How to Fabricate a Binder-free Supercapacitor Electrode — Materials, Steps and Scale Notes

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Binder-free Supercapacitor Electrode Technology Background and Objectives

Supercapacitors have emerged as critical energy storage devices in the landscape of renewable energy systems and portable electronics due to their high power density, rapid charge-discharge capabilities, and extended cycle life. The evolution of supercapacitor technology has been marked by continuous improvements in electrode materials, electrolytes, and fabrication techniques since their commercial introduction in the late 1970s. Traditional supercapacitor electrodes typically incorporate polymeric binders to maintain structural integrity, but these binders often introduce limitations including decreased conductivity, reduced active material utilization, and compromised electrochemical performance.

Binder-free supercapacitor electrodes represent a significant technological advancement that addresses these fundamental limitations. By eliminating the non-conductive binder component, these electrodes offer enhanced electrical conductivity, improved ion transport kinetics, and maximized active material utilization. The development trajectory of binder-free electrodes has accelerated notably over the past decade, driven by innovations in nanomaterial synthesis and advanced fabrication techniques.

The primary objective of binder-free supercapacitor electrode technology is to achieve superior energy and power densities while maintaining excellent cycling stability. Current research aims to develop electrodes with capacitance values exceeding 1000 F/g, energy densities approaching 100 Wh/kg, and power densities above 10 kW/kg—metrics that would position supercapacitors as viable alternatives to batteries in certain applications.

Another critical goal is to develop scalable, cost-effective fabrication methods that can transition binder-free electrode technology from laboratory demonstrations to commercial production. This includes establishing reproducible processes for direct growth of active materials on conductive substrates, self-assembly techniques, and advanced deposition methods that maintain performance at larger scales.

Environmental sustainability represents an increasingly important objective in this field. Research is focused on developing binder-free electrodes using abundant, non-toxic materials through environmentally benign processes. This aligns with global initiatives to create greener energy storage solutions with reduced environmental footprints throughout their lifecycle.

The integration of binder-free electrodes with flexible and wearable electronics constitutes another significant technological goal. This requires developing electrodes that maintain performance under mechanical stress while conforming to various form factors—a challenge that demands innovative material design and fabrication approaches.

Looking forward, the field is moving toward multifunctional binder-free electrodes that combine energy storage capabilities with additional functionalities such as self-healing, self-charging, or sensing capabilities. This convergence of technologies aims to create next-generation energy storage systems that can adapt to diverse application requirements while delivering enhanced performance metrics.

Binder-free supercapacitor electrodes represent a significant technological advancement that addresses these fundamental limitations. By eliminating the non-conductive binder component, these electrodes offer enhanced electrical conductivity, improved ion transport kinetics, and maximized active material utilization. The development trajectory of binder-free electrodes has accelerated notably over the past decade, driven by innovations in nanomaterial synthesis and advanced fabrication techniques.

The primary objective of binder-free supercapacitor electrode technology is to achieve superior energy and power densities while maintaining excellent cycling stability. Current research aims to develop electrodes with capacitance values exceeding 1000 F/g, energy densities approaching 100 Wh/kg, and power densities above 10 kW/kg—metrics that would position supercapacitors as viable alternatives to batteries in certain applications.

Another critical goal is to develop scalable, cost-effective fabrication methods that can transition binder-free electrode technology from laboratory demonstrations to commercial production. This includes establishing reproducible processes for direct growth of active materials on conductive substrates, self-assembly techniques, and advanced deposition methods that maintain performance at larger scales.

Environmental sustainability represents an increasingly important objective in this field. Research is focused on developing binder-free electrodes using abundant, non-toxic materials through environmentally benign processes. This aligns with global initiatives to create greener energy storage solutions with reduced environmental footprints throughout their lifecycle.

The integration of binder-free electrodes with flexible and wearable electronics constitutes another significant technological goal. This requires developing electrodes that maintain performance under mechanical stress while conforming to various form factors—a challenge that demands innovative material design and fabrication approaches.

Looking forward, the field is moving toward multifunctional binder-free electrodes that combine energy storage capabilities with additional functionalities such as self-healing, self-charging, or sensing capabilities. This convergence of technologies aims to create next-generation energy storage systems that can adapt to diverse application requirements while delivering enhanced performance metrics.

Market Analysis for Binder-free Energy Storage Solutions

The global market for binder-free energy storage solutions is experiencing significant growth, driven by increasing demand for high-performance energy storage devices across multiple sectors. The supercapacitor market specifically is projected to reach $16.95 billion by 2027, with a compound annual growth rate of 23.3% from 2020. Binder-free electrodes represent an emerging segment within this market, offering enhanced performance characteristics that traditional binder-based systems cannot match.

Consumer electronics remains the largest application segment, accounting for approximately 32% of the total market share. This is followed by automotive applications at 28%, renewable energy storage at 18%, industrial systems at 14%, and other applications comprising the remaining 8%. The automotive sector is experiencing the fastest growth rate as electric vehicles and hybrid electric vehicles continue to gain market traction.

Regionally, Asia-Pacific dominates the market with 45% share, led by China, Japan, and South Korea where major manufacturers have established production facilities. North America follows with 27% market share, while Europe accounts for 21%. The remaining regions collectively represent 7% of the global market. China specifically has shown remarkable growth, with domestic production capacity increasing by 35% annually over the past three years.

Market demand is primarily driven by the superior performance characteristics of binder-free electrodes, including higher energy density, improved power density, and extended cycle life. End-users are increasingly willing to pay premium prices for these advantages, with price premiums ranging from 15% to 40% compared to conventional technologies.

Key market restraints include high production costs, with binder-free manufacturing processes currently costing 30-50% more than traditional methods. Technical challenges in scaling production and ensuring consistent quality also limit market penetration. However, recent technological advancements have reduced production costs by approximately 18% compared to 2018 levels.

The market shows strong growth potential in emerging applications such as wearable electronics, medical devices, and aerospace systems. These sectors value the compact size and high performance that binder-free supercapacitors offer. Industry analysts predict that these emerging applications could represent a $3.2 billion opportunity by 2025.

Customer preferences increasingly favor sustainable and environmentally friendly energy storage solutions. Binder-free electrodes align with this trend as they typically eliminate the need for toxic solvents used in conventional electrode manufacturing processes, potentially reducing environmental impact by up to 40% across the product lifecycle.

Consumer electronics remains the largest application segment, accounting for approximately 32% of the total market share. This is followed by automotive applications at 28%, renewable energy storage at 18%, industrial systems at 14%, and other applications comprising the remaining 8%. The automotive sector is experiencing the fastest growth rate as electric vehicles and hybrid electric vehicles continue to gain market traction.

Regionally, Asia-Pacific dominates the market with 45% share, led by China, Japan, and South Korea where major manufacturers have established production facilities. North America follows with 27% market share, while Europe accounts for 21%. The remaining regions collectively represent 7% of the global market. China specifically has shown remarkable growth, with domestic production capacity increasing by 35% annually over the past three years.

Market demand is primarily driven by the superior performance characteristics of binder-free electrodes, including higher energy density, improved power density, and extended cycle life. End-users are increasingly willing to pay premium prices for these advantages, with price premiums ranging from 15% to 40% compared to conventional technologies.

Key market restraints include high production costs, with binder-free manufacturing processes currently costing 30-50% more than traditional methods. Technical challenges in scaling production and ensuring consistent quality also limit market penetration. However, recent technological advancements have reduced production costs by approximately 18% compared to 2018 levels.

The market shows strong growth potential in emerging applications such as wearable electronics, medical devices, and aerospace systems. These sectors value the compact size and high performance that binder-free supercapacitors offer. Industry analysts predict that these emerging applications could represent a $3.2 billion opportunity by 2025.

Customer preferences increasingly favor sustainable and environmentally friendly energy storage solutions. Binder-free electrodes align with this trend as they typically eliminate the need for toxic solvents used in conventional electrode manufacturing processes, potentially reducing environmental impact by up to 40% across the product lifecycle.

Current Challenges in Binder-free Electrode Fabrication

Despite significant advancements in binder-free supercapacitor electrode fabrication, several critical challenges continue to impede widespread commercial adoption and optimal performance. The primary technical obstacle remains achieving consistent mechanical stability without sacrificing electrochemical performance. Current binder-free electrodes often exhibit poor adhesion between active materials and current collectors, resulting in material detachment during cycling and consequent capacity fading.

Scalability presents another major hurdle, as most successful binder-free fabrication techniques have been demonstrated only at laboratory scale. The transition from small-scale production to industrial manufacturing faces difficulties in maintaining uniform material deposition, consistent porosity, and structural integrity across larger surface areas. This scale-up challenge is particularly pronounced for techniques like chemical vapor deposition and hydrothermal growth that require precise control of reaction conditions.

Process complexity and reproducibility constitute significant barriers to standardization. Many advanced fabrication methods such as electrodeposition, hydrothermal synthesis, and chemical vapor deposition demand sophisticated equipment, precise parameter control, and extensive optimization. The sensitivity of these processes to minor variations in conditions often leads to batch-to-batch inconsistencies, hampering quality control in production environments.

Cost-effectiveness remains problematic as numerous binder-free fabrication approaches utilize expensive precursors, catalysts, or energy-intensive processes. The economic viability of these methods is questionable when compared to conventional binder-based technologies, especially considering the additional capital investment required for specialized equipment.

Material selection limitations further constrain innovation, as not all electroactive materials are compatible with direct growth or deposition techniques. This restricts the diversity of materials that can be incorporated into binder-free architectures, potentially limiting performance optimization for specific applications.

Environmental and safety concerns have emerged regarding certain fabrication methods that employ hazardous chemicals, generate toxic byproducts, or require extreme processing conditions. These issues must be addressed to ensure sustainable manufacturing practices and workplace safety.

Lastly, the integration challenge persists when incorporating binder-free electrodes into complete device architectures. The interface between the electrode and other components (electrolytes, separators, packaging) often requires redesign of assembly processes and compatibility testing, adding complexity to the manufacturing pipeline and potentially introducing new failure modes in the final supercapacitor devices.

Scalability presents another major hurdle, as most successful binder-free fabrication techniques have been demonstrated only at laboratory scale. The transition from small-scale production to industrial manufacturing faces difficulties in maintaining uniform material deposition, consistent porosity, and structural integrity across larger surface areas. This scale-up challenge is particularly pronounced for techniques like chemical vapor deposition and hydrothermal growth that require precise control of reaction conditions.

Process complexity and reproducibility constitute significant barriers to standardization. Many advanced fabrication methods such as electrodeposition, hydrothermal synthesis, and chemical vapor deposition demand sophisticated equipment, precise parameter control, and extensive optimization. The sensitivity of these processes to minor variations in conditions often leads to batch-to-batch inconsistencies, hampering quality control in production environments.

Cost-effectiveness remains problematic as numerous binder-free fabrication approaches utilize expensive precursors, catalysts, or energy-intensive processes. The economic viability of these methods is questionable when compared to conventional binder-based technologies, especially considering the additional capital investment required for specialized equipment.

Material selection limitations further constrain innovation, as not all electroactive materials are compatible with direct growth or deposition techniques. This restricts the diversity of materials that can be incorporated into binder-free architectures, potentially limiting performance optimization for specific applications.

Environmental and safety concerns have emerged regarding certain fabrication methods that employ hazardous chemicals, generate toxic byproducts, or require extreme processing conditions. These issues must be addressed to ensure sustainable manufacturing practices and workplace safety.

Lastly, the integration challenge persists when incorporating binder-free electrodes into complete device architectures. The interface between the electrode and other components (electrolytes, separators, packaging) often requires redesign of assembly processes and compatibility testing, adding complexity to the manufacturing pipeline and potentially introducing new failure modes in the final supercapacitor devices.

Current Fabrication Methods for Binder-free Electrodes

01 Direct growth methods for binder-free electrodes

Direct growth methods involve growing active materials directly onto conductive substrates without using binders. Techniques such as hydrothermal synthesis, chemical vapor deposition, and electrodeposition allow for the formation of well-adhered active materials on substrates like carbon cloth, metal foils, or 3D frameworks. These methods create strong interfaces between the active material and substrate, enhancing electrical conductivity and eliminating the need for binders that can reduce performance.- Direct growth methods for binder-free electrodes: Direct growth methods involve growing active materials directly on conductive substrates without using binders. Techniques such as chemical vapor deposition, hydrothermal synthesis, and electrodeposition allow for the formation of active materials like metal oxides, carbon nanostructures, or conductive polymers directly on substrates such as carbon cloth, metal foils, or graphene. This approach creates strong adhesion between the active material and substrate, eliminating the need for binders while improving electrical conductivity and electrochemical performance.

- Self-assembly techniques for binder-free electrodes: Self-assembly techniques utilize the intrinsic properties of materials to form structured electrodes without binders. These methods involve the spontaneous organization of active materials through interactions such as van der Waals forces, hydrogen bonding, or electrostatic attractions. Self-assembled electrodes can form 3D networks, hierarchical structures, or interwoven architectures that provide mechanical stability while maintaining high surface area and efficient ion transport pathways, resulting in enhanced capacitance and cycling stability.

- Carbon-based binder-free electrode fabrication: Carbon-based binder-free electrodes utilize various carbon allotropes such as graphene, carbon nanotubes, or activated carbon to create self-supporting structures. Fabrication methods include vacuum filtration, freeze-drying, template-assisted growth, and laser scribing. These techniques create interconnected carbon networks with high electrical conductivity, large surface area, and good mechanical integrity. The resulting electrodes offer excellent electrochemical performance with fast electron transport and efficient ion diffusion without the limitations introduced by insulating binder materials.

- Metal oxide/hydroxide-based binder-free electrode fabrication: Metal oxide or hydroxide-based binder-free electrodes are fabricated using methods such as electrodeposition, anodization, hydrothermal synthesis, or chemical bath deposition. These techniques allow for the direct growth of pseudocapacitive materials like nickel hydroxide, manganese oxide, or cobalt oxide on conductive substrates. The resulting electrodes exhibit high specific capacitance due to the faradaic reactions while maintaining good mechanical stability and electrical contact without requiring polymer binders that would otherwise limit performance.

- Composite and hybrid binder-free electrode structures: Composite and hybrid binder-free electrodes combine multiple active materials to create synergistic effects without using traditional binders. These electrodes often integrate carbon materials with metal oxides/hydroxides or conductive polymers through methods such as layer-by-layer deposition, co-deposition, or sequential growth processes. The resulting hierarchical structures leverage the high conductivity of carbon materials with the high capacitance of pseudocapacitive materials, creating electrodes with enhanced energy density, power density, and cycling stability while maintaining mechanical integrity.

02 Carbon-based binder-free electrode fabrication

Carbon-based materials such as graphene, carbon nanotubes, and activated carbon can be processed into self-supporting structures without binders. Techniques include vacuum filtration to create free-standing films, freeze-drying to produce aerogels, and direct carbonization of precursors on substrates. These carbon-based binder-free electrodes offer excellent electrical conductivity, high surface area, and mechanical flexibility, making them ideal for high-performance supercapacitors.Expand Specific Solutions03 Metal oxide/hydroxide nanostructure synthesis

Metal oxides and hydroxides can be synthesized as nanostructures directly on conductive substrates to create binder-free electrodes. Methods include electrodeposition, anodization, and solution-based growth techniques that create arrays of nanowires, nanosheets, or 3D hierarchical structures. These nanostructured materials provide high surface area and short ion diffusion paths, enhancing the electrochemical performance of supercapacitor electrodes without requiring binders.Expand Specific Solutions04 Composite electrode fabrication techniques

Composite binder-free electrodes combine multiple active materials to achieve synergistic effects. Fabrication methods include layer-by-layer assembly, co-deposition techniques, and in-situ growth of one material on another. These composites often pair carbon materials with metal compounds or conductive polymers to enhance both electrical conductivity and electrochemical activity, resulting in superior energy and power densities without the limitations imposed by binders.Expand Specific Solutions05 Post-processing treatments for performance enhancement

Post-processing treatments can significantly improve the performance of binder-free supercapacitor electrodes. These include thermal annealing to improve crystallinity and remove defects, surface modification to enhance wettability and ion accessibility, and activation processes to increase surface area. Electrochemical activation and plasma treatments can also be employed to optimize the interface properties and create additional active sites for charge storage, maximizing the performance of binder-free electrodes.Expand Specific Solutions

Leading Companies and Research Institutions in Supercapacitor Technology

The supercapacitor electrode fabrication market is currently in a growth phase, with an estimated global market size of $2-3 billion and projected annual growth of 20-25%. The technology landscape shows varying maturity levels across different approaches. Academic institutions like Central South University, Ulsan National Institute of Science & Technology, and Xi'an Jiaotong University are pioneering fundamental research, while commercial entities including Blue Solutions, Samsung Electro-Mechanics, and Capacitech Energy are advancing practical applications. The competitive landscape reveals three distinct segments: established electronics manufacturers (Samsung, KEPCO) leveraging existing infrastructure; specialized energy storage companies (Nanocomp Technologies, BatScap) focusing on proprietary technologies; and research institutions collaborating with industry partners to bridge the lab-to-market gap. Material innovation remains the primary competitive differentiator in this rapidly evolving field.

Nanocomp Technologies, Inc.

Technical Solution: Nanocomp Technologies has developed an advanced manufacturing platform for binder-free supercapacitor electrodes based on their proprietary carbon nanotube (CNT) sheet and yarn technologies. Their process involves direct synthesis of millimeter-long CNTs through catalytic chemical vapor deposition, followed by proprietary post-processing to create self-supporting, highly conductive sheets without requiring binders. The company has scaled this technology to produce continuous CNT sheets up to 1.2m wide with controlled thickness (10-100 μm). These sheets serve as both active material and current collector, eliminating multiple components in traditional designs. Their manufacturing process includes optional activation steps using KOH treatment at controlled temperatures (700-850°C) to increase surface area from 200 to over 1000 m²/g. Nanocomp's electrodes demonstrate exceptional mechanical properties (tensile strength >200 MPa) while delivering specific capacitances of 120-150 F/g with nearly 100% capacity retention after 100,000 cycles.

Strengths: Dual functionality as both active material and current collector reduces component count; exceptional mechanical properties enable flexible and structural energy storage; highly scalable continuous production process. Weaknesses: Higher raw material costs compared to activated carbon approaches; specialized equipment requirements for CNT synthesis; limited volumetric energy density compared to some pseudocapacitive materials.

Nanotek Instruments Group LLC

Technical Solution: Nanotek Instruments has developed a groundbreaking approach to fabricating binder-free supercapacitor electrodes using graphene-based materials. Their patented process involves direct deposition of graphene onto current collectors through chemical vapor deposition (CVD), eliminating the need for polymeric binders. The company has pioneered a scalable manufacturing technique that creates 3D porous graphene networks with exceptional surface area (>2000 m²/g) and electrical conductivity. Their process includes controlled thermal reduction of graphene oxide at temperatures between 600-1000°C in inert atmosphere, followed by nitrogen doping to enhance capacitance. Nanotek's electrodes demonstrate specific capacitances exceeding 350 F/g with 98% capacity retention after 10,000 cycles, significantly outperforming conventional electrodes that use PVDF or other binders.

Strengths: Superior electrical conductivity without resistance from binders; excellent mechanical integrity; enhanced ion transport pathways through 3D architecture; scalable manufacturing process. Weaknesses: Higher production costs compared to conventional methods; requires specialized equipment for CVD processes; thermal reduction steps are energy-intensive.

Key Materials and Structural Innovations for Enhanced Performance

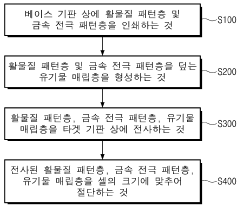

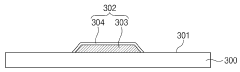

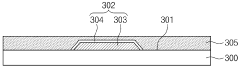

A method of fabrication of supercapacitor electrode

PatentInactiveKR1020200066511A

Innovation

- A manufacturing method involving sequential printing of active and metal electrode pattern layers on a base substrate, followed by an organic buried layer, lamination, delamination, and transfer to a target substrate, ensuring a flat surface.

Environmental Impact and Sustainability Considerations

The fabrication of binder-free supercapacitor electrodes represents a significant advancement in sustainable energy storage technology. When evaluating the environmental impact and sustainability considerations of these manufacturing processes, several critical factors emerge that warrant careful examination.

Traditional supercapacitor electrode fabrication typically involves polymer binders that often derive from non-renewable petroleum sources. The elimination of these binders not only simplifies the production process but also substantially reduces the environmental footprint by decreasing the use of toxic solvents like N-Methyl-2-pyrrolidone (NMP), which is commonly employed in conventional electrode preparation.

The materials selection for binder-free electrodes significantly influences their environmental profile. Carbon-based materials such as graphene, carbon nanotubes, and activated carbon can be derived from renewable sources or waste products, offering circular economy benefits. Metal oxides used in pseudocapacitive electrodes, however, may involve energy-intensive mining operations and potentially toxic extraction processes, necessitating careful sourcing and life cycle assessment.

Energy consumption during fabrication represents another crucial sustainability factor. Methods like hydrothermal synthesis and chemical vapor deposition often require substantial energy inputs, whereas techniques such as electrodeposition and direct growth can be more energy-efficient when optimized properly. The implementation of renewable energy sources for powering these manufacturing processes could further enhance their sustainability credentials.

Water usage and waste generation during electrode fabrication also merit consideration. Hydrothermal methods typically consume significant water resources, while certain chemical processes may generate hazardous waste streams requiring specialized treatment. Closed-loop systems that recycle process water and recover valuable materials from waste streams can substantially mitigate these impacts.

The longevity and end-of-life management of binder-free electrodes contribute significantly to their overall sustainability profile. Their enhanced mechanical stability often translates to extended operational lifespans, reducing replacement frequency and associated resource consumption. Additionally, the absence of binders potentially simplifies recycling processes, allowing more efficient recovery of valuable electrode materials at end-of-life.

Scale-up considerations introduce additional environmental dimensions. While laboratory-scale production may demonstrate promising sustainability metrics, industrial-scale manufacturing may encounter efficiency challenges that affect the overall environmental footprint. Continuous production methods generally offer improved resource efficiency compared to batch processes when implemented at commercial scales.

Traditional supercapacitor electrode fabrication typically involves polymer binders that often derive from non-renewable petroleum sources. The elimination of these binders not only simplifies the production process but also substantially reduces the environmental footprint by decreasing the use of toxic solvents like N-Methyl-2-pyrrolidone (NMP), which is commonly employed in conventional electrode preparation.

The materials selection for binder-free electrodes significantly influences their environmental profile. Carbon-based materials such as graphene, carbon nanotubes, and activated carbon can be derived from renewable sources or waste products, offering circular economy benefits. Metal oxides used in pseudocapacitive electrodes, however, may involve energy-intensive mining operations and potentially toxic extraction processes, necessitating careful sourcing and life cycle assessment.

Energy consumption during fabrication represents another crucial sustainability factor. Methods like hydrothermal synthesis and chemical vapor deposition often require substantial energy inputs, whereas techniques such as electrodeposition and direct growth can be more energy-efficient when optimized properly. The implementation of renewable energy sources for powering these manufacturing processes could further enhance their sustainability credentials.

Water usage and waste generation during electrode fabrication also merit consideration. Hydrothermal methods typically consume significant water resources, while certain chemical processes may generate hazardous waste streams requiring specialized treatment. Closed-loop systems that recycle process water and recover valuable materials from waste streams can substantially mitigate these impacts.

The longevity and end-of-life management of binder-free electrodes contribute significantly to their overall sustainability profile. Their enhanced mechanical stability often translates to extended operational lifespans, reducing replacement frequency and associated resource consumption. Additionally, the absence of binders potentially simplifies recycling processes, allowing more efficient recovery of valuable electrode materials at end-of-life.

Scale-up considerations introduce additional environmental dimensions. While laboratory-scale production may demonstrate promising sustainability metrics, industrial-scale manufacturing may encounter efficiency challenges that affect the overall environmental footprint. Continuous production methods generally offer improved resource efficiency compared to batch processes when implemented at commercial scales.

Cost Analysis and Commercial Viability Assessment

The economic feasibility of binder-free supercapacitor electrodes represents a critical factor in their potential market adoption. Current manufacturing processes for traditional supercapacitor electrodes with binders typically cost between $20-35 per kilogram, depending on material selection and production scale. In contrast, binder-free fabrication methods can potentially reduce costs by 15-25% through elimination of binder materials and associated processing steps.

Material costs constitute approximately 60-70% of the total production expenses for binder-free electrodes. Carbon-based materials like graphene and carbon nanotubes range from $50-200 per kilogram at industrial scale, while transition metal oxides and hydroxides vary between $30-150 per kilogram. Conductive substrates such as nickel foam or carbon cloth add $15-40 per square meter to the overall cost structure.

Equipment investment presents a significant initial barrier, with specialized deposition systems requiring $100,000-500,000 capital expenditure. However, these costs can be amortized over large production volumes, contributing only $1-3 per kilogram to unit costs at scale. Energy consumption during hydrothermal synthesis, electrodeposition, or chemical vapor deposition processes adds $0.5-2 per kilogram depending on the specific technique employed.

Commercial viability assessment indicates promising market potential, with the global supercapacitor market projected to reach $5.4 billion by 2025, growing at a CAGR of 12.5%. Binder-free electrodes could potentially capture 15-20% of this market within the next five years, particularly in high-performance applications where their superior electrical conductivity and mechanical stability justify premium pricing.

Break-even analysis suggests that medium-scale production facilities (500-1000 kg/month) can achieve profitability within 2-3 years, assuming average selling prices of $45-60 per kilogram for finished electrodes. Large-scale production (>5000 kg/month) could reduce unit costs below $25 per kilogram, making these electrodes competitive with conventional alternatives even in cost-sensitive applications.

Sensitivity analysis reveals that material cost fluctuations present the highest risk factor, with a 20% increase in raw material prices potentially reducing profit margins by 12-15%. Process yield improvements of 10% could conversely enhance profitability by 8-10%, highlighting the importance of optimizing fabrication protocols and reducing material waste during manufacturing.

Material costs constitute approximately 60-70% of the total production expenses for binder-free electrodes. Carbon-based materials like graphene and carbon nanotubes range from $50-200 per kilogram at industrial scale, while transition metal oxides and hydroxides vary between $30-150 per kilogram. Conductive substrates such as nickel foam or carbon cloth add $15-40 per square meter to the overall cost structure.

Equipment investment presents a significant initial barrier, with specialized deposition systems requiring $100,000-500,000 capital expenditure. However, these costs can be amortized over large production volumes, contributing only $1-3 per kilogram to unit costs at scale. Energy consumption during hydrothermal synthesis, electrodeposition, or chemical vapor deposition processes adds $0.5-2 per kilogram depending on the specific technique employed.

Commercial viability assessment indicates promising market potential, with the global supercapacitor market projected to reach $5.4 billion by 2025, growing at a CAGR of 12.5%. Binder-free electrodes could potentially capture 15-20% of this market within the next five years, particularly in high-performance applications where their superior electrical conductivity and mechanical stability justify premium pricing.

Break-even analysis suggests that medium-scale production facilities (500-1000 kg/month) can achieve profitability within 2-3 years, assuming average selling prices of $45-60 per kilogram for finished electrodes. Large-scale production (>5000 kg/month) could reduce unit costs below $25 per kilogram, making these electrodes competitive with conventional alternatives even in cost-sensitive applications.

Sensitivity analysis reveals that material cost fluctuations present the highest risk factor, with a 20% increase in raw material prices potentially reducing profit margins by 12-15%. Process yield improvements of 10% could conversely enhance profitability by 8-10%, highlighting the importance of optimizing fabrication protocols and reducing material waste during manufacturing.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!