How to Evaluate Supercapacitor Cycle Life: Protocols, Failure Modes and Reporting Metrics

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Supercapacitor Cycle Life Evaluation Background and Objectives

Supercapacitors have emerged as critical energy storage devices over the past three decades, offering unique advantages in power density, charging speed, and operational temperature range compared to traditional batteries. The evolution of supercapacitor technology has progressed from basic carbon-based electrodes to advanced materials incorporating pseudocapacitive elements, hybrid structures, and engineered electrolytes, significantly enhancing their performance characteristics.

The evaluation of supercapacitor cycle life represents a fundamental aspect of their commercial viability and technological advancement. Historically, cycle life testing methodologies have evolved from simple charge-discharge protocols to sophisticated accelerated aging techniques that better simulate real-world applications. This evolution reflects the growing understanding of failure mechanisms and the increasing demands of modern energy storage applications.

Current industry standards for supercapacitor cycle life evaluation remain inconsistent, with various testing protocols employed across academic research, manufacturing quality control, and end-user validation. This inconsistency creates challenges in comparing performance claims and establishing reliable lifetime predictions, ultimately impacting market adoption and technological development trajectories.

The primary objective of this technical research is to establish a comprehensive framework for evaluating supercapacitor cycle life that addresses current methodological gaps. This includes standardizing testing protocols that accurately reflect diverse application environments, identifying and characterizing predominant failure modes across different supercapacitor technologies, and developing consistent reporting metrics that facilitate meaningful performance comparisons.

Additionally, this research aims to correlate accelerated testing methodologies with real-world performance, enabling more accurate lifetime predictions without requiring prohibitively long testing periods. Understanding the relationship between testing conditions and degradation mechanisms will provide valuable insights for both manufacturers and end-users.

The technological significance of improved cycle life evaluation extends beyond quality assurance to inform material selection, cell design, and system integration strategies. By establishing clear connections between specific design choices and long-term performance, this research will guide future innovation pathways in supercapacitor development.

Furthermore, as supercapacitors increasingly find applications in critical infrastructure, renewable energy systems, and transportation, reliable lifetime prediction becomes essential for total cost of ownership calculations, maintenance scheduling, and system reliability assessments. This research therefore addresses both immediate technical needs and broader market requirements in the evolving energy storage landscape.

The evaluation of supercapacitor cycle life represents a fundamental aspect of their commercial viability and technological advancement. Historically, cycle life testing methodologies have evolved from simple charge-discharge protocols to sophisticated accelerated aging techniques that better simulate real-world applications. This evolution reflects the growing understanding of failure mechanisms and the increasing demands of modern energy storage applications.

Current industry standards for supercapacitor cycle life evaluation remain inconsistent, with various testing protocols employed across academic research, manufacturing quality control, and end-user validation. This inconsistency creates challenges in comparing performance claims and establishing reliable lifetime predictions, ultimately impacting market adoption and technological development trajectories.

The primary objective of this technical research is to establish a comprehensive framework for evaluating supercapacitor cycle life that addresses current methodological gaps. This includes standardizing testing protocols that accurately reflect diverse application environments, identifying and characterizing predominant failure modes across different supercapacitor technologies, and developing consistent reporting metrics that facilitate meaningful performance comparisons.

Additionally, this research aims to correlate accelerated testing methodologies with real-world performance, enabling more accurate lifetime predictions without requiring prohibitively long testing periods. Understanding the relationship between testing conditions and degradation mechanisms will provide valuable insights for both manufacturers and end-users.

The technological significance of improved cycle life evaluation extends beyond quality assurance to inform material selection, cell design, and system integration strategies. By establishing clear connections between specific design choices and long-term performance, this research will guide future innovation pathways in supercapacitor development.

Furthermore, as supercapacitors increasingly find applications in critical infrastructure, renewable energy systems, and transportation, reliable lifetime prediction becomes essential for total cost of ownership calculations, maintenance scheduling, and system reliability assessments. This research therefore addresses both immediate technical needs and broader market requirements in the evolving energy storage landscape.

Market Demand Analysis for Reliable Supercapacitor Testing

The global supercapacitor market is experiencing significant growth, driven by increasing demand for reliable energy storage solutions across multiple industries. Market research indicates that the supercapacitor market is projected to grow at a CAGR of 20-25% through 2030, with particular acceleration in automotive, renewable energy, and consumer electronics sectors.

Reliable testing protocols for supercapacitor cycle life have become a critical market need as manufacturers and end-users seek to validate performance claims and ensure product longevity. This demand stems from several market factors, including the widening gap between manufacturer specifications and real-world performance, which has created trust issues among industrial buyers and system integrators.

The automotive sector represents one of the largest demand drivers for standardized supercapacitor testing. With electric and hybrid vehicles increasingly incorporating supercapacitors for regenerative braking and power management, automotive manufacturers require consistent and reliable testing protocols to ensure components meet stringent performance and safety requirements over vehicle lifetimes.

Renewable energy applications present another significant market segment demanding improved testing methodologies. As grid storage systems increasingly utilize supercapacitors for frequency regulation and power quality improvement, utility companies and system integrators need accurate cycle life predictions to calculate total cost of ownership and maintenance schedules.

Consumer electronics manufacturers have also expressed growing demand for reliable testing standards as supercapacitors find applications in smartphones, wearables, and portable devices. The need for rapid charging capabilities while maintaining long-term reliability has pushed manufacturers to seek better validation methods for component selection.

Industrial equipment manufacturers represent another key market segment requiring standardized testing protocols. In applications such as heavy machinery, transportation, and manufacturing equipment, where unexpected downtime carries substantial costs, accurate prediction of supercapacitor performance degradation has become essential for maintenance planning and system reliability.

Market research indicates that testing equipment manufacturers are responding to this demand with specialized instruments designed specifically for supercapacitor evaluation. The market for such testing equipment is growing at approximately 15% annually, reflecting the increasing importance of reliable performance validation.

Geographically, the demand for standardized testing protocols is strongest in regions with established electronics manufacturing and automotive industries, particularly East Asia, North America, and Europe. However, emerging markets are showing increased interest as local manufacturing capabilities expand and quality standards rise to meet international requirements.

Reliable testing protocols for supercapacitor cycle life have become a critical market need as manufacturers and end-users seek to validate performance claims and ensure product longevity. This demand stems from several market factors, including the widening gap between manufacturer specifications and real-world performance, which has created trust issues among industrial buyers and system integrators.

The automotive sector represents one of the largest demand drivers for standardized supercapacitor testing. With electric and hybrid vehicles increasingly incorporating supercapacitors for regenerative braking and power management, automotive manufacturers require consistent and reliable testing protocols to ensure components meet stringent performance and safety requirements over vehicle lifetimes.

Renewable energy applications present another significant market segment demanding improved testing methodologies. As grid storage systems increasingly utilize supercapacitors for frequency regulation and power quality improvement, utility companies and system integrators need accurate cycle life predictions to calculate total cost of ownership and maintenance schedules.

Consumer electronics manufacturers have also expressed growing demand for reliable testing standards as supercapacitors find applications in smartphones, wearables, and portable devices. The need for rapid charging capabilities while maintaining long-term reliability has pushed manufacturers to seek better validation methods for component selection.

Industrial equipment manufacturers represent another key market segment requiring standardized testing protocols. In applications such as heavy machinery, transportation, and manufacturing equipment, where unexpected downtime carries substantial costs, accurate prediction of supercapacitor performance degradation has become essential for maintenance planning and system reliability.

Market research indicates that testing equipment manufacturers are responding to this demand with specialized instruments designed specifically for supercapacitor evaluation. The market for such testing equipment is growing at approximately 15% annually, reflecting the increasing importance of reliable performance validation.

Geographically, the demand for standardized testing protocols is strongest in regions with established electronics manufacturing and automotive industries, particularly East Asia, North America, and Europe. However, emerging markets are showing increased interest as local manufacturing capabilities expand and quality standards rise to meet international requirements.

Current Challenges in Supercapacitor Longevity Assessment

Despite significant advancements in supercapacitor technology, the field faces several critical challenges in accurately assessing device longevity. One fundamental issue is the lack of standardized testing protocols across the industry. Different manufacturers and research institutions employ varying methodologies for cycle life evaluation, making direct comparisons between products and research findings problematic. This inconsistency creates significant barriers to technology advancement and market transparency.

The accelerated testing methods currently used present another major challenge. While necessary to obtain timely results, these methods often fail to accurately represent real-world operating conditions. The correlation between accelerated test results and actual field performance remains poorly understood, leading to potential overestimation or underestimation of supercapacitor lifespan in practical applications.

Environmental factors significantly complicate longevity assessment. Supercapacitors deployed in automotive, renewable energy, or industrial settings experience widely varying temperature, humidity, and vibration conditions. Current testing protocols rarely account for these environmental variations comprehensively, creating a disconnect between laboratory results and field performance.

The identification and characterization of failure modes represent another substantial challenge. Unlike batteries with well-documented degradation mechanisms, supercapacitor failure pathways are less thoroughly mapped. Common failure modes include electrolyte degradation, electrode material breakdown, and separator deterioration, but the relative importance of each mechanism under different operating conditions remains unclear.

Reporting metrics present additional complications. The industry lacks consensus on which parameters best indicate supercapacitor health. While capacity retention is commonly reported, other critical factors such as equivalent series resistance (ESR) increase, self-discharge rate changes, and power capability degradation are inconsistently monitored and reported.

The time-intensive nature of longevity testing creates practical challenges for both manufacturers and researchers. Even accelerated testing protocols can require weeks or months to complete, creating bottlenecks in product development cycles and delaying the introduction of innovations to market.

Finally, there exists a significant gap between academic research and industrial practice in longevity assessment. Academic studies often focus on novel materials and configurations under idealized conditions, while industry requires practical, reproducible testing methods applicable to mass-produced devices. Bridging this gap requires greater collaboration and standardization efforts across the supercapacitor ecosystem.

The accelerated testing methods currently used present another major challenge. While necessary to obtain timely results, these methods often fail to accurately represent real-world operating conditions. The correlation between accelerated test results and actual field performance remains poorly understood, leading to potential overestimation or underestimation of supercapacitor lifespan in practical applications.

Environmental factors significantly complicate longevity assessment. Supercapacitors deployed in automotive, renewable energy, or industrial settings experience widely varying temperature, humidity, and vibration conditions. Current testing protocols rarely account for these environmental variations comprehensively, creating a disconnect between laboratory results and field performance.

The identification and characterization of failure modes represent another substantial challenge. Unlike batteries with well-documented degradation mechanisms, supercapacitor failure pathways are less thoroughly mapped. Common failure modes include electrolyte degradation, electrode material breakdown, and separator deterioration, but the relative importance of each mechanism under different operating conditions remains unclear.

Reporting metrics present additional complications. The industry lacks consensus on which parameters best indicate supercapacitor health. While capacity retention is commonly reported, other critical factors such as equivalent series resistance (ESR) increase, self-discharge rate changes, and power capability degradation are inconsistently monitored and reported.

The time-intensive nature of longevity testing creates practical challenges for both manufacturers and researchers. Even accelerated testing protocols can require weeks or months to complete, creating bottlenecks in product development cycles and delaying the introduction of innovations to market.

Finally, there exists a significant gap between academic research and industrial practice in longevity assessment. Academic studies often focus on novel materials and configurations under idealized conditions, while industry requires practical, reproducible testing methods applicable to mass-produced devices. Bridging this gap requires greater collaboration and standardization efforts across the supercapacitor ecosystem.

Standard Protocols for Supercapacitor Cycle Life Testing

01 Electrode materials for extended cycle life

The choice of electrode materials significantly impacts the cycle life of supercapacitors. Advanced carbon-based materials, metal oxides, and composite electrodes can enhance cycling stability. Optimized electrode structures with controlled porosity and surface area help maintain performance over thousands of charge-discharge cycles by reducing degradation mechanisms and improving ion transport pathways.- Electrode materials for extended cycle life: The choice of electrode materials significantly impacts the cycle life of supercapacitors. Advanced carbon-based materials, metal oxides, and composite electrodes can enhance durability during charge-discharge cycles. Optimizing the electrode structure and composition helps minimize degradation mechanisms such as material dissolution, structural collapse, and surface passivation, thereby extending the operational lifetime of supercapacitors.

- Electrolyte formulations for stability: Electrolyte composition plays a crucial role in determining supercapacitor cycle life. Specialized electrolyte formulations can reduce side reactions at electrode interfaces, prevent corrosion, and maintain ionic conductivity over extended periods. Additives that form protective films on electrode surfaces or scavenge impurities can significantly improve cycling stability and prevent capacity fade during long-term operation.

- Thermal management systems: Effective thermal management is essential for maintaining supercapacitor cycle life. Systems that regulate operating temperature can prevent accelerated degradation mechanisms triggered by heat. Advanced cooling designs, thermal interface materials, and temperature monitoring systems help maintain optimal operating conditions, reducing stress on components and extending the useful lifetime of supercapacitor devices.

- Charge-discharge control algorithms: Sophisticated control algorithms can optimize the charging and discharging processes to extend supercapacitor cycle life. These algorithms monitor parameters such as voltage, current, and temperature to prevent operation outside safe limits. Adaptive control strategies that adjust charging profiles based on device condition and usage patterns can significantly reduce stress on components and minimize degradation mechanisms that limit cycle life.

- Diagnostic and predictive maintenance systems: Advanced diagnostic tools and predictive maintenance systems can monitor supercapacitor health and predict end-of-life. These systems analyze performance data to detect early signs of degradation and recommend preventive actions. Machine learning algorithms can identify patterns associated with capacity fade and resistance increase, enabling timely intervention to extend operational lifetime and optimize replacement schedules.

02 Electrolyte formulations for stability

Electrolyte composition plays a crucial role in determining supercapacitor cycle life. Advanced electrolyte formulations with additives that prevent electrode degradation and reduce side reactions can significantly extend operational lifespan. Ionic liquids and gel electrolytes offer improved voltage stability and reduced electrolyte decomposition, leading to enhanced cycling performance and longer device lifetime.Expand Specific Solutions03 Thermal management systems

Effective thermal management is essential for maintaining supercapacitor cycle life. Systems that regulate operating temperature prevent accelerated aging and degradation mechanisms. Advanced cooling techniques and thermal interface materials help dissipate heat generated during rapid charge-discharge cycles, preserving electrode and electrolyte integrity and extending the overall operational lifespan of supercapacitor devices.Expand Specific Solutions04 Charge-discharge control algorithms

Sophisticated charge-discharge control algorithms can significantly extend supercapacitor cycle life. These algorithms optimize current distribution, prevent voltage spikes, and manage depth of discharge to minimize stress on the electrodes and electrolyte. Adaptive control systems that adjust parameters based on operating conditions and aging status help maintain performance consistency throughout the device lifetime.Expand Specific Solutions05 Diagnostic and monitoring systems

Advanced diagnostic and monitoring systems enable real-time assessment of supercapacitor health and remaining cycle life. These systems track key performance indicators such as equivalent series resistance, capacitance retention, and leakage current to identify early signs of degradation. Predictive analytics and machine learning algorithms process this data to optimize operating conditions and maintenance schedules, thereby extending the effective cycle life of supercapacitor systems.Expand Specific Solutions

Key Industry Players in Supercapacitor Testing Equipment

The supercapacitor cycle life evaluation market is currently in a growth phase, with increasing adoption across automotive, renewable energy, and power grid sectors. The global market size is projected to expand significantly as energy storage solutions become critical for sustainable technologies. From a technical maturity perspective, established players like Maxwell Technologies (now part of Tesla) have developed standardized testing protocols, while companies such as VINATECH, Shanghai Aowei Technology, and Shenzhen TIG Technology are advancing failure mode analysis methodologies. Johnson Controls, Mitsubishi Electric, and General Motors are integrating supercapacitors into commercial applications, driving the need for reliable cycle life metrics. The industry is moving toward consensus on reporting standards, with research institutions like Hunan University of Science & Technology and power companies like Guangdong Power Grid contributing to protocol development.

Shanghai Aowei Technology Development Co., Ltd.

Technical Solution: Shanghai Aowei has pioneered a specialized evaluation framework for supercapacitors in transportation applications, particularly for electric buses and trams. Their cycle life testing protocol emphasizes high-power charge-discharge cycles (up to 10C rates) that replicate the rapid charging at stations and energy recovery during braking. Aowei's methodology incorporates vibration stress testing simultaneously with cycling to simulate real transportation conditions. They've developed a unique "power capability retention" metric that evaluates not just capacitance but the ability to deliver high power after numerous cycles. Their failure mode analysis focuses particularly on thermal runaway prevention and cell balancing degradation in large series-connected modules. Aowei conducts extended testing beyond 1 million cycles for transportation applications, with intermediate checkpoints every 100,000 cycles. Their reporting includes spatial temperature mapping during cycling to identify hotspots that may indicate potential failure points within large supercapacitor banks[4][7].

Strengths: Highly specialized expertise in transportation applications with testing protocols that accurately simulate the unique demands of electric transit systems. Their combined mechanical and electrical stress testing provides more realistic performance predictions. Weaknesses: Their evaluation methods are heavily tailored to public transportation use cases, potentially limiting applicability to other sectors. The extended testing periods (>1 million cycles) require significant time investment before obtaining complete lifecycle data.

China Southern Power Grid Research Institute Co., Ltd.

Technical Solution: China Southern Power Grid Research Institute has developed an advanced evaluation framework specifically for grid-scale supercapacitor applications. Their methodology focuses on high-voltage supercapacitor modules (>1000V) used in power quality improvement and grid stabilization. Their protocols include specialized frequency response testing that evaluates performance under various grid disturbance scenarios, including voltage sags, swells, and frequency variations. The institute employs a unique "grid event simulation" approach that subjects supercapacitors to recorded waveforms from actual grid disturbances to assess real-world performance. Their failure mode analysis particularly focuses on module-level issues such as voltage imbalance between cells and thermal management system degradation. Their reporting metrics include a proprietary "grid support capability index" that quantifies how supercapacitor performance in frequency regulation and voltage support applications degrades over time. The institute conducts parallel testing of multiple identical modules to establish statistical reliability data, with particular attention to outlier detection that might indicate potential manufacturing quality issues[9][10].

Strengths: Unparalleled expertise in grid-scale applications with testing protocols specifically designed for power quality and grid stabilization use cases. Their use of actual grid event data provides highly realistic performance evaluation. Weaknesses: Their evaluation methods are heavily specialized for utility-scale applications and may have limited relevance to smaller-scale uses. The testing infrastructure required for high-voltage, high-power evaluation necessitates significant specialized equipment and safety protocols.

Critical Analysis of Failure Mode Detection Techniques

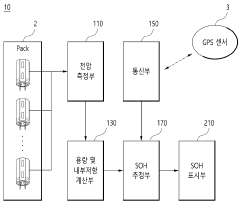

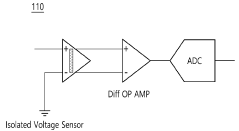

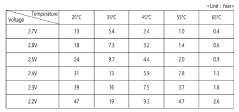

Method for estimating state of health of supercapacitor pack using sensor, recording medium and device for performing the method

PatentActiveKR1020220134374A

Innovation

- A method using a sensor to measure voltage and internal resistance of supercapacitor packs at regular intervals, combined with GPS data to account for external environmental factors like temperature, humidity, and weather, allowing for precise estimation of SOH through capacity and resistance changes.

Method and assessment unit for determining the remaining service life of a capacitor, and system

PatentActiveEP3555644A1

Innovation

- A method and evaluation unit that measure voltage change and discharge current across a capacitor during discharge time to determine actual capacitance, apply error correction to account for temperature influences, and calculate the remaining service life based on the difference between corrected and initial capacitance, allowing for precise assessment of capacitor aging.

Environmental Factors Affecting Supercapacitor Degradation

Environmental factors play a crucial role in determining the degradation rate and overall cycle life of supercapacitors. Temperature stands as the most significant environmental parameter affecting supercapacitor performance and longevity. At elevated temperatures (typically above 65°C), the electrolyte experiences accelerated decomposition, leading to increased internal resistance and decreased capacitance. Conversely, extremely low temperatures reduce ion mobility within the electrolyte, temporarily diminishing power capability and apparent capacitance.

Humidity represents another critical environmental factor, particularly for supercapacitors with aqueous electrolytes or those lacking proper sealing. Moisture ingress can contaminate the electrolyte, potentially causing electrochemical side reactions at electrode surfaces and accelerating degradation processes. In severe cases, water contamination may lead to gas generation and subsequent pressure build-up within the cell.

Atmospheric pressure variations, though less commonly discussed, can impact hermetically sealed supercapacitors by creating mechanical stress on sealing components. This stress may compromise seal integrity over time, especially during rapid pressure changes or when devices operate at high altitudes or underwater environments.

Exposure to ultraviolet radiation can degrade polymer components in supercapacitor packaging, potentially compromising sealing integrity and allowing electrolyte evaporation or contamination. This factor becomes particularly relevant for outdoor applications or those involving direct sunlight exposure.

Mechanical vibration and shock represent significant environmental stressors in automotive, aerospace, and industrial applications. Continuous vibration can lead to electrode material detachment from current collectors, internal short circuits, or connection failures between cells in a module. The severity of these effects depends on vibration frequency, amplitude, and duration.

Atmospheric contaminants, including airborne particulates, corrosive gases (SO2, NOx, H2S), and salt spray in coastal environments, can accelerate corrosion of external terminals and packaging materials. Without adequate protection, these contaminants may eventually penetrate the device and compromise internal components.

Electrical environment factors, such as electromagnetic interference (EMI) and voltage transients from nearby equipment, can induce additional stress on supercapacitors. While modern devices incorporate protection mechanisms, persistent exposure to harsh electrical environments may accelerate aging processes through mechanisms not observed in standard laboratory testing.

Humidity represents another critical environmental factor, particularly for supercapacitors with aqueous electrolytes or those lacking proper sealing. Moisture ingress can contaminate the electrolyte, potentially causing electrochemical side reactions at electrode surfaces and accelerating degradation processes. In severe cases, water contamination may lead to gas generation and subsequent pressure build-up within the cell.

Atmospheric pressure variations, though less commonly discussed, can impact hermetically sealed supercapacitors by creating mechanical stress on sealing components. This stress may compromise seal integrity over time, especially during rapid pressure changes or when devices operate at high altitudes or underwater environments.

Exposure to ultraviolet radiation can degrade polymer components in supercapacitor packaging, potentially compromising sealing integrity and allowing electrolyte evaporation or contamination. This factor becomes particularly relevant for outdoor applications or those involving direct sunlight exposure.

Mechanical vibration and shock represent significant environmental stressors in automotive, aerospace, and industrial applications. Continuous vibration can lead to electrode material detachment from current collectors, internal short circuits, or connection failures between cells in a module. The severity of these effects depends on vibration frequency, amplitude, and duration.

Atmospheric contaminants, including airborne particulates, corrosive gases (SO2, NOx, H2S), and salt spray in coastal environments, can accelerate corrosion of external terminals and packaging materials. Without adequate protection, these contaminants may eventually penetrate the device and compromise internal components.

Electrical environment factors, such as electromagnetic interference (EMI) and voltage transients from nearby equipment, can induce additional stress on supercapacitors. While modern devices incorporate protection mechanisms, persistent exposure to harsh electrical environments may accelerate aging processes through mechanisms not observed in standard laboratory testing.

Standardization Efforts in Supercapacitor Reporting

The supercapacitor industry has recognized the critical need for standardized testing and reporting protocols to ensure consistency and comparability across research and commercial applications. Several international organizations have been actively working to establish comprehensive standards for supercapacitor evaluation, with cycle life assessment being a key focus area.

The International Electrotechnical Commission (IEC) has developed the IEC 62391 standard, which provides guidelines for fixed electric double-layer capacitors for use in electronic equipment. This standard includes specific protocols for cycle life testing, though industry experts have noted that these protocols require updates to address emerging supercapacitor technologies and applications.

The IEEE Working Group P2470 has been developing standards specifically for energy storage systems, including supercapacitors. Their work aims to create uniform testing methodologies that enable fair comparison between different manufacturers' products and research outcomes, with particular emphasis on cycle life reporting metrics.

In the United States, the Department of Energy has funded initiatives through national laboratories to establish standardized testing protocols for energy storage devices. These efforts include detailed procedures for accelerated aging tests and failure mode identification in supercapacitors, which are crucial for accurate cycle life prediction.

The European Committee for Electrotechnical Standardization (CENELEC) has also contributed to standardization efforts through technical committees focused on electrical energy storage systems. Their work includes harmonizing testing procedures across European markets and aligning with global standards.

Industry consortia, such as the International Supercapacitor Manufacturers Association (ISMA), have been collaborating to develop best practices for cycle life evaluation. These industry-led initiatives often complement formal standardization efforts by providing practical insights from manufacturing and application perspectives.

Despite these efforts, significant challenges remain in standardization. Different application requirements (automotive, grid storage, consumer electronics) necessitate varied testing protocols, making universal standards difficult to establish. Additionally, the rapid evolution of supercapacitor materials and designs requires continuous updates to testing methodologies.

Current standardization gaps include insufficient guidance on reporting environmental conditions during testing, limited consensus on end-of-life criteria definitions, and inadequate protocols for hybrid supercapacitor technologies that combine features of batteries and traditional supercapacitors.

The International Electrotechnical Commission (IEC) has developed the IEC 62391 standard, which provides guidelines for fixed electric double-layer capacitors for use in electronic equipment. This standard includes specific protocols for cycle life testing, though industry experts have noted that these protocols require updates to address emerging supercapacitor technologies and applications.

The IEEE Working Group P2470 has been developing standards specifically for energy storage systems, including supercapacitors. Their work aims to create uniform testing methodologies that enable fair comparison between different manufacturers' products and research outcomes, with particular emphasis on cycle life reporting metrics.

In the United States, the Department of Energy has funded initiatives through national laboratories to establish standardized testing protocols for energy storage devices. These efforts include detailed procedures for accelerated aging tests and failure mode identification in supercapacitors, which are crucial for accurate cycle life prediction.

The European Committee for Electrotechnical Standardization (CENELEC) has also contributed to standardization efforts through technical committees focused on electrical energy storage systems. Their work includes harmonizing testing procedures across European markets and aligning with global standards.

Industry consortia, such as the International Supercapacitor Manufacturers Association (ISMA), have been collaborating to develop best practices for cycle life evaluation. These industry-led initiatives often complement formal standardization efforts by providing practical insights from manufacturing and application perspectives.

Despite these efforts, significant challenges remain in standardization. Different application requirements (automotive, grid storage, consumer electronics) necessitate varied testing protocols, making universal standards difficult to establish. Additionally, the rapid evolution of supercapacitor materials and designs requires continuous updates to testing methodologies.

Current standardization gaps include insufficient guidance on reporting environmental conditions during testing, limited consensus on end-of-life criteria definitions, and inadequate protocols for hybrid supercapacitor technologies that combine features of batteries and traditional supercapacitors.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!