How Cladding Structure Influences Guiding Efficiency in PCFs

OCT 11, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PCF Cladding Structure Evolution and Objectives

Photonic Crystal Fibers (PCFs) have revolutionized optical waveguide technology since their introduction in the late 1990s. The evolution of PCF cladding structures represents one of the most significant advancements in optical fiber technology over the past two decades. Initially, PCFs featured simple hexagonal arrangements of air holes in silica, providing basic light-guiding capabilities through either modified total internal reflection or photonic bandgap effects.

The developmental trajectory of PCF cladding structures has been marked by progressive refinement and diversification. Early designs focused primarily on achieving fundamental waveguiding properties, while subsequent generations have explored increasingly complex geometrical arrangements to enhance specific performance characteristics. This evolution has been driven by both theoretical advancements in understanding light-material interactions at the microscale and improvements in fabrication technologies that enable more precise control over structural parameters.

A significant milestone in PCF development was the transition from uniform air hole distributions to designs incorporating deliberate structural variations. These include gradient-index cladding structures, selectively filled air holes, and asymmetric arrangements that enable unprecedented control over modal properties, dispersion characteristics, and nonlinear effects. The introduction of hybrid materials beyond traditional silica has further expanded the design space for PCF cladding structures.

The primary objectives in PCF cladding structure development have centered on enhancing guiding efficiency while tailoring specific optical properties for targeted applications. Key performance metrics include minimizing confinement loss, controlling modal characteristics, managing dispersion profiles, and enhancing nonlinear interactions. Recent research has increasingly focused on specialized objectives such as achieving single-mode operation over broad wavelength ranges, enhancing birefringence for polarization-maintaining applications, and creating highly nonlinear fibers for supercontinuum generation.

Current research trends are exploring novel cladding geometries that transcend conventional periodic structures. These include fractal designs, quasi-periodic arrangements, and topologically protected structures that offer robust guiding properties. Additionally, active research is investigating dynamic cladding structures whose properties can be modified post-fabrication through various stimuli, including thermal, electrical, or optical inputs.

The ultimate goal of PCF cladding structure development is to achieve unprecedented control over light propagation characteristics while maintaining practical manufacturability. This includes pushing the boundaries of what is possible in terms of modal confinement, dispersion engineering, and nonlinear interactions, while simultaneously addressing challenges related to fabrication tolerances, structural stability, and integration with conventional optical systems.

The developmental trajectory of PCF cladding structures has been marked by progressive refinement and diversification. Early designs focused primarily on achieving fundamental waveguiding properties, while subsequent generations have explored increasingly complex geometrical arrangements to enhance specific performance characteristics. This evolution has been driven by both theoretical advancements in understanding light-material interactions at the microscale and improvements in fabrication technologies that enable more precise control over structural parameters.

A significant milestone in PCF development was the transition from uniform air hole distributions to designs incorporating deliberate structural variations. These include gradient-index cladding structures, selectively filled air holes, and asymmetric arrangements that enable unprecedented control over modal properties, dispersion characteristics, and nonlinear effects. The introduction of hybrid materials beyond traditional silica has further expanded the design space for PCF cladding structures.

The primary objectives in PCF cladding structure development have centered on enhancing guiding efficiency while tailoring specific optical properties for targeted applications. Key performance metrics include minimizing confinement loss, controlling modal characteristics, managing dispersion profiles, and enhancing nonlinear interactions. Recent research has increasingly focused on specialized objectives such as achieving single-mode operation over broad wavelength ranges, enhancing birefringence for polarization-maintaining applications, and creating highly nonlinear fibers for supercontinuum generation.

Current research trends are exploring novel cladding geometries that transcend conventional periodic structures. These include fractal designs, quasi-periodic arrangements, and topologically protected structures that offer robust guiding properties. Additionally, active research is investigating dynamic cladding structures whose properties can be modified post-fabrication through various stimuli, including thermal, electrical, or optical inputs.

The ultimate goal of PCF cladding structure development is to achieve unprecedented control over light propagation characteristics while maintaining practical manufacturability. This includes pushing the boundaries of what is possible in terms of modal confinement, dispersion engineering, and nonlinear interactions, while simultaneously addressing challenges related to fabrication tolerances, structural stability, and integration with conventional optical systems.

Market Applications and Demand for Efficient PCFs

The global market for Photonic Crystal Fibers (PCFs) with enhanced guiding efficiency continues to expand rapidly, driven by increasing demands across multiple sectors. Telecommunications remains the primary market driver, with the need for higher bandwidth and lower signal loss becoming critical as global data traffic surges. Efficient PCFs offer solutions for next-generation optical networks, particularly in long-haul transmission systems where minimizing signal degradation translates directly to cost savings and performance improvements.

Medical applications represent another significant market segment, with demand growing at approximately 12% annually. Surgical procedures utilizing laser delivery systems benefit substantially from PCFs with optimized cladding structures that maintain beam quality and power delivery efficiency. The precision medicine field particularly values PCFs that can transmit specific wavelengths with minimal distortion for diagnostic and therapeutic applications.

Industrial laser systems constitute a market valued at several billion dollars globally, where beam quality and power handling capabilities directly impact manufacturing precision and throughput. High-power laser cutting, welding, and material processing operations require PCFs with specialized cladding designs that can maintain single-mode operation while handling kilowatt-level powers without degradation.

Sensing applications have emerged as a rapidly growing market segment, particularly in harsh environment monitoring for oil and gas, aerospace, and structural health monitoring. The ability of efficiently-guided PCFs to maintain signal integrity under extreme conditions of temperature, pressure, or radiation exposure creates substantial value propositions for these industries.

Research institutions and defense applications represent smaller but premium market segments where performance requirements often supersede cost considerations. These sectors demand customized PCF solutions with precisely engineered cladding structures for specialized applications in quantum optics, high-energy physics, and advanced sensing systems.

Geographically, North America and Europe currently dominate market demand for high-efficiency PCFs, though Asia-Pacific regions show the fastest growth rates, particularly in telecommunications and industrial applications. This regional expansion is creating new market opportunities for PCF manufacturers who can deliver cost-effective solutions with optimized guiding properties.

The market increasingly values PCFs that offer multifunctional capabilities—fibers that can simultaneously guide light efficiently while performing additional functions such as sensing, filtering, or polarization maintenance. This trend toward integrated functionality is reshaping product development roadmaps across the industry and expanding potential application spaces.

Medical applications represent another significant market segment, with demand growing at approximately 12% annually. Surgical procedures utilizing laser delivery systems benefit substantially from PCFs with optimized cladding structures that maintain beam quality and power delivery efficiency. The precision medicine field particularly values PCFs that can transmit specific wavelengths with minimal distortion for diagnostic and therapeutic applications.

Industrial laser systems constitute a market valued at several billion dollars globally, where beam quality and power handling capabilities directly impact manufacturing precision and throughput. High-power laser cutting, welding, and material processing operations require PCFs with specialized cladding designs that can maintain single-mode operation while handling kilowatt-level powers without degradation.

Sensing applications have emerged as a rapidly growing market segment, particularly in harsh environment monitoring for oil and gas, aerospace, and structural health monitoring. The ability of efficiently-guided PCFs to maintain signal integrity under extreme conditions of temperature, pressure, or radiation exposure creates substantial value propositions for these industries.

Research institutions and defense applications represent smaller but premium market segments where performance requirements often supersede cost considerations. These sectors demand customized PCF solutions with precisely engineered cladding structures for specialized applications in quantum optics, high-energy physics, and advanced sensing systems.

Geographically, North America and Europe currently dominate market demand for high-efficiency PCFs, though Asia-Pacific regions show the fastest growth rates, particularly in telecommunications and industrial applications. This regional expansion is creating new market opportunities for PCF manufacturers who can deliver cost-effective solutions with optimized guiding properties.

The market increasingly values PCFs that offer multifunctional capabilities—fibers that can simultaneously guide light efficiently while performing additional functions such as sensing, filtering, or polarization maintenance. This trend toward integrated functionality is reshaping product development roadmaps across the industry and expanding potential application spaces.

Current PCF Cladding Technologies and Challenges

Photonic Crystal Fibers (PCFs) have revolutionized optical waveguide technology through their unique cladding structures. Current PCF cladding technologies primarily revolve around two fundamental designs: index-guiding PCFs and photonic bandgap fibers (PBGFs). Index-guiding PCFs utilize a solid core surrounded by a periodic array of air holes, creating an effective refractive index contrast that confines light through modified total internal reflection. Conversely, PBGFs employ a hollow core surrounded by a photonic crystal structure that prohibits certain wavelengths from propagating in the cladding, thereby confining them to the core.

The fabrication of these complex microstructures presents significant challenges. Stack-and-draw remains the predominant manufacturing technique, where capillary tubes are arranged in a specific pattern, fused, and drawn into fiber. However, this method struggles with maintaining precise geometry during the drawing process, particularly for structures requiring submicron features or non-circular hole shapes. Alternative approaches include extrusion, drilling, and sol-gel casting, each with their own limitations regarding scalability and precision.

Material selection introduces another layer of complexity. While silica remains the standard material due to its low optical loss and thermal stability, its processing temperature limits design flexibility. Polymer-based PCFs offer easier fabrication at lower temperatures but suffer from higher attenuation and environmental sensitivity. Soft glass and chalcogenide PCFs enable mid-IR applications but present handling and stability challenges.

A critical technical hurdle involves controlling structural deformation during fiber drawing. As preforms are heated and stretched, surface tension forces tend to collapse smaller air holes and distort the intended geometry. This effect becomes particularly problematic when attempting to create fibers with high air-filling fractions or non-circular air holes, which often offer superior guiding properties.

Recent innovations have focused on developing hybrid cladding structures that combine different guiding mechanisms. These include suspended-core fibers, antiresonant hollow-core fibers, and nested capillary designs. While promising, these approaches face integration challenges with conventional optical systems due to their specialized nature and complex coupling requirements.

The trade-off between mechanical robustness and optical performance represents another significant challenge. Increasing the air-filling fraction generally improves waveguiding properties but compromises structural integrity. This becomes particularly problematic in sensing applications where fibers may experience bending, tension, or environmental stressors that can alter the cladding geometry and subsequently degrade performance.

Scaling production while maintaining quality consistency remains an industry-wide challenge, with current manufacturing processes struggling to deliver high-volume production with the precision required for advanced applications in telecommunications, sensing, and high-power laser delivery.

The fabrication of these complex microstructures presents significant challenges. Stack-and-draw remains the predominant manufacturing technique, where capillary tubes are arranged in a specific pattern, fused, and drawn into fiber. However, this method struggles with maintaining precise geometry during the drawing process, particularly for structures requiring submicron features or non-circular hole shapes. Alternative approaches include extrusion, drilling, and sol-gel casting, each with their own limitations regarding scalability and precision.

Material selection introduces another layer of complexity. While silica remains the standard material due to its low optical loss and thermal stability, its processing temperature limits design flexibility. Polymer-based PCFs offer easier fabrication at lower temperatures but suffer from higher attenuation and environmental sensitivity. Soft glass and chalcogenide PCFs enable mid-IR applications but present handling and stability challenges.

A critical technical hurdle involves controlling structural deformation during fiber drawing. As preforms are heated and stretched, surface tension forces tend to collapse smaller air holes and distort the intended geometry. This effect becomes particularly problematic when attempting to create fibers with high air-filling fractions or non-circular air holes, which often offer superior guiding properties.

Recent innovations have focused on developing hybrid cladding structures that combine different guiding mechanisms. These include suspended-core fibers, antiresonant hollow-core fibers, and nested capillary designs. While promising, these approaches face integration challenges with conventional optical systems due to their specialized nature and complex coupling requirements.

The trade-off between mechanical robustness and optical performance represents another significant challenge. Increasing the air-filling fraction generally improves waveguiding properties but compromises structural integrity. This becomes particularly problematic in sensing applications where fibers may experience bending, tension, or environmental stressors that can alter the cladding geometry and subsequently degrade performance.

Scaling production while maintaining quality consistency remains an industry-wide challenge, with current manufacturing processes struggling to deliver high-volume production with the precision required for advanced applications in telecommunications, sensing, and high-power laser delivery.

Contemporary Cladding Structure Solutions for Enhanced Guiding

01 Structural design for improved guiding efficiency

The structural design of photonic crystal fibers significantly impacts their guiding efficiency. By optimizing the arrangement of air holes, core size, and cladding structure, light confinement can be enhanced. Specific designs include modified air-hole patterns, dual-core structures, and specialized cladding geometries that reduce light leakage and improve mode confinement, resulting in higher guiding efficiency across various wavelengths.- Microstructure design for improved guiding efficiency: The microstructure design of photonic crystal fibers significantly impacts their guiding efficiency. By carefully engineering the arrangement, size, and shape of air holes or other microstructures within the fiber, light confinement and transmission can be optimized. These designs can include specific patterns of air holes, varying hole diameters, or specialized core structures that enhance the waveguiding properties and reduce transmission losses, ultimately improving the overall guiding efficiency of PCFs.

- Novel materials and fabrication techniques: Advanced materials and innovative fabrication techniques play a crucial role in enhancing the guiding efficiency of photonic crystal fibers. By utilizing specialized materials with optimized optical properties or developing new manufacturing processes, the quality and performance of PCFs can be significantly improved. These approaches may include the use of novel glass compositions, polymer materials, or composite structures, as well as refined drawing techniques that ensure precise control over the fiber geometry and minimize structural defects.

- Core design and doping strategies: The design of the core region and strategic doping approaches are essential for optimizing the guiding efficiency of photonic crystal fibers. By carefully engineering the core structure or incorporating specific dopants, the light-guiding properties can be enhanced. Various core designs, such as hollow cores, solid cores with modified refractive indices, or specialized geometries, along with selective doping of the core or cladding regions with rare-earth elements or other materials, can significantly improve the waveguiding characteristics and reduce transmission losses.

- Specialized PCF structures for specific applications: Specialized photonic crystal fiber structures designed for specific applications can achieve optimized guiding efficiency for particular wavelengths or operating conditions. These tailored designs may include polarization-maintaining PCFs, large-mode-area fibers, dispersion-compensating structures, or fibers optimized for nonlinear applications. By customizing the fiber structure to meet the requirements of specific applications, the guiding efficiency can be maximized for the intended use case, whether it involves high-power transmission, sensing, or specialized optical signal processing.

- Hybrid and composite PCF structures: Hybrid and composite photonic crystal fiber structures combine different design approaches or materials to achieve enhanced guiding efficiency. These innovative structures may integrate conventional fiber designs with photonic crystal elements, incorporate multiple materials with complementary properties, or feature gradient structures that optimize light propagation. By leveraging the advantages of different fiber technologies or material combinations, these hybrid approaches can overcome limitations of traditional PCF designs and achieve superior guiding performance for various applications.

02 Air-hole configuration optimization

The configuration of air holes in photonic crystal fibers plays a crucial role in determining guiding efficiency. By carefully controlling parameters such as air-hole diameter, pitch, and distribution pattern, the fiber's waveguiding properties can be tailored for specific applications. Optimized air-hole configurations can create effective photonic bandgaps, reduce confinement losses, and enhance modal characteristics, leading to improved light transmission efficiency.Expand Specific Solutions03 Material composition for enhanced light transmission

The material composition of photonic crystal fibers significantly affects their guiding efficiency. By incorporating specialized materials with optimized refractive indices, optical losses can be minimized while enhancing light transmission. Advanced materials such as doped silica, specialized polymers, or hybrid compositions can improve the fiber's performance by reducing absorption and scattering losses, resulting in higher guiding efficiency across broader wavelength ranges.Expand Specific Solutions04 Novel fabrication techniques for high-efficiency PCFs

Innovative fabrication techniques have been developed to create photonic crystal fibers with enhanced guiding efficiency. These methods include advanced stack-and-draw processes, precision drilling, selective etching, and specialized fusion techniques. By improving manufacturing precision and reducing structural imperfections, these fabrication approaches minimize light scattering and confinement losses, resulting in PCFs with superior guiding characteristics and higher transmission efficiency.Expand Specific Solutions05 Specialized PCF designs for application-specific efficiency

Specialized photonic crystal fiber designs have been developed to optimize guiding efficiency for specific applications. These include hollow-core fibers for gas-based applications, highly nonlinear fibers for signal processing, polarization-maintaining designs for sensing, and dispersion-engineered fibers for telecommunications. By tailoring the fiber structure to match specific operational requirements, these designs achieve optimal guiding efficiency for their intended applications while minimizing unwanted optical effects.Expand Specific Solutions

Leading Manufacturers and Research Institutions in PCF Technology

The photonic crystal fiber (PCF) cladding structure efficiency market is currently in a growth phase, with increasing adoption across telecommunications, sensing, and medical applications. The global market size for PCF technology is expanding steadily, driven by demand for higher bandwidth and specialized optical applications. From a technical maturity perspective, the field shows varied development levels among key players. Research institutions like Zhejiang University of Technology, Beihang University, and XLIM (partnered with GLOphotonics) are advancing fundamental understanding, while established companies including NKT Photonics, OFS Fitel, and Corning lead commercial implementation with mature product lines. Emerging players such as IMRA America and Lumentum are developing application-specific innovations, particularly in laser systems. The competitive landscape reflects a balance between academic research excellence and industrial commercialization efforts focused on improving guiding efficiency through novel cladding designs.

NKT Photonics A/S

Technical Solution: NKT Photonics has pioneered innovative cladding structures in PCFs through their patented "Crystal Fibre" technology. Their approach involves precisely arranged air holes in silica glass that form the photonic crystal cladding, creating a microstructured optical fiber with exceptional guiding properties. NKT's advanced stack-and-draw fabrication process enables precise control of hole size, spacing, and pattern geometry, allowing them to engineer the effective refractive index contrast between core and cladding with unprecedented precision. Their latest designs incorporate complex hexagonal lattice structures with varying air-filling fractions across different cladding rings, enabling tailored dispersion characteristics and enhanced modal confinement. NKT has demonstrated that strategic manipulation of the air hole diameter-to-pitch ratio (d/Λ) significantly impacts guiding efficiency, with their proprietary designs achieving transmission losses below 0.5 dB/km in certain wavelength bands.

Strengths: Industry-leading fabrication precision allowing complex microstructure designs; extensive patent portfolio covering various cladding geometries; commercial-scale production capabilities. Weaknesses: Higher production costs compared to conventional fibers; some designs require extremely precise manufacturing tolerances that limit mass production scalability.

Centre National de la Recherche Scientifique

Technical Solution: CNRS has conducted groundbreaking research on how cladding structures influence guiding efficiency in PCFs through their specialized photonics laboratories. Their approach focuses on fundamental physics of light propagation in complex microstructured media, developing theoretical models that precisely predict guiding behavior based on cladding geometry. CNRS researchers have pioneered "topological cladding designs" that leverage concepts from topological photonics to create robust guiding mechanisms resistant to structural imperfections. Their work demonstrates that carefully engineered defects in otherwise periodic cladding structures can create localized states that enhance guiding efficiency in specific spectral regions. CNRS has developed comprehensive numerical simulation frameworks that account for material dispersion, structural deformation, and fabrication tolerances to optimize cladding designs before physical implementation. Their latest research explores hybrid cladding structures combining conventional air holes with resonant inclusions to create novel guiding mechanisms beyond traditional index-guiding or bandgap effects, potentially opening new avenues for ultra-efficient light transmission in specialized wavelength bands.

Strengths: World-class theoretical foundation; cutting-edge research on novel guiding mechanisms; strong collaboration network with fabrication partners. Weaknesses: Less direct commercial application focus; designs sometimes prioritize scientific novelty over manufacturing practicality; dependent on industrial partners for large-scale production.

Key Patents and Research on PCF Cladding-Guidance Relationships

Improvements in and relating to photonic-band-gap guidance in photonic-crystal fibres

PatentInactiveAU2003271846A1

Innovation

- The optical fiber design features a higher filling fraction of elongate cylindrical elements in the cladding region than what maximizes the frequency width of the bandgap, allowing for a larger range of frequencies to be guided by optimizing the overlap of the bandgap with the light line, thereby tilting the bandgap areas in the ω-k plane to encompass more frequencies.

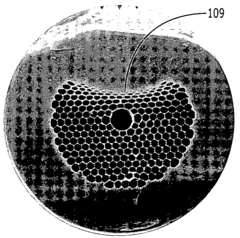

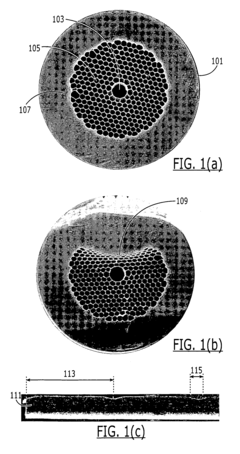

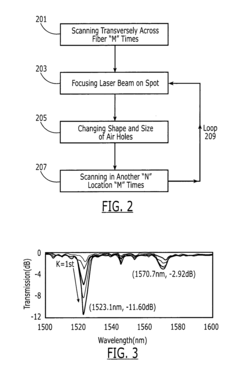

Long period gratings on hollow-core fibers

PatentInactiveUS20090194891A1

Innovation

- The formation of LPGs in hollow-core photonic bandgap fibers is achieved by periodically varying the shape, size, and distribution of air-holes along the fiber's longitudinal direction, using a pulsed CO2 laser to create notches in the cladding region without deforming the hollow core, facilitating resonant coupling between core and cladding modes.

Material Science Advancements for PCF Cladding

Material science has undergone significant evolution in the development of photonic crystal fiber (PCF) cladding structures, directly impacting guiding efficiency. Traditional silica-based materials have been the foundation of PCF fabrication, but recent advancements have introduced novel compositions that enhance performance characteristics. Researchers have developed specialized doped silica variants incorporating germanium, fluorine, and rare-earth elements that modify the refractive index profile while maintaining mechanical stability.

Polymer-based cladding materials represent another frontier, offering flexibility in manufacturing and unique optical properties. These materials allow for greater design freedom in creating complex microstructures with precisely controlled air-hole patterns. Notably, PMMA (polymethyl methacrylate) and CYTOP (perfluorinated polymer) have demonstrated promising results in experimental PCFs, particularly for applications requiring high flexibility or extreme environmental resistance.

Composite materials combining ceramics and glasses have emerged as solutions for high-power applications where thermal management is critical. These advanced composites maintain structural integrity under intense optical loads while providing the necessary refractive index contrast for efficient light guiding. Aluminum nitride and specialized ceramic-glass hybrids have shown particular promise in managing thermal expansion issues that traditionally limit power handling capabilities.

Nanomaterial integration represents the cutting edge of PCF cladding development. The incorporation of nanoparticles, quantum dots, and two-dimensional materials like graphene into the cladding structure has enabled unprecedented control over optical properties. These nanomaterials create localized modifications to the refractive index, allowing for highly customized light-guiding characteristics and enhanced nonlinear effects that can be leveraged for specialized applications.

Manufacturing techniques have evolved in parallel with material advancements. Techniques such as sol-gel processing, chemical vapor deposition, and advanced extrusion methods have enabled the creation of increasingly complex cladding structures with nanometer-scale precision. These fabrication approaches allow for the realization of theoretical designs that were previously impossible to manufacture, including gradient-index cladding structures and photonic bandgap materials with complete three-dimensional periodicity.

The relationship between material properties and guiding mechanisms has been extensively studied, revealing that material selection directly influences modal characteristics, dispersion profiles, and confinement losses. Researchers have established quantitative models linking material composition to guiding efficiency, providing valuable design tools for application-specific PCF development. These models account for wavelength-dependent material responses and structural parameters to predict performance across operating conditions.

Polymer-based cladding materials represent another frontier, offering flexibility in manufacturing and unique optical properties. These materials allow for greater design freedom in creating complex microstructures with precisely controlled air-hole patterns. Notably, PMMA (polymethyl methacrylate) and CYTOP (perfluorinated polymer) have demonstrated promising results in experimental PCFs, particularly for applications requiring high flexibility or extreme environmental resistance.

Composite materials combining ceramics and glasses have emerged as solutions for high-power applications where thermal management is critical. These advanced composites maintain structural integrity under intense optical loads while providing the necessary refractive index contrast for efficient light guiding. Aluminum nitride and specialized ceramic-glass hybrids have shown particular promise in managing thermal expansion issues that traditionally limit power handling capabilities.

Nanomaterial integration represents the cutting edge of PCF cladding development. The incorporation of nanoparticles, quantum dots, and two-dimensional materials like graphene into the cladding structure has enabled unprecedented control over optical properties. These nanomaterials create localized modifications to the refractive index, allowing for highly customized light-guiding characteristics and enhanced nonlinear effects that can be leveraged for specialized applications.

Manufacturing techniques have evolved in parallel with material advancements. Techniques such as sol-gel processing, chemical vapor deposition, and advanced extrusion methods have enabled the creation of increasingly complex cladding structures with nanometer-scale precision. These fabrication approaches allow for the realization of theoretical designs that were previously impossible to manufacture, including gradient-index cladding structures and photonic bandgap materials with complete three-dimensional periodicity.

The relationship between material properties and guiding mechanisms has been extensively studied, revealing that material selection directly influences modal characteristics, dispersion profiles, and confinement losses. Researchers have established quantitative models linking material composition to guiding efficiency, providing valuable design tools for application-specific PCF development. These models account for wavelength-dependent material responses and structural parameters to predict performance across operating conditions.

Simulation and Modeling Techniques for PCF Performance Prediction

Accurate prediction of photonic crystal fiber (PCF) performance requires sophisticated simulation and modeling techniques that can capture the complex interactions between light and the microstructured cladding. Finite Element Method (FEM) and Finite-Difference Time-Domain (FDTD) approaches have emerged as the predominant computational tools for PCF analysis, with each offering distinct advantages for different aspects of performance prediction.

FEM excels in modal analysis by discretizing the cross-sectional geometry into triangular or tetrahedral elements, allowing for precise representation of irregular cladding structures. This method is particularly valuable for calculating effective mode indices, confinement losses, and dispersion characteristics across various wavelengths. Commercial software packages such as COMSOL Multiphysics and ANSYS have implemented specialized modules for PCF simulation that incorporate material dispersion models and perfectly matched layer (PML) boundary conditions.

FDTD simulations complement FEM by providing time-domain analysis capabilities, enabling researchers to visualize light propagation through PCFs and predict transmission characteristics. This approach is especially useful for studying nonlinear effects and coupling behaviors in complex cladding arrangements. The computational demands of FDTD simulations have been addressed through parallel processing implementations and GPU acceleration, making previously intractable problems solvable within reasonable timeframes.

Beam propagation methods (BPM) offer an alternative approach for modeling light propagation in PCFs, though with limitations in handling strong index contrasts typical in air-hole structures. Modified versions incorporating wide-angle formulations have improved accuracy for PCF applications, particularly for analyzing coupling efficiency and bend losses.

Recent advances in machine learning techniques have begun to transform PCF performance prediction. Neural networks trained on extensive simulation datasets can now predict guiding properties of novel cladding configurations with remarkable accuracy while reducing computational time by orders of magnitude. These AI-assisted design tools are particularly valuable for inverse design problems, where optimal cladding structures are derived from desired performance specifications.

Multiphysics modeling approaches have gained importance as researchers seek to understand the interplay between optical, thermal, and mechanical properties in PCFs. These integrated simulations are crucial for applications in high-power fiber lasers and sensors, where thermal gradients and mechanical stresses can significantly alter guiding characteristics through thermo-optic and stress-optic effects.

Validation methodologies comparing simulation results with experimental measurements remain essential for refining modeling techniques. Scanning near-field optical microscopy (SNOM) and interferometric techniques provide experimental benchmarks against which simulation accuracy can be assessed, driving continuous improvement in computational methods.

FEM excels in modal analysis by discretizing the cross-sectional geometry into triangular or tetrahedral elements, allowing for precise representation of irregular cladding structures. This method is particularly valuable for calculating effective mode indices, confinement losses, and dispersion characteristics across various wavelengths. Commercial software packages such as COMSOL Multiphysics and ANSYS have implemented specialized modules for PCF simulation that incorporate material dispersion models and perfectly matched layer (PML) boundary conditions.

FDTD simulations complement FEM by providing time-domain analysis capabilities, enabling researchers to visualize light propagation through PCFs and predict transmission characteristics. This approach is especially useful for studying nonlinear effects and coupling behaviors in complex cladding arrangements. The computational demands of FDTD simulations have been addressed through parallel processing implementations and GPU acceleration, making previously intractable problems solvable within reasonable timeframes.

Beam propagation methods (BPM) offer an alternative approach for modeling light propagation in PCFs, though with limitations in handling strong index contrasts typical in air-hole structures. Modified versions incorporating wide-angle formulations have improved accuracy for PCF applications, particularly for analyzing coupling efficiency and bend losses.

Recent advances in machine learning techniques have begun to transform PCF performance prediction. Neural networks trained on extensive simulation datasets can now predict guiding properties of novel cladding configurations with remarkable accuracy while reducing computational time by orders of magnitude. These AI-assisted design tools are particularly valuable for inverse design problems, where optimal cladding structures are derived from desired performance specifications.

Multiphysics modeling approaches have gained importance as researchers seek to understand the interplay between optical, thermal, and mechanical properties in PCFs. These integrated simulations are crucial for applications in high-power fiber lasers and sensors, where thermal gradients and mechanical stresses can significantly alter guiding characteristics through thermo-optic and stress-optic effects.

Validation methodologies comparing simulation results with experimental measurements remain essential for refining modeling techniques. Scanning near-field optical microscopy (SNOM) and interferometric techniques provide experimental benchmarks against which simulation accuracy can be assessed, driving continuous improvement in computational methods.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!