Integration of Photonic Crystal Fibers into Fiber Lasers

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PCF-Fiber Laser Integration Background and Objectives

Photonic Crystal Fibers (PCFs) represent a revolutionary advancement in optical fiber technology, characterized by their unique microstructured design featuring air holes arranged in specific patterns throughout the fiber length. Since their introduction in the late 1990s, PCFs have evolved from experimental curiosities to essential components in advanced photonic systems, particularly in high-power fiber lasers.

The evolution of PCF technology has followed a trajectory marked by significant breakthroughs in manufacturing techniques, structural design optimization, and material science innovations. Initially limited by fabrication challenges, modern PCFs now benefit from sophisticated stack-and-draw processes and advanced material compositions that enable precise control over optical properties previously unattainable in conventional fibers.

The integration of PCFs into fiber laser systems represents a convergence of two transformative optical technologies. Fiber lasers have independently undergone remarkable development, transitioning from low-power novelties to industrial-grade tools capable of multi-kilowatt output powers with exceptional beam quality. This progression has been driven by applications in materials processing, medical procedures, telecommunications, and defense systems.

The primary technical objective of PCF-fiber laser integration is to overcome fundamental limitations in conventional fiber laser designs. These limitations include nonlinear effects that emerge at high power levels, modal instabilities that degrade beam quality, and thermal management challenges that restrict scaling capabilities. PCFs offer unique solutions through their customizable dispersion profiles, large mode areas, and enhanced thermal properties.

Current research trends focus on several key areas: developing large-mode-area PCFs that maintain single-mode operation at high powers; engineering novel PCF structures with enhanced nonlinearity management; creating all-fiber integrated systems that eliminate bulk optical components; and exploring specialty dopant distributions within PCF structures to optimize gain characteristics.

The anticipated technological trajectory suggests continued refinement of PCF designs specifically tailored for fiber laser applications, with particular emphasis on power scaling beyond current limitations while maintaining beam quality. Emerging research indicates potential for revolutionary PCF-based fiber laser architectures that could enable compact, efficient systems with unprecedented performance characteristics.

The ultimate goal of this technological integration extends beyond incremental improvements, aiming instead for transformative capabilities that could redefine application possibilities across multiple industries. Success in this domain would represent not merely an enhancement of existing laser technology but potentially a paradigm shift in how high-power coherent light sources are conceptualized and implemented.

The evolution of PCF technology has followed a trajectory marked by significant breakthroughs in manufacturing techniques, structural design optimization, and material science innovations. Initially limited by fabrication challenges, modern PCFs now benefit from sophisticated stack-and-draw processes and advanced material compositions that enable precise control over optical properties previously unattainable in conventional fibers.

The integration of PCFs into fiber laser systems represents a convergence of two transformative optical technologies. Fiber lasers have independently undergone remarkable development, transitioning from low-power novelties to industrial-grade tools capable of multi-kilowatt output powers with exceptional beam quality. This progression has been driven by applications in materials processing, medical procedures, telecommunications, and defense systems.

The primary technical objective of PCF-fiber laser integration is to overcome fundamental limitations in conventional fiber laser designs. These limitations include nonlinear effects that emerge at high power levels, modal instabilities that degrade beam quality, and thermal management challenges that restrict scaling capabilities. PCFs offer unique solutions through their customizable dispersion profiles, large mode areas, and enhanced thermal properties.

Current research trends focus on several key areas: developing large-mode-area PCFs that maintain single-mode operation at high powers; engineering novel PCF structures with enhanced nonlinearity management; creating all-fiber integrated systems that eliminate bulk optical components; and exploring specialty dopant distributions within PCF structures to optimize gain characteristics.

The anticipated technological trajectory suggests continued refinement of PCF designs specifically tailored for fiber laser applications, with particular emphasis on power scaling beyond current limitations while maintaining beam quality. Emerging research indicates potential for revolutionary PCF-based fiber laser architectures that could enable compact, efficient systems with unprecedented performance characteristics.

The ultimate goal of this technological integration extends beyond incremental improvements, aiming instead for transformative capabilities that could redefine application possibilities across multiple industries. Success in this domain would represent not merely an enhancement of existing laser technology but potentially a paradigm shift in how high-power coherent light sources are conceptualized and implemented.

Market Analysis for PCF-Enhanced Fiber Lasers

The global market for PCF-enhanced fiber lasers has experienced significant growth over the past decade, driven by increasing demand across multiple industrial, medical, and research applications. Current market valuations indicate that the PCF-integrated fiber laser segment represents approximately 18% of the overall fiber laser market, which was valued at $2.1 billion in 2022, with projections suggesting annual growth rates of 11-13% through 2028.

Industrial manufacturing remains the dominant application sector, accounting for nearly 42% of PCF-enhanced fiber laser deployments. Within this sector, metal cutting and welding applications lead adoption due to the superior beam quality and power scaling capabilities that photonic crystal fiber integration enables. The medical sector follows at 27% market share, where precision surgical procedures and ophthalmological treatments benefit from the enhanced wavelength flexibility and beam stability.

Regional analysis reveals that Asia-Pacific currently dominates the market with 39% share, primarily driven by rapid industrialization in China, Japan, and South Korea. North America follows at 31%, with particularly strong demand in defense applications and scientific research. European markets account for 24%, with Germany and the UK showing the highest adoption rates within the region.

Market segmentation by power range shows that high-power systems (>500W) represent the fastest-growing segment with 16% annual growth, reflecting industrial users' increasing preference for PCF-enhanced systems that offer better thermal management and higher beam quality at elevated power levels.

Customer surveys indicate that key purchasing factors include beam quality maintenance at high powers (cited by 78% of respondents), operational wavelength flexibility (65%), and total cost of ownership (59%). The premium pricing of PCF-enhanced systems remains a significant barrier to wider adoption, with current price premiums averaging 30-40% compared to conventional fiber laser systems.

Competitive analysis reveals a market dominated by five major players controlling approximately 67% of global sales. However, the emergence of specialized manufacturers focusing exclusively on PCF-enhanced systems is gradually reshaping the competitive landscape, with these niche players growing at twice the market rate.

Future market projections suggest that as manufacturing costs decrease through economies of scale and improved production techniques, the price premium for PCF-enhanced systems could drop to 15-20% by 2026, potentially accelerating market penetration. Additionally, emerging applications in quantum communications, advanced sensing, and ultrafast laser processing are expected to create new market opportunities, potentially adding $300-400 million to the market size by 2027.

Industrial manufacturing remains the dominant application sector, accounting for nearly 42% of PCF-enhanced fiber laser deployments. Within this sector, metal cutting and welding applications lead adoption due to the superior beam quality and power scaling capabilities that photonic crystal fiber integration enables. The medical sector follows at 27% market share, where precision surgical procedures and ophthalmological treatments benefit from the enhanced wavelength flexibility and beam stability.

Regional analysis reveals that Asia-Pacific currently dominates the market with 39% share, primarily driven by rapid industrialization in China, Japan, and South Korea. North America follows at 31%, with particularly strong demand in defense applications and scientific research. European markets account for 24%, with Germany and the UK showing the highest adoption rates within the region.

Market segmentation by power range shows that high-power systems (>500W) represent the fastest-growing segment with 16% annual growth, reflecting industrial users' increasing preference for PCF-enhanced systems that offer better thermal management and higher beam quality at elevated power levels.

Customer surveys indicate that key purchasing factors include beam quality maintenance at high powers (cited by 78% of respondents), operational wavelength flexibility (65%), and total cost of ownership (59%). The premium pricing of PCF-enhanced systems remains a significant barrier to wider adoption, with current price premiums averaging 30-40% compared to conventional fiber laser systems.

Competitive analysis reveals a market dominated by five major players controlling approximately 67% of global sales. However, the emergence of specialized manufacturers focusing exclusively on PCF-enhanced systems is gradually reshaping the competitive landscape, with these niche players growing at twice the market rate.

Future market projections suggest that as manufacturing costs decrease through economies of scale and improved production techniques, the price premium for PCF-enhanced systems could drop to 15-20% by 2026, potentially accelerating market penetration. Additionally, emerging applications in quantum communications, advanced sensing, and ultrafast laser processing are expected to create new market opportunities, potentially adding $300-400 million to the market size by 2027.

Current PCF Integration Challenges

Despite the significant advancements in Photonic Crystal Fiber (PCF) technology, several critical challenges persist in their integration with fiber laser systems. The primary obstacle remains the splicing of PCFs with conventional fibers, as their microstructured geometry creates fundamental incompatibilities. When heat is applied during fusion splicing, the air holes in PCFs tend to collapse, significantly altering their waveguide properties and causing substantial coupling losses at splice points, often exceeding 2-3 dB per junction.

Mode field diameter (MFD) mismatch between PCFs and conventional fibers presents another substantial challenge. This mismatch leads to increased insertion losses and back-reflections, which can destabilize laser operation and reduce overall system efficiency. While mode field adapters and tapered fiber transitions offer potential solutions, they add complexity and cost to the manufacturing process.

Thermal management issues also complicate PCF integration. The air-hole structure of PCFs creates unique heat dissipation characteristics that differ significantly from conventional fibers. In high-power laser applications, this can lead to thermal lensing effects, structural deformation, and ultimately catastrophic damage to the fiber. Current thermal management solutions often involve complex cooling systems that increase system bulk and cost.

Manufacturing consistency represents another significant hurdle. The production of PCFs with precisely controlled microstructures remains challenging, resulting in fiber-to-fiber variations that complicate integration and mass production. This inconsistency necessitates individual characterization and adaptation strategies for each fiber segment, making standardized integration protocols difficult to establish.

The polarization behavior of PCFs introduces additional complexity. Many PCF designs exhibit complex polarization-dependent properties that can fluctuate with environmental conditions and mechanical stress. Maintaining polarization stability throughout the integrated laser system requires sophisticated management techniques that add to system complexity.

Packaging and long-term reliability concerns further complicate PCF integration. The microstructured nature of PCFs makes them potentially more susceptible to contamination, mechanical stress, and environmental degradation than conventional fibers. Developing robust packaging solutions that protect the PCF structure while maintaining optical performance remains challenging.

Cost considerations also present significant barriers to widespread adoption. The specialized manufacturing processes required for PCFs, combined with the additional components needed for successful integration, result in substantially higher system costs compared to conventional fiber laser technologies. This cost premium limits market penetration, particularly in price-sensitive application segments.

Mode field diameter (MFD) mismatch between PCFs and conventional fibers presents another substantial challenge. This mismatch leads to increased insertion losses and back-reflections, which can destabilize laser operation and reduce overall system efficiency. While mode field adapters and tapered fiber transitions offer potential solutions, they add complexity and cost to the manufacturing process.

Thermal management issues also complicate PCF integration. The air-hole structure of PCFs creates unique heat dissipation characteristics that differ significantly from conventional fibers. In high-power laser applications, this can lead to thermal lensing effects, structural deformation, and ultimately catastrophic damage to the fiber. Current thermal management solutions often involve complex cooling systems that increase system bulk and cost.

Manufacturing consistency represents another significant hurdle. The production of PCFs with precisely controlled microstructures remains challenging, resulting in fiber-to-fiber variations that complicate integration and mass production. This inconsistency necessitates individual characterization and adaptation strategies for each fiber segment, making standardized integration protocols difficult to establish.

The polarization behavior of PCFs introduces additional complexity. Many PCF designs exhibit complex polarization-dependent properties that can fluctuate with environmental conditions and mechanical stress. Maintaining polarization stability throughout the integrated laser system requires sophisticated management techniques that add to system complexity.

Packaging and long-term reliability concerns further complicate PCF integration. The microstructured nature of PCFs makes them potentially more susceptible to contamination, mechanical stress, and environmental degradation than conventional fibers. Developing robust packaging solutions that protect the PCF structure while maintaining optical performance remains challenging.

Cost considerations also present significant barriers to widespread adoption. The specialized manufacturing processes required for PCFs, combined with the additional components needed for successful integration, result in substantially higher system costs compared to conventional fiber laser technologies. This cost premium limits market penetration, particularly in price-sensitive application segments.

Current PCF-Fiber Laser Integration Methods

01 Structure and design of photonic crystal fibers

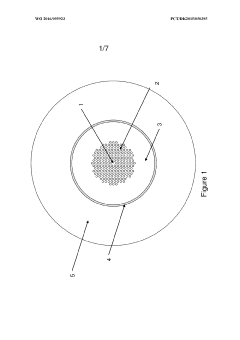

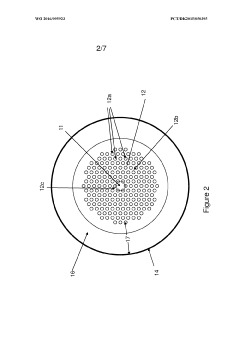

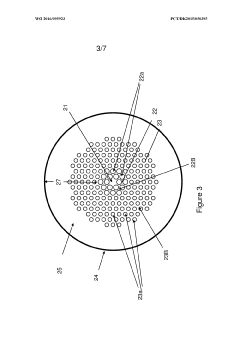

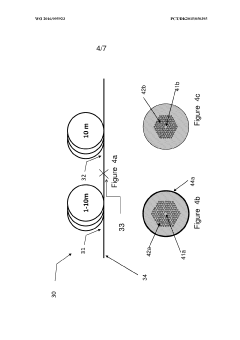

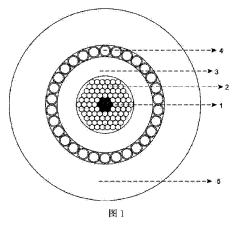

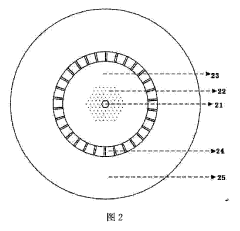

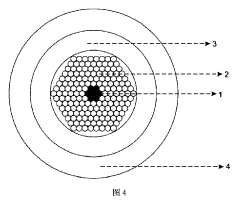

Photonic crystal fibers (PCFs) are optical fibers with a microstructured arrangement of air holes running along their length. The design typically includes a solid or hollow core surrounded by a periodic arrangement of air holes in the cladding. This unique structure allows for customizable light guidance properties, including single-mode operation over wide wavelength ranges, high numerical apertures, and tailored dispersion characteristics. Various structural designs can be implemented to achieve specific optical properties for different applications.- Structure and design of photonic crystal fibers: Photonic crystal fibers (PCFs) are optical fibers with a microstructured arrangement of air holes running along their length. The design typically includes a solid or hollow core surrounded by a periodic arrangement of air holes in the cladding. This unique structure allows for customizable light guidance properties, including single-mode operation over wide wavelength ranges, high numerical apertures, and tailored dispersion characteristics. Various geometric parameters such as hole size, spacing, and pattern can be optimized for specific applications.

- Nonlinear optical applications of photonic crystal fibers: Photonic crystal fibers exhibit enhanced nonlinear optical properties due to their ability to confine light in small core areas and engineer dispersion. These properties make them ideal for applications such as supercontinuum generation, four-wave mixing, and soliton formation. The high power densities achievable in PCFs enable efficient nonlinear processes at relatively low input powers. By controlling the fiber structure, nonlinear effects can be either enhanced for applications like frequency conversion or suppressed when linear transmission is desired.

- Hollow-core photonic crystal fibers: Hollow-core photonic crystal fibers guide light primarily in an air core rather than in solid material. This design offers several advantages including reduced material absorption, lower nonlinearity, higher damage thresholds, and the ability to fill the core with gases or liquids for sensing applications. The light guidance mechanism in hollow-core PCFs typically relies on photonic bandgap effects or antiresonant reflection. These fibers are particularly valuable for high-power laser delivery, gas-based nonlinear optics, and precision spectroscopy.

- Sensing and detection applications using photonic crystal fibers: Photonic crystal fibers offer unique capabilities for sensing and detection applications due to their customizable light-matter interaction properties. The air holes in PCFs can be filled with analytes or functionalized for chemical and biological sensing. Enhanced evanescent field interaction in certain PCF designs improves sensitivity for refractive index measurements. PCFs are also used in interferometric sensors, distributed sensing systems, and as transducers for physical parameters such as temperature, pressure, and strain. Their design flexibility allows optimization for specific sensing requirements.

- Fabrication methods for photonic crystal fibers: Manufacturing techniques for photonic crystal fibers have evolved to enable complex microstructures with precise control. The stack-and-draw method involves arranging capillary tubes and rods in a specific pattern before drawing them into fiber. Drilling methods directly create hole patterns in preforms. Extrusion techniques push soft glass through structured dies. Sol-gel casting allows for intricate structures in silica. Advanced fabrication approaches include 3D printing of preforms and tapering techniques to modify PCF properties along their length. These methods enable customization of optical properties for specific applications.

02 Nonlinear optical applications of photonic crystal fibers

Photonic crystal fibers exhibit enhanced nonlinear optical properties due to their ability to confine light in small core areas and maintain high intensities over long interaction lengths. These properties make them ideal for nonlinear applications such as supercontinuum generation, four-wave mixing, and soliton formation. The nonlinear characteristics can be tailored by adjusting the fiber structure, core size, and material composition, enabling applications in frequency conversion, pulse compression, and ultrafast laser systems.Expand Specific Solutions03 Sensing and detection applications using photonic crystal fibers

Photonic crystal fibers offer unique advantages for sensing applications due to their customizable light-matter interaction capabilities. They can be designed with hollow cores or side channels that allow sample introduction directly into the optical path, enhancing sensitivity. These fibers are used in chemical, biological, and physical sensing applications, including gas detection, temperature measurement, pressure sensing, and biomolecule detection. The high sensitivity and specificity make them valuable tools for environmental monitoring and medical diagnostics.Expand Specific Solutions04 Manufacturing methods for photonic crystal fibers

Various manufacturing techniques are employed to produce photonic crystal fibers with precise microstructures. The stack-and-draw method involves arranging capillary tubes and rods in a specific pattern before drawing them into a fiber. Other techniques include drilling, extrusion, and sol-gel casting. Advanced manufacturing methods allow for complex designs with varying hole sizes, non-periodic structures, and incorporation of different materials. These fabrication processes enable customization of optical properties for specific applications while maintaining structural integrity throughout the fiber length.Expand Specific Solutions05 Dispersion management in photonic crystal fibers

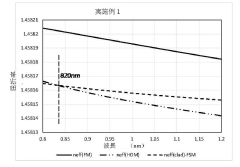

Photonic crystal fibers offer unprecedented control over chromatic dispersion properties, which is crucial for many applications including telecommunications and ultrafast optics. By carefully designing the air hole pattern, size, and spacing, engineers can create fibers with anomalous dispersion at visible wavelengths, zero-dispersion wavelengths at desired positions, or flat dispersion over broad spectral ranges. This dispersion management capability enables applications such as pulse compression, dispersion compensation, and supercontinuum generation with tailored spectral characteristics.Expand Specific Solutions

Leading PCF and Fiber Laser Manufacturers

The integration of Photonic Crystal Fibers (PCFs) into fiber lasers represents an emerging technology at the intersection of photonics and laser engineering. Currently in the growth phase, this field is experiencing rapid technological advancement with an estimated global market size of $350-400 million, projected to expand at 8-10% annually. The technology maturity varies across applications, with sensing and telecommunications leading while high-power laser applications remain less developed. Key industry players include specialized photonics companies like NKT Photonics and Fujikura Ltd., who lead in PCF manufacturing, alongside research-focused organizations such as MIT and Kyoto University advancing fundamental innovations. Major telecommunications corporations including Sumitomo Electric and Corning are increasingly integrating PCF technology into their fiber laser product portfolios, signaling growing commercial viability.

Fujikura Ltd.

Technical Solution: Fujikura has developed a sophisticated approach to integrating photonic crystal fibers into fiber laser systems through their "Air-Silica Nanostructure" technology. Their PCFs feature precisely engineered air hole patterns that enable exceptional control over modal properties and dispersion characteristics. Fujikura's manufacturing process employs proprietary drawing techniques that maintain structural integrity at the nanoscale, achieving remarkable consistency in optical performance. Their PCF-based fiber lasers demonstrate exceptional beam quality with M² values consistently below 1.1 even at multi-kilowatt power levels. Fujikura has pioneered large-mode-area PCFs with effective areas exceeding 1000μm² while maintaining single-mode operation, critical for high-power laser applications. Their recent innovations include gradient-index PCF structures that provide enhanced mode filtering capabilities, effectively eliminating higher-order modes that typically degrade beam quality in high-power operation.

Strengths: Exceptional manufacturing capabilities with high precision and consistency; strong integration with industrial laser systems; established presence in both telecommunications and specialty fiber markets. Weaknesses: More conservative approach to novel PCF designs; limited public research publications on proprietary technologies; primarily focused on established applications rather than emerging markets.

Massachusetts Institute of Technology

Technical Solution: MIT has pioneered fundamental research in photonic crystal fiber integration for advanced fiber laser systems. Their approach focuses on novel PCF designs that enable unprecedented control over light propagation and nonlinear interactions. MIT researchers have developed "Omniguide" PCFs featuring concentric rings of alternating high and low refractive index materials, creating photonic bandgaps that enable unique waveguiding properties impossible in conventional fibers. Their work on multi-material PCFs has demonstrated the integration of chalcogenide glasses with silica structures, enabling mid-IR fiber lasers with exceptional beam quality. MIT's research has established theoretical frameworks for understanding modal instabilities in high-power PCF-based lasers, leading to novel designs that mitigate these effects. Their recent innovations include topological PCF structures that leverage concepts from condensed matter physics to create robust optical states resistant to perturbations, critical for maintaining performance in harsh operating environments. MIT has also demonstrated PCF-based frequency comb generation with octave-spanning spectra, enabling precision metrology applications.

Strengths: Cutting-edge research pushing theoretical boundaries; interdisciplinary approach combining materials science, physics, and engineering; strong collaboration network with industry partners. Weaknesses: Focus on fundamental research rather than commercial applications; limited manufacturing capabilities compared to industrial players; technologies often require significant development before commercial viability.

Key Patents in PCF-Fiber Laser Systems

A photonic crystal fiber, a method of production thereof and a supercontinuum light source

PatentWO2016095923A1

Innovation

- A PCF with a degradation-resistant length section loaded with hydrogen or deuterium, surrounded by a hermetic main coating that prevents diffusion at temperatures below a certain threshold, combined with a method of applying a carbon or metal coating using chemical vapor deposition or liquid metal processes to enhance durability.

Photonic crystal fiber, its preform, method of manufacture and use

PatentActiveJP2022522371A

Innovation

- The use of fluorine-doped glass filaments and concentric nested structures with controlled refractive index differences and geometries to form high-quality, tunable photonic crystal fibers, enhancing thermal management and beam quality.

Thermal Management in PCF-Fiber Laser Systems

Thermal management represents a critical challenge in the integration of Photonic Crystal Fibers (PCFs) into fiber laser systems. The unique microstructure of PCFs, while advantageous for light guidance and dispersion control, creates distinctive thermal dissipation patterns that differ significantly from conventional optical fibers. The air-hole structure that defines PCFs often impedes efficient heat transfer, resulting in localized thermal hotspots that can compromise system performance and longevity.

Current thermal management approaches in PCF-fiber laser systems employ multiple strategies. Active cooling methods include forced air circulation, liquid cooling systems with specialized heat-transfer fluids, and thermoelectric coolers strategically positioned at critical thermal junctions. These active systems require careful integration with power supplies and control electronics to maintain optimal operating temperatures across varying operational loads.

Passive thermal management techniques have also demonstrated considerable efficacy. Advanced heat-sink designs utilizing materials with high thermal conductivity such as copper-tungsten alloys or aluminum nitride ceramics help dissipate heat from critical components. Thermal interface materials (TIMs) with engineered thermal conductivity profiles facilitate heat transfer between PCFs and cooling structures while accommodating the mechanical constraints of delicate optical components.

Computational fluid dynamics (CFD) modeling has emerged as an essential tool in thermal management design for PCF-laser systems. These simulations enable engineers to predict temperature distributions, identify potential hotspots, and optimize cooling strategies before physical prototyping. Recent advances in multi-physics modeling allow simultaneous simulation of optical, thermal, and mechanical effects, providing comprehensive insights into system behavior under various operating conditions.

The integration of temperature sensors and feedback control systems represents another significant advancement in PCF-laser thermal management. Distributed temperature sensing using fiber Bragg gratings or Raman-based techniques enables real-time monitoring of thermal conditions along the entire fiber length. This data feeds into adaptive control systems that can modulate pump power, cooling intensity, or even beam characteristics to maintain optimal thermal conditions throughout operation.

Emerging research directions include the development of microstructured PCFs with inherently improved thermal properties. These designs incorporate thermally conductive materials within the fiber structure or feature modified air-hole geometries that enhance heat dissipation while preserving desired optical characteristics. Preliminary studies suggest these thermally-optimized PCFs could significantly increase power handling capabilities in next-generation fiber laser systems.

Current thermal management approaches in PCF-fiber laser systems employ multiple strategies. Active cooling methods include forced air circulation, liquid cooling systems with specialized heat-transfer fluids, and thermoelectric coolers strategically positioned at critical thermal junctions. These active systems require careful integration with power supplies and control electronics to maintain optimal operating temperatures across varying operational loads.

Passive thermal management techniques have also demonstrated considerable efficacy. Advanced heat-sink designs utilizing materials with high thermal conductivity such as copper-tungsten alloys or aluminum nitride ceramics help dissipate heat from critical components. Thermal interface materials (TIMs) with engineered thermal conductivity profiles facilitate heat transfer between PCFs and cooling structures while accommodating the mechanical constraints of delicate optical components.

Computational fluid dynamics (CFD) modeling has emerged as an essential tool in thermal management design for PCF-laser systems. These simulations enable engineers to predict temperature distributions, identify potential hotspots, and optimize cooling strategies before physical prototyping. Recent advances in multi-physics modeling allow simultaneous simulation of optical, thermal, and mechanical effects, providing comprehensive insights into system behavior under various operating conditions.

The integration of temperature sensors and feedback control systems represents another significant advancement in PCF-laser thermal management. Distributed temperature sensing using fiber Bragg gratings or Raman-based techniques enables real-time monitoring of thermal conditions along the entire fiber length. This data feeds into adaptive control systems that can modulate pump power, cooling intensity, or even beam characteristics to maintain optimal thermal conditions throughout operation.

Emerging research directions include the development of microstructured PCFs with inherently improved thermal properties. These designs incorporate thermally conductive materials within the fiber structure or feature modified air-hole geometries that enhance heat dissipation while preserving desired optical characteristics. Preliminary studies suggest these thermally-optimized PCFs could significantly increase power handling capabilities in next-generation fiber laser systems.

Manufacturing Scalability of PCF-Integrated Lasers

The current manufacturing processes for PCF-integrated fiber lasers face significant scalability challenges that limit their widespread commercial adoption. Traditional fabrication methods involve complex multi-stage processes including stack-and-draw techniques for PCF production followed by precision integration with active gain media. These labor-intensive procedures result in high unit costs and inconsistent quality, with typical production yields below 70% for high-performance devices.

Industry analysis reveals that manufacturing throughput remains a critical bottleneck, with current production rates averaging only 5-10 specialized PCF-integrated lasers per day in advanced facilities. This limited scale creates a substantial gap between laboratory demonstrations and market-ready solutions, particularly for applications requiring thousands of units such as medical devices and telecommunications infrastructure.

Recent advancements in automated fiber drawing and fusion splicing technologies have begun addressing these challenges. Computer-controlled drawing towers with real-time monitoring systems have improved structural uniformity by approximately 40% compared to manual methods. Similarly, precision fusion splicing techniques using CO2 lasers or electrical arc systems have reduced coupling losses at PCF-standard fiber interfaces from typical values of 2-3 dB to below 0.5 dB in optimized systems.

Economic analysis indicates that current manufacturing costs for PCF-integrated lasers remain 3-5 times higher than conventional fiber lasers, primarily due to complex fabrication requirements and specialized equipment needs. The learning curve for manufacturing optimization suggests that a 10x increase in production volume could potentially reduce unit costs by 60-70%, making these devices more commercially viable.

Material supply chains present another scalability concern, particularly regarding high-purity silica and specialty dopants required for advanced PCF structures. Current global capacity for specialty optical fiber materials meets only about 60% of projected demand if PCF-integrated lasers were to achieve mainstream adoption in telecommunications and sensing applications.

Standardization efforts by industry consortia like the Photonic Crystal Fiber Manufacturing Alliance (PCFMA) have begun establishing common specifications and quality control metrics, which could accelerate manufacturing scalability. Their roadmap targets a 300% increase in production capacity by 2027 through implementation of automated fabrication lines and modular design approaches that simplify assembly while maintaining optical performance.

Industry analysis reveals that manufacturing throughput remains a critical bottleneck, with current production rates averaging only 5-10 specialized PCF-integrated lasers per day in advanced facilities. This limited scale creates a substantial gap between laboratory demonstrations and market-ready solutions, particularly for applications requiring thousands of units such as medical devices and telecommunications infrastructure.

Recent advancements in automated fiber drawing and fusion splicing technologies have begun addressing these challenges. Computer-controlled drawing towers with real-time monitoring systems have improved structural uniformity by approximately 40% compared to manual methods. Similarly, precision fusion splicing techniques using CO2 lasers or electrical arc systems have reduced coupling losses at PCF-standard fiber interfaces from typical values of 2-3 dB to below 0.5 dB in optimized systems.

Economic analysis indicates that current manufacturing costs for PCF-integrated lasers remain 3-5 times higher than conventional fiber lasers, primarily due to complex fabrication requirements and specialized equipment needs. The learning curve for manufacturing optimization suggests that a 10x increase in production volume could potentially reduce unit costs by 60-70%, making these devices more commercially viable.

Material supply chains present another scalability concern, particularly regarding high-purity silica and specialty dopants required for advanced PCF structures. Current global capacity for specialty optical fiber materials meets only about 60% of projected demand if PCF-integrated lasers were to achieve mainstream adoption in telecommunications and sensing applications.

Standardization efforts by industry consortia like the Photonic Crystal Fiber Manufacturing Alliance (PCFMA) have begun establishing common specifications and quality control metrics, which could accelerate manufacturing scalability. Their roadmap targets a 300% increase in production capacity by 2027 through implementation of automated fabrication lines and modular design approaches that simplify assembly while maintaining optical performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!