Standardization and Characterization of Photonic Crystal Fibers

OCT 11, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PCF Technology Background and Objectives

Photonic Crystal Fibers (PCFs) represent a revolutionary advancement in optical fiber technology, emerging in the late 1990s as a novel class of optical waveguides. Unlike conventional optical fibers, PCFs feature a microstructured arrangement of air holes running along their entire length, creating unique light-guiding properties that transcend the limitations of traditional fiber optics. The evolution of PCF technology has progressed through several significant phases, from theoretical conceptualization to practical implementation and commercial deployment.

The historical development of PCFs began with the pioneering work of Philip Russell and his team in the 1990s, who first demonstrated the feasibility of creating optical fibers with photonic crystal structures. This breakthrough was followed by rapid advancements in fabrication techniques, particularly the stack-and-draw method, which enabled more precise control over the microstructure geometry. The early 2000s witnessed the expansion of PCF applications beyond telecommunications into sensing, nonlinear optics, and high-power laser delivery.

Current technological trends in PCF development focus on enhancing performance parameters such as transmission bandwidth, nonlinearity control, dispersion management, and polarization maintenance. Researchers are exploring novel materials, hybrid structures, and advanced fabrication methods to push the boundaries of what PCFs can achieve. The integration of PCFs with other photonic components and systems represents another significant trend, enabling more compact and efficient optical devices.

The primary objectives of PCF standardization and characterization efforts are multifaceted. First, establishing standardized measurement protocols and reference parameters is essential for ensuring consistency and reliability in PCF performance evaluation across different laboratories and manufacturers. Second, developing comprehensive characterization methodologies that accurately capture the unique properties of PCFs, including mode field distribution, dispersion profiles, and nonlinear coefficients, is crucial for advancing both research and commercial applications.

Additionally, PCF technology aims to address specific challenges in optical communication systems, such as reducing signal attenuation, minimizing modal dispersion, and enhancing bandwidth capacity. In sensing applications, objectives include improving sensitivity, selectivity, and stability of PCF-based sensors. For high-power laser applications, the focus is on increasing damage thresholds, managing thermal effects, and maintaining beam quality.

The long-term vision for PCF technology encompasses its integration into next-generation photonic systems, enabling advancements in quantum communication, biomedical imaging, environmental monitoring, and industrial process control. Achieving this vision requires continued innovation in design principles, fabrication techniques, and characterization methods, supported by robust standardization frameworks that facilitate technology transfer and commercial adoption.

The historical development of PCFs began with the pioneering work of Philip Russell and his team in the 1990s, who first demonstrated the feasibility of creating optical fibers with photonic crystal structures. This breakthrough was followed by rapid advancements in fabrication techniques, particularly the stack-and-draw method, which enabled more precise control over the microstructure geometry. The early 2000s witnessed the expansion of PCF applications beyond telecommunications into sensing, nonlinear optics, and high-power laser delivery.

Current technological trends in PCF development focus on enhancing performance parameters such as transmission bandwidth, nonlinearity control, dispersion management, and polarization maintenance. Researchers are exploring novel materials, hybrid structures, and advanced fabrication methods to push the boundaries of what PCFs can achieve. The integration of PCFs with other photonic components and systems represents another significant trend, enabling more compact and efficient optical devices.

The primary objectives of PCF standardization and characterization efforts are multifaceted. First, establishing standardized measurement protocols and reference parameters is essential for ensuring consistency and reliability in PCF performance evaluation across different laboratories and manufacturers. Second, developing comprehensive characterization methodologies that accurately capture the unique properties of PCFs, including mode field distribution, dispersion profiles, and nonlinear coefficients, is crucial for advancing both research and commercial applications.

Additionally, PCF technology aims to address specific challenges in optical communication systems, such as reducing signal attenuation, minimizing modal dispersion, and enhancing bandwidth capacity. In sensing applications, objectives include improving sensitivity, selectivity, and stability of PCF-based sensors. For high-power laser applications, the focus is on increasing damage thresholds, managing thermal effects, and maintaining beam quality.

The long-term vision for PCF technology encompasses its integration into next-generation photonic systems, enabling advancements in quantum communication, biomedical imaging, environmental monitoring, and industrial process control. Achieving this vision requires continued innovation in design principles, fabrication techniques, and characterization methods, supported by robust standardization frameworks that facilitate technology transfer and commercial adoption.

Market Applications and Demand Analysis

The global market for Photonic Crystal Fibers (PCFs) has been experiencing significant growth, driven primarily by increasing demand for high-performance optical communication systems and advanced sensing applications. The telecommunications sector remains the largest consumer of PCF technology, with bandwidth demands continuing to rise exponentially due to cloud computing, video streaming services, and the proliferation of IoT devices. This sector alone accounts for approximately 40% of the current PCF market demand.

Healthcare and biomedical applications represent the fastest-growing segment for PCF technology. The unique properties of PCFs, particularly their ability to deliver high-power laser light with minimal loss and their enhanced sensing capabilities, make them invaluable for medical imaging, laser surgery, and diagnostic applications. Market research indicates that this segment is growing at a compound annual rate of 12%, significantly outpacing the overall fiber optics market.

Industrial sensing and monitoring applications constitute another substantial market for PCFs. Their superior performance in harsh environments, resistance to electromagnetic interference, and ability to measure multiple parameters simultaneously have driven adoption in oil and gas exploration, structural health monitoring, and industrial process control. The industrial sector currently represents about 25% of the total PCF market value.

Research institutions and defense organizations form a smaller but technologically significant market segment. These entities typically demand cutting-edge PCF designs for specialized applications such as quantum optics, high-energy physics experiments, and advanced military sensing systems. While representing only about 15% of market volume, this segment often drives innovation in PCF technology.

Geographically, North America and Europe currently lead in PCF adoption, collectively accounting for over 60% of global market share. However, the Asia-Pacific region is demonstrating the most rapid growth rate, particularly in countries like China, Japan, and South Korea, where significant investments are being made in telecommunications infrastructure and photonics research.

Market analysis reveals that standardization challenges are currently limiting broader commercial adoption. Potential users cite concerns about interoperability, reliability, and the lack of established performance benchmarks as barriers to implementation. Survey data from industry stakeholders indicates that 78% believe improved standardization would accelerate market adoption, particularly in conservative sectors like aerospace and critical infrastructure monitoring.

The demand for specialized PCF variants is also evolving, with hollow-core PCFs gaining particular interest for applications requiring minimal optical nonlinearity and dispersion. Market forecasts suggest that addressing these standardization and characterization challenges could potentially double the addressable market for PCF technology within the next five years.

Healthcare and biomedical applications represent the fastest-growing segment for PCF technology. The unique properties of PCFs, particularly their ability to deliver high-power laser light with minimal loss and their enhanced sensing capabilities, make them invaluable for medical imaging, laser surgery, and diagnostic applications. Market research indicates that this segment is growing at a compound annual rate of 12%, significantly outpacing the overall fiber optics market.

Industrial sensing and monitoring applications constitute another substantial market for PCFs. Their superior performance in harsh environments, resistance to electromagnetic interference, and ability to measure multiple parameters simultaneously have driven adoption in oil and gas exploration, structural health monitoring, and industrial process control. The industrial sector currently represents about 25% of the total PCF market value.

Research institutions and defense organizations form a smaller but technologically significant market segment. These entities typically demand cutting-edge PCF designs for specialized applications such as quantum optics, high-energy physics experiments, and advanced military sensing systems. While representing only about 15% of market volume, this segment often drives innovation in PCF technology.

Geographically, North America and Europe currently lead in PCF adoption, collectively accounting for over 60% of global market share. However, the Asia-Pacific region is demonstrating the most rapid growth rate, particularly in countries like China, Japan, and South Korea, where significant investments are being made in telecommunications infrastructure and photonics research.

Market analysis reveals that standardization challenges are currently limiting broader commercial adoption. Potential users cite concerns about interoperability, reliability, and the lack of established performance benchmarks as barriers to implementation. Survey data from industry stakeholders indicates that 78% believe improved standardization would accelerate market adoption, particularly in conservative sectors like aerospace and critical infrastructure monitoring.

The demand for specialized PCF variants is also evolving, with hollow-core PCFs gaining particular interest for applications requiring minimal optical nonlinearity and dispersion. Market forecasts suggest that addressing these standardization and characterization challenges could potentially double the addressable market for PCF technology within the next five years.

Global PCF Development Status and Challenges

Photonic Crystal Fibers (PCFs) have emerged as a revolutionary technology in optical communications and sensing applications, yet their global development faces significant standardization and characterization challenges. Currently, research institutions and companies across North America, Europe, and Asia are actively developing PCF technologies, with each region focusing on different aspects and applications.

In North America, research primarily centers on high-power applications and specialized sensing technologies, with institutions like MIT, Stanford, and companies such as Corning and OFS leading development efforts. European entities, particularly in Germany, UK, and Denmark, focus on precision manufacturing and theoretical modeling of PCFs, with NKT Photonics maintaining a dominant position in commercial PCF production.

The Asia-Pacific region, especially Japan, China, and South Korea, has rapidly expanded PCF research capabilities, emphasizing mass production techniques and cost-effective manufacturing processes. This geographical distribution has created challenges in establishing unified standards for PCF characterization and performance metrics.

A significant technical challenge facing global PCF development is the lack of standardized characterization methods. Unlike conventional optical fibers, PCFs exhibit complex modal behaviors, nonlinear properties, and dispersion characteristics that vary significantly with structural parameters. This complexity makes it difficult to establish universal testing protocols and performance benchmarks.

Manufacturing consistency represents another major obstacle. The intricate microstructure of PCFs requires precise control during fabrication, with even minor variations significantly affecting optical properties. Current production methods struggle to maintain consistent quality across batches, hampering widespread commercial adoption.

Interoperability issues further complicate PCF integration into existing optical systems. The unique coupling requirements and modal characteristics of PCFs often require specialized components and connection techniques, creating compatibility challenges with conventional fiber optic infrastructure.

Regulatory frameworks for PCF certification remain underdeveloped globally. While conventional optical fibers benefit from established standards (IEC, ITU-T), PCFs lack equivalent comprehensive guidelines, creating market entry barriers and limiting cross-border technology transfer.

Research coordination presents an additional challenge, with fragmented efforts across different geographical regions leading to duplication and inefficient resource allocation. Despite several international collaborative initiatives, a truly global approach to PCF standardization remains elusive.

These challenges collectively impede the broader commercialization of PCF technology, despite its tremendous potential. Addressing these issues requires coordinated international efforts to establish standardized characterization methods, manufacturing protocols, and regulatory frameworks that can support the next generation of PCF applications.

In North America, research primarily centers on high-power applications and specialized sensing technologies, with institutions like MIT, Stanford, and companies such as Corning and OFS leading development efforts. European entities, particularly in Germany, UK, and Denmark, focus on precision manufacturing and theoretical modeling of PCFs, with NKT Photonics maintaining a dominant position in commercial PCF production.

The Asia-Pacific region, especially Japan, China, and South Korea, has rapidly expanded PCF research capabilities, emphasizing mass production techniques and cost-effective manufacturing processes. This geographical distribution has created challenges in establishing unified standards for PCF characterization and performance metrics.

A significant technical challenge facing global PCF development is the lack of standardized characterization methods. Unlike conventional optical fibers, PCFs exhibit complex modal behaviors, nonlinear properties, and dispersion characteristics that vary significantly with structural parameters. This complexity makes it difficult to establish universal testing protocols and performance benchmarks.

Manufacturing consistency represents another major obstacle. The intricate microstructure of PCFs requires precise control during fabrication, with even minor variations significantly affecting optical properties. Current production methods struggle to maintain consistent quality across batches, hampering widespread commercial adoption.

Interoperability issues further complicate PCF integration into existing optical systems. The unique coupling requirements and modal characteristics of PCFs often require specialized components and connection techniques, creating compatibility challenges with conventional fiber optic infrastructure.

Regulatory frameworks for PCF certification remain underdeveloped globally. While conventional optical fibers benefit from established standards (IEC, ITU-T), PCFs lack equivalent comprehensive guidelines, creating market entry barriers and limiting cross-border technology transfer.

Research coordination presents an additional challenge, with fragmented efforts across different geographical regions leading to duplication and inefficient resource allocation. Despite several international collaborative initiatives, a truly global approach to PCF standardization remains elusive.

These challenges collectively impede the broader commercialization of PCF technology, despite its tremendous potential. Addressing these issues requires coordinated international efforts to establish standardized characterization methods, manufacturing protocols, and regulatory frameworks that can support the next generation of PCF applications.

Current Standardization Approaches for PCFs

01 Standardization methods for photonic crystal fibers

Various methods have been developed to standardize photonic crystal fibers (PCFs) to ensure consistent performance and quality. These standardization approaches include establishing uniform measurement protocols, defining geometric parameters, and creating reference standards for fiber characterization. Standardization efforts focus on core diameter, air hole arrangement, pitch, and other critical structural features that determine the optical properties of PCFs. These methods enable manufacturers and researchers to produce PCFs with predictable and reproducible characteristics.- Standardization methods for photonic crystal fibers: Various methods have been developed to standardize photonic crystal fibers (PCFs) to ensure consistent performance across different manufacturing processes. These standardization techniques include establishing uniform parameters for core diameter, air hole arrangement, pitch distance, and structural integrity. Standardized testing protocols help evaluate optical properties such as dispersion, birefringence, and transmission characteristics, enabling reliable comparison between different PCF designs and manufacturers.

- Characterization techniques for optical properties: Advanced characterization techniques are essential for measuring the optical properties of photonic crystal fibers. These include methods for analyzing mode field diameter, numerical aperture, dispersion profiles, and polarization-maintaining capabilities. Specialized equipment and procedures have been developed to accurately measure transmission losses, wavelength-dependent behavior, and nonlinear optical effects in PCFs. These characterization techniques enable precise evaluation of PCF performance for various applications.

- Structural characterization and quality control: Structural characterization of photonic crystal fibers involves analyzing the physical arrangement of air holes, core geometry, and material composition. Various imaging and measurement techniques are employed to verify manufacturing precision and detect defects that could affect optical performance. Quality control processes include dimensional verification, cross-sectional analysis, and structural integrity testing to ensure consistency across production batches and compliance with design specifications.

- Novel designs for specialized applications: Innovative photonic crystal fiber designs have been developed for specialized applications requiring specific optical characteristics. These include hollow-core fibers for high-power transmission, highly nonlinear fibers for frequency conversion, and polarization-maintaining structures for sensing applications. Design innovations focus on manipulating the arrangement, size, and shape of air holes to achieve desired properties such as enhanced birefringence, tailored dispersion profiles, or improved bend resistance while maintaining standardized characterization methods.

- Manufacturing processes and reproducibility: Consistent manufacturing processes are crucial for producing photonic crystal fibers with reproducible characteristics. Various fabrication techniques have been standardized, including stack-and-draw, drilling, and extrusion methods. Process parameters such as drawing temperature, tension control, and preform preparation have been optimized to ensure dimensional stability and structural integrity. These standardized manufacturing approaches enable reliable production of PCFs with consistent optical and mechanical properties across multiple production runs.

02 Characterization techniques for optical properties

Advanced techniques have been developed to characterize the optical properties of photonic crystal fibers. These include methods for measuring dispersion, birefringence, nonlinearity, and transmission spectra. Characterization approaches utilize specialized equipment such as optical spectrum analyzers, interferometric setups, and near-field scanning optical microscopy. These techniques allow for precise determination of modal properties, effective area, and wavelength-dependent behavior, which are essential for applications in telecommunications, sensing, and high-power laser systems.Expand Specific Solutions03 Structural analysis and quality control methods

Structural analysis and quality control methods for photonic crystal fibers involve techniques to verify the geometric integrity and consistency of the microstructure. These methods include electron microscopy, X-ray tomography, and optical coherence tomography to examine the arrangement and dimensions of air holes, defects, and structural uniformity along the fiber length. Quality control procedures ensure that manufactured fibers meet design specifications and maintain consistent performance characteristics, which is crucial for commercial applications and research reproducibility.Expand Specific Solutions04 Novel designs and fabrication techniques

Innovative designs and fabrication techniques have been developed to enhance the performance and functionality of photonic crystal fibers. These include methods for creating specialized structures such as hollow-core fibers, all-solid photonic bandgap fibers, and hybrid designs combining multiple materials. Advanced fabrication approaches involve stack-and-draw processes, sol-gel methods, and 3D printing technologies to create complex microstructures with precise control over geometric parameters. These innovations enable customized optical properties for specific applications in sensing, telecommunications, and laser systems.Expand Specific Solutions05 Application-specific characterization methods

Specialized characterization methods have been developed for application-specific evaluation of photonic crystal fibers. These include techniques for assessing polarization-maintaining properties, nonlinear coefficients, and sensing capabilities. Application-specific characterization involves testing under operational conditions such as high power, extreme temperatures, or chemical environments to evaluate performance in real-world scenarios. These methods help determine the suitability of specific fiber designs for applications in quantum optics, supercontinuum generation, environmental sensing, and biomedical diagnostics.Expand Specific Solutions

Leading PCF Manufacturers and Research Institutions

The photonic crystal fiber (PCF) standardization and characterization market is currently in a growth phase, with increasing adoption across telecommunications and sensing applications. The global market size is expanding steadily, driven by demand for advanced optical communication systems and specialized sensing solutions. From a technological maturity perspective, the field shows varied development levels, with established players like Corning, NKT Photonics, and Fujikura leading commercial standardization efforts. Research institutions including Max Planck Society and multiple universities are advancing characterization techniques, while telecommunications companies such as Samsung, NTT, and Fiberhome are integrating PCF technologies into their product ecosystems. The competitive landscape features collaboration between academic institutions and industry leaders to address manufacturing consistency challenges and establish universal characterization protocols.

Yangtze Optical Fibre & Cable Joint Stock Ltd. Co.

Technical Solution: Yangtze Optical has developed a comprehensive standardization framework for photonic crystal fibers focusing on mass-production compatibility. Their approach integrates modified chemical vapor deposition (MCVD) techniques with precision drilling methods to create highly uniform microstructured preforms. Their characterization protocol employs multi-dimensional analysis including high-resolution electron microscopy for structural verification (achieving <50nm resolution), spectral transmission measurements across 400-1700nm bands, and distributed sensing of structural uniformity. Yangtze has implemented an automated quality control system that monitors over 20 critical parameters during fabrication, including hole diameter consistency (maintained within ±1.5%), pitch uniformity (<±0.8μm deviation), and core concentricity (<0.2μm offset). Their standardization includes thermal cycling tests (-40°C to +85°C) and mechanical reliability assessments under various stress conditions. Additionally, they've established reference standards for PCF characterization that have been adopted by several regional standards organizations in Asia[4][6].

Strengths: Large-scale manufacturing capabilities with excellent cost efficiency; robust quality control systems ensuring consistent performance; strong position in establishing regional standards. Weaknesses: Less experience with exotic PCF designs compared to specialized manufacturers; characterization methods more focused on telecom applications than scientific research requirements.

NKT Photonics A/S

Technical Solution: NKT Photonics has developed a comprehensive standardization approach for photonic crystal fibers (PCFs) through their proprietary CRYSTAL FIBRE® technology. Their method involves precise control of the microstructure geometry during fabrication, ensuring consistent air-hole diameter and spacing across production batches. They've implemented automated characterization systems that measure critical parameters including mode field diameter, dispersion profiles, and birefringence with nanometer precision. NKT's standardization includes thermal and mechanical stability testing under various environmental conditions to ensure performance consistency. Their SuperK supercontinuum lasers incorporate these standardized PCFs to deliver predictable broadband light sources. Additionally, they've established industry reference standards for PCF characterization methods, including specialized interferometric techniques for measuring chromatic dispersion and polarization properties[1][3].

Strengths: Industry-leading expertise in PCF manufacturing with exceptional microstructure control; comprehensive characterization capabilities; established reference standards widely adopted in the industry. Weaknesses: Proprietary technologies may limit broader standardization efforts; higher production costs compared to conventional fibers; specialized equipment requirements for characterization.

Key Characterization Methods and Techniques

Photonic crystal fibers and methods for the production thereof

PatentWO2004038466A3

Innovation

- Integration of at least two metallic conductors near and along a central fiber in photonic crystal fibers, enabling new functionalities beyond traditional optical transmission.

- Novel geometric arrangement with at least six inner ducts bordering the central fiber core and outer ducts bordering the inner ducts, creating a more sophisticated photonic bandgap structure.

- Post-drawing metal filling technique where molten liquid metal is filled into hollow spaces of capillary elements after the drawing process is completed, allowing for hybrid optical-electrical functionality.

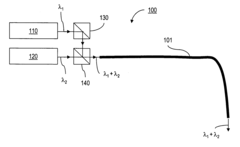

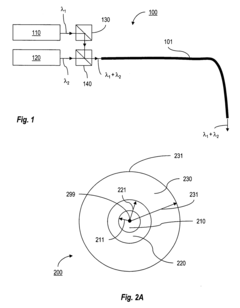

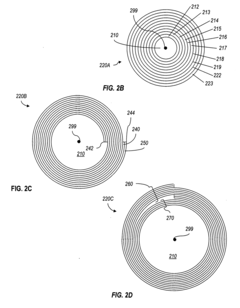

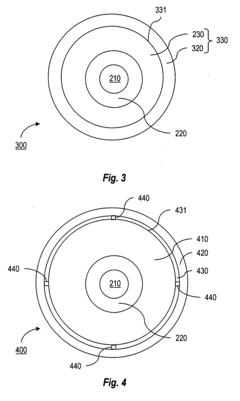

Photonic crystal fibers and systems using photonic crystal fibers

PatentInactiveUS20070147752A1

Innovation

- The development of photonic crystal fibers that incorporate a core and a confinement region with a cladding, allowing for the guidance of radiation at different wavelengths through both the core and cladding using photonic crystal structures and total internal reflection, enabling the simultaneous transmission of high-power infrared radiation and visible light.

International Standards and Compliance Requirements

The standardization landscape for Photonic Crystal Fibers (PCFs) remains fragmented compared to conventional optical fibers, presenting significant challenges for manufacturers, researchers, and end-users. Currently, the International Electrotechnical Commission (IEC) through its Technical Committee 86 on Fiber Optics has established several standards that partially address PCF technologies, including IEC 60793 series for optical fiber measurement methods and IEC 61280 series for fiber optic communication subsystem test procedures.

The International Telecommunication Union (ITU-T) has also developed recommendations under its G-series that indirectly impact PCF applications, though specific PCF standards remain limited. Notable is ITU-T G.651.1, which covers some aspects of multimode graded-index fiber characteristics that can be applied to certain PCF designs.

Regional standards bodies have made varying progress in PCF standardization. The European Telecommunications Standards Institute (ETSI) has incorporated some PCF considerations in their fiber optic standards, while the American National Standards Institute (ANSI) through the Telecommunications Industry Association (TIA) has developed the TIA-455 series that includes testing procedures applicable to specialty fibers including PCFs.

Compliance requirements for PCF technologies vary significantly by application domain. In telecommunications, PCFs must meet stringent performance metrics for attenuation, dispersion, and mechanical reliability. Medical applications of PCFs face additional regulatory hurdles, requiring compliance with ISO 13485 for medical devices and often FDA approval in the United States or CE marking in Europe, with particular emphasis on biocompatibility and sterilization compatibility.

Sensing applications utilizing PCFs must adhere to application-specific standards such as those from the International Society for Automation (ISA) or the American Petroleum Institute (API) for industrial sensing. Military and aerospace applications demand compliance with MIL-STD specifications and heightened reliability requirements.

A critical gap in the standardization ecosystem is the lack of unified characterization protocols specifically designed for PCF's unique microstructure. Parameters such as air-filling fraction, hole diameter, pitch, and structural irregularities require specialized measurement techniques not fully addressed in existing standards. This gap creates challenges in quality control, reproducibility, and cross-manufacturer compatibility.

Efforts to harmonize international standards for PCFs are underway through joint technical committees and industry consortia, with particular focus on standardizing characterization methods for microstructure geometry, modal properties, and nonlinear coefficients. These initiatives aim to establish a comprehensive framework that accommodates the diverse PCF designs while ensuring consistent performance evaluation methodologies across the global marketplace.

The International Telecommunication Union (ITU-T) has also developed recommendations under its G-series that indirectly impact PCF applications, though specific PCF standards remain limited. Notable is ITU-T G.651.1, which covers some aspects of multimode graded-index fiber characteristics that can be applied to certain PCF designs.

Regional standards bodies have made varying progress in PCF standardization. The European Telecommunications Standards Institute (ETSI) has incorporated some PCF considerations in their fiber optic standards, while the American National Standards Institute (ANSI) through the Telecommunications Industry Association (TIA) has developed the TIA-455 series that includes testing procedures applicable to specialty fibers including PCFs.

Compliance requirements for PCF technologies vary significantly by application domain. In telecommunications, PCFs must meet stringent performance metrics for attenuation, dispersion, and mechanical reliability. Medical applications of PCFs face additional regulatory hurdles, requiring compliance with ISO 13485 for medical devices and often FDA approval in the United States or CE marking in Europe, with particular emphasis on biocompatibility and sterilization compatibility.

Sensing applications utilizing PCFs must adhere to application-specific standards such as those from the International Society for Automation (ISA) or the American Petroleum Institute (API) for industrial sensing. Military and aerospace applications demand compliance with MIL-STD specifications and heightened reliability requirements.

A critical gap in the standardization ecosystem is the lack of unified characterization protocols specifically designed for PCF's unique microstructure. Parameters such as air-filling fraction, hole diameter, pitch, and structural irregularities require specialized measurement techniques not fully addressed in existing standards. This gap creates challenges in quality control, reproducibility, and cross-manufacturer compatibility.

Efforts to harmonize international standards for PCFs are underway through joint technical committees and industry consortia, with particular focus on standardizing characterization methods for microstructure geometry, modal properties, and nonlinear coefficients. These initiatives aim to establish a comprehensive framework that accommodates the diverse PCF designs while ensuring consistent performance evaluation methodologies across the global marketplace.

Material Science Advancements for PCF Development

The evolution of Photonic Crystal Fibers (PCFs) has been significantly influenced by advancements in material science. Traditional silica-based PCFs, while offering excellent optical properties, face limitations in terms of transmission range and nonlinear characteristics. Recent material science breakthroughs have expanded the possibilities for PCF development, enabling enhanced performance across various applications.

Silica remains the dominant material for PCF fabrication due to its low cost, high transparency, and established manufacturing processes. However, researchers have successfully incorporated various dopants such as germanium, fluorine, and rare-earth elements to modify the refractive index profile and introduce specific functionalities. These modifications have enabled the creation of PCFs with tailored dispersion characteristics, enhanced nonlinearity, and specialized sensing capabilities.

Beyond silica, chalcogenide glasses have emerged as promising materials for mid-infrared applications. These glasses, composed of elements like sulfur, selenium, and tellurium, offer extended transmission windows (2-10 μm) and significantly higher nonlinear coefficients compared to silica. This makes them particularly valuable for mid-IR sensing, supercontinuum generation, and nonlinear optical applications where silica becomes opaque.

Polymer-based PCFs represent another important material advancement, offering flexibility, biocompatibility, and ease of functionalization. PMMA (polymethyl methacrylate) and CYTOP (perfluorinated polymer) have been successfully employed in PCF structures, enabling applications in biosensing, terahertz wave guidance, and flexible photonic devices. The lower processing temperatures of polymers also facilitate the incorporation of thermally sensitive materials.

Hybrid material approaches have gained significant attention, combining the advantages of different materials in a single PCF structure. Examples include silica PCFs with liquid crystal infiltration for tunable devices, glass-polymer composite fibers for enhanced mechanical properties, and metal-dielectric structures for plasmonic applications. These hybrid approaches overcome the limitations of single-material PCFs and enable novel functionalities.

Nanomaterial integration represents the cutting edge of PCF material science. Carbon nanotubes, graphene, quantum dots, and metallic nanoparticles have been successfully incorporated into PCF structures, enabling enhanced nonlinearity, broadband absorption, and specialized sensing capabilities. These nanomaterial-enhanced PCFs demonstrate superior performance in applications such as ultrafast photonics, optical switching, and chemical detection.

Manufacturing techniques have evolved alongside material advancements, with methods such as stack-and-draw, extrusion, drilling, and 3D printing being adapted for various material systems. These fabrication innovations have enabled more complex PCF geometries and more precise control over structural parameters, further expanding the design space for specialized PCF applications.

Silica remains the dominant material for PCF fabrication due to its low cost, high transparency, and established manufacturing processes. However, researchers have successfully incorporated various dopants such as germanium, fluorine, and rare-earth elements to modify the refractive index profile and introduce specific functionalities. These modifications have enabled the creation of PCFs with tailored dispersion characteristics, enhanced nonlinearity, and specialized sensing capabilities.

Beyond silica, chalcogenide glasses have emerged as promising materials for mid-infrared applications. These glasses, composed of elements like sulfur, selenium, and tellurium, offer extended transmission windows (2-10 μm) and significantly higher nonlinear coefficients compared to silica. This makes them particularly valuable for mid-IR sensing, supercontinuum generation, and nonlinear optical applications where silica becomes opaque.

Polymer-based PCFs represent another important material advancement, offering flexibility, biocompatibility, and ease of functionalization. PMMA (polymethyl methacrylate) and CYTOP (perfluorinated polymer) have been successfully employed in PCF structures, enabling applications in biosensing, terahertz wave guidance, and flexible photonic devices. The lower processing temperatures of polymers also facilitate the incorporation of thermally sensitive materials.

Hybrid material approaches have gained significant attention, combining the advantages of different materials in a single PCF structure. Examples include silica PCFs with liquid crystal infiltration for tunable devices, glass-polymer composite fibers for enhanced mechanical properties, and metal-dielectric structures for plasmonic applications. These hybrid approaches overcome the limitations of single-material PCFs and enable novel functionalities.

Nanomaterial integration represents the cutting edge of PCF material science. Carbon nanotubes, graphene, quantum dots, and metallic nanoparticles have been successfully incorporated into PCF structures, enabling enhanced nonlinearity, broadband absorption, and specialized sensing capabilities. These nanomaterial-enhanced PCFs demonstrate superior performance in applications such as ultrafast photonics, optical switching, and chemical detection.

Manufacturing techniques have evolved alongside material advancements, with methods such as stack-and-draw, extrusion, drilling, and 3D printing being adapted for various material systems. These fabrication innovations have enabled more complex PCF geometries and more precise control over structural parameters, further expanding the design space for specialized PCF applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!