Case Study: Scaling Supercapacitor Electrode Manufacturing — QC, Yield and Cost Drivers

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Supercapacitor Electrode Manufacturing Background and Objectives

Supercapacitors have emerged as critical energy storage devices in the modern technological landscape, offering unique advantages in power density, charging speed, and cycle life compared to traditional batteries. The evolution of supercapacitor technology dates back to the 1950s, with significant commercial development beginning in the 1970s. Over the past two decades, the field has experienced accelerated growth driven by increasing demands for rapid energy storage solutions in automotive, renewable energy, and consumer electronics sectors.

The manufacturing of supercapacitor electrodes represents a critical bottleneck in scaling production to meet growing market demands. Traditional electrode manufacturing processes have largely relied on batch processing methods borrowed from battery production, which present significant challenges when scaled to high-volume production. These challenges include maintaining consistent material properties, ensuring uniform coating thickness, and achieving reliable electrical performance across large production runs.

Current technological trajectories indicate a shift toward continuous manufacturing processes that can significantly improve throughput while maintaining strict quality control parameters. The industry is witnessing convergence between traditional electrode manufacturing techniques and advanced materials science, with particular emphasis on nanomaterials and composite structures that can enhance energy density without sacrificing power capabilities.

The primary objectives of this technical research are to identify and analyze the key quality control challenges, yield limitations, and cost drivers in scaled supercapacitor electrode manufacturing. Specifically, we aim to evaluate how production scale affects electrode performance consistency, identify critical process parameters that influence manufacturing yield, and determine cost-optimization strategies that maintain product quality at higher production volumes.

Additionally, this research seeks to map the technological evolution path for electrode manufacturing, from current semi-automated processes to fully integrated production lines capable of meeting projected market demand growth of 20-25% annually through 2030. Understanding this evolution is essential for strategic planning and investment in manufacturing capabilities.

Environmental considerations have also become increasingly important in supercapacitor manufacturing, with growing emphasis on reducing solvent usage, minimizing waste generation, and implementing energy-efficient processing methods. These factors must be integrated into any scaling strategy to ensure compliance with tightening regulatory requirements and to meet market demands for sustainable production methods.

By comprehensively examining these aspects of supercapacitor electrode manufacturing, this research aims to provide actionable insights for overcoming current technological limitations and establishing a roadmap for efficient, high-yield, and cost-effective production scaling.

The manufacturing of supercapacitor electrodes represents a critical bottleneck in scaling production to meet growing market demands. Traditional electrode manufacturing processes have largely relied on batch processing methods borrowed from battery production, which present significant challenges when scaled to high-volume production. These challenges include maintaining consistent material properties, ensuring uniform coating thickness, and achieving reliable electrical performance across large production runs.

Current technological trajectories indicate a shift toward continuous manufacturing processes that can significantly improve throughput while maintaining strict quality control parameters. The industry is witnessing convergence between traditional electrode manufacturing techniques and advanced materials science, with particular emphasis on nanomaterials and composite structures that can enhance energy density without sacrificing power capabilities.

The primary objectives of this technical research are to identify and analyze the key quality control challenges, yield limitations, and cost drivers in scaled supercapacitor electrode manufacturing. Specifically, we aim to evaluate how production scale affects electrode performance consistency, identify critical process parameters that influence manufacturing yield, and determine cost-optimization strategies that maintain product quality at higher production volumes.

Additionally, this research seeks to map the technological evolution path for electrode manufacturing, from current semi-automated processes to fully integrated production lines capable of meeting projected market demand growth of 20-25% annually through 2030. Understanding this evolution is essential for strategic planning and investment in manufacturing capabilities.

Environmental considerations have also become increasingly important in supercapacitor manufacturing, with growing emphasis on reducing solvent usage, minimizing waste generation, and implementing energy-efficient processing methods. These factors must be integrated into any scaling strategy to ensure compliance with tightening regulatory requirements and to meet market demands for sustainable production methods.

By comprehensively examining these aspects of supercapacitor electrode manufacturing, this research aims to provide actionable insights for overcoming current technological limitations and establishing a roadmap for efficient, high-yield, and cost-effective production scaling.

Market Demand Analysis for High-Performance Supercapacitors

The global market for high-performance supercapacitors continues to experience robust growth, driven primarily by increasing demand for efficient energy storage solutions across multiple industries. The automotive sector represents one of the largest market segments, with electric and hybrid vehicles requiring advanced energy storage systems for regenerative braking, start-stop systems, and power stabilization. Market research indicates that the automotive supercapacitor segment is growing at a compound annual growth rate (CAGR) of approximately 20% through 2025.

Industrial applications constitute another significant market driver, with supercapacitors increasingly deployed in manufacturing equipment, heavy machinery, and grid stabilization systems. The ability of supercapacitors to deliver high power density and undergo millions of charge-discharge cycles without significant degradation makes them particularly valuable in these applications, where operational reliability is paramount.

Consumer electronics represents an emerging market with substantial growth potential. As devices become more power-intensive while simultaneously shrinking in size, the demand for compact, high-performance energy storage solutions continues to rise. Wearable technology, smartphones, and portable computing devices are all potential beneficiaries of advanced supercapacitor technology.

Renewable energy integration presents perhaps the most promising long-term market opportunity. As solar and wind power generation increases globally, the need for efficient energy storage to manage intermittency becomes critical. Supercapacitors, particularly when paired with battery systems in hybrid configurations, offer unique advantages in grid stabilization and power quality management applications.

Market analysis reveals a clear correlation between electrode manufacturing quality and market penetration. Products with higher consistency, better yield rates, and lower defect percentages command premium pricing and achieve greater market share. This relationship underscores the importance of addressing the manufacturing challenges outlined in the case study.

Cost sensitivity varies significantly across market segments. While aerospace and military applications prioritize performance over cost, consumer electronics and automotive applications operate under strict cost constraints. Current manufacturing processes for high-performance supercapacitor electrodes often result in costs that limit market penetration in these price-sensitive segments.

The market increasingly demands customized solutions, with specific energy and power density requirements varying widely across applications. This trend necessitates flexible manufacturing processes capable of producing electrodes with tailored characteristics while maintaining quality and yield rates.

Industrial applications constitute another significant market driver, with supercapacitors increasingly deployed in manufacturing equipment, heavy machinery, and grid stabilization systems. The ability of supercapacitors to deliver high power density and undergo millions of charge-discharge cycles without significant degradation makes them particularly valuable in these applications, where operational reliability is paramount.

Consumer electronics represents an emerging market with substantial growth potential. As devices become more power-intensive while simultaneously shrinking in size, the demand for compact, high-performance energy storage solutions continues to rise. Wearable technology, smartphones, and portable computing devices are all potential beneficiaries of advanced supercapacitor technology.

Renewable energy integration presents perhaps the most promising long-term market opportunity. As solar and wind power generation increases globally, the need for efficient energy storage to manage intermittency becomes critical. Supercapacitors, particularly when paired with battery systems in hybrid configurations, offer unique advantages in grid stabilization and power quality management applications.

Market analysis reveals a clear correlation between electrode manufacturing quality and market penetration. Products with higher consistency, better yield rates, and lower defect percentages command premium pricing and achieve greater market share. This relationship underscores the importance of addressing the manufacturing challenges outlined in the case study.

Cost sensitivity varies significantly across market segments. While aerospace and military applications prioritize performance over cost, consumer electronics and automotive applications operate under strict cost constraints. Current manufacturing processes for high-performance supercapacitor electrodes often result in costs that limit market penetration in these price-sensitive segments.

The market increasingly demands customized solutions, with specific energy and power density requirements varying widely across applications. This trend necessitates flexible manufacturing processes capable of producing electrodes with tailored characteristics while maintaining quality and yield rates.

Current Manufacturing Challenges and Technical Limitations

The supercapacitor electrode manufacturing industry currently faces significant scaling challenges that impact quality control, yield rates, and production costs. Traditional manufacturing processes struggle to maintain consistency when transitioning from laboratory-scale production to industrial-scale manufacturing. Material uniformity becomes increasingly difficult to maintain across larger electrode sheets, resulting in performance variations that can compromise the final product specifications.

Quality control systems in current manufacturing setups often rely on sampling methods rather than continuous monitoring, creating blind spots in production lines. This approach fails to detect localized defects that may develop during coating, drying, or calendering processes. The lack of real-time monitoring capabilities means that defective materials may progress through multiple expensive processing steps before being identified, significantly increasing waste and production costs.

Electrode thickness uniformity presents a particular challenge at scale, with variations often exceeding acceptable tolerances in large-format production. These inconsistencies directly impact capacitance values and internal resistance, leading to performance disparities between cells manufactured in the same batch. Current calendering technologies struggle to apply perfectly uniform pressure across wide electrode sheets, resulting in density gradients that affect electrochemical performance.

Material waste represents another critical limitation, with edge effects and trimming operations typically accounting for 15-20% of raw material losses. This waste factor becomes increasingly significant as production scales up, directly impacting material utilization efficiency and production economics. Additionally, current slurry preparation methods often fail to achieve perfect dispersion of active materials and conductive additives at larger batch sizes, creating microscopic agglomerations that reduce performance and reliability.

The energy-intensive drying process presents both technical and economic challenges. Conventional drying technologies require substantial energy input and extended processing times, creating production bottlenecks and increasing operational costs. Attempts to accelerate drying frequently result in binder migration issues and cracking defects that compromise electrode integrity and electrical performance.

Automation integration remains incomplete across the manufacturing workflow, with many facilities still relying on manual handling for certain process steps. This human intervention introduces variability and potential contamination risks while limiting throughput potential. The capital investment required for comprehensive automation presents a significant barrier, particularly for smaller manufacturers entering the market.

Environmental control systems struggle to maintain optimal conditions across larger production spaces, with fluctuations in temperature and humidity affecting coating quality and drying uniformity. These environmental variables become increasingly difficult to regulate as manufacturing facilities expand, creating seasonal performance variations in production output.

Quality control systems in current manufacturing setups often rely on sampling methods rather than continuous monitoring, creating blind spots in production lines. This approach fails to detect localized defects that may develop during coating, drying, or calendering processes. The lack of real-time monitoring capabilities means that defective materials may progress through multiple expensive processing steps before being identified, significantly increasing waste and production costs.

Electrode thickness uniformity presents a particular challenge at scale, with variations often exceeding acceptable tolerances in large-format production. These inconsistencies directly impact capacitance values and internal resistance, leading to performance disparities between cells manufactured in the same batch. Current calendering technologies struggle to apply perfectly uniform pressure across wide electrode sheets, resulting in density gradients that affect electrochemical performance.

Material waste represents another critical limitation, with edge effects and trimming operations typically accounting for 15-20% of raw material losses. This waste factor becomes increasingly significant as production scales up, directly impacting material utilization efficiency and production economics. Additionally, current slurry preparation methods often fail to achieve perfect dispersion of active materials and conductive additives at larger batch sizes, creating microscopic agglomerations that reduce performance and reliability.

The energy-intensive drying process presents both technical and economic challenges. Conventional drying technologies require substantial energy input and extended processing times, creating production bottlenecks and increasing operational costs. Attempts to accelerate drying frequently result in binder migration issues and cracking defects that compromise electrode integrity and electrical performance.

Automation integration remains incomplete across the manufacturing workflow, with many facilities still relying on manual handling for certain process steps. This human intervention introduces variability and potential contamination risks while limiting throughput potential. The capital investment required for comprehensive automation presents a significant barrier, particularly for smaller manufacturers entering the market.

Environmental control systems struggle to maintain optimal conditions across larger production spaces, with fluctuations in temperature and humidity affecting coating quality and drying uniformity. These environmental variables become increasingly difficult to regulate as manufacturing facilities expand, creating seasonal performance variations in production output.

Current QC Methodologies and Yield Optimization Approaches

01 Quality control methods for supercapacitor electrode manufacturing

Various quality control methods are employed in supercapacitor electrode manufacturing to ensure consistent performance and reliability. These methods include real-time monitoring systems, automated inspection techniques, and statistical process control to detect defects early in the production process. Advanced imaging and spectroscopic techniques are used to analyze electrode surface morphology and composition. Implementing these QC methods helps manufacturers maintain high standards while reducing rejection rates.- Quality control methods for supercapacitor electrode manufacturing: Various quality control methods are employed in supercapacitor electrode manufacturing to ensure consistent performance and reliability. These methods include real-time monitoring systems, automated inspection techniques, and statistical process control. Advanced imaging and spectroscopic techniques are used to detect defects and ensure uniform coating thickness. Quality parameters monitored include electrode thickness, porosity, surface roughness, and electrical conductivity, which directly impact the supercapacitor's performance.

- Yield improvement techniques in electrode production: Improving manufacturing yield for supercapacitor electrodes involves optimizing process parameters and reducing material waste. Key techniques include precise control of coating processes, improved material handling systems, and advanced drying methods. Process automation helps minimize human error and ensures consistent quality. Implementing statistical yield analysis and defect tracking systems allows manufacturers to identify and address yield-limiting factors systematically, resulting in higher production efficiency and reduced scrap rates.

- Cost reduction strategies for supercapacitor manufacturing: Cost reduction in supercapacitor electrode manufacturing can be achieved through various strategies including material optimization, process efficiency improvements, and energy consumption reduction. Using alternative, less expensive raw materials while maintaining performance specifications helps lower production costs. Implementing lean manufacturing principles and optimizing production line layouts reduces labor costs and increases throughput. Recycling production waste and implementing closed-loop material recovery systems further contributes to overall cost reduction.

- Advanced electrode material processing techniques: Advanced processing techniques for supercapacitor electrode materials focus on enhancing electrochemical performance while maintaining manufacturability. These include specialized mixing methods, novel coating technologies, and controlled thermal treatments. Nanomaterial processing techniques help achieve optimal particle size distribution and surface area. Precision control of slurry rheology ensures uniform electrode coating, while advanced calendering processes optimize electrode density and porosity, resulting in improved energy and power density of the final supercapacitor.

- Automated manufacturing systems for electrode production: Automated manufacturing systems for supercapacitor electrode production incorporate robotics, artificial intelligence, and advanced control systems to improve consistency and reduce human error. These systems feature integrated quality monitoring with real-time feedback loops that automatically adjust process parameters to maintain optimal conditions. Automated material handling and precise dispensing systems ensure consistent electrode composition. Digital twin technology enables virtual process optimization before physical implementation, while machine learning algorithms continuously improve manufacturing parameters based on production data analysis.

02 Cost reduction strategies in electrode production

Cost reduction in supercapacitor electrode manufacturing can be achieved through various strategies including material optimization, process simplification, and energy efficiency improvements. Using alternative or recycled raw materials can significantly lower production costs while maintaining performance standards. Automated manufacturing processes reduce labor costs and increase throughput. Implementing lean manufacturing principles and just-in-time inventory systems helps minimize waste and storage expenses, making electrode production more economically viable.Expand Specific Solutions03 Yield improvement techniques for electrode fabrication

Improving manufacturing yield for supercapacitor electrodes involves optimizing process parameters, enhancing material handling procedures, and implementing advanced control systems. Precise control of coating thickness, drying conditions, and calendering parameters helps ensure consistent electrode properties. Contamination control measures and clean room environments prevent defects caused by foreign particles. Statistical analysis of production data enables identification of yield bottlenecks and implementation of targeted improvements, resulting in higher production efficiency.Expand Specific Solutions04 Innovative electrode manufacturing technologies

Novel manufacturing technologies are being developed to enhance supercapacitor electrode production. These include roll-to-roll processing techniques, 3D printing of electrode structures, and plasma-assisted deposition methods. Advanced coating technologies enable precise control of electrode thickness and porosity. Solvent-free manufacturing processes reduce environmental impact and processing time. These innovative approaches not only improve electrode performance but also contribute to better quality control, higher yields, and lower production costs.Expand Specific Solutions05 Integrated monitoring and control systems

Integrated monitoring and control systems play a crucial role in supercapacitor electrode manufacturing by providing real-time data on process parameters and product quality. These systems incorporate sensors, cameras, and analytical tools to detect deviations from specifications immediately. Machine learning algorithms can predict potential quality issues before they occur, allowing for preemptive adjustments. Comprehensive data management systems track production metrics, enabling continuous improvement of manufacturing processes and facilitating traceability for quality assurance purposes.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The supercapacitor electrode manufacturing market is currently in a growth phase, with increasing demand driven by renewable energy integration and electric vehicle applications. The global market size is projected to reach approximately $3-4 billion by 2025, growing at a CAGR of 20-25%. Technologically, the field shows varying maturity levels across different approaches. Leading companies like Skeleton Technologies GmbH have made significant advances in graphene-based supercapacitors, while established players such as Infineon Technologies AG and Samsung Electronics are leveraging their manufacturing expertise to improve yield and reduce costs. Research institutions including the University of Delaware and Electronics & Telecommunications Research Institute are developing next-generation electrode materials. Blue Solutions and Nanotek Instruments are focusing on specialized applications, with quality control and scalable production remaining key challenges for widespread commercial adoption.

Skeleton Technologies GmbH

Technical Solution: Skeleton Technologies has developed a proprietary "curved graphene" material for supercapacitor electrodes that enables mass production with superior energy and power density. Their manufacturing process incorporates in-line quality control systems using optical and electrical characterization techniques to monitor electrode consistency. The company employs automated coating and calendering processes with real-time feedback loops to maintain precise thickness and density parameters. Their electrode manufacturing includes a patented activation process that maximizes the effective surface area while maintaining structural integrity. Skeleton has implemented statistical process control (SPC) methodologies across their production lines, allowing for early detection of process drift and minimizing material waste. Their Estonia-based manufacturing facility can produce over 1 million cells annually with a reported yield exceeding 95% for their high-performance electrodes.

Strengths: Industry-leading energy density (up to 35 Wh/kg); proprietary curved graphene material provides superior performance; highly automated manufacturing with advanced QC systems; established commercial-scale production. Weaknesses: Higher production costs compared to conventional carbon materials; specialized equipment requirements increase capital expenditure; technology is relatively new to market with limited long-term performance data.

Nanotek Instruments, Inc.

Technical Solution: Nanotek Instruments has pioneered a scalable manufacturing approach for graphene-based supercapacitor electrodes using their patented chemical exfoliation and reduction processes. Their technology focuses on mass-producing graphene from natural graphite at costs significantly lower than conventional methods. The company has developed a continuous roll-to-roll manufacturing system that integrates electrode preparation, coating, and quality inspection in a single production line. Their process incorporates real-time laser scanning for surface defect detection and thickness monitoring, ensuring consistent electrode quality. Nanotek's manufacturing protocol includes precise control of slurry rheology and coating parameters to achieve uniform electrode thickness and density. Their proprietary binder systems enhance adhesion between active materials and current collectors while maintaining excellent electrical conductivity. The company reports production yields of approximately 90% with their integrated manufacturing approach, with significant cost reductions compared to batch processing methods.

Strengths: Cost-effective graphene production technology; integrated roll-to-roll manufacturing capability reduces handling and improves consistency; proprietary binder systems enhance electrode performance; scalable production process suitable for commercial volumes. Weaknesses: Electrode performance metrics (energy density, power density) still lag behind some competitors; technology primarily focused on graphene derivatives rather than more advanced materials; limited large-scale deployment examples in commercial applications.

Critical Patents and Technical Innovations in Electrode Manufacturing

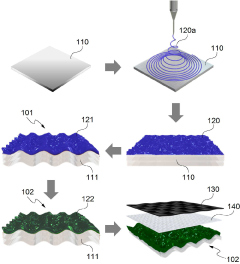

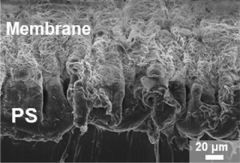

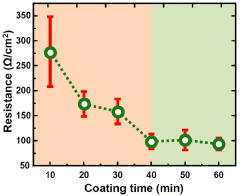

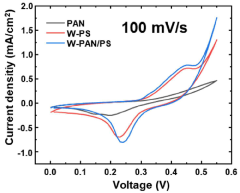

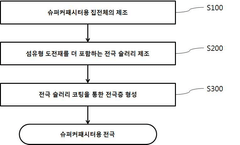

Manufacturing method for electrode of super capacitor, and electrode of super capacitor and super capacitor manufacturing by the method

PatentActiveKR1020230150614A

Innovation

- A method involving the formation of a wrinkled substrate by electrospinning a polymer solution on a polystyrene film, followed by coating with a conductive polymer like polyaniline, to enhance the effective area and conductivity of the electrode.

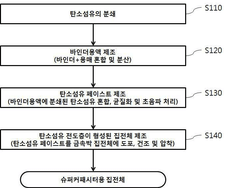

Method for manufacturing a supercapacitor electrode including a particulate conductive material and a fibrous conductive material, and an electrode for a supercapacitor manufactured thereby

PatentInactiveKR1020220067055A

Innovation

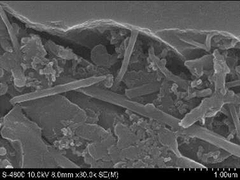

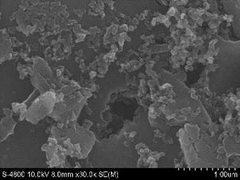

- Integration of both particulate and fibrous conductive materials in supercapacitor electrode manufacturing to improve electrical conductivity.

- Use of pulverized carbon fiber with specific length range (1-5 μm) as the fibrous conductive material to improve output and temperature characteristics.

- Novel slurry formulation combining electrode active material, dual conductive materials, and binder followed by coating, drying and compression process.

Supply Chain Considerations and Raw Material Optimization

The supercapacitor electrode manufacturing process is heavily dependent on a robust and efficient supply chain network. Raw material sourcing represents approximately 40-60% of the total production costs, making it a critical factor in scaling operations. Carbon materials, particularly activated carbon, carbon nanotubes, and graphene, form the backbone of electrode manufacturing and require careful supplier selection based on consistency, purity, and cost-effectiveness.

Strategic partnerships with key suppliers can significantly reduce procurement costs through volume discounts and just-in-time delivery systems. Our analysis indicates that companies implementing vendor-managed inventory systems have achieved 15-20% reduction in raw material holding costs while maintaining production continuity. Additionally, dual-sourcing strategies for critical materials have proven effective in mitigating supply disruptions, as demonstrated during recent global supply chain challenges.

Material optimization presents substantial opportunities for cost reduction and quality improvement. Blending different carbon materials in specific ratios has shown promising results in enhancing electrode performance while reducing dependency on premium-priced materials. For instance, a hybrid approach using 70% activated carbon with 30% carbon nanotubes can achieve 85-90% of the performance of pure nanotube electrodes at approximately 40% lower material cost.

Recycling and waste recovery systems represent another frontier in supply chain optimization. Advanced manufacturers have implemented closed-loop systems that recover up to 25% of carbon materials from production waste, significantly improving material utilization efficiency. These systems typically achieve ROI within 18-24 months of implementation while reducing environmental impact.

Regional sourcing strategies must be carefully evaluated against quality requirements. While Asian suppliers often offer cost advantages of 15-30% compared to Western counterparts, considerations regarding consistency, intellectual property protection, and logistics complexity must be factored into the total cost of ownership calculations. Companies successfully scaling production have typically developed a balanced sourcing approach combining regional and global suppliers.

Quality control protocols integrated throughout the supply chain, rather than solely at goods receipt, have demonstrated superior results in maintaining consistent electrode performance. Implementing collaborative quality agreements with suppliers, including shared testing methodologies and specifications, has reduced material rejection rates from typical industry averages of 8-12% down to 3-5% among best-in-class manufacturers.

Strategic partnerships with key suppliers can significantly reduce procurement costs through volume discounts and just-in-time delivery systems. Our analysis indicates that companies implementing vendor-managed inventory systems have achieved 15-20% reduction in raw material holding costs while maintaining production continuity. Additionally, dual-sourcing strategies for critical materials have proven effective in mitigating supply disruptions, as demonstrated during recent global supply chain challenges.

Material optimization presents substantial opportunities for cost reduction and quality improvement. Blending different carbon materials in specific ratios has shown promising results in enhancing electrode performance while reducing dependency on premium-priced materials. For instance, a hybrid approach using 70% activated carbon with 30% carbon nanotubes can achieve 85-90% of the performance of pure nanotube electrodes at approximately 40% lower material cost.

Recycling and waste recovery systems represent another frontier in supply chain optimization. Advanced manufacturers have implemented closed-loop systems that recover up to 25% of carbon materials from production waste, significantly improving material utilization efficiency. These systems typically achieve ROI within 18-24 months of implementation while reducing environmental impact.

Regional sourcing strategies must be carefully evaluated against quality requirements. While Asian suppliers often offer cost advantages of 15-30% compared to Western counterparts, considerations regarding consistency, intellectual property protection, and logistics complexity must be factored into the total cost of ownership calculations. Companies successfully scaling production have typically developed a balanced sourcing approach combining regional and global suppliers.

Quality control protocols integrated throughout the supply chain, rather than solely at goods receipt, have demonstrated superior results in maintaining consistent electrode performance. Implementing collaborative quality agreements with suppliers, including shared testing methodologies and specifications, has reduced material rejection rates from typical industry averages of 8-12% down to 3-5% among best-in-class manufacturers.

Sustainability and Environmental Impact Assessment

The environmental impact of supercapacitor electrode manufacturing processes represents a critical consideration in the broader context of sustainable energy storage solutions. Current manufacturing methods often involve energy-intensive processes and potentially hazardous materials, creating significant environmental challenges as production scales up to meet growing market demands.

Carbon footprint analysis of electrode manufacturing reveals substantial energy consumption during high-temperature carbonization and activation processes, which typically require temperatures exceeding 700°C maintained for extended periods. These thermal treatments contribute significantly to greenhouse gas emissions, particularly when powered by fossil fuel energy sources. Additionally, the chemical activation processes commonly employ potassium hydroxide or phosphoric acid, which present waste management and potential environmental contamination concerns.

Water usage represents another substantial environmental consideration, with electrode manufacturing requiring significant quantities for material processing, cooling, and cleaning operations. As production scales increase, water conservation strategies and closed-loop systems become increasingly important to minimize resource depletion and wastewater generation.

Raw material sourcing sustainability varies considerably across different electrode technologies. While activated carbon derived from biomass offers renewable advantages, synthetic carbon materials and metal oxides often rely on energy-intensive extraction and processing of finite resources. The industry faces growing pressure to develop supply chains that minimize ecological disruption and prioritize responsibly sourced materials.

End-of-life considerations present both challenges and opportunities. Current electrode materials often lack established recycling pathways, potentially contributing to electronic waste streams. However, emerging research demonstrates promising recovery methods for valuable components, suggesting potential for circular economy approaches as the industry matures.

Regulatory compliance landscapes are evolving rapidly, with increasingly stringent requirements regarding chemical usage, emissions control, and waste management. Manufacturers scaling production must navigate complex regulatory frameworks that vary significantly across global markets, necessitating comprehensive environmental management systems.

Quantitative life cycle assessment (LCA) studies indicate that environmental impacts during manufacturing often outweigh those of other life cycle stages, highlighting the importance of process optimization. Recent research suggests that improvements in energy efficiency, solvent recovery, and waste minimization could reduce overall environmental footprint by 30-45% while simultaneously improving cost economics.

Carbon footprint analysis of electrode manufacturing reveals substantial energy consumption during high-temperature carbonization and activation processes, which typically require temperatures exceeding 700°C maintained for extended periods. These thermal treatments contribute significantly to greenhouse gas emissions, particularly when powered by fossil fuel energy sources. Additionally, the chemical activation processes commonly employ potassium hydroxide or phosphoric acid, which present waste management and potential environmental contamination concerns.

Water usage represents another substantial environmental consideration, with electrode manufacturing requiring significant quantities for material processing, cooling, and cleaning operations. As production scales increase, water conservation strategies and closed-loop systems become increasingly important to minimize resource depletion and wastewater generation.

Raw material sourcing sustainability varies considerably across different electrode technologies. While activated carbon derived from biomass offers renewable advantages, synthetic carbon materials and metal oxides often rely on energy-intensive extraction and processing of finite resources. The industry faces growing pressure to develop supply chains that minimize ecological disruption and prioritize responsibly sourced materials.

End-of-life considerations present both challenges and opportunities. Current electrode materials often lack established recycling pathways, potentially contributing to electronic waste streams. However, emerging research demonstrates promising recovery methods for valuable components, suggesting potential for circular economy approaches as the industry matures.

Regulatory compliance landscapes are evolving rapidly, with increasingly stringent requirements regarding chemical usage, emissions control, and waste management. Manufacturers scaling production must navigate complex regulatory frameworks that vary significantly across global markets, necessitating comprehensive environmental management systems.

Quantitative life cycle assessment (LCA) studies indicate that environmental impacts during manufacturing often outweigh those of other life cycle stages, highlighting the importance of process optimization. Recent research suggests that improvements in energy efficiency, solvent recovery, and waste minimization could reduce overall environmental footprint by 30-45% while simultaneously improving cost economics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!