Photonic Crystal Fibers for Terahertz and Mid-Infrared Guidance

OCT 11, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PCF Technology Background and Objectives

Photonic Crystal Fibers (PCFs) represent a revolutionary advancement in optical waveguide technology, emerging in the late 1990s as a novel class of optical fibers characterized by their microstructured arrangement of air holes running along the entire fiber length. The development of PCFs marked a significant departure from conventional optical fibers, offering unprecedented control over light propagation characteristics through geometric manipulation rather than solely relying on material properties.

The evolution of PCF technology has progressed through several distinct phases. Initially, research focused on silica-based PCFs operating in the visible and near-infrared regions. As the technology matured, attention expanded to explore alternative materials and extended operational wavelength ranges, particularly into the terahertz (0.1-10 THz) and mid-infrared (3-50 μm) regions, which present substantial scientific and commercial opportunities.

These spectral regions are particularly valuable for applications in spectroscopy, sensing, medical diagnostics, and security screening due to their unique interaction with molecular structures. However, conventional waveguide solutions face significant limitations in these wavelength domains, primarily due to material absorption, dispersion challenges, and fabrication complexities at the required dimensional scales.

The fundamental objective of PCF technology for terahertz and mid-infrared guidance is to overcome these inherent limitations by developing waveguides capable of efficiently transmitting electromagnetic radiation in these challenging spectral regions. This involves addressing several critical technical goals: minimizing transmission losses, managing dispersion characteristics, enhancing modal properties, and ensuring practical fabrication feasibility.

Current research trajectories are exploring diverse approaches, including hollow-core PCFs that guide light primarily through air to minimize material absorption, suspended-core designs that reduce the light-material interaction, and novel material compositions specifically engineered for these wavelength regions. Each approach presents unique advantages and challenges in the context of terahertz and mid-infrared applications.

The technological evolution is increasingly driven by computational modeling and simulation tools that enable precise prediction of optical properties before physical fabrication. This has accelerated the design optimization process and facilitated the exploration of complex geometrical structures that would be difficult to conceptualize through intuitive approaches alone.

Looking forward, the field is moving toward integration of PCF technology with other photonic components to create complete systems for specific applications. The convergence of advanced materials science, precision fabrication techniques, and sophisticated computational design methods is expected to yield significant breakthroughs in PCF performance for terahertz and mid-infrared guidance in the coming years, potentially revolutionizing fields ranging from biomedical imaging to environmental monitoring.

The evolution of PCF technology has progressed through several distinct phases. Initially, research focused on silica-based PCFs operating in the visible and near-infrared regions. As the technology matured, attention expanded to explore alternative materials and extended operational wavelength ranges, particularly into the terahertz (0.1-10 THz) and mid-infrared (3-50 μm) regions, which present substantial scientific and commercial opportunities.

These spectral regions are particularly valuable for applications in spectroscopy, sensing, medical diagnostics, and security screening due to their unique interaction with molecular structures. However, conventional waveguide solutions face significant limitations in these wavelength domains, primarily due to material absorption, dispersion challenges, and fabrication complexities at the required dimensional scales.

The fundamental objective of PCF technology for terahertz and mid-infrared guidance is to overcome these inherent limitations by developing waveguides capable of efficiently transmitting electromagnetic radiation in these challenging spectral regions. This involves addressing several critical technical goals: minimizing transmission losses, managing dispersion characteristics, enhancing modal properties, and ensuring practical fabrication feasibility.

Current research trajectories are exploring diverse approaches, including hollow-core PCFs that guide light primarily through air to minimize material absorption, suspended-core designs that reduce the light-material interaction, and novel material compositions specifically engineered for these wavelength regions. Each approach presents unique advantages and challenges in the context of terahertz and mid-infrared applications.

The technological evolution is increasingly driven by computational modeling and simulation tools that enable precise prediction of optical properties before physical fabrication. This has accelerated the design optimization process and facilitated the exploration of complex geometrical structures that would be difficult to conceptualize through intuitive approaches alone.

Looking forward, the field is moving toward integration of PCF technology with other photonic components to create complete systems for specific applications. The convergence of advanced materials science, precision fabrication techniques, and sophisticated computational design methods is expected to yield significant breakthroughs in PCF performance for terahertz and mid-infrared guidance in the coming years, potentially revolutionizing fields ranging from biomedical imaging to environmental monitoring.

Market Applications for THz and Mid-IR Guidance

The terahertz (THz) and mid-infrared (Mid-IR) spectral regions have emerged as critical domains for numerous high-value applications across multiple industries. The THz market, currently valued at approximately $590 million, is projected to grow at a CAGR of 25.2% through 2028, driven primarily by security screening, non-destructive testing, and biomedical imaging applications.

In the security and defense sector, THz guidance systems enable detection of concealed weapons, explosives, and illicit substances through clothing and packaging materials. This capability has created a robust market for airport security systems, border control, and military applications. The non-invasive nature of THz radiation makes it particularly valuable for screening without privacy concerns associated with traditional X-ray systems.

The biomedical field represents another significant market opportunity, with THz imaging and spectroscopy offering unique capabilities for cancer detection, dental diagnostics, and pharmaceutical quality control. The ability to detect molecular signatures without tissue damage positions photonic crystal fiber (PCF) THz systems as valuable tools for early disease detection and treatment monitoring.

For industrial applications, THz guidance systems provide non-destructive testing capabilities for detecting structural defects in composites, ceramics, and semiconductor materials. The automotive and aerospace industries have adopted these technologies for quality control processes, creating a steady demand for advanced PCF-based inspection systems.

The Mid-IR guidance market overlaps with THz applications but extends into additional domains including environmental monitoring, chemical sensing, and industrial process control. The global Mid-IR sensor market exceeds $1.2 billion with growth rates of 8-10% annually, driven by increasing regulatory requirements for emissions monitoring and industrial safety.

Gas sensing represents a particularly valuable Mid-IR application, with PCF-based systems enabling detection of greenhouse gases, industrial pollutants, and hazardous substances at parts-per-billion sensitivity levels. This capability has created markets in environmental compliance, industrial safety, and homeland security.

Emerging applications include precision agriculture, where Mid-IR guidance systems monitor crop health and soil conditions, and smart building technology, where they detect air quality issues and potential hazards. The Internet of Things (IoT) integration has further expanded market opportunities by connecting PCF-based sensing systems to cloud analytics platforms.

Regional market distribution shows North America leading in security and defense applications, while Asia-Pacific demonstrates the fastest growth rate in industrial applications. European markets focus heavily on environmental monitoring and medical diagnostics, reflecting regional regulatory priorities and healthcare systems.

In the security and defense sector, THz guidance systems enable detection of concealed weapons, explosives, and illicit substances through clothing and packaging materials. This capability has created a robust market for airport security systems, border control, and military applications. The non-invasive nature of THz radiation makes it particularly valuable for screening without privacy concerns associated with traditional X-ray systems.

The biomedical field represents another significant market opportunity, with THz imaging and spectroscopy offering unique capabilities for cancer detection, dental diagnostics, and pharmaceutical quality control. The ability to detect molecular signatures without tissue damage positions photonic crystal fiber (PCF) THz systems as valuable tools for early disease detection and treatment monitoring.

For industrial applications, THz guidance systems provide non-destructive testing capabilities for detecting structural defects in composites, ceramics, and semiconductor materials. The automotive and aerospace industries have adopted these technologies for quality control processes, creating a steady demand for advanced PCF-based inspection systems.

The Mid-IR guidance market overlaps with THz applications but extends into additional domains including environmental monitoring, chemical sensing, and industrial process control. The global Mid-IR sensor market exceeds $1.2 billion with growth rates of 8-10% annually, driven by increasing regulatory requirements for emissions monitoring and industrial safety.

Gas sensing represents a particularly valuable Mid-IR application, with PCF-based systems enabling detection of greenhouse gases, industrial pollutants, and hazardous substances at parts-per-billion sensitivity levels. This capability has created markets in environmental compliance, industrial safety, and homeland security.

Emerging applications include precision agriculture, where Mid-IR guidance systems monitor crop health and soil conditions, and smart building technology, where they detect air quality issues and potential hazards. The Internet of Things (IoT) integration has further expanded market opportunities by connecting PCF-based sensing systems to cloud analytics platforms.

Regional market distribution shows North America leading in security and defense applications, while Asia-Pacific demonstrates the fastest growth rate in industrial applications. European markets focus heavily on environmental monitoring and medical diagnostics, reflecting regional regulatory priorities and healthcare systems.

Current PCF Development Status and Challenges

Photonic Crystal Fibers (PCFs) have emerged as a revolutionary technology in optical waveguiding, particularly for challenging spectral regions like terahertz (THz) and mid-infrared (MIR). The current development status of PCFs for these applications reveals significant progress alongside persistent challenges that require innovative solutions.

In the THz domain, PCF development has focused primarily on overcoming the inherent high material absorption of conventional materials. Hollow-core PCFs have demonstrated promising results by confining most of the light in air, thereby reducing material-induced losses. Recent advancements include the development of porous-core PCFs, where the introduction of air holes in the core region further reduces the material absorption. However, these designs still struggle with maintaining low loss over broad bandwidths exceeding 1 THz.

For MIR applications, silicon-based and chalcogenide glass PCFs represent the current state-of-the-art. These materials offer extended transmission windows compared to silica, with chalcogenide glasses enabling guidance up to 20 μm. Notable progress has been made in fabricating complex microstructures in these materials, though manufacturing consistency remains problematic, particularly for large-scale production.

The geographical distribution of PCF research shows concentration in specific regions. North America and Europe lead in fundamental research and theoretical modeling, while Asia, particularly Japan and China, demonstrates strength in fabrication techniques and material science innovations. This distribution creates both collaborative opportunities and competitive challenges in advancing the technology globally.

A significant technical hurdle in current PCF development is the trade-off between confinement loss and material absorption. As designers attempt to increase the air-filling fraction to reduce material interaction, structural integrity and mechanical stability often become compromised. This fundamental challenge has limited the practical deployment of PCFs in real-world THz and MIR systems.

Manufacturing precision represents another major constraint. The fabrication of PCFs with precisely controlled microstructures at the necessary scales (particularly for THz, where features are typically hundreds of micrometers) requires specialized equipment and expertise. Current production methods struggle with reproducibility and yield rates, driving up costs and limiting commercial viability.

Integration challenges further complicate PCF advancement. Coupling light efficiently into these specialized fibers, particularly from conventional sources, remains difficult. The mode field mismatch and alignment requirements create significant insertion losses that can negate the propagation advantages of the PCF design itself.

Environmental stability presents an ongoing concern, especially for outdoor applications. Temperature fluctuations can alter the microstructure dimensions and material properties, causing performance drift. Humidity sensitivity is particularly problematic for hygroscopic materials used in some PCF designs, necessitating protective packaging that adds complexity and cost.

In the THz domain, PCF development has focused primarily on overcoming the inherent high material absorption of conventional materials. Hollow-core PCFs have demonstrated promising results by confining most of the light in air, thereby reducing material-induced losses. Recent advancements include the development of porous-core PCFs, where the introduction of air holes in the core region further reduces the material absorption. However, these designs still struggle with maintaining low loss over broad bandwidths exceeding 1 THz.

For MIR applications, silicon-based and chalcogenide glass PCFs represent the current state-of-the-art. These materials offer extended transmission windows compared to silica, with chalcogenide glasses enabling guidance up to 20 μm. Notable progress has been made in fabricating complex microstructures in these materials, though manufacturing consistency remains problematic, particularly for large-scale production.

The geographical distribution of PCF research shows concentration in specific regions. North America and Europe lead in fundamental research and theoretical modeling, while Asia, particularly Japan and China, demonstrates strength in fabrication techniques and material science innovations. This distribution creates both collaborative opportunities and competitive challenges in advancing the technology globally.

A significant technical hurdle in current PCF development is the trade-off between confinement loss and material absorption. As designers attempt to increase the air-filling fraction to reduce material interaction, structural integrity and mechanical stability often become compromised. This fundamental challenge has limited the practical deployment of PCFs in real-world THz and MIR systems.

Manufacturing precision represents another major constraint. The fabrication of PCFs with precisely controlled microstructures at the necessary scales (particularly for THz, where features are typically hundreds of micrometers) requires specialized equipment and expertise. Current production methods struggle with reproducibility and yield rates, driving up costs and limiting commercial viability.

Integration challenges further complicate PCF advancement. Coupling light efficiently into these specialized fibers, particularly from conventional sources, remains difficult. The mode field mismatch and alignment requirements create significant insertion losses that can negate the propagation advantages of the PCF design itself.

Environmental stability presents an ongoing concern, especially for outdoor applications. Temperature fluctuations can alter the microstructure dimensions and material properties, causing performance drift. Humidity sensitivity is particularly problematic for hygroscopic materials used in some PCF designs, necessitating protective packaging that adds complexity and cost.

Current PCF Fabrication Techniques

01 Photonic bandgap guidance mechanisms

Photonic crystal fibers can guide light through photonic bandgap mechanisms, where light is confined in a hollow core or low-index region by the surrounding periodic structure. This guidance mechanism differs from conventional total internal reflection and allows for unique properties such as low nonlinearity, reduced dispersion, and the ability to guide light in air or other gases. The periodic arrangement of holes or rods creates a photonic bandgap that prevents certain wavelengths from propagating in the cladding, effectively trapping them in the core region.- Photonic bandgap guidance in hollow-core PCFs: Hollow-core photonic crystal fibers (PCFs) guide light through photonic bandgap effects rather than total internal reflection. These fibers have a central air core surrounded by a periodic arrangement of air holes in glass, creating a photonic bandgap that confines light to the hollow core. This guidance mechanism allows for low-loss transmission, reduced nonlinearity, and higher damage thresholds since light propagates mainly through air rather than solid material.

- Modified total internal reflection guidance in solid-core PCFs: Solid-core photonic crystal fibers guide light through a modified form of total internal reflection. These fibers feature a solid glass core surrounded by a microstructured cladding with air holes, creating an effective refractive index contrast. This design allows for unique dispersion properties, endlessly single-mode operation, and high nonlinearity that can be engineered by controlling the geometry of the air hole pattern in the cladding region.

- Specialty PCF designs for specific applications: Specialized photonic crystal fiber designs have been developed for specific applications such as high-power laser delivery, sensing, and nonlinear optics. These include large-mode-area fibers for high-power handling, polarization-maintaining PCFs, hybrid guidance PCFs combining bandgap and index-guiding mechanisms, and fibers with special dopants or materials incorporated into the structure to enhance particular properties or functionalities.

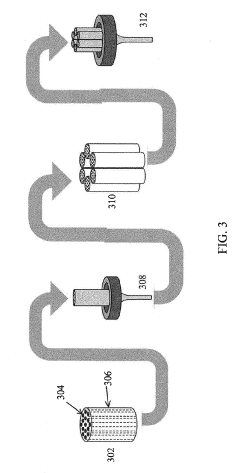

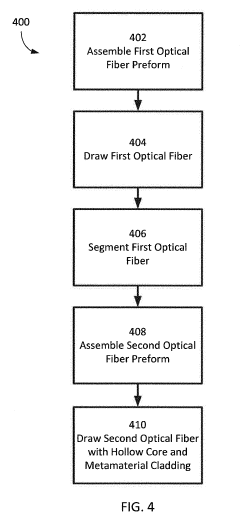

- Manufacturing techniques for PCFs: Various manufacturing techniques have been developed for producing photonic crystal fibers with precise microstructures. These include stack-and-draw methods where capillary tubes are arranged in a specific pattern and then drawn into fiber, extrusion processes for complex structures, drilling methods for creating hole patterns, and sol-gel techniques. Advanced fabrication approaches enable the creation of complex geometries with precisely controlled air hole sizes, shapes, and arrangements to achieve desired guidance properties.

- Novel materials and structures for enhanced PCF guidance: Research has explored novel materials and structural designs to enhance photonic crystal fiber guidance properties. These innovations include incorporating liquid crystals or other functional materials into the holes for tunable guidance, using non-silica glasses or polymers as base materials, developing hybrid structures combining different guidance mechanisms, and creating fibers with gradient or chirped structures to control dispersion and modal properties over broader wavelength ranges.

02 Modified total internal reflection guidance

Some photonic crystal fibers operate on a modified form of total internal reflection, where the effective index of the microstructured cladding is lower than that of the solid core. This guidance mechanism allows for single-mode operation over a wide wavelength range, large mode areas, and tailorable dispersion characteristics. The air holes in the cladding reduce its effective refractive index, creating the index contrast necessary for waveguiding while offering design flexibility not available in conventional fibers.Expand Specific Solutions03 Specialty applications and enhanced functionalities

Photonic crystal fibers enable specialized applications through their unique guidance properties, including high-power laser delivery, supercontinuum generation, gas sensing, and nonlinear optics. Their customizable structure allows for enhanced functionalities such as polarization maintenance, dispersion engineering, and modal control. By carefully designing the geometry, size, and arrangement of holes or inclusions in the fiber structure, specific optical properties can be achieved for targeted applications in telecommunications, sensing, and medical fields.Expand Specific Solutions04 Hybrid and composite guidance structures

Hybrid photonic crystal fibers combine multiple guidance mechanisms or incorporate additional materials to achieve enhanced performance. These structures may integrate conventional fiber designs with photonic crystal elements or combine solid and hollow cores in the same fiber. Composite structures can include doped regions, liquid crystals, or other functional materials to enable active devices, tunable properties, or multi-functional fibers that can simultaneously guide light and perform sensing or signal processing functions.Expand Specific Solutions05 Fabrication methods for guidance optimization

Advanced fabrication techniques are crucial for creating photonic crystal fibers with optimal guidance properties. Methods include stack-and-draw processes, drilling, extrusion, and sol-gel approaches to create precise microstructures. Post-processing techniques such as selective hole inflation, tapering, or filling with functional materials can further enhance or modify the guidance properties. These fabrication approaches enable precise control over structural parameters that determine guidance mechanisms, including hole size, pitch, symmetry, and core design.Expand Specific Solutions

Leading Research Groups and Manufacturers

The photonic crystal fiber (PCF) market for terahertz and mid-infrared guidance is currently in a growth phase, with increasing applications in sensing, medical diagnostics, and telecommunications. The global market size is expanding steadily, driven by demand for advanced optical transmission solutions in specialized wavelength regions. Technologically, the field shows moderate maturity with ongoing innovation. Key players include NKT Photonics, a leading supplier of photonic crystal fibers, OmniGuide with its CO2 laser delivery systems, and SCHOTT AG offering specialty glass solutions. Academic institutions like California Institute of Technology and The Hong Kong Polytechnic University contribute significant research advances. Industrial players such as Raytheon and Thales are exploring defense and security applications, while companies like Crystal Fibre (acquired by NKT) focus on specialized PCF manufacturing and development.

OmniGuide, Inc.

Technical Solution: OmniGuide has developed specialized photonic crystal fibers based on omnidirectional reflector technology for mid-infrared guidance, particularly for medical and industrial applications. Their proprietary OmniGuide fiber design incorporates multiple alternating layers of high and low refractive index materials (typically chalcogenide glass and polymer) wrapped in a cylindrical structure to create an omnidirectional mirror that guides light within a hollow core. This approach enables efficient transmission of CO2 laser radiation at 10.6 μm wavelength with losses below 1 dB/m. For terahertz applications, OmniGuide has pioneered composite fibers with subwavelength features that support surface plasmon modes, allowing for enhanced field confinement and reduced radiation losses. Their manufacturing process involves precision deposition of multilayer films followed by a thermal drawing process that maintains the integrity of the multilayer structure while reducing its dimensions to the microscale.

Strengths: Highly specialized in medical applications of mid-IR photonic fibers; established commercial products for surgical laser delivery; excellent beam quality maintenance. Weaknesses: Limited flexibility in fiber design parameters; higher production complexity and cost; narrower operational wavelength range compared to some competing technologies.

SCHOTT AG

Technical Solution: SCHOTT AG has developed advanced photonic crystal fibers for terahertz and mid-infrared guidance based on their expertise in specialty glass manufacturing. Their approach utilizes non-silica glass compositions, particularly chalcogenide and fluoride glasses, which offer superior transmission properties in the mid-infrared spectrum. SCHOTT's innovative "IRIS" fiber technology incorporates a microstructured cladding with precisely controlled air hole dimensions and spacing, engineered to create photonic bandgaps aligned with specific mid-infrared transmission windows (3-12 μm). For terahertz guidance, SCHOTT has pioneered hybrid polymer-glass PCF structures that combine the low material absorption of polymers in the THz range with the structural stability of glass support elements. Their manufacturing process employs precision extrusion techniques for preform creation, followed by carefully controlled drawing processes that maintain the complex microstructure geometry. SCHOTT has recently demonstrated fibers with attenuation below 0.5 dB/m across selected bands in the 2-10 μm range, enabling applications in spectroscopy, thermal imaging, and chemical sensing.

Strengths: Exceptional material expertise and glass chemistry knowledge; vertically integrated manufacturing capabilities; high production consistency and quality control. Weaknesses: Higher material costs for specialty glasses; limited flexibility in post-production fiber modification; challenges in scaling production for certain complex designs.

Key Innovations in THz and Mid-IR PCF Design

Low-latency, hollow-core optical fiber with total internal reflection mode confinement

PatentActiveUS20190235162A1

Innovation

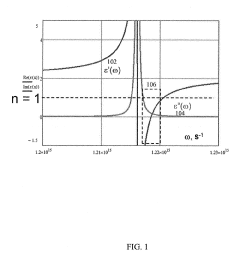

- An air core optical fiber with an engineered all-dielectric metamaterial cladding having a refractive index less than unity, utilizing a periodic array of subwavelength features to guide optical energy through total internal reflection, minimizing latency and maximizing propagation speed.

Standardization Efforts in PCF Technology

Standardization efforts in Photonic Crystal Fiber (PCF) technology have become increasingly important as these specialized optical fibers gain traction in terahertz and mid-infrared applications. The lack of unified standards has historically hindered widespread commercial adoption and interoperability between different manufacturers' products, creating significant market fragmentation.

Several international organizations have taken leadership roles in developing PCF standards. The International Electrotechnical Commission (IEC) through its Technical Committee 86 on Fiber Optics has established working groups specifically addressing PCF characterization methods. Similarly, the International Telecommunication Union (ITU-T) has incorporated PCF considerations into its G-series recommendations, particularly focusing on transmission parameters and test methods.

Industry consortia have emerged as crucial drivers of standardization. The Photonic Crystal Fiber Standardization Alliance (PCFSA), formed in 2018, brings together major manufacturers, research institutions, and end-users to develop consensus-based specifications. Their published guidelines on geometric tolerances for terahertz PCFs have been widely adopted, establishing critical parameters for core diameter variations, air-hole positioning precision, and structural uniformity along fiber length.

Testing and measurement protocols represent another vital area of standardization progress. The development of standardized characterization techniques for modal properties, dispersion characteristics, and transmission losses specific to terahertz and mid-infrared PCFs has enabled meaningful performance comparisons across different fiber designs. The IEEE Photonics Society has contributed significantly by publishing recommended practices for PCF measurement techniques.

Material standardization efforts have focused on establishing purity requirements and compositional specifications for materials used in PCF manufacturing. This includes standards for silica glass, polymers, and chalcogenide glasses commonly employed in mid-infrared PCFs, as well as specifications for protective coatings that maintain performance in harsh environments.

Terminology standardization has addressed the inconsistent nomenclature that previously complicated technical discussions. The SPIE Dictionary of Optics now includes standardized definitions for PCF-specific terms, creating a common language for researchers, manufacturers, and end-users across the photonics community.

Despite this progress, significant standardization gaps remain. Current efforts are increasingly focused on application-specific standards for medical, sensing, and telecommunications applications of terahertz and mid-infrared PCFs. Additionally, emerging work aims to establish interoperability standards for PCF-based systems and components, ensuring seamless integration across platforms and accelerating market adoption of this promising technology.

Several international organizations have taken leadership roles in developing PCF standards. The International Electrotechnical Commission (IEC) through its Technical Committee 86 on Fiber Optics has established working groups specifically addressing PCF characterization methods. Similarly, the International Telecommunication Union (ITU-T) has incorporated PCF considerations into its G-series recommendations, particularly focusing on transmission parameters and test methods.

Industry consortia have emerged as crucial drivers of standardization. The Photonic Crystal Fiber Standardization Alliance (PCFSA), formed in 2018, brings together major manufacturers, research institutions, and end-users to develop consensus-based specifications. Their published guidelines on geometric tolerances for terahertz PCFs have been widely adopted, establishing critical parameters for core diameter variations, air-hole positioning precision, and structural uniformity along fiber length.

Testing and measurement protocols represent another vital area of standardization progress. The development of standardized characterization techniques for modal properties, dispersion characteristics, and transmission losses specific to terahertz and mid-infrared PCFs has enabled meaningful performance comparisons across different fiber designs. The IEEE Photonics Society has contributed significantly by publishing recommended practices for PCF measurement techniques.

Material standardization efforts have focused on establishing purity requirements and compositional specifications for materials used in PCF manufacturing. This includes standards for silica glass, polymers, and chalcogenide glasses commonly employed in mid-infrared PCFs, as well as specifications for protective coatings that maintain performance in harsh environments.

Terminology standardization has addressed the inconsistent nomenclature that previously complicated technical discussions. The SPIE Dictionary of Optics now includes standardized definitions for PCF-specific terms, creating a common language for researchers, manufacturers, and end-users across the photonics community.

Despite this progress, significant standardization gaps remain. Current efforts are increasingly focused on application-specific standards for medical, sensing, and telecommunications applications of terahertz and mid-infrared PCFs. Additionally, emerging work aims to establish interoperability standards for PCF-based systems and components, ensuring seamless integration across platforms and accelerating market adoption of this promising technology.

Environmental Impact of PCF Manufacturing

The manufacturing of Photonic Crystal Fibers (PCFs) for terahertz and mid-infrared applications presents significant environmental considerations that warrant careful examination. Traditional optical fiber production typically involves high-temperature processes and potentially hazardous materials, and PCF manufacturing introduces additional complexities due to their intricate microstructured design.

The primary environmental concern in PCF manufacturing stems from the energy-intensive nature of the production process. The stack-and-draw technique, commonly employed for PCF fabrication, requires furnaces operating at temperatures exceeding 2000°C for extended periods. This substantial energy consumption contributes significantly to carbon emissions, particularly when powered by non-renewable energy sources.

Chemical etching methods used in some PCF manufacturing approaches involve hydrofluoric acid and other corrosive substances that pose serious environmental hazards if improperly handled or disposed of. These chemicals can contaminate water systems and harm aquatic ecosystems if released into the environment without adequate treatment. Additionally, the specialized glasses and dopants incorporated into PCFs for terahertz and mid-infrared applications often contain heavy metals and rare earth elements, the mining and processing of which are associated with substantial environmental degradation.

Material waste represents another environmental challenge in PCF production. The precision required for creating the complex microstructures in PCFs results in significant material rejection rates during manufacturing. While silica waste is relatively inert, specialized materials for mid-infrared PCFs may include compounds with greater environmental persistence and toxicity profiles.

Recent advancements in green manufacturing technologies are beginning to address these environmental concerns. Several research institutions and manufacturers have implemented closed-loop production systems that recycle process chemicals and capture waste materials. Energy efficiency improvements, including the development of lower-temperature drawing processes and more efficient furnace designs, have reduced the carbon footprint of PCF production by an estimated 15-20% in leading facilities.

Lifecycle assessment studies indicate that despite these environmental costs during manufacturing, PCFs for terahertz and mid-infrared applications may offer net environmental benefits through their operational use. Applications in environmental sensing, more efficient communications, and medical diagnostics potentially offset the initial environmental impact through improved resource efficiency and reduced energy consumption in deployed systems.

Industry standards for environmentally responsible PCF manufacturing are still evolving, with ISO 14001 certification becoming increasingly common among major producers. The development of biodegradable coating materials and less toxic alternatives to traditional dopants represents promising directions for further reducing the environmental footprint of specialized PCF production.

The primary environmental concern in PCF manufacturing stems from the energy-intensive nature of the production process. The stack-and-draw technique, commonly employed for PCF fabrication, requires furnaces operating at temperatures exceeding 2000°C for extended periods. This substantial energy consumption contributes significantly to carbon emissions, particularly when powered by non-renewable energy sources.

Chemical etching methods used in some PCF manufacturing approaches involve hydrofluoric acid and other corrosive substances that pose serious environmental hazards if improperly handled or disposed of. These chemicals can contaminate water systems and harm aquatic ecosystems if released into the environment without adequate treatment. Additionally, the specialized glasses and dopants incorporated into PCFs for terahertz and mid-infrared applications often contain heavy metals and rare earth elements, the mining and processing of which are associated with substantial environmental degradation.

Material waste represents another environmental challenge in PCF production. The precision required for creating the complex microstructures in PCFs results in significant material rejection rates during manufacturing. While silica waste is relatively inert, specialized materials for mid-infrared PCFs may include compounds with greater environmental persistence and toxicity profiles.

Recent advancements in green manufacturing technologies are beginning to address these environmental concerns. Several research institutions and manufacturers have implemented closed-loop production systems that recycle process chemicals and capture waste materials. Energy efficiency improvements, including the development of lower-temperature drawing processes and more efficient furnace designs, have reduced the carbon footprint of PCF production by an estimated 15-20% in leading facilities.

Lifecycle assessment studies indicate that despite these environmental costs during manufacturing, PCFs for terahertz and mid-infrared applications may offer net environmental benefits through their operational use. Applications in environmental sensing, more efficient communications, and medical diagnostics potentially offset the initial environmental impact through improved resource efficiency and reduced energy consumption in deployed systems.

Industry standards for environmentally responsible PCF manufacturing are still evolving, with ISO 14001 certification becoming increasingly common among major producers. The development of biodegradable coating materials and less toxic alternatives to traditional dopants represents promising directions for further reducing the environmental footprint of specialized PCF production.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!