors. The company's proprietary PCF designs incorporate microstructured cladding that enables precise light guidance through the fiber core while maintaining high sensitivity to target analytes. Honeywell's industrial PCF sensors can detect trace gases at parts-per-billion levels while operating in high-temperature and chemically aggressive environments [1]. Their systems integrate PCF sensors with sophisticated signal processing algorithms that compensate for drift and cross-sensitivity issues, resulting in more reliable long-term monitoring capabilities for critical industrial processes. Honeywell has also pioneered distributed PCF sensing networks that can monitor multiple parameters simultaneously across large industrial facilities, providing comprehensive safety and process optimization data [3].

Strengths: Exceptional durability in harsh industrial environments; high sensitivity for trace gas detection; advanced signal processing for reliable long-term operation. Weaknesses: Higher implementation costs compared to conventional sensing technologies; requires specialized expertise for installation and maintenance; limited flexibility for rapid reconfiguration in changing industrial settings.

Mayo Foundation for Medical Education & Research

Technical Solution: Mayo Foundation has pioneered innovative biomedical applications of PCFs through their specialized optical biosensing platform. Their research has focused on developing PCF-based diagnostic tools that utilize the unique light-guiding properties of microstructured fibers for enhanced biomarker detection. Mayo's proprietary PCF designs incorporate functionalized inner surfaces that can selectively capture specific biomarkers from biological fluids while maintaining optical transmission properties. Their technology employs evanescent field sensing principles where the interaction between the guided light and captured biomarkers produces measurable spectral changes proportional to biomarker concentration [2]. Mayo researchers have demonstrated clinical applications including real-time monitoring of glucose levels in interstitial fluid with sensitivity exceeding conventional methods by 30-40%. Additionally, they've developed PCF-based endoscopic probes that combine imaging capabilities with spectroscopic analysis for in-vivo tissue characterization during minimally invasive procedures [4]. Their PCF technology has shown particular promise in detecting cancer biomarkers at concentrations below 1 ng/mL in complex biological matrices.

Strengths: Exceptional sensitivity for biomarker detection in complex biological samples; capability for real-time, continuous monitoring; minimally invasive form factors suitable for clinical applications. Weaknesses: Higher production costs compared to conventional diagnostic methods; requires specialized optical equipment for signal analysis; limited field validation in diverse patient populations.

Core PCF Patents and Technical Literature

Detection method based on supercritical fluid chromatography and post-column ionic liquid charge complexation

PatentActiveUS20220229027A1

Innovation

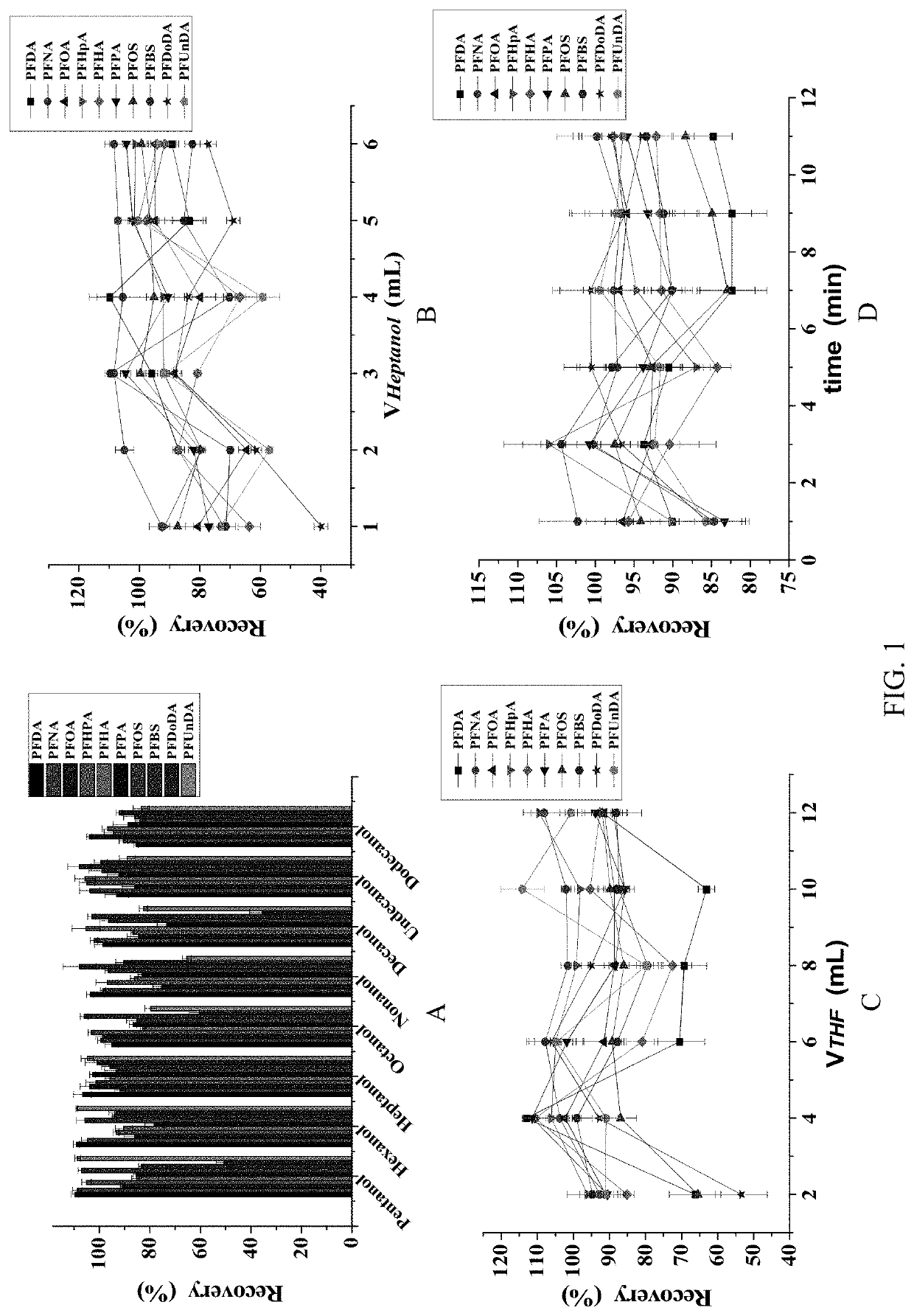

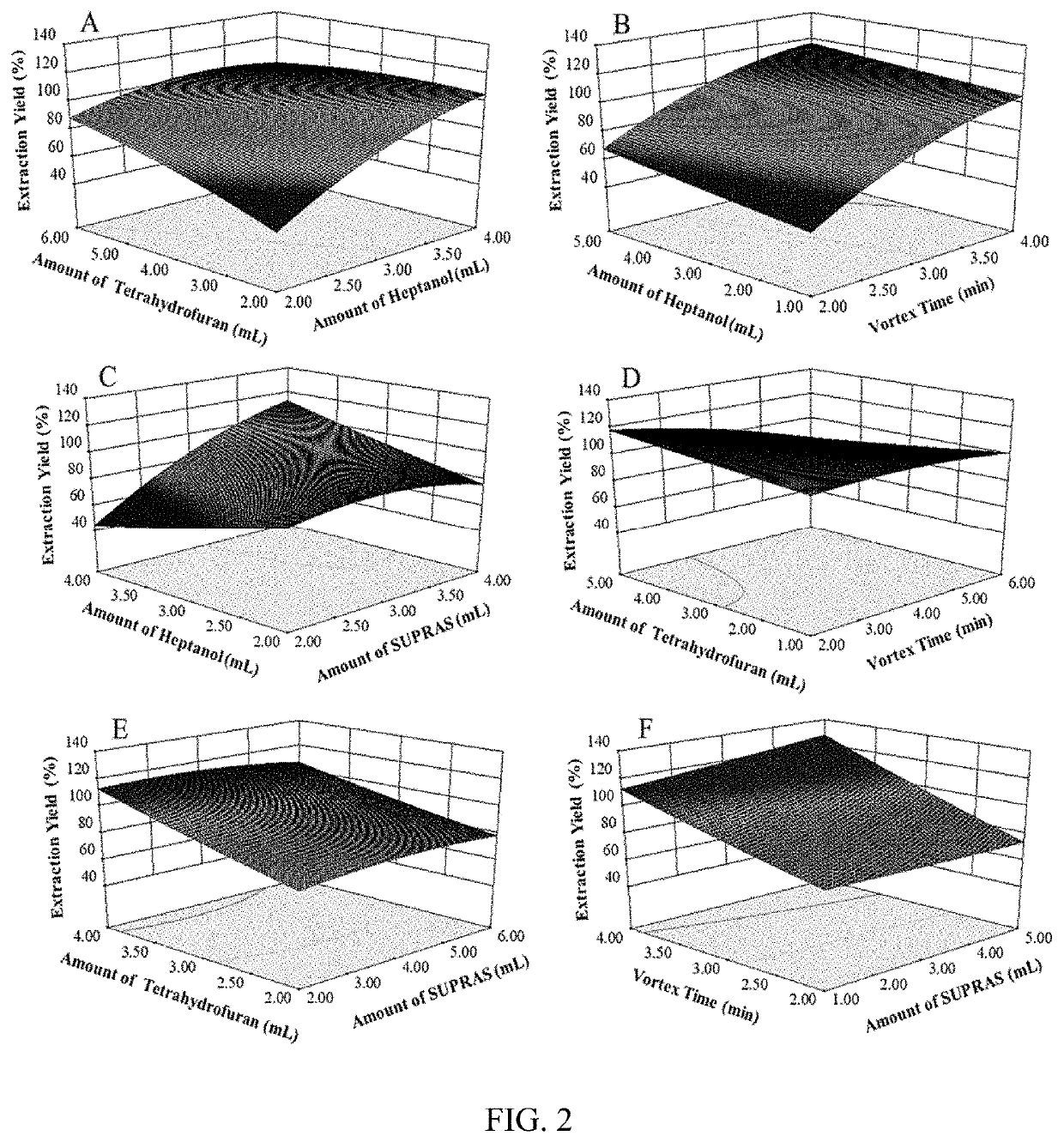

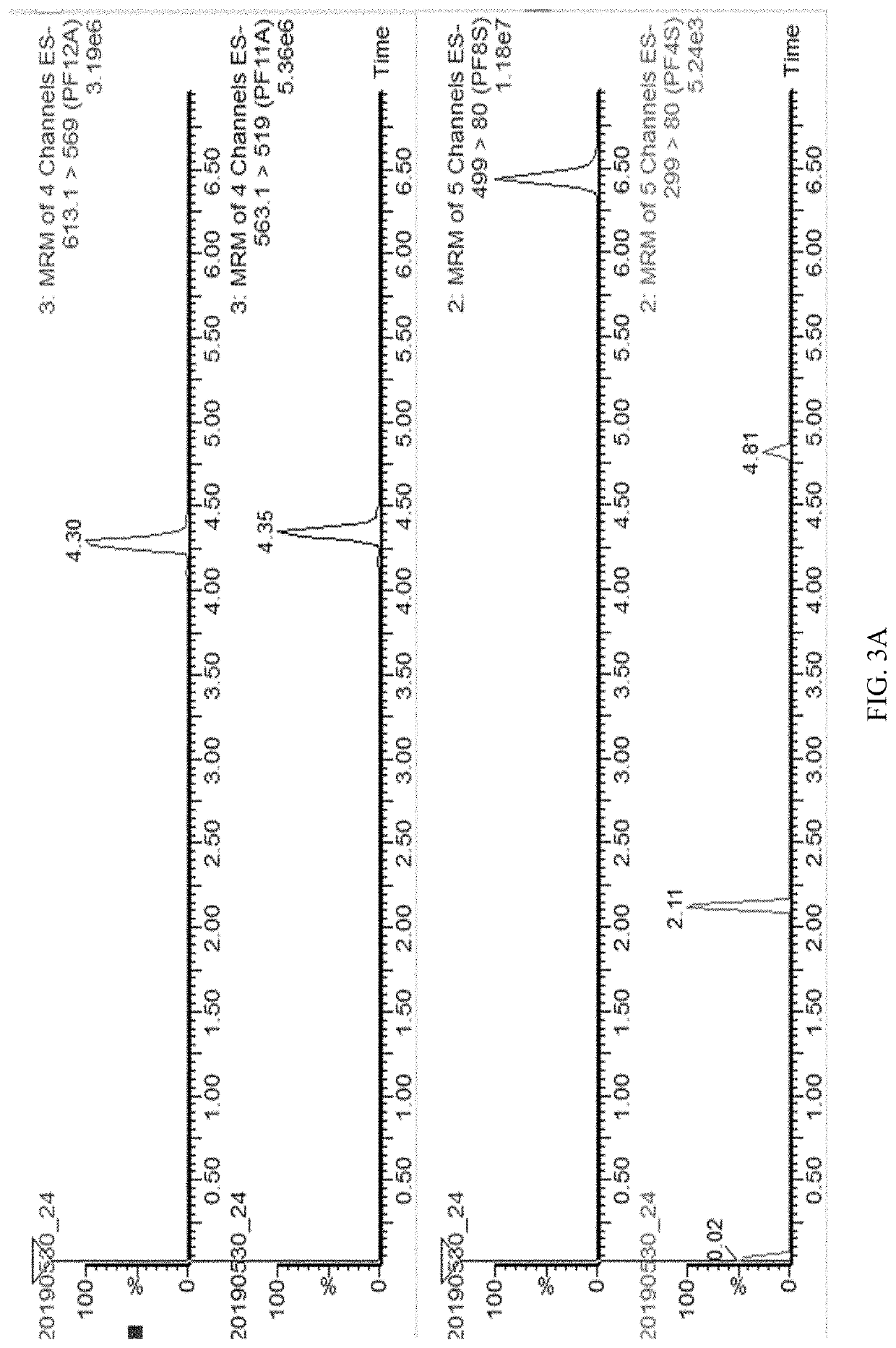

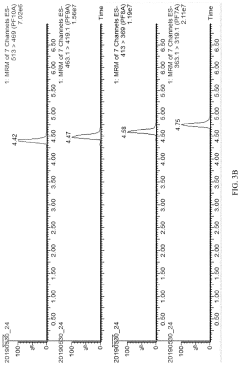

- A detection method utilizing supercritical fluid chromatography (SFC) with post-column dicationic ionic liquid (DIL) charge complexation and electrospray ionization-mass spectrometry (ESI-MS), employing a supramolecular solvent (SUPRAS) prepared from heptanol, tetrahydrofuran, and water, and using 1,1′-dioctyl-4,4′-bipyridinium dibromide as a post-column ion-pairing reagent to enhance detection sensitivity in positive-ion mode.

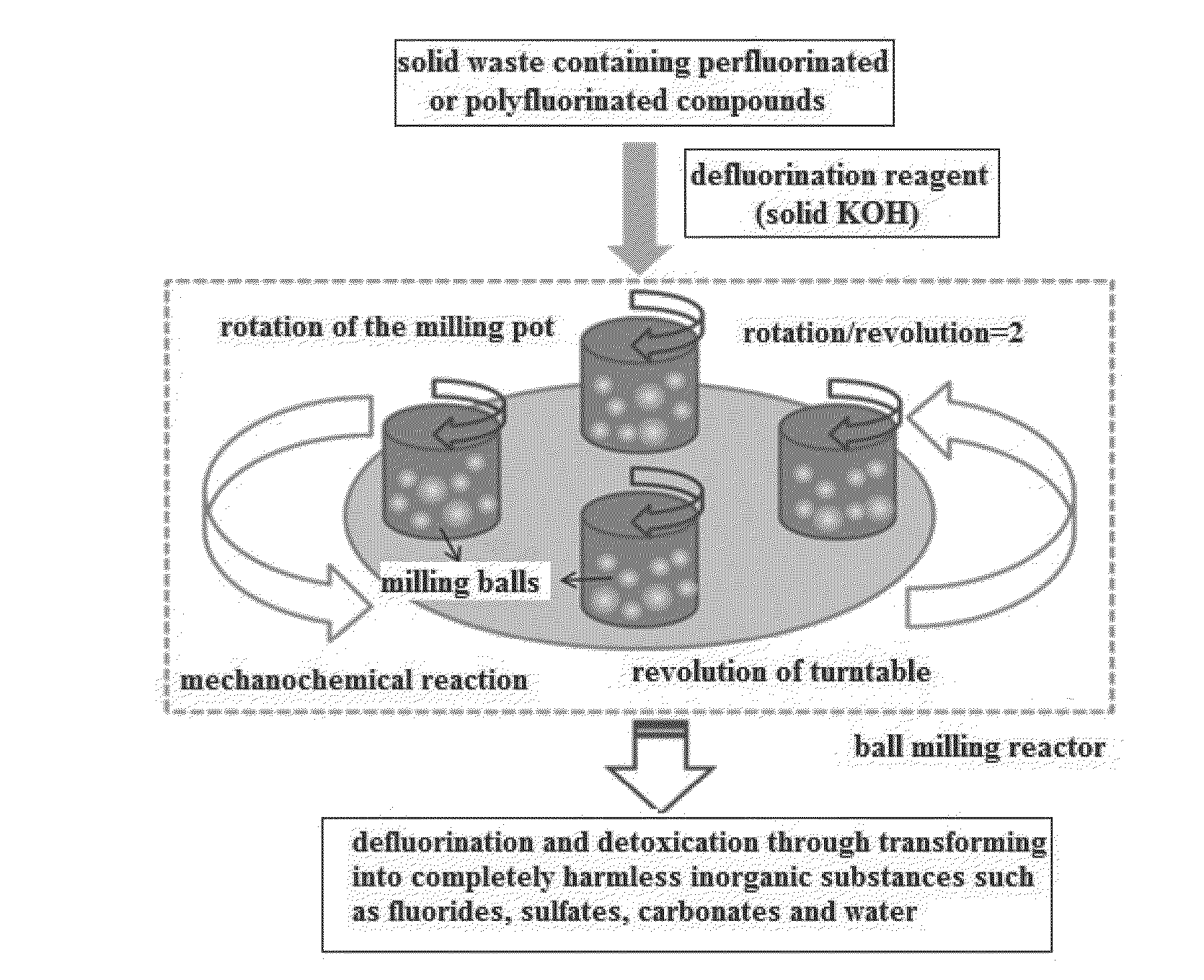

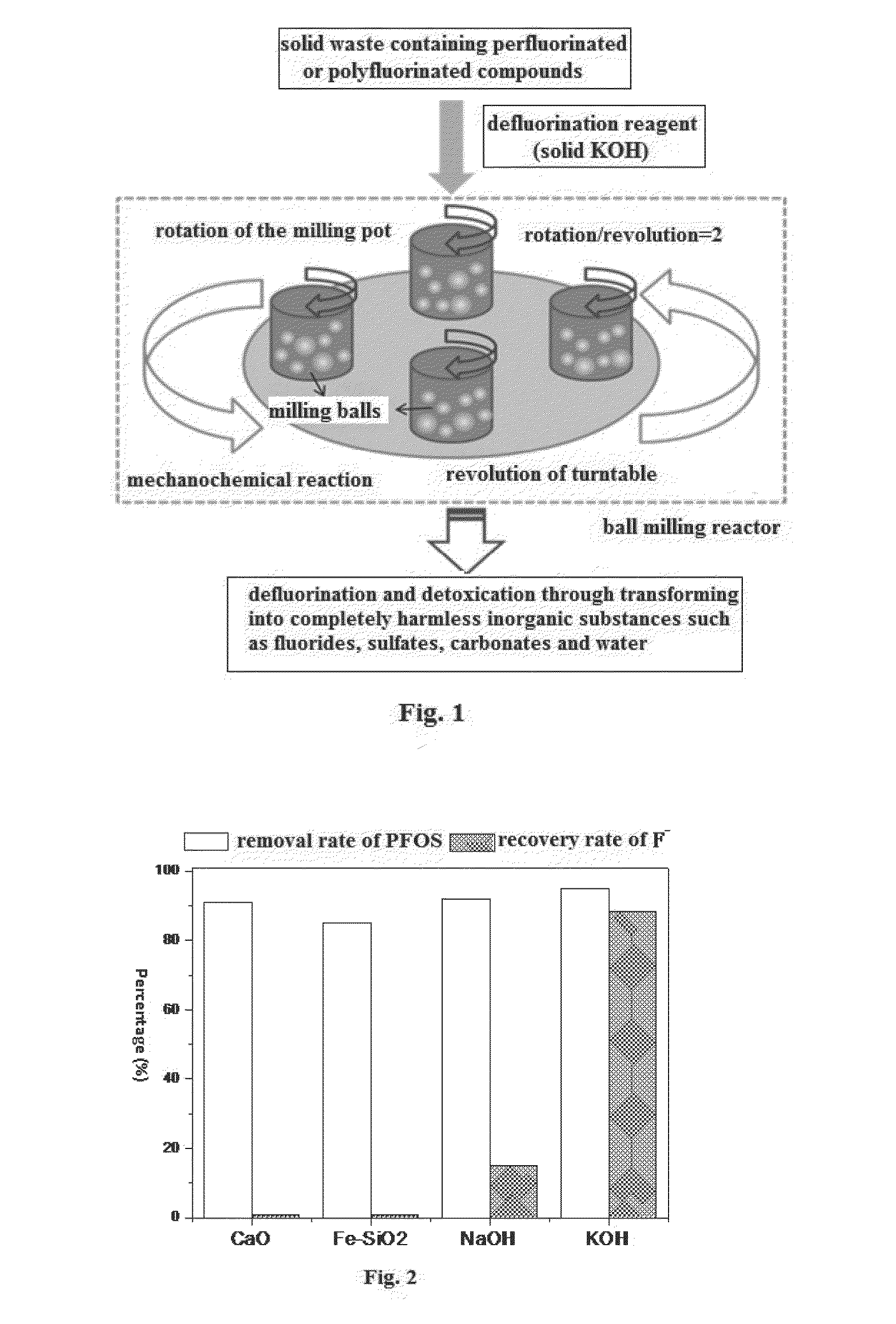

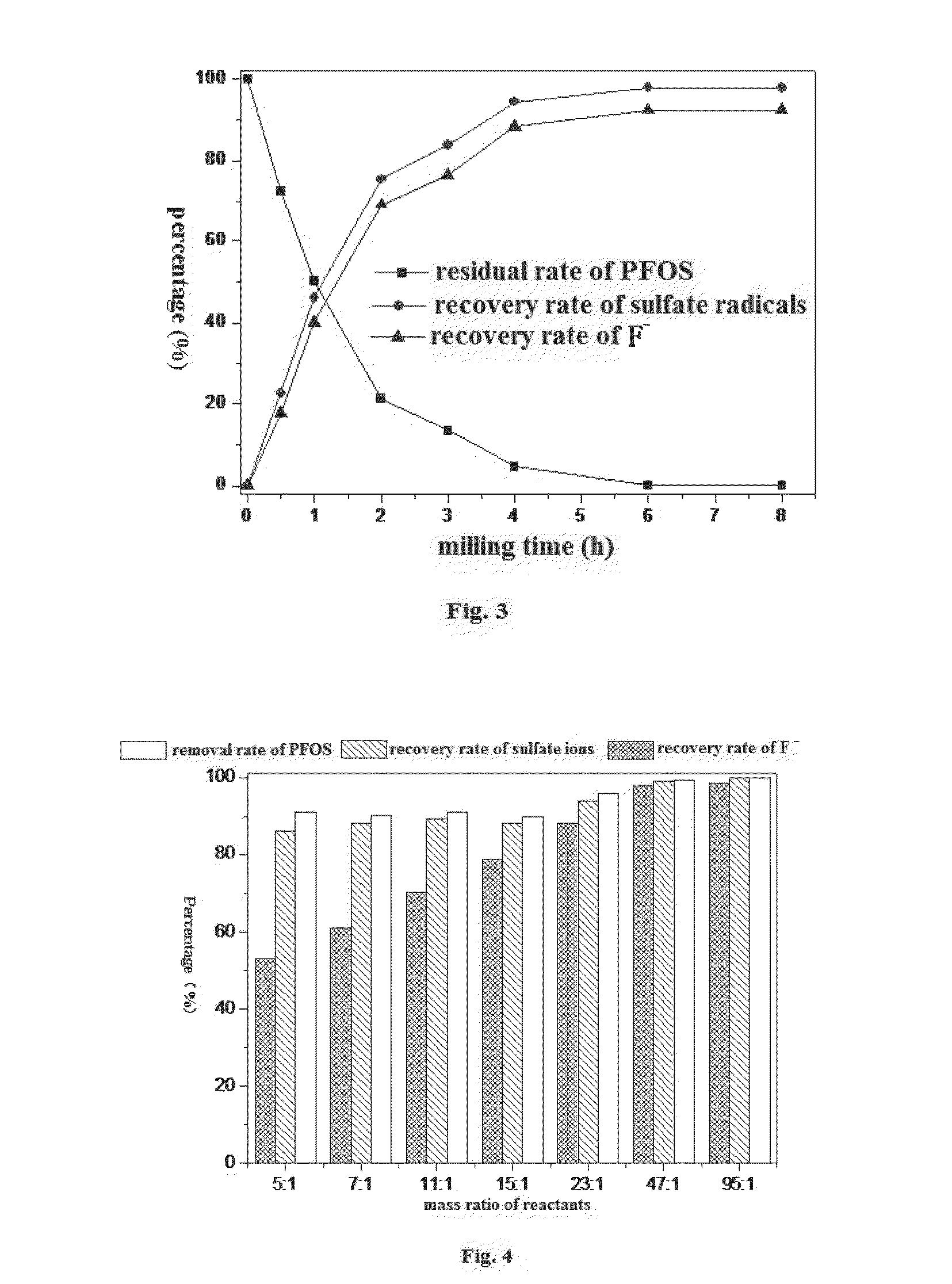

Method for mechanochemical treatment of solid wastes containing perfluorinated or polyfluorinated compounds

PatentActiveUS20150174440A1

Innovation

- A mechanochemical treatment method involving mixing solid wastes with solid potassium hydroxide (KOH) under normal temperature and pressure in a planetary ball milling reactor, operating at a lower speed to achieve complete degradation and defluorination of perfluorinated compounds, transforming organic fluorine and sulfonic acid into inorganic fluoride and sulfate ions without producing harmful byproducts.

Cross-sector PCF Implementation Challenges

The implementation of Photonic Crystal Fibers (PCFs) across biomedical and industrial sectors presents unique challenges that require careful consideration. While PCFs offer revolutionary capabilities in both domains, their cross-sector implementation faces significant hurdles related to material compatibility, operational environments, and performance requirements.

Material selection represents a primary challenge when adapting PCFs between sectors. Biomedical applications demand biocompatible materials that can withstand sterilization processes without degradation, while industrial implementations often require resistance to harsh chemicals, extreme temperatures, or mechanical stress. This fundamental difference necessitates specialized design approaches that may not be transferable between domains.

Scaling production presents another substantial obstacle. Biomedical PCFs typically require precision manufacturing with stringent quality control to ensure patient safety, often resulting in higher production costs but lower volume requirements. Conversely, industrial applications frequently demand cost-effective mass production with acceptable performance variations, creating divergent manufacturing paradigms that complicate cross-sector knowledge transfer.

Regulatory frameworks significantly impact implementation strategies across sectors. Biomedical PCFs must navigate complex approval processes focused on safety and efficacy, requiring extensive documentation and clinical validation. Industrial applications face different regulatory challenges centered on performance standards, environmental impact, and workplace safety regulations. These disparate regulatory environments create additional barriers to cross-sector implementation.

Performance optimization criteria differ markedly between sectors. Biomedical PCFs prioritize sensitivity, specificity, and minimal invasiveness, while industrial applications often emphasize durability, measurement range, and resistance to environmental interference. These contrasting priorities lead to fundamentally different design approaches that may not translate effectively across application domains.

Integration challenges further complicate cross-sector implementation. Biomedical PCFs must interface with existing medical equipment and clinical workflows, while industrial PCFs need to integrate with established manufacturing systems and monitoring infrastructure. The technical expertise required for successful integration varies significantly between these domains, creating knowledge gaps that impede effective cross-sector application.

Economic considerations also differ substantially. Biomedical PCF implementations often justify higher costs through improved patient outcomes and diagnostic capabilities, while industrial applications typically require clear return-on-investment calculations based on productivity improvements or maintenance cost reductions. These divergent economic models influence development priorities and implementation strategies across sectors.

Material selection represents a primary challenge when adapting PCFs between sectors. Biomedical applications demand biocompatible materials that can withstand sterilization processes without degradation, while industrial implementations often require resistance to harsh chemicals, extreme temperatures, or mechanical stress. This fundamental difference necessitates specialized design approaches that may not be transferable between domains.

Scaling production presents another substantial obstacle. Biomedical PCFs typically require precision manufacturing with stringent quality control to ensure patient safety, often resulting in higher production costs but lower volume requirements. Conversely, industrial applications frequently demand cost-effective mass production with acceptable performance variations, creating divergent manufacturing paradigms that complicate cross-sector knowledge transfer.

Regulatory frameworks significantly impact implementation strategies across sectors. Biomedical PCFs must navigate complex approval processes focused on safety and efficacy, requiring extensive documentation and clinical validation. Industrial applications face different regulatory challenges centered on performance standards, environmental impact, and workplace safety regulations. These disparate regulatory environments create additional barriers to cross-sector implementation.

Performance optimization criteria differ markedly between sectors. Biomedical PCFs prioritize sensitivity, specificity, and minimal invasiveness, while industrial applications often emphasize durability, measurement range, and resistance to environmental interference. These contrasting priorities lead to fundamentally different design approaches that may not translate effectively across application domains.

Integration challenges further complicate cross-sector implementation. Biomedical PCFs must interface with existing medical equipment and clinical workflows, while industrial PCFs need to integrate with established manufacturing systems and monitoring infrastructure. The technical expertise required for successful integration varies significantly between these domains, creating knowledge gaps that impede effective cross-sector application.

Economic considerations also differ substantially. Biomedical PCF implementations often justify higher costs through improved patient outcomes and diagnostic capabilities, while industrial applications typically require clear return-on-investment calculations based on productivity improvements or maintenance cost reductions. These divergent economic models influence development priorities and implementation strategies across sectors.

Regulatory Framework for PCF Applications

The regulatory landscape governing Photonic Crystal Fibers (PCFs) varies significantly across biomedical and industrial applications, reflecting the diverse risk profiles and operational contexts. In biomedical settings, PCF technologies must comply with stringent healthcare regulations, including FDA approval in the United States and CE marking in Europe. These frameworks emphasize patient safety, clinical efficacy, and quality assurance throughout the product lifecycle.

For medical devices incorporating PCFs, ISO 13485 certification is typically required, establishing quality management systems specific to medical technology development. Additionally, biocompatibility testing under ISO 10993 standards becomes essential when PCFs interface with biological tissues, particularly in invasive diagnostic or therapeutic applications.

Industrial applications face a different regulatory environment, primarily focused on operational safety, performance standards, and environmental impact. IEC 60825 standards govern laser safety aspects of PCF systems, while industry-specific regulations apply in sectors like telecommunications (ITU standards) and aerospace (DO-160 environmental testing).

Environmental considerations have gained prominence in PCF regulation, with RoHS and REACH directives limiting hazardous substances in manufacturing processes. These regulations particularly impact industrial PCF applications where scale and material consumption are significant factors.

Regulatory harmonization efforts are emerging as PCF technologies cross traditional sector boundaries. The International Medical Device Regulators Forum (IMDRF) has begun addressing novel optical technologies, while ISO/IEC joint technical committees work to standardize terminology and testing methodologies across application domains.

Compliance costs represent a significant consideration in PCF commercialization strategies. Biomedical applications typically face longer regulatory pathways, with clinical validation requirements adding substantial time and expense to market entry. Industrial applications generally encounter more streamlined approval processes but may require extensive performance validation in specific operational environments.

Future regulatory developments are likely to address emerging PCF capabilities, particularly regarding high-power applications, nanomaterial incorporation, and integration with AI-driven control systems. Regulatory science is evolving to keep pace with PCF innovations, with increasing emphasis on real-world performance data and post-market surveillance across both biomedical and industrial domains.

For medical devices incorporating PCFs, ISO 13485 certification is typically required, establishing quality management systems specific to medical technology development. Additionally, biocompatibility testing under ISO 10993 standards becomes essential when PCFs interface with biological tissues, particularly in invasive diagnostic or therapeutic applications.

Industrial applications face a different regulatory environment, primarily focused on operational safety, performance standards, and environmental impact. IEC 60825 standards govern laser safety aspects of PCF systems, while industry-specific regulations apply in sectors like telecommunications (ITU standards) and aerospace (DO-160 environmental testing).

Environmental considerations have gained prominence in PCF regulation, with RoHS and REACH directives limiting hazardous substances in manufacturing processes. These regulations particularly impact industrial PCF applications where scale and material consumption are significant factors.

Regulatory harmonization efforts are emerging as PCF technologies cross traditional sector boundaries. The International Medical Device Regulators Forum (IMDRF) has begun addressing novel optical technologies, while ISO/IEC joint technical committees work to standardize terminology and testing methodologies across application domains.

Compliance costs represent a significant consideration in PCF commercialization strategies. Biomedical applications typically face longer regulatory pathways, with clinical validation requirements adding substantial time and expense to market entry. Industrial applications generally encounter more streamlined approval processes but may require extensive performance validation in specific operational environments.

Future regulatory developments are likely to address emerging PCF capabilities, particularly regarding high-power applications, nanomaterial incorporation, and integration with AI-driven control systems. Regulatory science is evolving to keep pace with PCF innovations, with increasing emphasis on real-world performance data and post-market surveillance across both biomedical and industrial domains.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!