Regulatory Standards for Optical Fiber Testing and Qualification

OCT 11, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Optical Fiber Testing Standards Evolution and Objectives

Optical fiber technology has evolved significantly since its commercial introduction in the 1970s, with testing standards developing in parallel to ensure reliability, interoperability, and performance. The evolution of these standards reflects the growing sophistication of optical fiber systems and their expanding applications across telecommunications, data centers, and industrial environments.

Initially, optical fiber testing focused primarily on basic transmission parameters such as attenuation and bandwidth. The first standardized testing methods emerged in the 1980s through organizations like the International Electrotechnical Commission (IEC) and the International Telecommunication Union (ITU). These early standards established fundamental measurement techniques for fiber characterization but lacked the comprehensive approach needed for modern applications.

The 1990s marked a significant advancement in testing standards with the introduction of more sophisticated measurement parameters including chromatic dispersion, polarization mode dispersion, and geometrical characteristics. This period coincided with the rapid expansion of fiber optic networks for telecommunications infrastructure, driving the need for more rigorous qualification processes.

The early 2000s saw the development of standards specifically addressing the requirements of wavelength division multiplexing (WDM) systems, which demanded more precise characterization of fiber performance across multiple wavelengths. Standards organizations expanded their focus to include testing methodologies for specialized fiber types such as dispersion-shifted and non-zero dispersion-shifted fibers.

Recent developments have been driven by the emergence of high-speed data transmission technologies, including 100G, 400G, and beyond. These applications require extremely precise testing of parameters such as effective area, bend insensitivity, and nonlinear coefficients. Testing standards have evolved to incorporate these requirements, with organizations like TIA, IEC, and ISO continuously updating their specifications.

The primary objective of current optical fiber testing standards is to ensure consistent quality and performance across global manufacturing and deployment. This includes establishing reproducible measurement methodologies that can be implemented across different testing laboratories while yielding comparable results. Standards aim to provide clear pass/fail criteria that correlate with actual performance in deployed systems.

Another key objective is to anticipate future technological developments and create testing frameworks that can accommodate emerging fiber technologies and applications. This forward-looking approach helps prevent standards from becoming obsolete as technology advances, providing a stable foundation for industry innovation while ensuring backward compatibility.

The harmonization of international standards represents another critical goal, as global supply chains require consistent testing methodologies across different regions. Organizations like the IEC and ITU work to align their standards with regional bodies such as ANSI/TIA in North America and CENELEC in Europe, facilitating international trade and technology adoption.

Initially, optical fiber testing focused primarily on basic transmission parameters such as attenuation and bandwidth. The first standardized testing methods emerged in the 1980s through organizations like the International Electrotechnical Commission (IEC) and the International Telecommunication Union (ITU). These early standards established fundamental measurement techniques for fiber characterization but lacked the comprehensive approach needed for modern applications.

The 1990s marked a significant advancement in testing standards with the introduction of more sophisticated measurement parameters including chromatic dispersion, polarization mode dispersion, and geometrical characteristics. This period coincided with the rapid expansion of fiber optic networks for telecommunications infrastructure, driving the need for more rigorous qualification processes.

The early 2000s saw the development of standards specifically addressing the requirements of wavelength division multiplexing (WDM) systems, which demanded more precise characterization of fiber performance across multiple wavelengths. Standards organizations expanded their focus to include testing methodologies for specialized fiber types such as dispersion-shifted and non-zero dispersion-shifted fibers.

Recent developments have been driven by the emergence of high-speed data transmission technologies, including 100G, 400G, and beyond. These applications require extremely precise testing of parameters such as effective area, bend insensitivity, and nonlinear coefficients. Testing standards have evolved to incorporate these requirements, with organizations like TIA, IEC, and ISO continuously updating their specifications.

The primary objective of current optical fiber testing standards is to ensure consistent quality and performance across global manufacturing and deployment. This includes establishing reproducible measurement methodologies that can be implemented across different testing laboratories while yielding comparable results. Standards aim to provide clear pass/fail criteria that correlate with actual performance in deployed systems.

Another key objective is to anticipate future technological developments and create testing frameworks that can accommodate emerging fiber technologies and applications. This forward-looking approach helps prevent standards from becoming obsolete as technology advances, providing a stable foundation for industry innovation while ensuring backward compatibility.

The harmonization of international standards represents another critical goal, as global supply chains require consistent testing methodologies across different regions. Organizations like the IEC and ITU work to align their standards with regional bodies such as ANSI/TIA in North America and CENELEC in Europe, facilitating international trade and technology adoption.

Market Requirements for Fiber Optic Qualification

The global optical fiber market is experiencing significant growth driven by increasing demand for high-speed internet connectivity, 5G network deployment, and data center expansion. Market research indicates that telecommunications operators and internet service providers are seeking fiber optic solutions that meet stringent regulatory standards while delivering enhanced performance characteristics. The qualification requirements for optical fibers have evolved substantially as applications become more demanding and diverse.

Network operators require fibers that comply with international standards such as those established by the International Telecommunication Union (ITU-T), International Electrotechnical Commission (IEC), and Telecommunications Industry Association (TIA). These standards ensure interoperability, reliability, and performance consistency across global networks. Market feedback shows that compliance with these standards is not merely a technical preference but a fundamental business requirement for procurement decisions.

Performance requirements have become increasingly stringent, with customers demanding lower attenuation rates, higher bandwidth capacity, improved bend resistance, and enhanced durability. For modern data centers and 5G networks, there is particular emphasis on fibers that can support higher transmission speeds while maintaining signal integrity over longer distances. The market shows clear preference for fibers that exceed minimum regulatory standards rather than merely meeting them.

Testing and certification documentation has emerged as a critical market requirement. End users now demand comprehensive test reports that verify compliance with applicable standards and validate performance claims. This documentation serves as quality assurance and risk mitigation for network planners and operators. The trend toward more transparent and detailed qualification reporting reflects the high-stakes nature of fiber optic infrastructure investments.

Regional variations in qualification requirements present challenges for manufacturers operating in global markets. While core technical standards are increasingly harmonized, certification processes and specific testing protocols can vary significantly between North America, Europe, Asia-Pacific, and emerging markets. This creates demand for flexible qualification approaches that can address diverse regulatory environments while maintaining cost-effectiveness.

Environmental and sustainability considerations are becoming more prominent in fiber qualification requirements. Customers increasingly seek products that not only meet technical specifications but also demonstrate environmental compliance, reduced carbon footprint, and sustainable manufacturing practices. This trend is particularly strong in European markets but is gaining traction globally as corporate sustainability initiatives expand.

Time-to-market pressures have intensified qualification requirements, with customers expecting faster certification processes without compromising thoroughness. This has created demand for streamlined testing methodologies and more efficient qualification protocols that can accelerate product deployment while maintaining regulatory compliance and quality assurance.

Network operators require fibers that comply with international standards such as those established by the International Telecommunication Union (ITU-T), International Electrotechnical Commission (IEC), and Telecommunications Industry Association (TIA). These standards ensure interoperability, reliability, and performance consistency across global networks. Market feedback shows that compliance with these standards is not merely a technical preference but a fundamental business requirement for procurement decisions.

Performance requirements have become increasingly stringent, with customers demanding lower attenuation rates, higher bandwidth capacity, improved bend resistance, and enhanced durability. For modern data centers and 5G networks, there is particular emphasis on fibers that can support higher transmission speeds while maintaining signal integrity over longer distances. The market shows clear preference for fibers that exceed minimum regulatory standards rather than merely meeting them.

Testing and certification documentation has emerged as a critical market requirement. End users now demand comprehensive test reports that verify compliance with applicable standards and validate performance claims. This documentation serves as quality assurance and risk mitigation for network planners and operators. The trend toward more transparent and detailed qualification reporting reflects the high-stakes nature of fiber optic infrastructure investments.

Regional variations in qualification requirements present challenges for manufacturers operating in global markets. While core technical standards are increasingly harmonized, certification processes and specific testing protocols can vary significantly between North America, Europe, Asia-Pacific, and emerging markets. This creates demand for flexible qualification approaches that can address diverse regulatory environments while maintaining cost-effectiveness.

Environmental and sustainability considerations are becoming more prominent in fiber qualification requirements. Customers increasingly seek products that not only meet technical specifications but also demonstrate environmental compliance, reduced carbon footprint, and sustainable manufacturing practices. This trend is particularly strong in European markets but is gaining traction globally as corporate sustainability initiatives expand.

Time-to-market pressures have intensified qualification requirements, with customers expecting faster certification processes without compromising thoroughness. This has created demand for streamlined testing methodologies and more efficient qualification protocols that can accelerate product deployment while maintaining regulatory compliance and quality assurance.

Current Testing Methodologies and Technical Barriers

Optical fiber testing methodologies have evolved significantly over the past decades, with several standardized approaches now established across the industry. The primary testing categories include geometric, optical, mechanical, and environmental testing, each governed by specific regulatory frameworks such as IEC, ITU-T, TIA/EIA, and ISO standards.

Geometric testing focuses on physical dimensions and includes measurements of cladding diameter, core concentricity, and coating geometry. These parameters are typically assessed using high-precision microscopy and laser-based measurement systems. Current methodologies employ automated systems capable of sub-micron accuracy, though calibration drift remains a persistent challenge.

Optical performance testing encompasses attenuation, bandwidth, chromatic dispersion, and polarization mode dispersion measurements. The industry standard for attenuation testing is the cut-back method (IEC 60793-1-40), while chromatic dispersion is commonly measured using phase-shift techniques (IEC 60793-1-42). These methods, while effective, often require specialized equipment and significant technical expertise.

Mechanical strength testing evaluates fiber durability through tensile strength, bending, and fatigue tests. The two-point bending test (IEC 60793-1-31) and proof testing (IEC 60793-1-30) are widely implemented, though correlation between laboratory test results and real-world performance continues to present analytical challenges.

Environmental testing assesses fiber performance under varying temperature, humidity, and chemical exposure conditions. Temperature cycling tests (IEC 60793-1-52) and hydrogen aging tests are particularly critical for fibers deployed in harsh environments. Current methodologies struggle with accelerated aging protocols that accurately predict long-term performance.

Several technical barriers impede advancement in optical fiber testing. First, there exists a significant measurement uncertainty gap between laboratory conditions and field deployments, particularly for next-generation fibers with enhanced performance characteristics. This discrepancy often leads to inconsistent qualification results across different testing facilities.

Second, the increasing complexity of specialty fibers, including multi-core and few-mode fibers for space-division multiplexing, has outpaced standardized testing methodologies. Current standards primarily address conventional single-mode and multi-mode fibers, creating regulatory gaps for emerging fiber technologies.

Third, interoperability testing between components from different manufacturers remains challenging due to variations in interpretation of standards and implementation practices. This has led to compatibility issues in complex optical networks, particularly in high-speed transmission systems exceeding 400G.

Finally, the industry faces a growing need for non-destructive testing methods that can be applied throughout the fiber lifecycle, from manufacturing to installation and maintenance. Current destructive testing approaches limit comprehensive quality assurance and increase production costs.

Geometric testing focuses on physical dimensions and includes measurements of cladding diameter, core concentricity, and coating geometry. These parameters are typically assessed using high-precision microscopy and laser-based measurement systems. Current methodologies employ automated systems capable of sub-micron accuracy, though calibration drift remains a persistent challenge.

Optical performance testing encompasses attenuation, bandwidth, chromatic dispersion, and polarization mode dispersion measurements. The industry standard for attenuation testing is the cut-back method (IEC 60793-1-40), while chromatic dispersion is commonly measured using phase-shift techniques (IEC 60793-1-42). These methods, while effective, often require specialized equipment and significant technical expertise.

Mechanical strength testing evaluates fiber durability through tensile strength, bending, and fatigue tests. The two-point bending test (IEC 60793-1-31) and proof testing (IEC 60793-1-30) are widely implemented, though correlation between laboratory test results and real-world performance continues to present analytical challenges.

Environmental testing assesses fiber performance under varying temperature, humidity, and chemical exposure conditions. Temperature cycling tests (IEC 60793-1-52) and hydrogen aging tests are particularly critical for fibers deployed in harsh environments. Current methodologies struggle with accelerated aging protocols that accurately predict long-term performance.

Several technical barriers impede advancement in optical fiber testing. First, there exists a significant measurement uncertainty gap between laboratory conditions and field deployments, particularly for next-generation fibers with enhanced performance characteristics. This discrepancy often leads to inconsistent qualification results across different testing facilities.

Second, the increasing complexity of specialty fibers, including multi-core and few-mode fibers for space-division multiplexing, has outpaced standardized testing methodologies. Current standards primarily address conventional single-mode and multi-mode fibers, creating regulatory gaps for emerging fiber technologies.

Third, interoperability testing between components from different manufacturers remains challenging due to variations in interpretation of standards and implementation practices. This has led to compatibility issues in complex optical networks, particularly in high-speed transmission systems exceeding 400G.

Finally, the industry faces a growing need for non-destructive testing methods that can be applied throughout the fiber lifecycle, from manufacturing to installation and maintenance. Current destructive testing approaches limit comprehensive quality assurance and increase production costs.

Contemporary Fiber Qualification Protocols

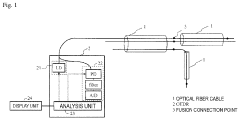

01 Optical Time Domain Reflectometry (OTDR) Testing Methods

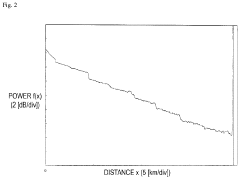

OTDR is a key technique for testing optical fibers by analyzing the backscattered light to detect faults, measure attenuation, and evaluate splice losses. Advanced OTDR systems can provide detailed characterization of fiber links, including distance measurements to breaks or anomalies. These methods enable non-destructive testing of installed fiber networks and can be automated for efficient field deployment.- Optical Time Domain Reflectometry (OTDR) Testing Methods: OTDR is a key technique for testing optical fibers by analyzing the backscattered light to detect faults, measure attenuation, and evaluate splice losses. Advanced OTDR systems can provide detailed characterization of fiber links, including distance measurements to breaks or anomalies. These methods enable non-destructive testing of installed fiber networks and can be automated for efficient field testing.

- Automated Fiber Qualification Systems: Automated systems for qualifying optical fibers incorporate hardware and software solutions that streamline the testing process. These systems can perform multiple tests in sequence, including insertion loss, return loss, and polarization measurements. They often feature pass/fail criteria based on industry standards and can generate comprehensive test reports. Such automation reduces human error and increases testing efficiency in manufacturing and field environments.

- Bend and Stress Testing Methodologies: Specialized techniques for evaluating how optical fibers perform under bending and mechanical stress conditions are crucial for qualification. These methods measure macrobending and microbending losses under various bend radii and stress conditions. Testing equipment may apply controlled stress while simultaneously measuring optical performance parameters. Such tests are particularly important for fibers deployed in challenging environmental conditions or those requiring high flexibility.

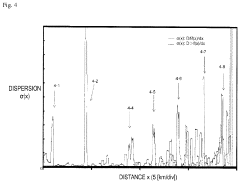

- Bandwidth and Transmission Capacity Testing: Methods for evaluating the bandwidth and data transmission capabilities of optical fibers involve measuring parameters such as chromatic dispersion, polarization mode dispersion, and effective modal bandwidth. These tests determine the maximum data rates that can be supported over various distances. Advanced testing equipment can characterize fiber performance across multiple wavelengths and modulation formats to ensure compatibility with high-speed communication systems.

- Environmental and Reliability Testing: Comprehensive qualification of optical fibers includes testing their performance under various environmental conditions such as temperature extremes, humidity, and mechanical vibration. Accelerated aging tests help predict long-term reliability and lifetime performance. These methods often involve specialized environmental chambers and long-term monitoring of optical parameters to ensure fibers will maintain performance throughout their expected service life in real-world deployment scenarios.

02 Fiber Qualification and Certification Standards

Standardized procedures for qualifying optical fibers ensure they meet industry specifications for parameters such as bandwidth, attenuation, chromatic dispersion, and polarization mode dispersion. Certification processes involve comprehensive testing against established benchmarks to verify performance characteristics. These standards are essential for ensuring interoperability between different network components and maintaining quality across fiber optic installations.Expand Specific Solutions03 Automated Testing Systems and Equipment

Specialized equipment for automated optical fiber testing includes integrated test platforms that can perform multiple measurements simultaneously. These systems often feature user-friendly interfaces, data logging capabilities, and remote operation functionality. Automated testing reduces human error, increases testing speed, and provides consistent, repeatable results across multiple fiber installations.Expand Specific Solutions04 Fiber Fault Detection and Diagnosis

Advanced methods for detecting and diagnosing faults in optical fibers include real-time monitoring systems that can identify issues such as breaks, bends, or degradation. These techniques often employ machine learning algorithms to analyze test data and predict potential failures before they occur. Fault location accuracy has improved significantly with newer technologies, allowing for precise identification of problem areas in complex fiber networks.Expand Specific Solutions05 Field Testing and Portable Solutions

Portable testing equipment enables on-site qualification of optical fibers during installation or maintenance. These compact solutions provide essential measurements including insertion loss, return loss, and visual fault location. Field testing tools are designed to withstand harsh environmental conditions while maintaining measurement accuracy. Many modern portable testers include wireless connectivity for immediate data sharing and cloud-based reporting capabilities.Expand Specific Solutions

Leading Organizations and Standardization Bodies

The optical fiber testing and qualification market is in a mature growth phase, characterized by established regulatory standards and increasing demand for high-quality fiber infrastructure. The global market size is substantial, driven by telecommunications expansion, data center growth, and 5G deployment, with projections exceeding $1 billion annually. Technologically, the field demonstrates high maturity with sophisticated testing methodologies. Key industry players include established equipment manufacturers like EXFO, Fluke Corp., and Photon Kinetics providing specialized testing solutions, while fiber producers such as Corning, Prysmian, Furukawa Electric, and Sumitomo Electric maintain comprehensive in-house testing capabilities. Telecommunications giants including Huawei, ZTE, and NTT have also developed significant testing expertise to ensure network reliability and performance across their global infrastructure deployments.

EXFO, Inc.

Technical Solution: EXFO has developed comprehensive optical fiber testing solutions that comply with international standards including IEC, TIA/EIA, and Telcordia. Their FTB platform integrates multiple test capabilities including OTDR (Optical Time Domain Reflectometer), optical loss testing, and dispersion measurement in a single device. EXFO's iOLM (intelligent Optical Link Mapper) technology automates complex OTDR testing by using multiple acquisitions and advanced algorithms to create accurate fiber characterization regardless of the technician's experience level[1]. Their solutions support testing across various fiber types including single-mode, multimode, and specialty fibers, with capabilities for measuring parameters such as insertion loss, return loss, chromatic dispersion, and polarization mode dispersion according to standards like TIA-568, IEC 61280, and IEC 61300[2]. EXFO also provides cloud-based test data management systems that enable centralized compliance reporting and certification documentation.

Strengths: Industry-leading automation capabilities reduce human error and testing time; comprehensive test parameter coverage in single platforms; strong software integration for results management and reporting. Weaknesses: Higher initial investment compared to basic testing equipment; some advanced features may require specialized training; proprietary software ecosystems can create vendor lock-in for organizations.

Corning, Inc.

Technical Solution: Corning has developed an integrated approach to optical fiber testing and qualification that spans the entire product lifecycle. Their testing methodology begins with raw material qualification and continues through manufacturing process controls to final product verification. Corning's optical fiber testing solutions comply with TIA/EIA-455 (FOTP), IEC 60793, and Telcordia GR-20 standards, covering mechanical, environmental, and optical performance parameters[3]. Their CertiFi system provides comprehensive documentation and certification for installed fiber networks, ensuring compliance with industry standards. Corning has pioneered advanced measurement techniques for specialized parameters like bend insensitivity testing according to IEC 60793-1-47 and has developed proprietary methods for characterizing their ClearCurve® bend-insensitive fibers[4]. Their testing protocols include accelerated aging tests that simulate decades of deployment conditions to verify long-term reliability and performance stability, particularly important for mission-critical applications in harsh environments.

Strengths: Vertical integration allows for comprehensive quality control from glass manufacturing through final testing; extensive R&D capabilities enable development of specialized test methodologies for next-generation fibers; global presence ensures familiarity with regional regulatory requirements. Weaknesses: Testing solutions are often optimized for Corning's own fiber products; limited focus on field testing equipment compared to dedicated test equipment manufacturers; higher cost structure for comprehensive testing services.

Critical Patents and Innovations in Optical Testing

Fiber optic test methods, fiber optic test equipment, and programs

PatentActiveUS12007298B2

Innovation

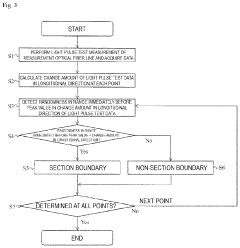

- The method involves acquiring return light intensity over time from a light pulse emitted into an optical fiber, calculating change and randomness values along the fiber, and comparing these to determine the boundary point, using the increased dispersion caused by noise as a threshold to accurately identify the connection point.

Optical fiber test apparatus and optical fiber test method

PatentActiveJP2015206594A

Innovation

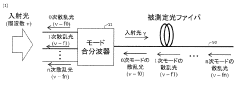

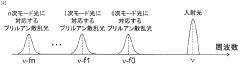

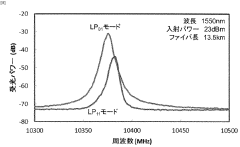

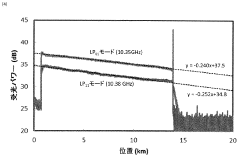

- The method utilizes Brillouin scattering characteristics, where the optical frequency of Brillouin scattered light differs for each propagation mode, allowing for precise loss measurement by detecting the change in longitudinal direction of Brillouin scattering.

International Compliance Framework for Fiber Optics

The global fiber optic industry operates within a complex web of regulatory frameworks that vary by region yet share fundamental principles aimed at ensuring quality, safety, and interoperability. These frameworks establish the minimum requirements for optical fiber performance, testing methodologies, and certification processes that manufacturers must adhere to before bringing products to market.

At the international level, the International Electrotechnical Commission (IEC) serves as the primary standards-setting body, with its IEC 60793 series providing comprehensive specifications for optical fibers and cables. These standards define critical parameters such as attenuation, bandwidth, numerical aperture, and mechanical properties that must be verified through standardized testing procedures.

Complementing the IEC, the International Telecommunication Union (ITU-T) has developed the G-series recommendations, particularly G.651 through G.657, which classify fibers based on their transmission characteristics and intended applications. These recommendations have been widely adopted across national regulatory frameworks, creating a foundation for global harmonization.

Regional bodies have established their own compliance frameworks that generally align with international standards while addressing specific regional concerns. The European Telecommunications Standards Institute (ETSI) implements the IEC and ITU standards through the EN 60793 series, which is mandatory for products sold within the European Union under the CE marking scheme.

In North America, the Telecommunications Industry Association (TIA) and the American National Standards Institute (ANSI) jointly maintain the ANSI/TIA-568 standards, which incorporate fiber optic specifications particularly relevant to structured cabling systems. These standards are often referenced in building codes and installation requirements throughout the United States and Canada.

The Asia-Pacific region demonstrates greater regulatory diversity, with Japan's JIS standards, China's YD/T specifications, and Australia's AS/NZS frameworks each maintaining distinct requirements while generally aligning with international norms. This regional variation creates compliance challenges for global manufacturers who must navigate multiple certification processes.

Testing laboratories accredited under the International Laboratory Accreditation Cooperation (ILAC) play a crucial role in the compliance ecosystem by providing independent verification of fiber optic performance claims. These facilities must maintain rigorous quality management systems and demonstrate technical competence in optical measurement techniques to maintain their accreditation status.

Recent trends indicate movement toward greater international harmonization, with mutual recognition agreements reducing duplicate testing requirements and facilitating global trade in fiber optic products. However, emerging technologies such as specialty fibers for sensing applications and space-division multiplexing systems are creating new regulatory challenges that existing frameworks are still adapting to address.

At the international level, the International Electrotechnical Commission (IEC) serves as the primary standards-setting body, with its IEC 60793 series providing comprehensive specifications for optical fibers and cables. These standards define critical parameters such as attenuation, bandwidth, numerical aperture, and mechanical properties that must be verified through standardized testing procedures.

Complementing the IEC, the International Telecommunication Union (ITU-T) has developed the G-series recommendations, particularly G.651 through G.657, which classify fibers based on their transmission characteristics and intended applications. These recommendations have been widely adopted across national regulatory frameworks, creating a foundation for global harmonization.

Regional bodies have established their own compliance frameworks that generally align with international standards while addressing specific regional concerns. The European Telecommunications Standards Institute (ETSI) implements the IEC and ITU standards through the EN 60793 series, which is mandatory for products sold within the European Union under the CE marking scheme.

In North America, the Telecommunications Industry Association (TIA) and the American National Standards Institute (ANSI) jointly maintain the ANSI/TIA-568 standards, which incorporate fiber optic specifications particularly relevant to structured cabling systems. These standards are often referenced in building codes and installation requirements throughout the United States and Canada.

The Asia-Pacific region demonstrates greater regulatory diversity, with Japan's JIS standards, China's YD/T specifications, and Australia's AS/NZS frameworks each maintaining distinct requirements while generally aligning with international norms. This regional variation creates compliance challenges for global manufacturers who must navigate multiple certification processes.

Testing laboratories accredited under the International Laboratory Accreditation Cooperation (ILAC) play a crucial role in the compliance ecosystem by providing independent verification of fiber optic performance claims. These facilities must maintain rigorous quality management systems and demonstrate technical competence in optical measurement techniques to maintain their accreditation status.

Recent trends indicate movement toward greater international harmonization, with mutual recognition agreements reducing duplicate testing requirements and facilitating global trade in fiber optic products. However, emerging technologies such as specialty fibers for sensing applications and space-division multiplexing systems are creating new regulatory challenges that existing frameworks are still adapting to address.

Environmental Impact of Testing Procedures

The environmental impact of optical fiber testing procedures has become increasingly significant as global sustainability concerns grow. Traditional testing methods often involve chemicals such as isopropyl alcohol, acetone, and various cleaning solvents that can release volatile organic compounds (VOCs) into the atmosphere. These substances contribute to air pollution and may pose health risks to laboratory personnel when improperly handled or disposed of. Additionally, certain fiber coating removal processes utilize thermal techniques that generate toxic fumes, requiring specialized ventilation systems to mitigate workplace hazards.

Water consumption represents another critical environmental consideration in optical fiber testing. Cleaning procedures and cooling systems for testing equipment can consume substantial quantities of water, particularly in high-volume manufacturing environments. The resulting wastewater often contains trace amounts of chemicals and particulates that require treatment before discharge, adding complexity to waste management protocols.

Energy usage during qualification testing presents a substantial environmental footprint. Environmental chamber testing, which subjects fibers to extreme temperature cycling and humidity conditions, demands significant electricity consumption. Similarly, mechanical durability tests and long-duration reliability assessments require continuous operation of specialized equipment, contributing to carbon emissions when powered by non-renewable energy sources.

Recent regulatory developments have begun addressing these environmental concerns. The European Union's Restriction of Hazardous Substances (RoHS) directive has implications for testing equipment and materials, while ISO 14001 certification increasingly influences laboratory practices. Leading testing facilities have implemented environmental management systems that track resource consumption and waste generation, establishing benchmarks for industry-wide improvement.

Emerging green testing methodologies offer promising alternatives to conventional approaches. Non-destructive testing techniques reduce material waste by enabling the reuse of test samples. Virtual qualification models, though still developing, show potential for reducing physical testing requirements through simulation. Additionally, miniaturization of testing equipment has decreased energy and material requirements while maintaining measurement precision.

The telecommunications industry has begun establishing collaborative initiatives to standardize environmentally responsible testing practices. These efforts include developing shared databases of environmental impact assessments for common testing procedures and creating certification programs that recognize laboratories implementing sustainable practices. Such industry-wide approaches help establish consistent environmental performance metrics across the global optical fiber testing ecosystem.

Water consumption represents another critical environmental consideration in optical fiber testing. Cleaning procedures and cooling systems for testing equipment can consume substantial quantities of water, particularly in high-volume manufacturing environments. The resulting wastewater often contains trace amounts of chemicals and particulates that require treatment before discharge, adding complexity to waste management protocols.

Energy usage during qualification testing presents a substantial environmental footprint. Environmental chamber testing, which subjects fibers to extreme temperature cycling and humidity conditions, demands significant electricity consumption. Similarly, mechanical durability tests and long-duration reliability assessments require continuous operation of specialized equipment, contributing to carbon emissions when powered by non-renewable energy sources.

Recent regulatory developments have begun addressing these environmental concerns. The European Union's Restriction of Hazardous Substances (RoHS) directive has implications for testing equipment and materials, while ISO 14001 certification increasingly influences laboratory practices. Leading testing facilities have implemented environmental management systems that track resource consumption and waste generation, establishing benchmarks for industry-wide improvement.

Emerging green testing methodologies offer promising alternatives to conventional approaches. Non-destructive testing techniques reduce material waste by enabling the reuse of test samples. Virtual qualification models, though still developing, show potential for reducing physical testing requirements through simulation. Additionally, miniaturization of testing equipment has decreased energy and material requirements while maintaining measurement precision.

The telecommunications industry has begun establishing collaborative initiatives to standardize environmentally responsible testing practices. These efforts include developing shared databases of environmental impact assessments for common testing procedures and creating certification programs that recognize laboratories implementing sustainable practices. Such industry-wide approaches help establish consistent environmental performance metrics across the global optical fiber testing ecosystem.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!