Optomechanical Coupling Effects in Photonic Crystal Fiber Systems

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Optomechanical Coupling Background and Objectives

Optomechanical coupling in photonic crystal fiber (PCF) systems represents a fascinating intersection of optical physics and mechanical engineering that has evolved significantly over the past two decades. This phenomenon describes the interaction between optical fields and mechanical motion within specialized optical fiber structures, where light can exert forces on mechanical resonators while mechanical vibrations simultaneously modulate optical properties.

The historical development of this field traces back to the late 1990s when photonic crystal fibers were first fabricated, offering unprecedented control over light propagation through periodic microstructures. Early research focused primarily on the optical properties of these fibers, with little attention to mechanical aspects. By the mid-2000s, researchers began observing unexpected behaviors in high-power applications, leading to the recognition of optomechanical effects within these specialized waveguides.

The technological evolution accelerated around 2010 when theoretical frameworks for describing optomechanical coupling in PCF systems were formalized, incorporating concepts from cavity optomechanics into fiber optics. This convergence of disciplines opened new avenues for exploiting mechanical resonances in optical systems that were previously unexplored in conventional fiber technologies.

Current trends indicate growing interest in leveraging these coupling effects for sensing applications, quantum information processing, and precision measurement systems. The ability to enhance optomechanical interactions through careful design of the photonic crystal structure represents a key advantage over conventional optical fibers, potentially enabling new classes of devices with unprecedented sensitivity and functionality.

The primary objectives of this technical investigation are threefold. First, we aim to comprehensively map the current state of optomechanical coupling technologies in PCF systems, identifying key physical mechanisms and implementation approaches. Second, we seek to evaluate the performance limitations of existing systems, particularly regarding coupling strength, mechanical quality factors, and optical losses that constrain practical applications.

Finally, we intend to establish clear technical pathways for overcoming current limitations, with specific focus on enhancing optomechanical coupling coefficients through novel PCF designs, improving mechanical isolation techniques to increase quality factors, and developing integrated solutions that can transition from laboratory demonstrations to commercially viable products.

This investigation will provide crucial insights for strategic R&D planning, identifying high-potential research directions and technological approaches that could yield significant competitive advantages in emerging applications ranging from quantum-enhanced sensing to next-generation optical communication systems.

The historical development of this field traces back to the late 1990s when photonic crystal fibers were first fabricated, offering unprecedented control over light propagation through periodic microstructures. Early research focused primarily on the optical properties of these fibers, with little attention to mechanical aspects. By the mid-2000s, researchers began observing unexpected behaviors in high-power applications, leading to the recognition of optomechanical effects within these specialized waveguides.

The technological evolution accelerated around 2010 when theoretical frameworks for describing optomechanical coupling in PCF systems were formalized, incorporating concepts from cavity optomechanics into fiber optics. This convergence of disciplines opened new avenues for exploiting mechanical resonances in optical systems that were previously unexplored in conventional fiber technologies.

Current trends indicate growing interest in leveraging these coupling effects for sensing applications, quantum information processing, and precision measurement systems. The ability to enhance optomechanical interactions through careful design of the photonic crystal structure represents a key advantage over conventional optical fibers, potentially enabling new classes of devices with unprecedented sensitivity and functionality.

The primary objectives of this technical investigation are threefold. First, we aim to comprehensively map the current state of optomechanical coupling technologies in PCF systems, identifying key physical mechanisms and implementation approaches. Second, we seek to evaluate the performance limitations of existing systems, particularly regarding coupling strength, mechanical quality factors, and optical losses that constrain practical applications.

Finally, we intend to establish clear technical pathways for overcoming current limitations, with specific focus on enhancing optomechanical coupling coefficients through novel PCF designs, improving mechanical isolation techniques to increase quality factors, and developing integrated solutions that can transition from laboratory demonstrations to commercially viable products.

This investigation will provide crucial insights for strategic R&D planning, identifying high-potential research directions and technological approaches that could yield significant competitive advantages in emerging applications ranging from quantum-enhanced sensing to next-generation optical communication systems.

Market Applications of PCF Optomechanical Systems

The market for optomechanical systems based on photonic crystal fibers (PCFs) is experiencing significant growth across multiple sectors. The unique ability of these systems to leverage light-matter interactions at the micro and nano scale has created diverse commercial opportunities that extend beyond traditional telecommunications applications.

In the sensing and measurement industry, PCF optomechanical systems are revolutionizing precision instrumentation. These systems enable ultra-sensitive detection of physical parameters such as strain, temperature, pressure, and acoustic waves. The market for distributed fiber sensing systems utilizing optomechanical effects in PCFs has gained particular traction in structural health monitoring of critical infrastructure including bridges, dams, and high-rise buildings.

The biomedical sector represents another rapidly expanding market for PCF optomechanical technologies. These systems are being integrated into next-generation medical devices for applications ranging from minimally invasive surgery to advanced diagnostic imaging. The enhanced sensitivity of optomechanical PCF sensors allows for detection of biomolecules at unprecedented concentrations, creating new possibilities for early disease detection and personalized medicine approaches.

Aerospace and defense applications constitute a premium market segment where PCF optomechanical systems command high value. These technologies are deployed in gyroscopes, accelerometers, and other navigation systems where their immunity to electromagnetic interference and ability to operate in harsh environments provide significant advantages over conventional electronic solutions.

The telecommunications industry continues to be a major market driver, with PCF optomechanical coupling effects enabling novel signal processing capabilities, optical switching mechanisms, and bandwidth enhancement technologies. Network operators are increasingly adopting these solutions to address growing data transmission demands while minimizing energy consumption.

Emerging applications in quantum information processing represent perhaps the most promising future market. PCF optomechanical systems provide an ideal platform for quantum state manipulation, entanglement generation, and quantum memory development. As quantum technologies move from laboratory demonstrations toward commercial viability, the market for specialized PCF components is expected to expand dramatically.

Industrial process monitoring represents another significant market opportunity, with PCF optomechanical sensors being deployed in manufacturing environments where conventional electronic sensors cannot operate due to extreme conditions or electromagnetic interference. These systems enable real-time quality control and process optimization in industries ranging from petrochemical processing to semiconductor fabrication.

In the sensing and measurement industry, PCF optomechanical systems are revolutionizing precision instrumentation. These systems enable ultra-sensitive detection of physical parameters such as strain, temperature, pressure, and acoustic waves. The market for distributed fiber sensing systems utilizing optomechanical effects in PCFs has gained particular traction in structural health monitoring of critical infrastructure including bridges, dams, and high-rise buildings.

The biomedical sector represents another rapidly expanding market for PCF optomechanical technologies. These systems are being integrated into next-generation medical devices for applications ranging from minimally invasive surgery to advanced diagnostic imaging. The enhanced sensitivity of optomechanical PCF sensors allows for detection of biomolecules at unprecedented concentrations, creating new possibilities for early disease detection and personalized medicine approaches.

Aerospace and defense applications constitute a premium market segment where PCF optomechanical systems command high value. These technologies are deployed in gyroscopes, accelerometers, and other navigation systems where their immunity to electromagnetic interference and ability to operate in harsh environments provide significant advantages over conventional electronic solutions.

The telecommunications industry continues to be a major market driver, with PCF optomechanical coupling effects enabling novel signal processing capabilities, optical switching mechanisms, and bandwidth enhancement technologies. Network operators are increasingly adopting these solutions to address growing data transmission demands while minimizing energy consumption.

Emerging applications in quantum information processing represent perhaps the most promising future market. PCF optomechanical systems provide an ideal platform for quantum state manipulation, entanglement generation, and quantum memory development. As quantum technologies move from laboratory demonstrations toward commercial viability, the market for specialized PCF components is expected to expand dramatically.

Industrial process monitoring represents another significant market opportunity, with PCF optomechanical sensors being deployed in manufacturing environments where conventional electronic sensors cannot operate due to extreme conditions or electromagnetic interference. These systems enable real-time quality control and process optimization in industries ranging from petrochemical processing to semiconductor fabrication.

Current Challenges in Photonic Crystal Fiber Coupling

Photonic Crystal Fiber (PCF) systems face several significant challenges in achieving optimal optomechanical coupling. The fundamental issue stems from the complex microstructure of PCFs, which typically consist of a solid core surrounded by a periodic arrangement of air holes. This unique geometry creates difficulties in achieving efficient light coupling between conventional optical fibers and PCFs due to mode field diameter mismatches and numerical aperture differences.

One major challenge is the alignment precision required for effective coupling. The core diameter of PCFs often ranges from 2-10 μm, necessitating sub-micron alignment accuracy. Environmental factors such as temperature fluctuations and mechanical vibrations can disrupt this precision, leading to coupling instability in practical applications. This becomes particularly problematic in field deployments where controlled laboratory conditions cannot be maintained.

Modal mismatch represents another significant obstacle. The unique mode profiles in PCFs differ substantially from conventional fibers, resulting in coupling losses that can exceed 3 dB even with perfect alignment. This issue is exacerbated when coupling broadband light sources, as the coupling efficiency becomes wavelength-dependent due to the inherent dispersive properties of PCFs.

The mechanical fragility of PCF structures presents additional challenges. The air-hole structure makes these fibers more susceptible to deformation under mechanical stress compared to solid fibers. When coupling requires physical contact or pressure, structural integrity can be compromised, altering the optical properties and coupling characteristics of the fiber.

Thermal management issues also plague PCF coupling systems. The air-silica structure of PCFs creates different thermal expansion characteristics compared to solid fibers, leading to alignment drift during operation. This thermal sensitivity becomes particularly problematic in high-power applications where localized heating at the coupling interface can induce temporary or permanent changes to the PCF structure.

Manufacturing variations further complicate coupling strategies. Despite advances in fabrication techniques, PCFs still exhibit greater structural variations than conventional fibers. These inconsistencies make it difficult to develop standardized coupling solutions, often requiring custom approaches for each fiber batch or even individual fibers.

Recent research has identified back-reflection as another significant challenge. The interface between different fiber types creates Fresnel reflections that can destabilize laser sources and introduce noise in sensing applications. While anti-reflection coatings offer partial solutions, they add complexity and cost to the coupling system while potentially altering the mechanical properties at the fiber interface.

One major challenge is the alignment precision required for effective coupling. The core diameter of PCFs often ranges from 2-10 μm, necessitating sub-micron alignment accuracy. Environmental factors such as temperature fluctuations and mechanical vibrations can disrupt this precision, leading to coupling instability in practical applications. This becomes particularly problematic in field deployments where controlled laboratory conditions cannot be maintained.

Modal mismatch represents another significant obstacle. The unique mode profiles in PCFs differ substantially from conventional fibers, resulting in coupling losses that can exceed 3 dB even with perfect alignment. This issue is exacerbated when coupling broadband light sources, as the coupling efficiency becomes wavelength-dependent due to the inherent dispersive properties of PCFs.

The mechanical fragility of PCF structures presents additional challenges. The air-hole structure makes these fibers more susceptible to deformation under mechanical stress compared to solid fibers. When coupling requires physical contact or pressure, structural integrity can be compromised, altering the optical properties and coupling characteristics of the fiber.

Thermal management issues also plague PCF coupling systems. The air-silica structure of PCFs creates different thermal expansion characteristics compared to solid fibers, leading to alignment drift during operation. This thermal sensitivity becomes particularly problematic in high-power applications where localized heating at the coupling interface can induce temporary or permanent changes to the PCF structure.

Manufacturing variations further complicate coupling strategies. Despite advances in fabrication techniques, PCFs still exhibit greater structural variations than conventional fibers. These inconsistencies make it difficult to develop standardized coupling solutions, often requiring custom approaches for each fiber batch or even individual fibers.

Recent research has identified back-reflection as another significant challenge. The interface between different fiber types creates Fresnel reflections that can destabilize laser sources and introduce noise in sensing applications. While anti-reflection coatings offer partial solutions, they add complexity and cost to the coupling system while potentially altering the mechanical properties at the fiber interface.

State-of-the-Art Optomechanical Coupling Techniques

01 Photonic crystal fiber design for optomechanical coupling

Specialized designs of photonic crystal fibers (PCFs) can enhance optomechanical coupling effects. These designs include specific arrangements of air holes, core structures, and cladding configurations that facilitate the interaction between optical and mechanical modes. By optimizing the geometry and material properties of PCFs, the strength of optomechanical coupling can be significantly increased, leading to improved performance in sensing and signal processing applications.- Photonic crystal fiber design for optomechanical coupling: Specific designs of photonic crystal fibers can enhance optomechanical coupling effects. These designs include specialized microstructures, hole arrangements, and core configurations that facilitate the interaction between optical and mechanical modes. By optimizing the geometry and material properties of the fiber, the strength of optomechanical coupling can be significantly increased, enabling applications in sensing and signal processing.

- Sensing applications utilizing optomechanical coupling in PCF systems: Photonic crystal fiber systems with optomechanical coupling effects are particularly valuable for sensing applications. These systems can detect minute mechanical perturbations through their effect on light propagation. Applications include acoustic sensing, vibration detection, pressure measurement, and structural health monitoring. The high sensitivity of these systems allows for detection of extremely small physical changes in the surrounding environment.

- Integration of PCF systems in optical communication networks: Photonic crystal fibers with controlled optomechanical coupling can be integrated into optical communication networks to enhance performance. These systems allow for dynamic control of signal properties through mechanical modulation, enabling advanced signal processing functionalities. The integration includes specialized connectors, coupling mechanisms, and interface designs that maintain the unique properties of the photonic crystal fibers while ensuring compatibility with conventional optical systems.

- Novel materials and fabrication techniques for enhanced optomechanical effects: Advanced materials and fabrication techniques can significantly enhance optomechanical coupling in photonic crystal fiber systems. These include the use of specialized glasses, polymers, and composite materials with tailored mechanical and optical properties. Novel fabrication methods such as 3D printing, nanoimprinting, and selective etching enable the creation of complex microstructures that maximize the interaction between optical and mechanical modes while maintaining low optical losses.

- Quantum applications of optomechanical coupling in PCF systems: Photonic crystal fiber systems with optomechanical coupling effects have emerging applications in quantum information processing and quantum sensing. These systems can generate and manipulate quantum states of light through controlled mechanical interactions. Applications include quantum-enhanced sensing, quantum memory, and quantum state transfer. The unique properties of photonic crystal fibers allow for precise control of quantum states while maintaining long coherence times necessary for quantum applications.

02 Sensing applications utilizing optomechanical coupling in PCFs

Optomechanical coupling effects in photonic crystal fiber systems can be leveraged for various sensing applications. These include high-precision strain sensors, temperature sensors, and acoustic sensors. The interaction between light propagation and mechanical vibrations in PCFs enables the detection of minute physical changes in the surrounding environment. This sensing capability can be utilized in structural health monitoring, biomedical diagnostics, and environmental monitoring with high sensitivity and accuracy.Expand Specific Solutions03 Integration of PCF optomechanical systems with other photonic components

Photonic crystal fibers exhibiting optomechanical coupling can be integrated with other photonic components to create complex optical systems. These integrated systems may include resonators, interferometers, and optical filters that enhance the functionality of the overall device. The integration enables the development of compact, multifunctional photonic devices that can perform signal processing, filtering, and modulation while maintaining high efficiency and low power consumption.Expand Specific Solutions04 Novel materials and fabrication techniques for enhanced optomechanical coupling

Advanced materials and fabrication techniques can significantly improve optomechanical coupling effects in photonic crystal fiber systems. These include the use of specialty glasses, polymers, and composite materials with tailored optical and mechanical properties. Novel fabrication methods such as direct laser writing, nanoimprinting, and advanced drawing techniques enable precise control over the microstructure of PCFs, resulting in optimized optomechanical performance and increased reliability in various operating conditions.Expand Specific Solutions05 Quantum effects and nonlinear phenomena in PCF optomechanical systems

Optomechanical coupling in photonic crystal fibers can give rise to quantum effects and nonlinear phenomena that have applications in quantum information processing and communication. These effects include optomechanically induced transparency, quantum entanglement between optical and mechanical modes, and nonlinear optical processes enhanced by mechanical resonances. By harnessing these quantum and nonlinear effects, PCF systems can be used to develop quantum sensors, quantum memory elements, and components for quantum communication networks.Expand Specific Solutions

Leading Research Groups and Industry Players

The optomechanical coupling effects in photonic crystal fiber systems market is currently in a growth phase, with increasing research interest and commercial applications emerging. The global market size is estimated to be moderate but expanding, driven by telecommunications, sensing, and quantum information processing applications. Technologically, this field is in mid-maturity, with established players like Fujikura and Hamamatsu Photonics leading commercial development through their advanced fiber optic manufacturing capabilities. Research institutions such as CNRS and Beihang University are advancing fundamental understanding, while telecommunications giants including Huawei, NTT, and Deutsche Telekom are exploring practical applications. Companies like Crystal Fibre (NKT) and SWCC Corp have specialized expertise in photonic crystal fiber manufacturing, positioning them advantageously as the technology moves toward broader commercialization and standardization.

Hamamatsu Photonics KK

Technical Solution: Hamamatsu Photonics has developed advanced optomechanical coupling systems in photonic crystal fibers (PCFs) that leverage their expertise in photonics technology. Their approach integrates specialized microstructured optical fibers with precisely engineered air holes that enhance mechanical vibration sensitivity while maintaining optical transmission properties. The company has pioneered techniques for creating PCFs with optimized air-filling fractions and hole geometries that maximize optomechanical interactions. Their systems utilize stimulated Brillouin scattering (SBS) effects to achieve enhanced coupling between optical and acoustic modes within the fiber structure. Hamamatsu's technology incorporates proprietary fiber drawing techniques that maintain precise geometric tolerances required for consistent optomechanical performance across production batches. Their solutions include specialized coating materials that protect the fiber structure while allowing mechanical vibrations to effectively couple with the optical modes.

Strengths: Superior manufacturing precision allowing for consistent air hole geometry and spacing in PCF structures; extensive experience in photonics integration enabling complete system solutions. Weaknesses: Higher production costs compared to conventional optical fibers; limited scalability for mass production applications requiring extremely consistent optomechanical coupling characteristics.

Huawei Technologies Co., Ltd.

Technical Solution: Huawei Technologies has developed sophisticated optomechanical coupling solutions for photonic crystal fiber systems aimed at next-generation optical communications and sensing applications. Their approach integrates specialized PCF designs with proprietary signal processing algorithms to enhance detection sensitivity in distributed fiber sensing systems. Huawei's technology utilizes engineered PCF structures with optimized air-hole patterns that enhance acoustic-optical interactions while maintaining compatibility with existing fiber optic infrastructure. Their systems leverage stimulated Brillouin scattering (SBS) effects in specially designed PCFs to achieve distributed strain and temperature sensing with sub-meter spatial resolution over distances exceeding 100km. Huawei has implemented advanced manufacturing techniques that enable precise control of the microstructure geometry throughout the fiber drawing process, ensuring consistent optomechanical coupling characteristics. Their solutions incorporate specialized interrogation units that utilize coherent detection schemes to extract maximum information from optomechanical interactions within the fiber, enabling applications in structural health monitoring, perimeter security, and subsea cable protection.

Strengths: Extensive integration capabilities allowing for complete end-to-end solutions from fiber design to signal processing; substantial R&D resources enabling rapid technology development and deployment. Weaknesses: Potential market access limitations in some regions due to geopolitical considerations; relatively recent entry into specialized photonic crystal fiber technology compared to established players.

Key Patents and Breakthroughs in PCF Coupling

Optical fiber component

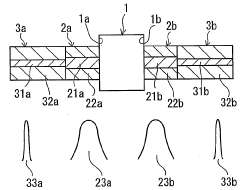

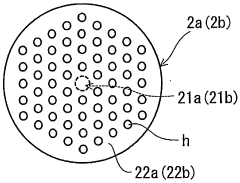

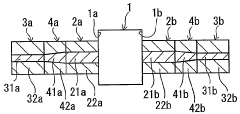

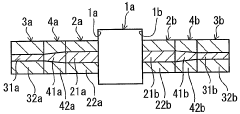

PatentWO2004011973A1

Innovation

- The use of photonic crystal fibers (PhC fibers) with larger Mode Field Diameters (MFD) optically connected to both ends of SM fibers and equipped with collimating lenses, allowing for easier alignment and reduced connection loss by expanding the core diameter and adjusting the MFD for efficient light coupling.

Fabrication Methods and Material Considerations

The fabrication of photonic crystal fibers (PCFs) capable of exhibiting significant optomechanical coupling effects requires sophisticated manufacturing techniques and careful material selection. Traditional PCF fabrication methods include stack-and-draw, drilling, extrusion, and sol-gel casting, each offering distinct advantages for specific applications in optomechanical systems.

The stack-and-draw technique remains the most widely employed method, allowing for precise control over the microstructure geometry. This process involves stacking capillary tubes and rods in a predetermined pattern, followed by drawing them into fiber under controlled temperature and tension conditions. For optomechanical applications, this method enables the creation of complex air-hole patterns that can enhance acoustic-optical interactions within the fiber structure.

Material selection plays a crucial role in determining the strength of optomechanical coupling. Silica remains the dominant material due to its excellent optical properties and established fabrication protocols. However, recent advancements have introduced alternative materials such as chalcogenide glasses, which offer higher nonlinearity and enhanced photoelastic coefficients, potentially increasing optomechanical coupling strength by an order of magnitude compared to silica-based systems.

Polymer-based PCFs represent another promising direction, offering greater mechanical flexibility and customizable acoustic properties. The viscoelastic nature of polymers can be leveraged to design structures with tailored mechanical resonances that match optical frequencies of interest. PMMA (polymethyl methacrylate) and CYTOP (perfluorinated polymer) have emerged as leading candidates due to their favorable optical transparency and mechanical characteristics.

Hybrid material systems combining silica with other materials have demonstrated enhanced optomechanical coupling. For instance, coating the air holes with thin layers of materials possessing high photoelastic coefficients can significantly amplify strain-induced refractive index changes. These composite structures require precise control during fabrication, often necessitating advanced deposition techniques such as chemical vapor deposition or atomic layer deposition.

The dimensional precision during fabrication directly impacts optomechanical performance. Even minor variations in hole diameter, pitch, or wall thickness can dramatically alter the mechanical resonance frequencies and optical mode profiles. State-of-the-art fabrication facilities now achieve sub-micron precision, with dimensional tolerances below 1% being essential for predictable optomechanical behavior in high-performance systems.

Post-processing techniques such as selective hole inflation, tapering, and annealing have emerged as valuable tools for fine-tuning optomechanical properties after initial fabrication. These methods allow researchers to optimize coupling strength by modifying the fiber geometry or relieving internal stresses that might otherwise dampen mechanical vibrations.

The stack-and-draw technique remains the most widely employed method, allowing for precise control over the microstructure geometry. This process involves stacking capillary tubes and rods in a predetermined pattern, followed by drawing them into fiber under controlled temperature and tension conditions. For optomechanical applications, this method enables the creation of complex air-hole patterns that can enhance acoustic-optical interactions within the fiber structure.

Material selection plays a crucial role in determining the strength of optomechanical coupling. Silica remains the dominant material due to its excellent optical properties and established fabrication protocols. However, recent advancements have introduced alternative materials such as chalcogenide glasses, which offer higher nonlinearity and enhanced photoelastic coefficients, potentially increasing optomechanical coupling strength by an order of magnitude compared to silica-based systems.

Polymer-based PCFs represent another promising direction, offering greater mechanical flexibility and customizable acoustic properties. The viscoelastic nature of polymers can be leveraged to design structures with tailored mechanical resonances that match optical frequencies of interest. PMMA (polymethyl methacrylate) and CYTOP (perfluorinated polymer) have emerged as leading candidates due to their favorable optical transparency and mechanical characteristics.

Hybrid material systems combining silica with other materials have demonstrated enhanced optomechanical coupling. For instance, coating the air holes with thin layers of materials possessing high photoelastic coefficients can significantly amplify strain-induced refractive index changes. These composite structures require precise control during fabrication, often necessitating advanced deposition techniques such as chemical vapor deposition or atomic layer deposition.

The dimensional precision during fabrication directly impacts optomechanical performance. Even minor variations in hole diameter, pitch, or wall thickness can dramatically alter the mechanical resonance frequencies and optical mode profiles. State-of-the-art fabrication facilities now achieve sub-micron precision, with dimensional tolerances below 1% being essential for predictable optomechanical behavior in high-performance systems.

Post-processing techniques such as selective hole inflation, tapering, and annealing have emerged as valuable tools for fine-tuning optomechanical properties after initial fabrication. These methods allow researchers to optimize coupling strength by modifying the fiber geometry or relieving internal stresses that might otherwise dampen mechanical vibrations.

Quantum Effects in PCF Optomechanical Systems

Quantum effects in PCF optomechanical systems represent a frontier area where photonic crystal fiber technology intersects with quantum mechanics. At the nanoscale, traditional classical physics descriptions become insufficient, necessitating quantum mechanical frameworks to accurately model system behavior. The quantum regime of optomechanical coupling in PCFs exhibits several distinctive phenomena, including zero-point fluctuations, quantum backaction, and quantum entanglement between optical and mechanical degrees of freedom.

Zero-point fluctuations, a fundamental quantum mechanical effect, create a baseline of mechanical motion even at absolute zero temperature. In PCF systems, these fluctuations can significantly influence the optomechanical coupling, especially in high-Q resonators where mechanical modes interact with confined optical fields. Recent experimental demonstrations have shown that these quantum fluctuations can be measured and potentially harnessed for quantum sensing applications.

Quantum backaction effects emerge when measurement precision approaches the standard quantum limit. In PCF optomechanical systems, the act of measuring mechanical motion with light introduces additional quantum noise, creating a fundamental limit to measurement precision. Advanced techniques such as quantum non-demolition measurements and backaction evasion protocols have been developed specifically for PCF platforms to circumvent these limitations.

The generation of quantum entanglement between optical and mechanical modes represents perhaps the most promising quantum effect in PCF optomechanical systems. This non-classical correlation can be achieved through parametric processes where photons and phonons become inextricably linked. Recent experimental demonstrations have achieved mechanical-optical entanglement in specialized PCF structures at cryogenic temperatures, opening pathways for quantum information processing applications.

Quantum coherent state transfer between optical and mechanical modes has also been demonstrated in PCF systems. This capability enables the conversion of quantum information between light and mechanical vibrations, potentially serving as a critical interface in hybrid quantum systems. The long coherence times achievable in carefully designed PCF structures make them particularly attractive for quantum memory applications.

The quantum regime also enables novel cooling mechanisms such as sideband cooling, where PCF optomechanical systems can reach mechanical ground states through quantum-assisted processes. This capability has profound implications for quantum state preparation and quantum information processing, allowing researchers to initialize mechanical systems in well-defined quantum states.

Zero-point fluctuations, a fundamental quantum mechanical effect, create a baseline of mechanical motion even at absolute zero temperature. In PCF systems, these fluctuations can significantly influence the optomechanical coupling, especially in high-Q resonators where mechanical modes interact with confined optical fields. Recent experimental demonstrations have shown that these quantum fluctuations can be measured and potentially harnessed for quantum sensing applications.

Quantum backaction effects emerge when measurement precision approaches the standard quantum limit. In PCF optomechanical systems, the act of measuring mechanical motion with light introduces additional quantum noise, creating a fundamental limit to measurement precision. Advanced techniques such as quantum non-demolition measurements and backaction evasion protocols have been developed specifically for PCF platforms to circumvent these limitations.

The generation of quantum entanglement between optical and mechanical modes represents perhaps the most promising quantum effect in PCF optomechanical systems. This non-classical correlation can be achieved through parametric processes where photons and phonons become inextricably linked. Recent experimental demonstrations have achieved mechanical-optical entanglement in specialized PCF structures at cryogenic temperatures, opening pathways for quantum information processing applications.

Quantum coherent state transfer between optical and mechanical modes has also been demonstrated in PCF systems. This capability enables the conversion of quantum information between light and mechanical vibrations, potentially serving as a critical interface in hybrid quantum systems. The long coherence times achievable in carefully designed PCF structures make them particularly attractive for quantum memory applications.

The quantum regime also enables novel cooling mechanisms such as sideband cooling, where PCF optomechanical systems can reach mechanical ground states through quantum-assisted processes. This capability has profound implications for quantum state preparation and quantum information processing, allowing researchers to initialize mechanical systems in well-defined quantum states.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!