Supercapacitor Electrode Materials: Activated Carbon vs MXene vs Graphene — Performance Matrix

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Supercapacitor Electrode Materials Background and Objectives

Supercapacitors have emerged as critical energy storage devices in the landscape of modern electronics and renewable energy systems. The evolution of supercapacitor technology can be traced back to the 1950s, with significant advancements occurring in the 1990s as demand for high-power energy storage solutions increased. The trajectory of development has been characterized by continuous improvements in electrode materials, which directly influence the performance metrics of these devices.

The electrode material serves as the foundation of supercapacitor functionality, determining key parameters such as energy density, power density, cycle life, and charge-discharge efficiency. Historically, activated carbon has dominated the commercial supercapacitor market due to its cost-effectiveness and reasonable performance characteristics. However, the emergence of two-dimensional nanomaterials—specifically MXenes and graphene—has introduced new possibilities for enhancing supercapacitor performance beyond traditional limitations.

Recent technological trends indicate a shift toward hybrid and composite electrode materials that combine the advantages of different materials to overcome individual limitations. This evolution is driven by increasing demands for higher energy densities while maintaining the inherent high power capabilities of supercapacitors. The integration of these advanced materials into practical devices represents a significant frontier in energy storage research.

The primary technical objective of this investigation is to conduct a comprehensive performance comparison between three prominent supercapacitor electrode materials: activated carbon, MXene, and graphene. This comparison aims to evaluate these materials across multiple performance dimensions, including specific capacitance, rate capability, cycling stability, and operational temperature range. Additionally, the analysis will consider practical aspects such as scalability, cost-effectiveness, and environmental impact.

Secondary objectives include identifying the fundamental mechanisms underlying the performance differences between these materials, exploring potential synergistic effects in hybrid configurations, and projecting future development pathways. Understanding the structure-property relationships in these materials is crucial for designing next-generation supercapacitors with optimized performance characteristics.

This technical assessment seeks to provide clarity on the relative advantages and limitations of each material class, thereby informing strategic research directions and potential commercial applications. The findings will contribute to the broader goal of advancing supercapacitor technology toward higher energy densities while maintaining their characteristic high power capabilities, rapid charging, and exceptional cycle life.

The electrode material serves as the foundation of supercapacitor functionality, determining key parameters such as energy density, power density, cycle life, and charge-discharge efficiency. Historically, activated carbon has dominated the commercial supercapacitor market due to its cost-effectiveness and reasonable performance characteristics. However, the emergence of two-dimensional nanomaterials—specifically MXenes and graphene—has introduced new possibilities for enhancing supercapacitor performance beyond traditional limitations.

Recent technological trends indicate a shift toward hybrid and composite electrode materials that combine the advantages of different materials to overcome individual limitations. This evolution is driven by increasing demands for higher energy densities while maintaining the inherent high power capabilities of supercapacitors. The integration of these advanced materials into practical devices represents a significant frontier in energy storage research.

The primary technical objective of this investigation is to conduct a comprehensive performance comparison between three prominent supercapacitor electrode materials: activated carbon, MXene, and graphene. This comparison aims to evaluate these materials across multiple performance dimensions, including specific capacitance, rate capability, cycling stability, and operational temperature range. Additionally, the analysis will consider practical aspects such as scalability, cost-effectiveness, and environmental impact.

Secondary objectives include identifying the fundamental mechanisms underlying the performance differences between these materials, exploring potential synergistic effects in hybrid configurations, and projecting future development pathways. Understanding the structure-property relationships in these materials is crucial for designing next-generation supercapacitors with optimized performance characteristics.

This technical assessment seeks to provide clarity on the relative advantages and limitations of each material class, thereby informing strategic research directions and potential commercial applications. The findings will contribute to the broader goal of advancing supercapacitor technology toward higher energy densities while maintaining their characteristic high power capabilities, rapid charging, and exceptional cycle life.

Market Demand Analysis for High-Performance Energy Storage

The global energy storage market is experiencing unprecedented growth, driven by the increasing adoption of renewable energy sources, electrification of transportation, and the proliferation of portable electronic devices. The market for high-performance energy storage solutions is projected to reach $546 billion by 2035, with supercapacitors representing one of the fastest-growing segments at a CAGR of 20.7% between 2023 and 2030.

Supercapacitors occupy a critical position in the energy storage spectrum, filling the gap between conventional capacitors and batteries by offering high power density, rapid charge-discharge capabilities, and exceptional cycle life. The demand for advanced electrode materials that can enhance supercapacitor performance metrics has intensified across multiple industries, particularly automotive, consumer electronics, renewable energy, and industrial applications.

In the automotive sector, the shift toward electric and hybrid vehicles has created substantial demand for supercapacitors that can handle regenerative braking systems and power management. These applications require electrode materials that deliver both high energy density and power density, with the ability to operate reliably under extreme temperature conditions. The market size for automotive supercapacitors is expected to grow at 25% annually through 2030.

Consumer electronics manufacturers are increasingly incorporating supercapacitors to complement batteries in smartphones, wearables, and portable devices. This market segment values electrode materials that enable miniaturization while maintaining performance, with particular emphasis on flexible and thin-film supercapacitors. Industry analysts report that 38% of next-generation portable devices will incorporate supercapacitor technology by 2028.

The renewable energy sector presents perhaps the most significant growth opportunity for high-performance supercapacitor materials. Grid stabilization, peak shaving, and energy harvesting applications require storage solutions that can rapidly absorb and release energy. This market segment is growing at 23% annually, with particular demand for electrode materials that can increase energy density while maintaining the inherent advantages of supercapacitors.

Industrial applications, including heavy machinery, elevators, and backup power systems, represent another substantial market for advanced supercapacitor electrode materials. These applications prioritize reliability, temperature stability, and long operational lifetimes, creating demand for materials that can withstand harsh operating environments.

The market is increasingly segmenting based on performance characteristics, with premium applications willing to pay significantly higher prices for electrode materials that deliver substantial improvements in energy density, power density, or cycle life. This trend has created market opportunities for newer materials like MXenes and graphene, despite their higher production costs compared to traditional activated carbon.

Supercapacitors occupy a critical position in the energy storage spectrum, filling the gap between conventional capacitors and batteries by offering high power density, rapid charge-discharge capabilities, and exceptional cycle life. The demand for advanced electrode materials that can enhance supercapacitor performance metrics has intensified across multiple industries, particularly automotive, consumer electronics, renewable energy, and industrial applications.

In the automotive sector, the shift toward electric and hybrid vehicles has created substantial demand for supercapacitors that can handle regenerative braking systems and power management. These applications require electrode materials that deliver both high energy density and power density, with the ability to operate reliably under extreme temperature conditions. The market size for automotive supercapacitors is expected to grow at 25% annually through 2030.

Consumer electronics manufacturers are increasingly incorporating supercapacitors to complement batteries in smartphones, wearables, and portable devices. This market segment values electrode materials that enable miniaturization while maintaining performance, with particular emphasis on flexible and thin-film supercapacitors. Industry analysts report that 38% of next-generation portable devices will incorporate supercapacitor technology by 2028.

The renewable energy sector presents perhaps the most significant growth opportunity for high-performance supercapacitor materials. Grid stabilization, peak shaving, and energy harvesting applications require storage solutions that can rapidly absorb and release energy. This market segment is growing at 23% annually, with particular demand for electrode materials that can increase energy density while maintaining the inherent advantages of supercapacitors.

Industrial applications, including heavy machinery, elevators, and backup power systems, represent another substantial market for advanced supercapacitor electrode materials. These applications prioritize reliability, temperature stability, and long operational lifetimes, creating demand for materials that can withstand harsh operating environments.

The market is increasingly segmenting based on performance characteristics, with premium applications willing to pay significantly higher prices for electrode materials that deliver substantial improvements in energy density, power density, or cycle life. This trend has created market opportunities for newer materials like MXenes and graphene, despite their higher production costs compared to traditional activated carbon.

Current Status and Challenges in Electrode Material Development

The supercapacitor electrode materials landscape has witnessed significant advancements in recent years, with three primary contenders dominating research and commercial applications: Activated Carbon, MXene, and Graphene. Each material presents distinct advantages and limitations that influence their performance in energy storage applications.

Activated Carbon remains the most widely commercialized electrode material due to its established manufacturing processes, relatively low cost, and reasonable performance metrics. Current commercial supercapacitors utilizing activated carbon electrodes achieve specific capacitances of 100-200 F/g and energy densities of 5-8 Wh/kg. However, the technology faces fundamental limitations in power density and rate capability due to its predominantly microporous structure that restricts ion transport kinetics.

MXene, a relatively newer class of two-dimensional transition metal carbides and nitrides, has demonstrated exceptional promise in laboratory settings. Recent research has achieved specific capacitances exceeding 300 F/g with excellent rate capabilities. The layered structure of MXenes facilitates rapid ion intercalation, addressing a key limitation of activated carbon. Nevertheless, MXene technology faces significant challenges in scalable synthesis, long-term stability in aqueous electrolytes, and cost-effective production methods.

Graphene-based electrodes represent another frontier in supercapacitor development, with theoretical specific surface areas approaching 2630 m²/g and electrical conductivities superior to both activated carbon and MXenes. Laboratory prototypes have demonstrated capacitances of 150-550 F/g depending on synthesis methods and structural configurations. However, graphene production faces persistent challenges in preventing restacking of layers during electrode fabrication, which significantly reduces effective surface area.

A critical technical barrier across all three materials involves the trade-off between energy density and power density. While recent hybrid structures combining different carbon allotropes have shown promise in optimizing this balance, fundamental limitations remain. Additionally, electrolyte compatibility issues persist, particularly for MXenes which exhibit varying stability profiles in different electrolyte environments.

Manufacturing scalability presents another significant challenge, especially for newer materials. While activated carbon benefits from established industrial production processes, both MXene and graphene face considerable hurdles in transitioning from laboratory to mass production scales without compromising performance characteristics or economic viability.

Geographically, research leadership in these materials shows distinct patterns. North America and Europe lead in fundamental research on novel graphene architectures, while China dominates in MXene development and scaled production technologies. Japan and South Korea maintain significant advantages in activated carbon optimization and commercial implementation of advanced carbon materials in consumer electronics.

Activated Carbon remains the most widely commercialized electrode material due to its established manufacturing processes, relatively low cost, and reasonable performance metrics. Current commercial supercapacitors utilizing activated carbon electrodes achieve specific capacitances of 100-200 F/g and energy densities of 5-8 Wh/kg. However, the technology faces fundamental limitations in power density and rate capability due to its predominantly microporous structure that restricts ion transport kinetics.

MXene, a relatively newer class of two-dimensional transition metal carbides and nitrides, has demonstrated exceptional promise in laboratory settings. Recent research has achieved specific capacitances exceeding 300 F/g with excellent rate capabilities. The layered structure of MXenes facilitates rapid ion intercalation, addressing a key limitation of activated carbon. Nevertheless, MXene technology faces significant challenges in scalable synthesis, long-term stability in aqueous electrolytes, and cost-effective production methods.

Graphene-based electrodes represent another frontier in supercapacitor development, with theoretical specific surface areas approaching 2630 m²/g and electrical conductivities superior to both activated carbon and MXenes. Laboratory prototypes have demonstrated capacitances of 150-550 F/g depending on synthesis methods and structural configurations. However, graphene production faces persistent challenges in preventing restacking of layers during electrode fabrication, which significantly reduces effective surface area.

A critical technical barrier across all three materials involves the trade-off between energy density and power density. While recent hybrid structures combining different carbon allotropes have shown promise in optimizing this balance, fundamental limitations remain. Additionally, electrolyte compatibility issues persist, particularly for MXenes which exhibit varying stability profiles in different electrolyte environments.

Manufacturing scalability presents another significant challenge, especially for newer materials. While activated carbon benefits from established industrial production processes, both MXene and graphene face considerable hurdles in transitioning from laboratory to mass production scales without compromising performance characteristics or economic viability.

Geographically, research leadership in these materials shows distinct patterns. North America and Europe lead in fundamental research on novel graphene architectures, while China dominates in MXene development and scaled production technologies. Japan and South Korea maintain significant advantages in activated carbon optimization and commercial implementation of advanced carbon materials in consumer electronics.

Comparative Analysis of AC, MXene, and Graphene Solutions

01 Activated carbon-based electrode materials for supercapacitors

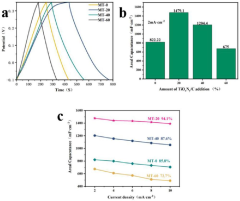

Activated carbon is widely used as an electrode material for supercapacitors due to its high specific surface area, good electrical conductivity, and cost-effectiveness. Various methods are employed to enhance its performance, including chemical activation processes, pore structure optimization, and surface functionalization. These modifications can significantly improve the energy density, power density, and cycle stability of supercapacitors using activated carbon electrodes.- Activated Carbon-based Electrode Materials: Activated carbon is widely used as an electrode material in supercapacitors due to its high surface area, good electrical conductivity, and cost-effectiveness. These materials can be derived from various carbon sources and undergo activation processes to enhance porosity and surface area. Activated carbon electrodes typically offer good cycling stability and moderate energy density, making them suitable for commercial applications where balance between cost and performance is required.

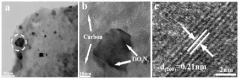

- MXene-based Electrode Materials: MXenes are two-dimensional transition metal carbides or nitrides that show promising performance as supercapacitor electrode materials. They offer high electrical conductivity, hydrophilic surfaces, and excellent ion transport capabilities. MXene-based electrodes demonstrate high volumetric capacitance and rate capability due to their layered structure that facilitates rapid ion intercalation/de-intercalation. Their performance can be further enhanced through surface modification or by creating composite structures with other materials.

- Graphene-based Electrode Materials: Graphene-based materials exhibit exceptional properties for supercapacitor applications, including high theoretical surface area, excellent electrical conductivity, and good mechanical strength. These materials can be synthesized through various methods and often show superior rate capability and energy density compared to conventional carbon materials. Graphene electrodes can be functionalized or combined with other materials to enhance their electrochemical performance and stability.

- Hybrid and Composite Electrode Materials: Hybrid and composite electrode materials combine different types of materials (such as activated carbon with MXene or graphene with metal oxides) to leverage the advantages of each component. These composites often demonstrate synergistic effects that enhance overall performance, including improved capacitance, better rate capability, and extended cycle life. The design of these hybrid structures allows for optimization of both energy and power density, addressing the limitations of single-component electrode materials.

- Performance Enhancement Strategies: Various strategies can be employed to enhance the performance of supercapacitor electrode materials, including heteroatom doping, hierarchical pore structure design, and surface modification. These approaches aim to improve specific capacitance, rate capability, and cycling stability by optimizing ion transport pathways, increasing active sites, and enhancing electrical conductivity. Advanced fabrication techniques and novel material architectures, such as 3D structures and nanocomposites, can significantly boost the electrochemical performance of supercapacitor electrodes.

02 MXene-based electrode materials for supercapacitors

MXene materials, a family of two-dimensional transition metal carbides and nitrides, demonstrate exceptional performance as supercapacitor electrodes due to their high electrical conductivity, hydrophilic surfaces, and layered structure. The intercalation of ions between MXene layers enables rapid charge/discharge rates and high capacitance. Various synthesis methods and surface modifications can further enhance their electrochemical performance, making them promising candidates for next-generation energy storage devices.Expand Specific Solutions03 Graphene-based electrode materials for supercapacitors

Graphene offers exceptional properties for supercapacitor electrodes, including high theoretical surface area, excellent electrical conductivity, and good mechanical flexibility. Various forms of graphene, such as reduced graphene oxide, graphene nanosheets, and three-dimensional graphene architectures, are utilized to maximize performance. Strategies to prevent graphene sheet restacking and to create hierarchical porous structures significantly enhance the capacitance and rate capability of graphene-based supercapacitors.Expand Specific Solutions04 Hybrid and composite electrode materials combining carbon-based materials

Hybrid electrode materials combining different carbon-based materials (activated carbon, graphene, carbon nanotubes) with metal oxides or conductive polymers demonstrate synergistic effects that enhance supercapacitor performance. These composites leverage the high surface area of carbon materials with the pseudocapacitive properties of metal oxides or polymers. The resulting electrodes exhibit improved energy density, power density, and cycling stability compared to single-component materials, addressing the limitations of individual materials.Expand Specific Solutions05 Novel fabrication techniques and performance optimization methods

Advanced fabrication techniques and optimization methods significantly impact the performance of supercapacitor electrode materials. These include hydrothermal synthesis, freeze-drying, template-assisted growth, and electrospinning. Post-treatment processes such as thermal annealing, chemical activation, and surface functionalization can further enhance electrochemical properties. Additionally, controlling parameters like particle size, pore distribution, and heteroatom doping plays a crucial role in maximizing capacitance, rate capability, and cycling stability of electrode materials.Expand Specific Solutions

Key Industry Players in Advanced Electrode Materials

The supercapacitor electrode materials market is currently in a growth phase, with activated carbon dominating due to its established manufacturing processes and cost-effectiveness. The global market is projected to reach $5-7 billion by 2027, with MXene and graphene technologies representing emerging segments with superior theoretical performance. Established companies like Sekisui Chemical and Murata Manufacturing are investing in activated carbon technologies, while research institutions (CSIC, KAIST, IIT Bombay) are advancing MXene development. Graphene commercialization is led by NanoXplore and specialized startups. Academic-industry partnerships are accelerating, with Zhejiang University, Cambridge Enterprise, and KAUST bridging the gap between laboratory breakthroughs and commercial applications in this rapidly evolving technological landscape.

Murata Manufacturing Co. Ltd.

Technical Solution: Murata has developed advanced activated carbon electrode materials for supercapacitors with hierarchical pore structures that optimize ion transport pathways. Their proprietary process creates activated carbon with surface areas exceeding 2000 m²/g and carefully controlled micro/mesopore distributions. Murata's technology incorporates nitrogen-doping of activated carbon to enhance pseudocapacitance while maintaining excellent cycle stability. Their electrodes demonstrate capacitance values of 150-180 F/g in organic electrolytes and power densities up to 20 kW/kg. Murata has also pioneered hybrid systems combining activated carbon with small amounts of graphene to improve conductivity while maintaining cost-effectiveness for mass production.

Strengths: Established mass production capabilities, excellent cycling stability (>1 million cycles), and cost-effective manufacturing processes. Weaknesses: Lower energy density compared to emerging materials like MXene, and relatively lower conductivity than graphene-based electrodes.

King Abdullah University of Science & Technology

Technical Solution: KAUST has pioneered breakthrough research in MXene-based supercapacitor electrodes, developing Ti3C2Tx MXene materials with exceptional volumetric capacitance exceeding 900 F/cm³ in aqueous electrolytes. Their proprietary synthesis methods create MXene flakes with controlled surface terminations (-O, -F, -OH) that optimize ion intercalation and charge storage. KAUST researchers have demonstrated hydrogel-like MXene electrodes with ultrafast ion transport pathways that enable charging rates of 10 V/s while maintaining 80% capacitance retention. Their latest innovation involves creating vertically aligned MXene architectures that achieve areal capacitances above 2000 mF/cm² and volumetric energy densities approaching 25 Wh/L, significantly outperforming both activated carbon and graphene in terms of volumetric performance.

Strengths: Exceptional volumetric capacitance, ultrafast charging capabilities, and hydrophilic nature enabling excellent performance in aqueous electrolytes. Weaknesses: Limited long-term stability due to oxidation concerns, higher production costs, and challenges in scaling production to industrial levels.

Critical Technical Innovations in Electrode Material Science

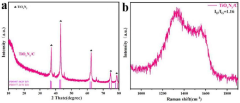

MXene/nitrogen-containing titanium oxide/carbon composite material as well as preparation method and application thereof

PatentActiveCN117854950A

Innovation

- Using MXene and nitrogen-containing titanium oxide/carbon composite materials, the first MXene and melamine are annealed in a protective gas to generate nitrogen-containing titanium oxide/carbon, and then compounded with the second MXene to form MXene/nitrogen-containing titanium oxide Material/carbon composite materials use external amorphous carbon layers to form a rich conductive network, which improves electron transmission efficiency and stabilizes the structure.

Sustainability and Life Cycle Assessment of Electrode Materials

The sustainability aspects of supercapacitor electrode materials are becoming increasingly critical as energy storage technologies scale up globally. When comparing activated carbon, MXene, and graphene as electrode materials, their environmental footprints differ significantly throughout their life cycles.

Activated carbon demonstrates notable sustainability advantages due to its production from renewable biomass sources such as coconut shells, wood, or agricultural waste. This renewable sourcing significantly reduces its carbon footprint compared to synthetic alternatives. The production process typically involves pyrolysis and chemical activation, which are relatively energy-efficient compared to nanomaterial synthesis. End-of-life management for activated carbon is also favorable, as it can be regenerated through thermal or chemical processes, extending its useful life.

MXene materials present a more complex sustainability profile. Their production requires energy-intensive etching processes using hazardous chemicals like hydrofluoric acid, raising significant environmental and safety concerns. The extraction of precursor materials, particularly transition metals like titanium, also carries substantial environmental impacts through mining operations. However, MXenes offer exceptional performance efficiency that may offset these production impacts through extended device lifetimes and improved energy efficiency during use.

Graphene's sustainability assessment reveals considerable challenges. Its production methods, particularly chemical vapor deposition, demand extremely high temperatures and energy inputs. The use of harsh chemicals in certain synthesis routes also raises toxicity concerns. Despite these drawbacks, graphene's extraordinary durability and performance characteristics may justify its environmental cost through significantly extended product lifecycles and reduced material requirements.

When evaluating these materials through comprehensive life cycle assessment (LCA) methodologies, several key metrics emerge. Energy return on investment (EROI) generally favors activated carbon due to its simpler production requirements. Water usage is highest for MXene production, while graphene synthesis typically generates the greatest greenhouse gas emissions per unit mass produced. Resource depletion impacts are most significant for MXene due to its reliance on relatively scarce transition metals.

Future sustainability improvements for these electrode materials will likely focus on greener synthesis routes, particularly for nanomaterials like graphene and MXene. Recycling technologies are also advancing, with promising developments in hydrometallurgical recovery processes for metal components and thermal recovery techniques for carbon-based materials. The integration of these materials into circular economy frameworks represents a critical challenge for ensuring their long-term sustainability in energy storage applications.

Activated carbon demonstrates notable sustainability advantages due to its production from renewable biomass sources such as coconut shells, wood, or agricultural waste. This renewable sourcing significantly reduces its carbon footprint compared to synthetic alternatives. The production process typically involves pyrolysis and chemical activation, which are relatively energy-efficient compared to nanomaterial synthesis. End-of-life management for activated carbon is also favorable, as it can be regenerated through thermal or chemical processes, extending its useful life.

MXene materials present a more complex sustainability profile. Their production requires energy-intensive etching processes using hazardous chemicals like hydrofluoric acid, raising significant environmental and safety concerns. The extraction of precursor materials, particularly transition metals like titanium, also carries substantial environmental impacts through mining operations. However, MXenes offer exceptional performance efficiency that may offset these production impacts through extended device lifetimes and improved energy efficiency during use.

Graphene's sustainability assessment reveals considerable challenges. Its production methods, particularly chemical vapor deposition, demand extremely high temperatures and energy inputs. The use of harsh chemicals in certain synthesis routes also raises toxicity concerns. Despite these drawbacks, graphene's extraordinary durability and performance characteristics may justify its environmental cost through significantly extended product lifecycles and reduced material requirements.

When evaluating these materials through comprehensive life cycle assessment (LCA) methodologies, several key metrics emerge. Energy return on investment (EROI) generally favors activated carbon due to its simpler production requirements. Water usage is highest for MXene production, while graphene synthesis typically generates the greatest greenhouse gas emissions per unit mass produced. Resource depletion impacts are most significant for MXene due to its reliance on relatively scarce transition metals.

Future sustainability improvements for these electrode materials will likely focus on greener synthesis routes, particularly for nanomaterials like graphene and MXene. Recycling technologies are also advancing, with promising developments in hydrometallurgical recovery processes for metal components and thermal recovery techniques for carbon-based materials. The integration of these materials into circular economy frameworks represents a critical challenge for ensuring their long-term sustainability in energy storage applications.

Manufacturing Scalability and Cost Considerations

Manufacturing scalability and cost considerations represent critical factors in determining the commercial viability of supercapacitor electrode materials. When comparing activated carbon, MXene, and graphene, significant differences emerge in their production processes, scalability potential, and economic feasibility.

Activated carbon benefits from well-established manufacturing processes that have been optimized over decades of industrial application. The raw materials for activated carbon production, primarily biomass or coal, are abundant and relatively inexpensive. Current production costs range from $10-30 per kilogram depending on quality requirements, making it the most economically viable option for mass production. The manufacturing infrastructure is already in place globally, allowing for economies of scale that further reduce costs.

MXene materials present more complex manufacturing challenges. The production process typically involves selective etching of MAX phases, requiring precise control of chemical reactions and subsequent delamination steps. Current manufacturing methods are primarily laboratory-scale, with limited industrial implementation. Production costs remain high, estimated between $200-1000 per gram, primarily due to complex synthesis procedures and expensive precursor materials. Scaling MXene production requires significant investment in specialized equipment and process optimization to reduce these costs.

Graphene manufacturing has seen substantial progress but continues to face scalability issues. Methods such as chemical vapor deposition (CVD) produce high-quality graphene but at prohibitively high costs for energy storage applications. More economical approaches like reduced graphene oxide (rGO) production offer better cost profiles ($50-200 per kilogram) but often yield materials with more defects. Several companies have developed intermediate-scale production facilities, but truly industrial-scale manufacturing remains challenging.

Environmental considerations also impact manufacturing economics. Activated carbon production can be environmentally sustainable when using biomass feedstocks but may involve high energy consumption during activation processes. MXene production typically requires hazardous chemicals like hydrofluoric acid, necessitating stringent safety protocols and waste management systems that add to production costs. Graphene manufacturing environmental impacts vary widely depending on the production method, with chemical approaches generally raising more environmental concerns than physical exfoliation techniques.

Future cost trajectories suggest activated carbon will maintain its cost advantage in the near term, while both MXene and graphene costs are expected to decrease significantly as manufacturing processes mature and production volumes increase. Industry analysts project potential cost reductions of 60-80% for MXene and graphene over the next decade, which could substantially alter the competitive landscape for supercapacitor electrode materials.

Activated carbon benefits from well-established manufacturing processes that have been optimized over decades of industrial application. The raw materials for activated carbon production, primarily biomass or coal, are abundant and relatively inexpensive. Current production costs range from $10-30 per kilogram depending on quality requirements, making it the most economically viable option for mass production. The manufacturing infrastructure is already in place globally, allowing for economies of scale that further reduce costs.

MXene materials present more complex manufacturing challenges. The production process typically involves selective etching of MAX phases, requiring precise control of chemical reactions and subsequent delamination steps. Current manufacturing methods are primarily laboratory-scale, with limited industrial implementation. Production costs remain high, estimated between $200-1000 per gram, primarily due to complex synthesis procedures and expensive precursor materials. Scaling MXene production requires significant investment in specialized equipment and process optimization to reduce these costs.

Graphene manufacturing has seen substantial progress but continues to face scalability issues. Methods such as chemical vapor deposition (CVD) produce high-quality graphene but at prohibitively high costs for energy storage applications. More economical approaches like reduced graphene oxide (rGO) production offer better cost profiles ($50-200 per kilogram) but often yield materials with more defects. Several companies have developed intermediate-scale production facilities, but truly industrial-scale manufacturing remains challenging.

Environmental considerations also impact manufacturing economics. Activated carbon production can be environmentally sustainable when using biomass feedstocks but may involve high energy consumption during activation processes. MXene production typically requires hazardous chemicals like hydrofluoric acid, necessitating stringent safety protocols and waste management systems that add to production costs. Graphene manufacturing environmental impacts vary widely depending on the production method, with chemical approaches generally raising more environmental concerns than physical exfoliation techniques.

Future cost trajectories suggest activated carbon will maintain its cost advantage in the near term, while both MXene and graphene costs are expected to decrease significantly as manufacturing processes mature and production volumes increase. Industry analysts project potential cost reductions of 60-80% for MXene and graphene over the next decade, which could substantially alter the competitive landscape for supercapacitor electrode materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!