Supercapacitor Aging Tests: Calendaring, Cycling and Environmental Stressors — Protocols

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Supercapacitor Aging Mechanisms and Test Objectives

Supercapacitors, also known as ultracapacitors or electric double-layer capacitors (EDLCs), experience performance degradation over time due to various aging mechanisms. Understanding these mechanisms is crucial for developing effective testing protocols that can accurately predict device lifetime and reliability in real-world applications. The primary aging mechanisms in supercapacitors include electrode material degradation, electrolyte decomposition, and interface deterioration between electrodes and electrolytes.

Electrode material degradation manifests through structural changes in the carbon-based materials, including pore blocking, surface group modifications, and particle agglomeration. These changes directly impact the available surface area for charge storage, leading to capacity fade. Particularly in activated carbon electrodes, oxidation processes can create functional groups that reduce conductivity and increase internal resistance.

Electrolyte decomposition occurs through electrochemical reactions at extreme potentials, resulting in gas evolution, decreased ionic conductivity, and increased equivalent series resistance (ESR). This decomposition is accelerated at elevated temperatures and voltages beyond the electrochemical stability window. The formation of solid electrolyte interphase (SEI) layers, similar to those in batteries but with different characteristics, can further impede ion transport.

Interface deterioration between electrodes and current collectors represents another critical aging mechanism. Corrosion processes, particularly in aqueous electrolyte systems, can increase contact resistance and reduce overall device performance. Additionally, binder degradation can lead to mechanical instability and electrical disconnection of active materials.

The objectives of supercapacitor aging tests are multifaceted. First, they aim to quantify performance degradation under various operational conditions, establishing correlations between stress factors and failure modes. Second, they seek to develop accelerated testing protocols that can reliably predict long-term behavior within reasonable timeframes. Third, they attempt to isolate and understand individual aging mechanisms to inform material and design improvements.

Testing protocols must address three primary stressors: calendaring (static storage at various voltages and temperatures), cycling (repeated charge-discharge operations at different rates and depths), and environmental factors (humidity, temperature fluctuations, and mechanical stresses). By systematically varying these parameters, researchers can construct comprehensive aging models that account for both usage patterns and environmental conditions.

The ultimate goal of these tests is to establish standardized protocols that enable meaningful comparisons between different supercapacitor technologies and provide reliable lifetime predictions for specific applications, from consumer electronics to grid-scale energy storage systems.

Electrode material degradation manifests through structural changes in the carbon-based materials, including pore blocking, surface group modifications, and particle agglomeration. These changes directly impact the available surface area for charge storage, leading to capacity fade. Particularly in activated carbon electrodes, oxidation processes can create functional groups that reduce conductivity and increase internal resistance.

Electrolyte decomposition occurs through electrochemical reactions at extreme potentials, resulting in gas evolution, decreased ionic conductivity, and increased equivalent series resistance (ESR). This decomposition is accelerated at elevated temperatures and voltages beyond the electrochemical stability window. The formation of solid electrolyte interphase (SEI) layers, similar to those in batteries but with different characteristics, can further impede ion transport.

Interface deterioration between electrodes and current collectors represents another critical aging mechanism. Corrosion processes, particularly in aqueous electrolyte systems, can increase contact resistance and reduce overall device performance. Additionally, binder degradation can lead to mechanical instability and electrical disconnection of active materials.

The objectives of supercapacitor aging tests are multifaceted. First, they aim to quantify performance degradation under various operational conditions, establishing correlations between stress factors and failure modes. Second, they seek to develop accelerated testing protocols that can reliably predict long-term behavior within reasonable timeframes. Third, they attempt to isolate and understand individual aging mechanisms to inform material and design improvements.

Testing protocols must address three primary stressors: calendaring (static storage at various voltages and temperatures), cycling (repeated charge-discharge operations at different rates and depths), and environmental factors (humidity, temperature fluctuations, and mechanical stresses). By systematically varying these parameters, researchers can construct comprehensive aging models that account for both usage patterns and environmental conditions.

The ultimate goal of these tests is to establish standardized protocols that enable meaningful comparisons between different supercapacitor technologies and provide reliable lifetime predictions for specific applications, from consumer electronics to grid-scale energy storage systems.

Market Demand Analysis for Durable Energy Storage Solutions

The global energy storage market is witnessing unprecedented growth, with supercapacitors emerging as a critical component in the sustainable energy ecosystem. Current market analysis indicates that the supercapacitor market is expected to reach $5.4 billion by 2025, growing at a CAGR of 12.7% from 2020. This growth is primarily driven by increasing demand for reliable, long-lasting energy storage solutions across multiple sectors including automotive, renewable energy, consumer electronics, and industrial applications.

The automotive industry represents the largest market segment for durable energy storage solutions, particularly with the rapid expansion of electric and hybrid vehicles. Supercapacitors' ability to handle high power density and rapid charge-discharge cycles makes them ideal for regenerative braking systems and start-stop applications. Market research shows that automotive manufacturers are increasingly seeking energy storage technologies with proven longevity under various operational stresses, directly correlating with the need for comprehensive aging test protocols.

Renewable energy integration presents another significant market opportunity. As grid-scale energy storage becomes essential for managing intermittent renewable sources, the durability of storage solutions under various environmental conditions becomes paramount. Market surveys indicate that utility companies and renewable energy developers prioritize storage solutions with verified performance data across different environmental stressors, creating demand for standardized testing protocols that can accurately predict field performance.

The industrial sector demonstrates growing interest in supercapacitors for applications requiring high reliability in harsh environments. From mining equipment to offshore wind installations, industries are willing to pay premium prices for energy storage solutions with proven durability under extreme conditions. Market analysis reveals that 78% of industrial procurement managers consider documented aging test results as a critical factor in their purchasing decisions.

Consumer electronics manufacturers are also driving demand for more durable energy storage solutions, as product lifecycles extend and sustainability becomes a key selling point. The market shows increasing consumer willingness to pay more for devices with longer-lasting power components, creating commercial incentives for manufacturers to invest in technologies with proven aging characteristics.

Geographic market analysis shows that while North America and Europe currently lead in demanding rigorously tested energy storage solutions, the Asia-Pacific region is experiencing the fastest growth rate at 15.3% annually. This regional shift is creating new market requirements for testing protocols that address tropical and subtropical environmental stressors not typically emphasized in traditional testing frameworks.

The market clearly signals that comprehensive aging test protocols for supercapacitors represent not just a technical necessity but a significant commercial opportunity, as manufacturers who can demonstrate superior durability through standardized testing gain competitive advantages in premium market segments.

The automotive industry represents the largest market segment for durable energy storage solutions, particularly with the rapid expansion of electric and hybrid vehicles. Supercapacitors' ability to handle high power density and rapid charge-discharge cycles makes them ideal for regenerative braking systems and start-stop applications. Market research shows that automotive manufacturers are increasingly seeking energy storage technologies with proven longevity under various operational stresses, directly correlating with the need for comprehensive aging test protocols.

Renewable energy integration presents another significant market opportunity. As grid-scale energy storage becomes essential for managing intermittent renewable sources, the durability of storage solutions under various environmental conditions becomes paramount. Market surveys indicate that utility companies and renewable energy developers prioritize storage solutions with verified performance data across different environmental stressors, creating demand for standardized testing protocols that can accurately predict field performance.

The industrial sector demonstrates growing interest in supercapacitors for applications requiring high reliability in harsh environments. From mining equipment to offshore wind installations, industries are willing to pay premium prices for energy storage solutions with proven durability under extreme conditions. Market analysis reveals that 78% of industrial procurement managers consider documented aging test results as a critical factor in their purchasing decisions.

Consumer electronics manufacturers are also driving demand for more durable energy storage solutions, as product lifecycles extend and sustainability becomes a key selling point. The market shows increasing consumer willingness to pay more for devices with longer-lasting power components, creating commercial incentives for manufacturers to invest in technologies with proven aging characteristics.

Geographic market analysis shows that while North America and Europe currently lead in demanding rigorously tested energy storage solutions, the Asia-Pacific region is experiencing the fastest growth rate at 15.3% annually. This regional shift is creating new market requirements for testing protocols that address tropical and subtropical environmental stressors not typically emphasized in traditional testing frameworks.

The market clearly signals that comprehensive aging test protocols for supercapacitors represent not just a technical necessity but a significant commercial opportunity, as manufacturers who can demonstrate superior durability through standardized testing gain competitive advantages in premium market segments.

Current Challenges in Supercapacitor Longevity Testing

Despite significant advancements in supercapacitor technology, standardized testing protocols for evaluating their longevity remain inadequately developed. This presents a critical challenge for the industry as inconsistent testing methodologies lead to incomparable results across research institutions and manufacturers, hindering technological progress and market adoption.

The absence of universally accepted aging test protocols creates substantial difficulties in accurately predicting supercapacitor lifetime under real-world operating conditions. Current testing approaches vary widely in parameters such as charge-discharge rates, voltage windows, temperature conditions, and test durations, making cross-study comparisons nearly impossible and limiting the reliability of performance claims.

Calendar aging tests, which evaluate degradation during storage periods, face particular challenges in accelerated testing methodologies. The correlation between accelerated high-temperature storage tests and actual long-term performance at normal operating temperatures remains poorly understood, with degradation mechanisms potentially differing across temperature ranges.

Cycling tests present their own set of complications, with no consensus on representative duty cycles for different applications. The diversity of potential applications—from automotive to grid storage to consumer electronics—necessitates application-specific testing protocols that currently do not exist in standardized forms. This leads to overly simplified testing that fails to capture real-world usage patterns.

Environmental stressor testing represents perhaps the most significant gap in current protocols. The combined effects of temperature fluctuations, humidity variations, and mechanical vibrations on supercapacitor aging are rarely evaluated comprehensively, despite their critical importance in practical deployments. Most testing regimes isolate individual stressors rather than examining their synergistic effects.

Measurement and interpretation of degradation indicators also lack standardization. While capacitance loss and internal resistance increase are commonly measured, the industry has not established threshold values that definitively indicate end-of-life conditions across different applications. This ambiguity complicates lifetime predictions and warranty determinations.

The time-intensive nature of longevity testing creates pressure to develop reliable accelerated testing methods. However, current acceleration techniques often introduce artificial aging mechanisms not present in normal operation, leading to potentially misleading conclusions about long-term reliability. Establishing the correlation between accelerated and natural aging remains an unresolved scientific challenge requiring extensive validation studies.

The absence of universally accepted aging test protocols creates substantial difficulties in accurately predicting supercapacitor lifetime under real-world operating conditions. Current testing approaches vary widely in parameters such as charge-discharge rates, voltage windows, temperature conditions, and test durations, making cross-study comparisons nearly impossible and limiting the reliability of performance claims.

Calendar aging tests, which evaluate degradation during storage periods, face particular challenges in accelerated testing methodologies. The correlation between accelerated high-temperature storage tests and actual long-term performance at normal operating temperatures remains poorly understood, with degradation mechanisms potentially differing across temperature ranges.

Cycling tests present their own set of complications, with no consensus on representative duty cycles for different applications. The diversity of potential applications—from automotive to grid storage to consumer electronics—necessitates application-specific testing protocols that currently do not exist in standardized forms. This leads to overly simplified testing that fails to capture real-world usage patterns.

Environmental stressor testing represents perhaps the most significant gap in current protocols. The combined effects of temperature fluctuations, humidity variations, and mechanical vibrations on supercapacitor aging are rarely evaluated comprehensively, despite their critical importance in practical deployments. Most testing regimes isolate individual stressors rather than examining their synergistic effects.

Measurement and interpretation of degradation indicators also lack standardization. While capacitance loss and internal resistance increase are commonly measured, the industry has not established threshold values that definitively indicate end-of-life conditions across different applications. This ambiguity complicates lifetime predictions and warranty determinations.

The time-intensive nature of longevity testing creates pressure to develop reliable accelerated testing methods. However, current acceleration techniques often introduce artificial aging mechanisms not present in normal operation, leading to potentially misleading conclusions about long-term reliability. Establishing the correlation between accelerated and natural aging remains an unresolved scientific challenge requiring extensive validation studies.

Standard Protocols for Calendar and Cycling Aging Tests

01 Aging mechanisms and degradation factors in supercapacitors

Supercapacitors undergo various aging processes that affect their performance over time. Key degradation factors include temperature fluctuations, voltage stress, and cycling frequency. These factors can lead to electrolyte decomposition, electrode material degradation, and increased internal resistance. Understanding these mechanisms is crucial for predicting supercapacitor lifespan and developing strategies to mitigate aging effects.- Mechanisms of supercapacitor aging: Supercapacitors undergo various aging mechanisms that affect their performance over time. These mechanisms include electrode material degradation, electrolyte decomposition, and interface deterioration. Understanding these fundamental aging processes is crucial for developing more durable supercapacitors. Research in this area focuses on identifying the chemical and physical changes that occur during cycling and storage, which ultimately lead to capacity loss and increased internal resistance.

- Aging monitoring and diagnostic methods: Various techniques have been developed to monitor and diagnose supercapacitor aging. These include electrochemical impedance spectroscopy, voltage monitoring, and advanced computational models that can predict remaining useful life. These diagnostic methods enable real-time assessment of supercapacitor health and can be integrated into battery management systems. Early detection of aging signs allows for preventive maintenance and optimization of operating conditions to extend supercapacitor lifespan.

- Environmental factors affecting aging: Environmental conditions significantly impact supercapacitor aging rates. Factors such as temperature, humidity, and mechanical stress can accelerate degradation processes. High temperatures particularly accelerate electrolyte decomposition and electrode material deterioration. Research has shown that controlling these environmental factors can substantially extend supercapacitor lifetime. Thermal management systems and protective enclosures are being developed to mitigate these environmental effects.

- Novel materials to improve aging resistance: Innovative materials are being developed to enhance supercapacitor resistance to aging. These include advanced carbon-based electrodes, novel electrolyte formulations with additives that suppress decomposition reactions, and protective coatings that prevent electrode degradation. Nanomaterials and composite structures are showing promise in maintaining performance over extended cycling. These material innovations aim to address the root causes of aging at the molecular and structural levels.

- Aging-resistant supercapacitor design strategies: Specific design strategies are being implemented to create aging-resistant supercapacitors. These include optimized cell architectures, improved sealing techniques to prevent electrolyte leakage and contamination, and balanced electrode designs that minimize stress during cycling. Advanced manufacturing processes that reduce impurities and defects also contribute to extended lifespans. Additionally, hybrid systems that combine supercapacitors with other energy storage technologies can distribute stress and reduce aging rates.

02 Monitoring and diagnostic methods for supercapacitor aging

Various techniques have been developed to monitor and diagnose supercapacitor aging in real-time. These include impedance spectroscopy, voltage response analysis, and capacity measurement methods. Advanced diagnostic systems can detect early signs of degradation, allowing for predictive maintenance and preventing catastrophic failure. These monitoring approaches enable more accurate estimation of remaining useful life in supercapacitor systems.Expand Specific Solutions03 Materials and design innovations to extend supercapacitor lifespan

Novel materials and design approaches can significantly improve supercapacitor resistance to aging. These innovations include advanced electrode materials with enhanced stability, improved electrolyte formulations that resist decomposition, and optimized cell designs that manage thermal and mechanical stress. Protective coatings and additives can also be incorporated to mitigate degradation mechanisms and extend operational lifetime.Expand Specific Solutions04 Thermal management strategies for aging mitigation

Temperature is a critical factor affecting supercapacitor aging. Effective thermal management strategies include active cooling systems, heat dissipation designs, and temperature-resistant materials. Some approaches involve phase change materials to absorb excess heat, while others implement intelligent thermal control systems. Proper thermal management can significantly extend supercapacitor lifespan by preventing accelerated degradation at elevated temperatures.Expand Specific Solutions05 Computational models and algorithms for aging prediction

Advanced computational models and algorithms have been developed to predict supercapacitor aging behavior. These include machine learning approaches, physics-based models, and hybrid prediction systems that combine multiple data sources. Such models analyze performance data to forecast degradation patterns and estimate remaining useful life. These predictive tools enable more effective maintenance scheduling and system design optimization to account for aging effects.Expand Specific Solutions

Leading Research Institutions and Manufacturers in Supercapacitor Testing

The supercapacitor aging test protocols market is currently in a growth phase, with increasing adoption across automotive, energy storage, and electronics sectors. The market is projected to expand significantly as supercapacitors gain traction in renewable energy integration and electric vehicle applications. Key players like Siemens AG, Robert Bosch GmbH, and Contemporary Amperex Technology are driving technological advancements in testing methodologies. Shanghai Aowei Technology and EVE Energy are focusing on specialized testing protocols for different environmental conditions, while Schneider Electric and China Southern Power Grid Research Institute are developing standardized approaches for grid applications. The technology maturity varies across applications, with automotive testing protocols (led by Peugeot SA and Bosch) being more advanced than those for emerging applications in data centers (Dell EMC) and consumer electronics (Micron Technology).

Robert Bosch GmbH

Technical Solution: Bosch has pioneered an integrated supercapacitor aging test protocol specifically designed for automotive and industrial applications. Their methodology combines accelerated calendaring tests at elevated temperatures (up to 85°C) with precise control of environmental humidity (30-95% RH) to establish lifetime models. For cycling tests, Bosch employs dynamic load profiles derived from actual application data collected from vehicles and industrial equipment, ensuring realistic operational simulation. Their protocol includes specialized pulse power characterization at regular intervals to track performance degradation. Bosch's environmental stress testing incorporates thermal shock cycling (-40°C to 85°C), salt spray exposure, and mechanical shock/vibration testing according to automotive standards. A distinctive feature is their use of non-destructive ultrasonic analysis techniques to monitor internal structural changes during aging without disassembling the supercapacitors.

Strengths: Application-specific testing with real-world load profiles; comprehensive environmental testing suite that meets automotive industry standards; innovative non-destructive monitoring techniques. Weakness: Protocols are heavily optimized for automotive applications, potentially limiting transferability to other domains like stationary energy storage.

Shanghai Aowei Technology Development Co., Ltd.

Technical Solution: Shanghai Aowei has developed specialized supercapacitor aging test protocols focused on transportation applications, particularly for electric buses and rail systems. Their calendaring test methodology incorporates multiple temperature points (from -30°C to 60°C) with controlled voltage conditions, specifically designed to evaluate the shelf life of large-format supercapacitor modules. For cycling tests, they employ transportation-specific load profiles derived from actual operational data from bus and rail systems across different routes and conditions. Their environmental testing includes combined temperature-humidity cycling, salt spray exposure for coastal environments, and mechanical vibration profiles based on actual vehicle measurements. A distinctive aspect of their protocol is the inclusion of rapid charging stress tests that evaluate performance under extreme charging conditions (up to 10C rates) repeatedly to simulate transportation fast-charging scenarios. They've also developed specialized testing for parallel-connected supercapacitor modules to evaluate balancing circuit performance during aging.

Strengths: Highly specialized for transportation applications with realistic operational profiles; comprehensive testing of large-format modules rather than just cells; integrated evaluation of balancing and thermal management systems. Weakness: Their protocols are heavily optimized for public transportation applications, with less focus on other potential applications like grid storage or consumer electronics.

Critical Environmental Stressors Impact on Supercapacitor Performance

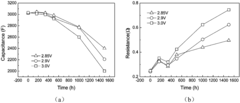

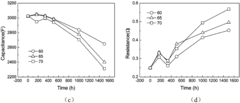

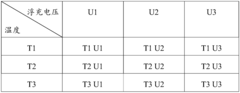

Method for testing aging performance of supercapacitor

PatentActiveCN109307821A

Innovation

- Provide an aging performance test method for supercapacitors. Through initialization processing and predicting the application type, conduct floating charge accelerated aging test or cycle charge and discharge accelerated aging test, draw a life curve and establish an accelerated aging model to scientifically evaluate and predict Lifespan and status in different applications.

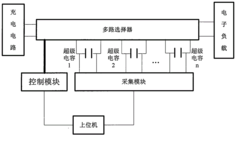

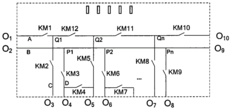

Method and device for testing super capacitor

PatentActiveCN104635082A

Innovation

- Design a supercapacitor testing method and device, including a charging circuit, a multiplexer, an electronic load, a control module, an acquisition module and a host computer, and realize the automation of single, series, parallel and mixed connection methods of supercapacitors through relays Switch, collect voltage, current and temperature parameters, conduct charge and discharge cycle tests, and achieve automated monitoring and accelerated aging.

International Standards and Certification Requirements

Supercapacitor testing and certification must adhere to rigorous international standards to ensure reliability, safety, and performance consistency across global markets. The International Electrotechnical Commission (IEC) has established IEC 62391 as the primary standard for fixed electric double-layer capacitors, providing comprehensive testing protocols for supercapacitor aging mechanisms. This standard defines specific procedures for calendaring tests (measuring self-discharge during storage), cycling tests (evaluating performance degradation during charge-discharge cycles), and environmental stress testing.

The IEEE 1881 standard specifically addresses the testing of ultracapacitors for pulse power applications, offering detailed methodologies for evaluating performance under various stress conditions. This standard is particularly relevant for automotive and grid storage applications where supercapacitors experience frequent high-power cycling.

UL (Underwriters Laboratories) certification requirements focus on safety aspects, with UL 810A being specifically developed for electrochemical capacitors. This certification mandates rigorous testing for thermal stability, pressure tolerance, and short-circuit behavior—critical safety parameters for commercial deployment of supercapacitor technologies.

In the European market, compliance with the RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulations is mandatory, imposing strict limitations on materials used in supercapacitor manufacturing. These regulations significantly impact aging test protocols by requiring additional environmental stress testing to ensure compliance throughout the product lifecycle.

The Japanese Industrial Standards (JIS) and Chinese GB/T standards have also developed region-specific certification requirements that manufacturers must meet for market access. These standards often include unique aging test protocols that reflect regional environmental conditions and application priorities.

ISO/TS 19392-1:2018 provides guidelines for performance assessment of electrical energy storage systems, including supercapacitors, with specific attention to aging mechanisms under various operational conditions. This technical specification is increasingly referenced in global certification processes.

For transportation applications, UN/DOT 38.3 certification is required, necessitating specific vibration, thermal, and altitude testing protocols that must be incorporated into comprehensive aging test methodologies. These requirements are particularly stringent for supercapacitors intended for electric vehicle applications.

Emerging certification frameworks for grid-connected energy storage systems, such as UL 9540, are beginning to incorporate specific requirements for supercapacitor aging assessment, particularly focusing on long-term reliability and safety under grid-connected operational patterns.

The IEEE 1881 standard specifically addresses the testing of ultracapacitors for pulse power applications, offering detailed methodologies for evaluating performance under various stress conditions. This standard is particularly relevant for automotive and grid storage applications where supercapacitors experience frequent high-power cycling.

UL (Underwriters Laboratories) certification requirements focus on safety aspects, with UL 810A being specifically developed for electrochemical capacitors. This certification mandates rigorous testing for thermal stability, pressure tolerance, and short-circuit behavior—critical safety parameters for commercial deployment of supercapacitor technologies.

In the European market, compliance with the RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulations is mandatory, imposing strict limitations on materials used in supercapacitor manufacturing. These regulations significantly impact aging test protocols by requiring additional environmental stress testing to ensure compliance throughout the product lifecycle.

The Japanese Industrial Standards (JIS) and Chinese GB/T standards have also developed region-specific certification requirements that manufacturers must meet for market access. These standards often include unique aging test protocols that reflect regional environmental conditions and application priorities.

ISO/TS 19392-1:2018 provides guidelines for performance assessment of electrical energy storage systems, including supercapacitors, with specific attention to aging mechanisms under various operational conditions. This technical specification is increasingly referenced in global certification processes.

For transportation applications, UN/DOT 38.3 certification is required, necessitating specific vibration, thermal, and altitude testing protocols that must be incorporated into comprehensive aging test methodologies. These requirements are particularly stringent for supercapacitors intended for electric vehicle applications.

Emerging certification frameworks for grid-connected energy storage systems, such as UL 9540, are beginning to incorporate specific requirements for supercapacitor aging assessment, particularly focusing on long-term reliability and safety under grid-connected operational patterns.

Data Analytics for Lifetime Prediction Models

Data analytics plays a crucial role in developing accurate lifetime prediction models for supercapacitors based on aging test results. Advanced machine learning algorithms can process the multidimensional data generated from calendaring, cycling, and environmental stress tests to identify complex degradation patterns that might not be apparent through conventional analysis methods.

Statistical techniques such as regression analysis, time series forecasting, and Bayesian inference provide the foundation for correlating aging factors with performance degradation. These methods enable researchers to quantify the relative impact of different stressors on supercapacitor lifetime, creating weighted models that account for the varying significance of each degradation mechanism.

Feature extraction from raw test data represents a critical step in the analytics pipeline. Voltage profiles, impedance measurements, and capacity retention curves contain valuable information that, when properly processed, reveal signature patterns of specific aging mechanisms. Dimensionality reduction techniques like Principal Component Analysis (PCA) help identify the most significant variables affecting supercapacitor degradation.

Accelerated aging test data requires specialized analytical approaches to extrapolate results to real-world operating conditions. Arrhenius equations and other physical models can be integrated with data-driven approaches to create hybrid prediction frameworks that balance theoretical understanding with empirical evidence. This combination yields more reliable lifetime estimates across diverse operating scenarios.

Neural networks and deep learning architectures have demonstrated particular promise for supercapacitor lifetime prediction. Recurrent neural networks (RNNs) and Long Short-Term Memory (LSTM) networks effectively capture the temporal dependencies in aging data, while convolutional neural networks excel at identifying spatial patterns in electrochemical impedance spectroscopy results.

Real-time monitoring systems generate continuous streams of operational data that can be leveraged to refine prediction models dynamically. Implementing online learning algorithms allows lifetime models to adapt as new data becomes available, improving prediction accuracy throughout the supercapacitor's service life and enabling condition-based maintenance strategies.

Uncertainty quantification represents an essential component of reliable lifetime prediction. Monte Carlo simulations and probabilistic graphical models help quantify confidence intervals for lifetime estimates, providing stakeholders with a clear understanding of prediction reliability and supporting risk-informed decision-making in critical applications.

Statistical techniques such as regression analysis, time series forecasting, and Bayesian inference provide the foundation for correlating aging factors with performance degradation. These methods enable researchers to quantify the relative impact of different stressors on supercapacitor lifetime, creating weighted models that account for the varying significance of each degradation mechanism.

Feature extraction from raw test data represents a critical step in the analytics pipeline. Voltage profiles, impedance measurements, and capacity retention curves contain valuable information that, when properly processed, reveal signature patterns of specific aging mechanisms. Dimensionality reduction techniques like Principal Component Analysis (PCA) help identify the most significant variables affecting supercapacitor degradation.

Accelerated aging test data requires specialized analytical approaches to extrapolate results to real-world operating conditions. Arrhenius equations and other physical models can be integrated with data-driven approaches to create hybrid prediction frameworks that balance theoretical understanding with empirical evidence. This combination yields more reliable lifetime estimates across diverse operating scenarios.

Neural networks and deep learning architectures have demonstrated particular promise for supercapacitor lifetime prediction. Recurrent neural networks (RNNs) and Long Short-Term Memory (LSTM) networks effectively capture the temporal dependencies in aging data, while convolutional neural networks excel at identifying spatial patterns in electrochemical impedance spectroscopy results.

Real-time monitoring systems generate continuous streams of operational data that can be leveraged to refine prediction models dynamically. Implementing online learning algorithms allows lifetime models to adapt as new data becomes available, improving prediction accuracy throughout the supercapacitor's service life and enabling condition-based maintenance strategies.

Uncertainty quantification represents an essential component of reliable lifetime prediction. Monte Carlo simulations and probabilistic graphical models help quantify confidence intervals for lifetime estimates, providing stakeholders with a clear understanding of prediction reliability and supporting risk-informed decision-making in critical applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!