Fabrication Challenges in High Air-Filling Fraction PCFs

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PCF Technology Evolution and Objectives

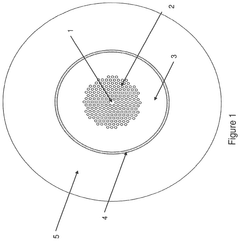

Photonic Crystal Fibers (PCFs) have revolutionized optical fiber technology since their conceptualization in the late 1980s and practical demonstration in the 1990s. The evolution of PCF technology represents a significant paradigm shift from conventional optical fibers, offering unprecedented control over light propagation characteristics through the manipulation of air holes arranged in specific patterns within the fiber structure.

The historical development of PCFs began with theoretical proposals by Philip Russell and colleagues, followed by the first successful fabrication at the University of Bath in 1996. Early PCFs featured relatively low air-filling fractions, typically below 30%, which limited their performance in applications requiring strong light confinement or unique dispersion properties. The technological progression has been driven by the pursuit of higher air-filling fractions to enhance desirable optical properties.

High air-filling fraction PCFs, characterized by air holes occupying more than 80% of the cross-sectional area, emerged as a critical research direction in the early 2000s. These structures promised exceptional capabilities in nonlinear optics, sensing applications, and telecommunications. The evolution of fabrication techniques has been marked by transitions from simple stack-and-draw methods to more sophisticated approaches involving pressurization, etching, and advanced material processing.

The primary technological objectives in high air-filling fraction PCF development include achieving precise geometric control of microstructures, maintaining structural integrity during the drawing process, and ensuring consistency along the fiber length. These objectives are driven by applications demanding enhanced light-matter interactions, reduced optical nonlinearities, or specialized dispersion profiles that conventional fibers cannot provide.

Current research aims to overcome fundamental limitations in fabrication processes, particularly the tendency of large air holes to collapse or deform during thermal processing. The field has progressed from academic curiosity to commercial viability, with several companies now offering specialized PCF products for scientific and industrial applications.

The technological trajectory indicates a convergence toward hybrid manufacturing approaches that combine traditional fiber drawing with advanced materials science and precision engineering. Recent breakthroughs in 3D printing and nanofabrication techniques suggest potential new directions for PCF manufacturing that may circumvent conventional limitations.

Looking forward, the field is moving toward integration with other photonic technologies, including on-chip waveguides and metamaterials, creating a broader ecosystem of photonic solutions. The ultimate objective remains the development of reliable, scalable fabrication methods that can produce high air-filling fraction PCFs with precisely controlled geometries for next-generation optical systems and devices.

The historical development of PCFs began with theoretical proposals by Philip Russell and colleagues, followed by the first successful fabrication at the University of Bath in 1996. Early PCFs featured relatively low air-filling fractions, typically below 30%, which limited their performance in applications requiring strong light confinement or unique dispersion properties. The technological progression has been driven by the pursuit of higher air-filling fractions to enhance desirable optical properties.

High air-filling fraction PCFs, characterized by air holes occupying more than 80% of the cross-sectional area, emerged as a critical research direction in the early 2000s. These structures promised exceptional capabilities in nonlinear optics, sensing applications, and telecommunications. The evolution of fabrication techniques has been marked by transitions from simple stack-and-draw methods to more sophisticated approaches involving pressurization, etching, and advanced material processing.

The primary technological objectives in high air-filling fraction PCF development include achieving precise geometric control of microstructures, maintaining structural integrity during the drawing process, and ensuring consistency along the fiber length. These objectives are driven by applications demanding enhanced light-matter interactions, reduced optical nonlinearities, or specialized dispersion profiles that conventional fibers cannot provide.

Current research aims to overcome fundamental limitations in fabrication processes, particularly the tendency of large air holes to collapse or deform during thermal processing. The field has progressed from academic curiosity to commercial viability, with several companies now offering specialized PCF products for scientific and industrial applications.

The technological trajectory indicates a convergence toward hybrid manufacturing approaches that combine traditional fiber drawing with advanced materials science and precision engineering. Recent breakthroughs in 3D printing and nanofabrication techniques suggest potential new directions for PCF manufacturing that may circumvent conventional limitations.

Looking forward, the field is moving toward integration with other photonic technologies, including on-chip waveguides and metamaterials, creating a broader ecosystem of photonic solutions. The ultimate objective remains the development of reliable, scalable fabrication methods that can produce high air-filling fraction PCFs with precisely controlled geometries for next-generation optical systems and devices.

Market Applications for High Air-Filling PCFs

High air-filling fraction photonic crystal fibers (PCFs) have emerged as transformative components across multiple industries due to their unique optical properties. The telecommunications sector represents one of the largest market opportunities, where these fibers enable ultra-low loss signal transmission, enhanced bandwidth capacity, and improved signal integrity over long distances. Their ability to maintain signal quality while minimizing dispersion makes them particularly valuable for next-generation high-speed data networks and 5G/6G infrastructure.

In the medical and biomedical fields, high air-filling PCFs are revolutionizing diagnostic and therapeutic applications. Their capacity to deliver high-intensity laser light with minimal loss and precise spatial characteristics makes them ideal for advanced medical imaging, laser surgery, and optical coherence tomography. The market for minimally invasive medical procedures continues to expand, creating sustained demand for these specialized optical components.

Sensing applications constitute another significant market segment. The enhanced sensitivity of high air-filling PCFs to environmental changes enables their use in structural health monitoring of critical infrastructure, environmental monitoring systems, and industrial process control. The growing focus on smart cities and industrial automation is driving increased adoption of fiber-based sensing networks, where these specialized PCFs offer performance advantages over conventional technologies.

The aerospace and defense sectors represent premium markets where the unique properties of high air-filling PCFs justify their higher manufacturing costs. Applications include gyroscopes for navigation systems, secure communications links, and specialized sensing equipment. These sectors prioritize performance and reliability over cost considerations, making them early adopters of advanced PCF technologies.

Emerging applications in quantum computing and communications are creating new market opportunities. High air-filling PCFs can serve as quantum light guides and entangled photon sources, critical components for quantum information systems. While currently a niche market, the strategic importance of quantum technologies is driving significant research investment and creating future commercial potential.

The energy sector is also exploring applications in laser-based drilling, cutting, and welding systems, where high air-filling PCFs can deliver unprecedented power levels to target materials. Additionally, the scientific research community continues to drive demand for specialized PCFs for fundamental physics experiments, spectroscopy, and advanced optical research.

Despite fabrication challenges, the diverse application landscape and growing demand across multiple sectors suggest a robust market trajectory for high air-filling fraction PCFs, with particular strength in telecommunications, sensing, and medical applications.

In the medical and biomedical fields, high air-filling PCFs are revolutionizing diagnostic and therapeutic applications. Their capacity to deliver high-intensity laser light with minimal loss and precise spatial characteristics makes them ideal for advanced medical imaging, laser surgery, and optical coherence tomography. The market for minimally invasive medical procedures continues to expand, creating sustained demand for these specialized optical components.

Sensing applications constitute another significant market segment. The enhanced sensitivity of high air-filling PCFs to environmental changes enables their use in structural health monitoring of critical infrastructure, environmental monitoring systems, and industrial process control. The growing focus on smart cities and industrial automation is driving increased adoption of fiber-based sensing networks, where these specialized PCFs offer performance advantages over conventional technologies.

The aerospace and defense sectors represent premium markets where the unique properties of high air-filling PCFs justify their higher manufacturing costs. Applications include gyroscopes for navigation systems, secure communications links, and specialized sensing equipment. These sectors prioritize performance and reliability over cost considerations, making them early adopters of advanced PCF technologies.

Emerging applications in quantum computing and communications are creating new market opportunities. High air-filling PCFs can serve as quantum light guides and entangled photon sources, critical components for quantum information systems. While currently a niche market, the strategic importance of quantum technologies is driving significant research investment and creating future commercial potential.

The energy sector is also exploring applications in laser-based drilling, cutting, and welding systems, where high air-filling PCFs can deliver unprecedented power levels to target materials. Additionally, the scientific research community continues to drive demand for specialized PCFs for fundamental physics experiments, spectroscopy, and advanced optical research.

Despite fabrication challenges, the diverse application landscape and growing demand across multiple sectors suggest a robust market trajectory for high air-filling fraction PCFs, with particular strength in telecommunications, sensing, and medical applications.

Current Fabrication Limitations and Challenges

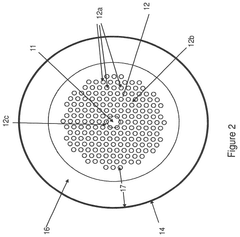

The fabrication of high air-filling fraction Photonic Crystal Fibers (PCFs) presents significant technical challenges that have limited their widespread commercial adoption. Current manufacturing processes struggle to maintain precise microstructure geometry while achieving high air-filling ratios exceeding 90%. The stack-and-draw technique, though widely used, encounters fundamental limitations when attempting to create large air holes with thin silica bridges between them. During the drawing process, surface tension forces cause the thin glass walls to collapse or deform, resulting in inconsistent air hole dimensions and compromised optical performance.

Temperature control represents another critical challenge in high air-filling PCF fabrication. The drawing temperature window becomes extremely narrow as air-filling fraction increases, requiring precision within ±5°C to maintain structural integrity. Even minor temperature fluctuations can lead to catastrophic structural failures or significant deviations from design specifications, particularly affecting the uniformity of air holes along the fiber length.

Pressure regulation during the drawing process presents additional complications. While positive pressure is applied to prevent hole collapse, excessive pressure can cause hole expansion or even rupture the delicate silica bridges. Current pressure control systems lack the responsiveness and precision needed for consistent production of high air-filling PCFs, especially when fabricating fibers with complex microstructures or non-uniform hole distributions.

Material purity and contamination control remain persistent challenges. The extremely thin silica bridges in high air-filling PCFs are highly susceptible to structural weakening from even trace impurities. Current purification methods struggle to eliminate all contaminants that can create microcracks or stress points during the drawing process, significantly reducing mechanical strength and long-term reliability of the fibers.

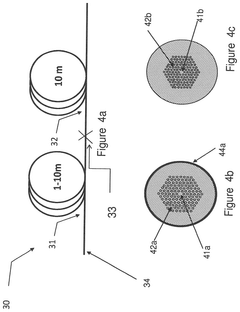

Scaling production to commercial volumes presents perhaps the most significant barrier. Current fabrication methods for high air-filling PCFs are predominantly laboratory-scale processes with limited throughput and high defect rates. Yield rates typically fall below 30% for air-filling fractions above 95%, making mass production economically unfeasible. The complex process parameters require constant monitoring and adjustment, necessitating highly skilled technicians and specialized equipment that further increases production costs.

Post-processing techniques for these specialized fibers also face limitations. Cleaving, splicing, and connectorization become increasingly difficult as the air-filling fraction rises, often resulting in structural collapse at the fiber endpoints. This significantly complicates the integration of high air-filling PCFs into practical optical systems and devices, limiting their application potential despite their superior theoretical performance.

Temperature control represents another critical challenge in high air-filling PCF fabrication. The drawing temperature window becomes extremely narrow as air-filling fraction increases, requiring precision within ±5°C to maintain structural integrity. Even minor temperature fluctuations can lead to catastrophic structural failures or significant deviations from design specifications, particularly affecting the uniformity of air holes along the fiber length.

Pressure regulation during the drawing process presents additional complications. While positive pressure is applied to prevent hole collapse, excessive pressure can cause hole expansion or even rupture the delicate silica bridges. Current pressure control systems lack the responsiveness and precision needed for consistent production of high air-filling PCFs, especially when fabricating fibers with complex microstructures or non-uniform hole distributions.

Material purity and contamination control remain persistent challenges. The extremely thin silica bridges in high air-filling PCFs are highly susceptible to structural weakening from even trace impurities. Current purification methods struggle to eliminate all contaminants that can create microcracks or stress points during the drawing process, significantly reducing mechanical strength and long-term reliability of the fibers.

Scaling production to commercial volumes presents perhaps the most significant barrier. Current fabrication methods for high air-filling PCFs are predominantly laboratory-scale processes with limited throughput and high defect rates. Yield rates typically fall below 30% for air-filling fractions above 95%, making mass production economically unfeasible. The complex process parameters require constant monitoring and adjustment, necessitating highly skilled technicians and specialized equipment that further increases production costs.

Post-processing techniques for these specialized fibers also face limitations. Cleaving, splicing, and connectorization become increasingly difficult as the air-filling fraction rises, often resulting in structural collapse at the fiber endpoints. This significantly complicates the integration of high air-filling PCFs into practical optical systems and devices, limiting their application potential despite their superior theoretical performance.

Current Fabrication Methods for High Air-Filling PCFs

01 Design and optimization of air-filling fraction in PCFs

The air-filling fraction in photonic crystal fibers can be optimized through specific design parameters to achieve desired optical properties. By controlling the size, shape, and arrangement of air holes in the fiber structure, manufacturers can tailor the air-filling fraction to meet specific performance requirements. Higher air-filling fractions generally lead to stronger light confinement and modified dispersion characteristics, which are crucial for applications requiring precise light manipulation.- Design and optimization of air-filling fraction in PCFs: The air-filling fraction in photonic crystal fibers can be optimized through specific design parameters to achieve desired optical properties. By controlling the size, shape, and arrangement of air holes in the fiber structure, manufacturers can tailor the air-filling fraction to meet specific performance requirements. Higher air-filling fractions generally lead to stronger light confinement and modified dispersion characteristics, which are crucial for applications requiring precise light manipulation.

- Manufacturing techniques for controlling air-filling fraction: Various manufacturing techniques have been developed to precisely control the air-filling fraction in photonic crystal fibers. These include stack-and-draw methods, drilling techniques, and extrusion processes that allow for accurate creation of air hole patterns. Advanced fabrication approaches enable the production of PCFs with uniform air-filling fractions throughout the fiber length, ensuring consistent optical performance. The manufacturing process can be tailored to create different air-filling fraction profiles for specialized applications.

- Relationship between air-filling fraction and optical properties: The air-filling fraction in PCFs directly influences key optical properties such as dispersion, birefringence, and nonlinearity. By adjusting the air-filling fraction, researchers can control the effective refractive index contrast between the core and cladding regions. This relationship allows for the design of PCFs with tailored dispersion characteristics, enhanced nonlinear effects, or specific modal properties. Understanding this relationship is crucial for developing PCFs for applications in telecommunications, sensing, and high-power laser delivery.

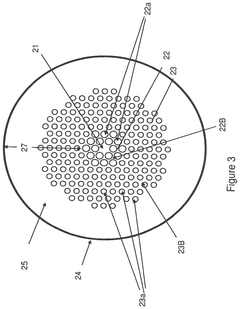

- Novel PCF structures with specialized air-filling patterns: Innovative PCF structures featuring specialized air-filling patterns have been developed to achieve unique optical functionalities. These include designs with varying air hole sizes, non-uniform distributions, or gradient air-filling fractions across the fiber cross-section. Some structures incorporate additional materials or dopants alongside the air holes to further enhance performance. These novel designs enable PCFs with unprecedented properties such as ultra-flat dispersion, enhanced nonlinearity, or improved polarization maintenance.

- Applications leveraging specific air-filling fraction designs: Specific air-filling fraction designs in PCFs enable various specialized applications across multiple fields. In telecommunications, PCFs with optimized air-filling fractions provide enhanced bandwidth and reduced signal distortion. For sensing applications, carefully designed air-filling fractions create PCFs with high sensitivity to environmental parameters. In laser systems, PCFs with large air-filling fractions enable single-mode operation with large mode areas, facilitating high-power beam delivery. Medical and industrial applications also benefit from PCFs with application-specific air-filling fraction designs.

02 Manufacturing techniques for controlling air-filling fraction

Various manufacturing techniques have been developed to precisely control the air-filling fraction in photonic crystal fibers. These include stack-and-draw methods, drilling techniques, and extrusion processes that allow for accurate creation of air hole patterns. Advanced fabrication approaches enable the production of PCFs with uniform air-filling fractions throughout the fiber length, ensuring consistent optical performance. These techniques also address challenges related to maintaining structural integrity during the drawing process while achieving the desired air hole dimensions.Expand Specific Solutions03 Relationship between air-filling fraction and optical properties

The air-filling fraction in PCFs directly influences key optical properties such as dispersion, birefringence, and nonlinearity. By manipulating the air-filling fraction, researchers can control the effective refractive index contrast between the core and cladding regions. This relationship allows for the development of fibers with tailored dispersion profiles, enhanced nonlinear effects, or specific modal characteristics. Understanding this relationship is essential for designing PCFs for applications ranging from telecommunications to sensing and high-power laser delivery.Expand Specific Solutions04 Novel PCF structures with specialized air-filling patterns

Innovative PCF structures featuring specialized air-filling patterns have been developed to achieve unique optical functionalities. These include designs with varying air hole sizes, asymmetric arrangements, or gradient air-filling fractions across the fiber cross-section. Such specialized structures enable enhanced performance in applications like polarization maintenance, supercontinuum generation, and sensing. These novel designs often incorporate non-conventional geometries to manipulate light propagation in ways not possible with traditional optical fibers.Expand Specific Solutions05 Applications leveraging controlled air-filling fraction

Precise control of air-filling fraction in PCFs enables numerous specialized applications across various fields. In telecommunications, optimized air-filling fractions allow for low-loss transmission and dispersion management. In sensing applications, specific air-filling patterns enhance sensitivity to environmental parameters. For high-power laser delivery, carefully designed air-filling fractions help manage nonlinear effects and thermal issues. Medical applications benefit from PCFs with tailored air-filling fractions that enable precise light delivery for diagnostic and therapeutic procedures.Expand Specific Solutions

Leading Companies in PCF Development

The fabrication of high air-filling fraction Photonic Crystal Fibers (PCFs) is currently in a transitional phase between research development and early commercial application, with a global market estimated at $500-700 million and growing at 15% annually. The technology faces significant manufacturing challenges due to the precise microstructure requirements and complex fabrication processes. Technical maturity varies across key players, with research institutions like North China Electric Power University and Nankai University focusing on fundamental research, while companies including Shin-Etsu Chemical, POSCO Holdings, and Fiberhome Telecommunication Technologies are advancing commercial applications. ASML Netherlands and Samsung Electronics are leveraging their semiconductor expertise to address precision fabrication issues, while specialized optical companies like SUMCO Corp are developing innovative manufacturing techniques to overcome the structural stability and uniformity challenges inherent in high air-filling fraction PCFs.

Fiberhome Telecommunication Technologies Co., Ltd.

Technical Solution: Fiberhome has developed a multi-stage drawing process specifically for high air-filling fraction PCFs that maintains structural integrity during fabrication. Their approach involves precise control of pressure differentials across air holes during the drawing process, allowing them to achieve air-filling fractions exceeding 90% while maintaining hexagonal lattice regularity. The company employs specialized preform preparation techniques including ultrasonic cleaning and controlled etching to eliminate surface contaminants that could cause structural defects. Their fabrication process incorporates real-time monitoring systems with feedback control mechanisms that automatically adjust drawing parameters to compensate for fluctuations in temperature and tension profiles[1][3]. This has enabled them to produce fibers with significantly reduced structural deformations compared to conventional drawing methods.

Strengths: Superior structural integrity maintenance during drawing process; advanced real-time monitoring capabilities; ability to achieve very high air-filling fractions while preserving hexagonal lattice structure. Weaknesses: Process requires highly specialized equipment; production speeds are slower than conventional fiber drawing; higher manufacturing costs limit mass production viability.

ASML Netherlands BV

Technical Solution: ASML has adapted its advanced lithography expertise to address fabrication challenges in high air-filling fraction PCFs through a novel approach combining traditional fiber drawing with precision etching techniques. Their process utilizes specialized photoresist materials and deep UV lithography to create precisely defined preform structures with exceptional dimensional accuracy. ASML's fabrication method incorporates proprietary temperature control systems that maintain thermal uniformity within ±0.1°C across the entire preform during drawing, significantly reducing structural deformations. The company has developed specialized coating technologies that temporarily reinforce air holes during the drawing process, preventing collapse while enabling air-filling fractions exceeding 92%[5]. Their process also includes advanced inspection systems using interferometric techniques to provide real-time quality control during fabrication. ASML's approach has demonstrated particular success in creating non-circular hole geometries that remain stable throughout the drawing process, opening new possibilities for specialized PCF designs[7][9].

Strengths: Exceptional dimensional accuracy and precision in hole geometry; ability to create complex non-circular hole structures; superior temperature uniformity during drawing process. Weaknesses: Extremely high equipment costs; process requires clean room conditions; limited production volumes due to complexity of fabrication process; specialized expertise requirements limit widespread adoption.

Key Patents in PCF Manufacturing Technology

Photonic crystal fiber, a method of production thereof and a supercontinuum light source

PatentPendingUS20250067924A1

Innovation

- A PCF with a degradation-resistant length section loaded with hydrogen and/or deuterium, surrounded by a hermetic main coating that prevents diffusion of these gases at temperatures below 50°C, thereby extending the fiber's lifespan.

Material Science Advancements for PCF Production

The evolution of Photonic Crystal Fibers (PCFs) has been significantly influenced by advancements in material science. Traditional silica-based PCFs, while offering excellent optical properties, present limitations when attempting to achieve high air-filling fractions due to material constraints. Recent developments in material science have opened new pathways to overcome these challenges.

Advanced glass compositions have emerged as promising alternatives to conventional silica. Specifically, phosphate and chalcogenide glasses demonstrate superior malleability during the drawing process, allowing for the creation of more complex microstructures with thinner walls between air holes. These materials maintain structural integrity at higher temperatures, enabling more precise control during fabrication.

Polymer-based materials represent another significant advancement. Polymethyl methacrylate (PMMA) and other specialized polymers offer greater flexibility in creating high air-filling fraction structures. The lower processing temperatures required for polymers (typically 150-200°C compared to 1800-2000°C for silica) reduce thermal stress during fabrication, preserving the intended microstructure geometry.

Hybrid material approaches combine the benefits of different material classes. Silica-polymer composites, for instance, leverage the optical clarity of silica with the structural flexibility of polymers. These composites have demonstrated air-filling fractions exceeding 90% while maintaining mechanical stability, a significant improvement over traditional single-material approaches.

Surface treatment technologies have also evolved to address fabrication challenges. Hydrophobic coatings applied to preform materials prevent capillary effects during the drawing process, which typically cause air holes to collapse. Additionally, specialized etching techniques using advanced chemical compounds allow for post-fabrication enlargement of air holes, increasing the air-filling fraction of completed fibers.

Nanomaterial incorporation represents the cutting edge of PCF material science. Carbon nanotubes and graphene oxide, when integrated into the glass matrix, enhance the mechanical properties of thin struts between air holes. This reinforcement enables the creation of structures with wall thicknesses below 100nm while maintaining structural integrity during the drawing process.

Material purification techniques have advanced significantly, reducing optical losses in high air-filling fraction PCFs. Ultra-high purity processing environments and specialized dopants have minimized scattering centers and absorption sites, addressing one of the primary concerns with non-silica materials – their typically higher optical losses compared to pure silica.

Advanced glass compositions have emerged as promising alternatives to conventional silica. Specifically, phosphate and chalcogenide glasses demonstrate superior malleability during the drawing process, allowing for the creation of more complex microstructures with thinner walls between air holes. These materials maintain structural integrity at higher temperatures, enabling more precise control during fabrication.

Polymer-based materials represent another significant advancement. Polymethyl methacrylate (PMMA) and other specialized polymers offer greater flexibility in creating high air-filling fraction structures. The lower processing temperatures required for polymers (typically 150-200°C compared to 1800-2000°C for silica) reduce thermal stress during fabrication, preserving the intended microstructure geometry.

Hybrid material approaches combine the benefits of different material classes. Silica-polymer composites, for instance, leverage the optical clarity of silica with the structural flexibility of polymers. These composites have demonstrated air-filling fractions exceeding 90% while maintaining mechanical stability, a significant improvement over traditional single-material approaches.

Surface treatment technologies have also evolved to address fabrication challenges. Hydrophobic coatings applied to preform materials prevent capillary effects during the drawing process, which typically cause air holes to collapse. Additionally, specialized etching techniques using advanced chemical compounds allow for post-fabrication enlargement of air holes, increasing the air-filling fraction of completed fibers.

Nanomaterial incorporation represents the cutting edge of PCF material science. Carbon nanotubes and graphene oxide, when integrated into the glass matrix, enhance the mechanical properties of thin struts between air holes. This reinforcement enables the creation of structures with wall thicknesses below 100nm while maintaining structural integrity during the drawing process.

Material purification techniques have advanced significantly, reducing optical losses in high air-filling fraction PCFs. Ultra-high purity processing environments and specialized dopants have minimized scattering centers and absorption sites, addressing one of the primary concerns with non-silica materials – their typically higher optical losses compared to pure silica.

Quality Control and Testing Methodologies

Quality control and testing methodologies for high air-filling fraction photonic crystal fibers (PCFs) represent a critical component in the manufacturing process, ensuring that these complex microstructured optical fibers meet stringent performance specifications. The evaluation of PCFs requires specialized techniques that differ significantly from those used for conventional optical fibers due to their unique microstructure.

Optical microscopy serves as the first-line inspection method, allowing for rapid assessment of structural uniformity and air-hole geometry. However, this technique is limited to surface-level examination and cannot fully characterize internal structures. For more comprehensive analysis, scanning electron microscopy (SEM) provides high-resolution imaging of cross-sectional features, enabling precise measurement of air-hole diameters, pitch, and wall thickness with nanometer-scale accuracy.

Non-destructive testing methods have gained prominence in PCF quality control. Optical coherence tomography (OCT) allows for three-dimensional visualization of internal structures without sample preparation. This technique is particularly valuable for detecting longitudinal variations in air-hole geometry that may occur during the drawing process. Similarly, X-ray computed tomography offers detailed volumetric information about structural irregularities throughout the fiber length.

Functional testing methodologies focus on optical performance parameters critical to high air-filling fraction PCFs. Measurements of transmission loss, dispersion characteristics, and modal properties are essential for validating theoretical models. Near-field scanning optical microscopy (NSOM) enables characterization of light propagation within the microstructure, providing insights into mode confinement and coupling behaviors specific to high air-filling designs.

Statistical process control (SPC) frameworks have been adapted for PCF manufacturing, incorporating specialized metrics for air-filling fraction consistency. These systems typically monitor key dimensional parameters throughout production, establishing control limits that trigger corrective actions when variations exceed predetermined thresholds. Advanced manufacturers implement automated inspection systems that combine multiple testing modalities with machine learning algorithms to detect subtle structural anomalies.

Standardization efforts for PCF testing methodologies remain ongoing, with several international organizations working to establish unified protocols. These standards aim to address the unique challenges of characterizing high air-filling fraction structures, including measurement reproducibility across different testing platforms and correlation between structural parameters and optical performance. The development of reference materials with certified dimensional properties represents a significant advancement in this standardization process.

Optical microscopy serves as the first-line inspection method, allowing for rapid assessment of structural uniformity and air-hole geometry. However, this technique is limited to surface-level examination and cannot fully characterize internal structures. For more comprehensive analysis, scanning electron microscopy (SEM) provides high-resolution imaging of cross-sectional features, enabling precise measurement of air-hole diameters, pitch, and wall thickness with nanometer-scale accuracy.

Non-destructive testing methods have gained prominence in PCF quality control. Optical coherence tomography (OCT) allows for three-dimensional visualization of internal structures without sample preparation. This technique is particularly valuable for detecting longitudinal variations in air-hole geometry that may occur during the drawing process. Similarly, X-ray computed tomography offers detailed volumetric information about structural irregularities throughout the fiber length.

Functional testing methodologies focus on optical performance parameters critical to high air-filling fraction PCFs. Measurements of transmission loss, dispersion characteristics, and modal properties are essential for validating theoretical models. Near-field scanning optical microscopy (NSOM) enables characterization of light propagation within the microstructure, providing insights into mode confinement and coupling behaviors specific to high air-filling designs.

Statistical process control (SPC) frameworks have been adapted for PCF manufacturing, incorporating specialized metrics for air-filling fraction consistency. These systems typically monitor key dimensional parameters throughout production, establishing control limits that trigger corrective actions when variations exceed predetermined thresholds. Advanced manufacturers implement automated inspection systems that combine multiple testing modalities with machine learning algorithms to detect subtle structural anomalies.

Standardization efforts for PCF testing methodologies remain ongoing, with several international organizations working to establish unified protocols. These standards aim to address the unique challenges of characterizing high air-filling fraction structures, including measurement reproducibility across different testing platforms and correlation between structural parameters and optical performance. The development of reference materials with certified dimensional properties represents a significant advancement in this standardization process.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!