Comparing AEC vs IEC Standards for Supercapacitor Safety Testing — What Engineers Need to Know

AUG 21, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Supercapacitor Safety Standards Background and Objectives

Supercapacitors have emerged as critical energy storage components in various industries, from automotive to renewable energy systems, due to their high power density, rapid charge-discharge capabilities, and long cycle life. The evolution of supercapacitor technology can be traced back to the 1950s, with significant commercial development beginning in the 1970s. As applications have expanded from simple memory backup systems to high-power automotive applications and grid-level energy storage, the need for comprehensive safety standards has become increasingly apparent.

The development of safety standards for supercapacitors has followed two primary paths: the International Electrotechnical Commission (IEC) standards, which have global reach, and the Automotive Electronics Council (AEC) standards, which focus specifically on automotive applications. These parallel development tracks reflect the diverse application environments in which supercapacitors operate, from consumer electronics to mission-critical automotive systems.

The IEC 62391 series, first published in 2006 and subsequently updated, established the foundation for supercapacitor classification, testing, and safety requirements. This was later complemented by IEC 62576, which specifically addresses electric double-layer capacitors for hybrid electric vehicles. These standards have evolved to address increasing energy densities and expanded application scenarios.

Concurrently, the automotive industry developed the AEC-Q200 qualification requirements for passive components, which include specific provisions for supercapacitors used in automotive environments. These standards emphasize reliability under extreme conditions, including temperature cycling, vibration resistance, and humidity testing that exceed typical consumer electronics requirements.

The technical objectives of modern supercapacitor safety standards encompass several critical dimensions: preventing catastrophic failures such as explosion or fire, ensuring performance stability across varying environmental conditions, establishing clear parameters for thermal management, defining electrical safety boundaries including maximum voltage and current limits, and creating standardized testing protocols that enable meaningful comparison between different manufacturers' products.

Recent technological advancements, including the development of hybrid supercapacitors and lithium-ion capacitors with significantly higher energy densities, have necessitated continuous evolution of these standards. The convergence of supercapacitor and battery technologies has created new safety challenges that existing standards must address, particularly regarding thermal runaway prevention and management of higher energy densities.

The ultimate goal of these standards is to establish a comprehensive framework that ensures supercapacitor safety across diverse applications while enabling continued innovation and technological advancement. Engineers must navigate these evolving standards to ensure their designs meet both current requirements and anticipate future regulatory developments.

The development of safety standards for supercapacitors has followed two primary paths: the International Electrotechnical Commission (IEC) standards, which have global reach, and the Automotive Electronics Council (AEC) standards, which focus specifically on automotive applications. These parallel development tracks reflect the diverse application environments in which supercapacitors operate, from consumer electronics to mission-critical automotive systems.

The IEC 62391 series, first published in 2006 and subsequently updated, established the foundation for supercapacitor classification, testing, and safety requirements. This was later complemented by IEC 62576, which specifically addresses electric double-layer capacitors for hybrid electric vehicles. These standards have evolved to address increasing energy densities and expanded application scenarios.

Concurrently, the automotive industry developed the AEC-Q200 qualification requirements for passive components, which include specific provisions for supercapacitors used in automotive environments. These standards emphasize reliability under extreme conditions, including temperature cycling, vibration resistance, and humidity testing that exceed typical consumer electronics requirements.

The technical objectives of modern supercapacitor safety standards encompass several critical dimensions: preventing catastrophic failures such as explosion or fire, ensuring performance stability across varying environmental conditions, establishing clear parameters for thermal management, defining electrical safety boundaries including maximum voltage and current limits, and creating standardized testing protocols that enable meaningful comparison between different manufacturers' products.

Recent technological advancements, including the development of hybrid supercapacitors and lithium-ion capacitors with significantly higher energy densities, have necessitated continuous evolution of these standards. The convergence of supercapacitor and battery technologies has created new safety challenges that existing standards must address, particularly regarding thermal runaway prevention and management of higher energy densities.

The ultimate goal of these standards is to establish a comprehensive framework that ensures supercapacitor safety across diverse applications while enabling continued innovation and technological advancement. Engineers must navigate these evolving standards to ensure their designs meet both current requirements and anticipate future regulatory developments.

Market Demand Analysis for Standardized Safety Testing

The global market for supercapacitor safety testing standards is experiencing significant growth, driven by the expanding applications of supercapacitors across multiple industries. With the increasing adoption of supercapacitors in automotive, renewable energy, consumer electronics, and industrial applications, the demand for standardized safety testing protocols has become more critical than ever.

Market research indicates that the supercapacitor market is projected to grow at a compound annual growth rate of 20% through 2028, with the safety testing equipment and services segment following a similar trajectory. This growth is particularly pronounced in regions with strong manufacturing bases for electronic components and energy storage systems, including East Asia, North America, and Europe.

The automotive sector represents the largest market segment demanding standardized supercapacitor safety testing. As electric and hybrid vehicles gain market share, automotive manufacturers and suppliers require consistent safety standards to ensure reliability and performance. The implementation of the Automotive Electronics Council (AEC) standards has become increasingly important for suppliers seeking to enter this competitive market.

Simultaneously, the industrial electronics sector shows growing demand for International Electrotechnical Commission (IEC) standards compliance, particularly in applications where supercapacitors are exposed to harsh environmental conditions or critical safety scenarios. The renewable energy sector, with its focus on energy storage solutions, has emerged as another significant market driver for standardized testing protocols.

Market surveys reveal that engineering teams across industries are facing challenges with the divergent requirements between AEC and IEC standards. Over 70% of engineers working with supercapacitors report spending additional resources to navigate these differences, creating a market opportunity for testing solutions that can address both standard frameworks efficiently.

The geographical distribution of market demand shows regional preferences, with North American manufacturers typically prioritizing AEC standards compliance, while European and Asian markets often emphasize IEC standards. This regional variation creates complexity for global suppliers and increases the value proposition for comprehensive testing solutions that address multiple standards.

Testing service providers report increasing client requests for comparative analyses between different standards, highlighting a market need for educational resources and consulting services that can help engineering teams navigate the complex regulatory landscape. This trend is particularly evident among small to medium-sized manufacturers who may lack the internal expertise to interpret and implement multiple standards simultaneously.

Market research indicates that the supercapacitor market is projected to grow at a compound annual growth rate of 20% through 2028, with the safety testing equipment and services segment following a similar trajectory. This growth is particularly pronounced in regions with strong manufacturing bases for electronic components and energy storage systems, including East Asia, North America, and Europe.

The automotive sector represents the largest market segment demanding standardized supercapacitor safety testing. As electric and hybrid vehicles gain market share, automotive manufacturers and suppliers require consistent safety standards to ensure reliability and performance. The implementation of the Automotive Electronics Council (AEC) standards has become increasingly important for suppliers seeking to enter this competitive market.

Simultaneously, the industrial electronics sector shows growing demand for International Electrotechnical Commission (IEC) standards compliance, particularly in applications where supercapacitors are exposed to harsh environmental conditions or critical safety scenarios. The renewable energy sector, with its focus on energy storage solutions, has emerged as another significant market driver for standardized testing protocols.

Market surveys reveal that engineering teams across industries are facing challenges with the divergent requirements between AEC and IEC standards. Over 70% of engineers working with supercapacitors report spending additional resources to navigate these differences, creating a market opportunity for testing solutions that can address both standard frameworks efficiently.

The geographical distribution of market demand shows regional preferences, with North American manufacturers typically prioritizing AEC standards compliance, while European and Asian markets often emphasize IEC standards. This regional variation creates complexity for global suppliers and increases the value proposition for comprehensive testing solutions that address multiple standards.

Testing service providers report increasing client requests for comparative analyses between different standards, highlighting a market need for educational resources and consulting services that can help engineering teams navigate the complex regulatory landscape. This trend is particularly evident among small to medium-sized manufacturers who may lack the internal expertise to interpret and implement multiple standards simultaneously.

AEC vs IEC Standards: Current Status and Challenges

The global supercapacitor market is witnessing significant growth, with projections indicating a CAGR of 20-25% over the next decade. As these energy storage devices become increasingly integrated into critical applications across automotive, renewable energy, and consumer electronics sectors, safety standards have emerged as a crucial consideration for manufacturers and engineers. Currently, two major standardization frameworks dominate the landscape: the Automotive Electronics Council (AEC) standards and the International Electrotechnical Commission (IEC) standards.

AEC standards, primarily developed for automotive applications, focus on rigorous environmental and electrical stress testing suitable for the demanding conditions of vehicle operations. These standards emphasize temperature cycling, vibration resistance, and electrical surge protection that align with automotive reliability requirements. However, the AEC framework currently lacks comprehensive supercapacitor-specific testing protocols, often requiring engineers to adapt existing component standards like AEC-Q200 (for passive components) to supercapacitor applications.

In contrast, IEC standards provide more explicit guidance for supercapacitor testing through IEC 62391 and IEC 62576, which specifically address electric double-layer capacitors for various applications. These standards offer detailed testing methodologies for electrical characteristics, endurance, and safety parameters. The IEC framework benefits from broader international consensus but may not fully address the unique demands of automotive environments.

A significant challenge facing the industry is the lack of harmonization between these standards. Engineers must often navigate overlapping and sometimes contradictory requirements, particularly when developing supercapacitors for global markets. This discrepancy creates compliance complexities and potentially increases development costs as manufacturers must satisfy multiple testing regimes.

Technical limitations also exist within both frameworks. Neither standard fully addresses emerging supercapacitor technologies such as hybrid supercapacitors or graphene-based devices, creating uncertainty around certification requirements for next-generation products. Additionally, safety testing for high-voltage supercapacitor arrays, increasingly common in renewable energy applications, lacks standardized protocols in both frameworks.

Regional variations further complicate the standardization landscape. While IEC standards enjoy broader global recognition, AEC standards hold particular influence in North American and European automotive supply chains. Meanwhile, China has developed its own national standards (GB/T) for supercapacitors that incorporate elements of both frameworks but add unique requirements, creating additional compliance challenges for global manufacturers.

The industry is gradually moving toward greater alignment, with technical committees from both organizations engaging in collaborative efforts to develop more harmonized approaches to supercapacitor safety testing. However, this process remains in its early stages, leaving engineers to navigate a complex standards environment for the foreseeable future.

AEC standards, primarily developed for automotive applications, focus on rigorous environmental and electrical stress testing suitable for the demanding conditions of vehicle operations. These standards emphasize temperature cycling, vibration resistance, and electrical surge protection that align with automotive reliability requirements. However, the AEC framework currently lacks comprehensive supercapacitor-specific testing protocols, often requiring engineers to adapt existing component standards like AEC-Q200 (for passive components) to supercapacitor applications.

In contrast, IEC standards provide more explicit guidance for supercapacitor testing through IEC 62391 and IEC 62576, which specifically address electric double-layer capacitors for various applications. These standards offer detailed testing methodologies for electrical characteristics, endurance, and safety parameters. The IEC framework benefits from broader international consensus but may not fully address the unique demands of automotive environments.

A significant challenge facing the industry is the lack of harmonization between these standards. Engineers must often navigate overlapping and sometimes contradictory requirements, particularly when developing supercapacitors for global markets. This discrepancy creates compliance complexities and potentially increases development costs as manufacturers must satisfy multiple testing regimes.

Technical limitations also exist within both frameworks. Neither standard fully addresses emerging supercapacitor technologies such as hybrid supercapacitors or graphene-based devices, creating uncertainty around certification requirements for next-generation products. Additionally, safety testing for high-voltage supercapacitor arrays, increasingly common in renewable energy applications, lacks standardized protocols in both frameworks.

Regional variations further complicate the standardization landscape. While IEC standards enjoy broader global recognition, AEC standards hold particular influence in North American and European automotive supply chains. Meanwhile, China has developed its own national standards (GB/T) for supercapacitors that incorporate elements of both frameworks but add unique requirements, creating additional compliance challenges for global manufacturers.

The industry is gradually moving toward greater alignment, with technical committees from both organizations engaging in collaborative efforts to develop more harmonized approaches to supercapacitor safety testing. However, this process remains in its early stages, leaving engineers to navigate a complex standards environment for the foreseeable future.

Technical Comparison of AEC and IEC Testing Methodologies

01 IEC standards for supercapacitor safety testing

The International Electrotechnical Commission (IEC) has established specific standards for testing the safety of supercapacitors. These standards include protocols for thermal stability, voltage endurance, and short circuit protection. IEC standards are widely adopted globally and provide comprehensive guidelines for manufacturers to ensure their supercapacitors meet international safety requirements before market release.- IEC standards for supercapacitor safety testing: The International Electrotechnical Commission (IEC) has established specific standards for testing the safety of supercapacitors. These standards include protocols for thermal stability, electrical performance under various conditions, and durability testing. IEC standards are widely adopted globally and provide comprehensive guidelines for manufacturers to ensure their supercapacitors meet international safety requirements before market release.

- AEC standards for automotive supercapacitor applications: The Automotive Electronics Council (AEC) has developed specialized standards for supercapacitors used in automotive applications. These standards focus on reliability under extreme temperature conditions, vibration resistance, and long-term performance stability. AEC qualification testing is particularly rigorous due to the demanding environment of automotive applications and includes stress tests that simulate real-world conditions vehicles may encounter.

- Comparative analysis of safety testing methodologies: Different safety testing methodologies exist between AEC and IEC standards, with variations in test parameters, acceptance criteria, and application focus. The AEC standards typically impose more stringent requirements for temperature cycling, humidity resistance, and mechanical shock compared to IEC standards. Understanding these differences is crucial for manufacturers developing supercapacitors for specific markets or applications, as compliance with the appropriate standard can affect product certification and market access.

- Testing equipment and facilities for supercapacitor safety evaluation: Specialized testing equipment and facilities are required to conduct comprehensive safety evaluations of supercapacitors according to both AEC and IEC standards. This includes thermal chambers for temperature cycling tests, electrical load testing systems, and mechanical stress testing apparatus. The testing setup must be calibrated and certified to ensure accurate and reproducible results that comply with the relevant standards' requirements.

- Emerging safety testing protocols for next-generation supercapacitors: As supercapacitor technology evolves, new safety testing protocols are being developed to address emerging risks and applications. These include testing for newer electrolyte formulations, higher energy density designs, and flexible or wearable supercapacitor configurations. Both AEC and IEC standards are continuously updated to incorporate these new testing requirements, ensuring that safety standards keep pace with technological advancements in the field.

02 AEC standards for automotive supercapacitor applications

The Automotive Electronics Council (AEC) has developed specialized standards for supercapacitors used in automotive applications. These standards focus on reliability under extreme conditions such as temperature cycling, vibration resistance, and humidity exposure. AEC qualification is particularly important for supercapacitors intended for use in electric and hybrid vehicles, where safety and reliability under harsh operating conditions are critical concerns.Expand Specific Solutions03 Comparative analysis of testing methodologies between standards

There are significant differences between AEC and IEC testing methodologies for supercapacitors. While IEC standards tend to focus on general electrical safety parameters, AEC standards emphasize automotive-specific requirements such as extended temperature ranges and mechanical shock resistance. Understanding these differences is crucial for manufacturers developing supercapacitors for specific applications, as compliance with the appropriate standard depends on the intended use case and market requirements.Expand Specific Solutions04 Testing equipment and facilities for supercapacitor safety evaluation

Specialized testing equipment and facilities are required to properly evaluate supercapacitor safety according to both AEC and IEC standards. This includes thermal chambers for temperature cycling tests, high-precision voltage monitoring systems, and dedicated short-circuit testing apparatus. The testing environment must be carefully controlled to ensure accurate and reproducible results, with proper safety measures in place to handle potential failures during extreme testing conditions.Expand Specific Solutions05 Emerging safety concerns and evolving test standards

As supercapacitor technology advances and applications expand, safety testing standards continue to evolve. New concerns such as long-term aging effects, environmental impact, and integration with other energy storage systems are driving updates to both AEC and IEC standards. Industry stakeholders are working to develop more comprehensive testing protocols that address emerging safety risks while supporting innovation in supercapacitor design and manufacturing techniques.Expand Specific Solutions

Key Organizations and Stakeholders in Standards Development

The supercapacitor safety testing standards market is currently in a growth phase, with increasing adoption across energy storage applications. The competition between AEC (Automotive Electronics Council) and IEC (International Electrotechnical Commission) standards reflects the industry's maturation, with an estimated global supercapacitor market approaching $5 billion by 2025. Key players demonstrate varying levels of technical maturity: established electronics manufacturers like Renesas Electronics, NXP USA, and Robert Bosch lead with comprehensive testing protocols; energy specialists including Shanghai Aowei Technology and Tianjin Lishen Battery are advancing application-specific standards; while research institutions such as Central South University and Texas Tech University System contribute to fundamental safety innovations. The convergence of automotive and industrial standards indicates the technology's transition from specialized to mainstream applications, with safety testing becoming a critical competitive differentiator.

Shanghai Aowei Technology Development Co., Ltd.

Technical Solution: Shanghai Aowei has developed comprehensive supercapacitor safety testing protocols that bridge both AEC (Automotive Electronics Council) and IEC (International Electrotechnical Commission) standards. Their approach incorporates AEC-Q200 qualification requirements for passive components with IEC 62391 standards specific to supercapacitors. Their testing methodology includes enhanced thermal cycling (-55°C to +105°C) exceeding IEC requirements, while implementing AEC's more stringent humidity and vibration testing parameters. Aowei has pioneered a hybrid testing framework that addresses the automotive industry's reliability concerns while maintaining compliance with international safety standards. Their testing facilities can simulate extreme conditions including thermal shock, mechanical shock, and terminal strength tests that satisfy both standards simultaneously, providing comprehensive validation for supercapacitors used in automotive and industrial applications.

Strengths: Specialized expertise in supercapacitor technology with testing capabilities that satisfy both automotive and international standards. Their hybrid approach provides comprehensive validation without redundant testing. Weakness: Their testing protocols may be overly customized to Chinese market requirements, potentially limiting global applicability in regions where AEC standards are more strictly enforced.

KEMET Electronics Corp.

Technical Solution: KEMET has established a sophisticated testing methodology for supercapacitor safety that bridges AEC and IEC standards. Their approach leverages their extensive experience in passive component manufacturing to create a comprehensive testing protocol that satisfies both automotive and international requirements. KEMET's testing includes enhanced thermal shock testing (-55°C to +125°C with 1000 cycles), humidity-loaded life testing at 85°C/85% RH for 1000 hours, and mechanical vibration testing at frequencies up to 2000Hz with 20g acceleration. Their facilities utilize specialized equipment for measuring capacitance stability, ESR changes, and leakage current under various environmental stresses. KEMET has developed proprietary testing methodologies for supercapacitor-specific failure modes including pressure relief functionality, electrolyte leakage detection, and internal short circuit prevention. Their approach ensures supercapacitors meet both AEC-Q200 qualification requirements for automotive applications and IEC 62391 standards for general electronic applications.

Strengths: Deep expertise in passive component manufacturing and testing provides comprehensive understanding of failure mechanisms. Their established presence in automotive supply chains ensures practical application of standards. Weakness: Their testing methodology may emphasize traditional capacitor failure modes over supercapacitor-specific concerns, potentially missing unique characteristics of carbon-based energy storage systems.

Critical Safety Parameters and Test Procedures Analysis

Compact AED with integrated CPR coaching

PatentActiveUS20230310873A1

Innovation

- A compact AED design with integrated CPR sensors and a front-body housing that attaches to the patient's chest, allowing for real-time coaching and ECG signal processing to improve CPR performance, while also minimizing storage space and cord length by using alternative electrode configurations and adhesive pads.

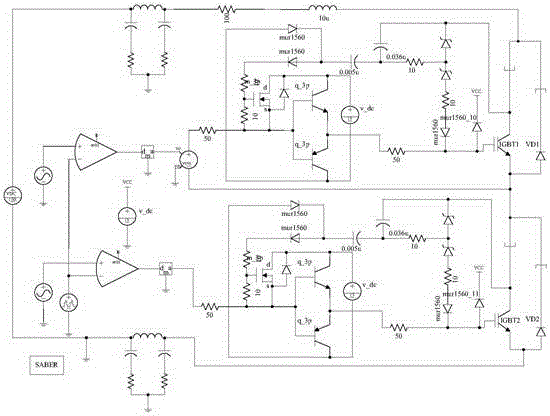

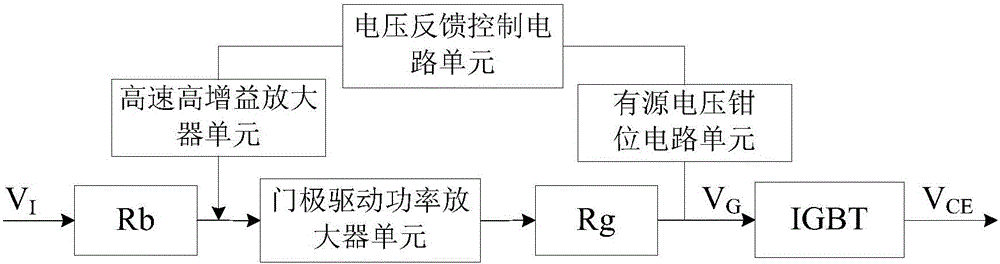

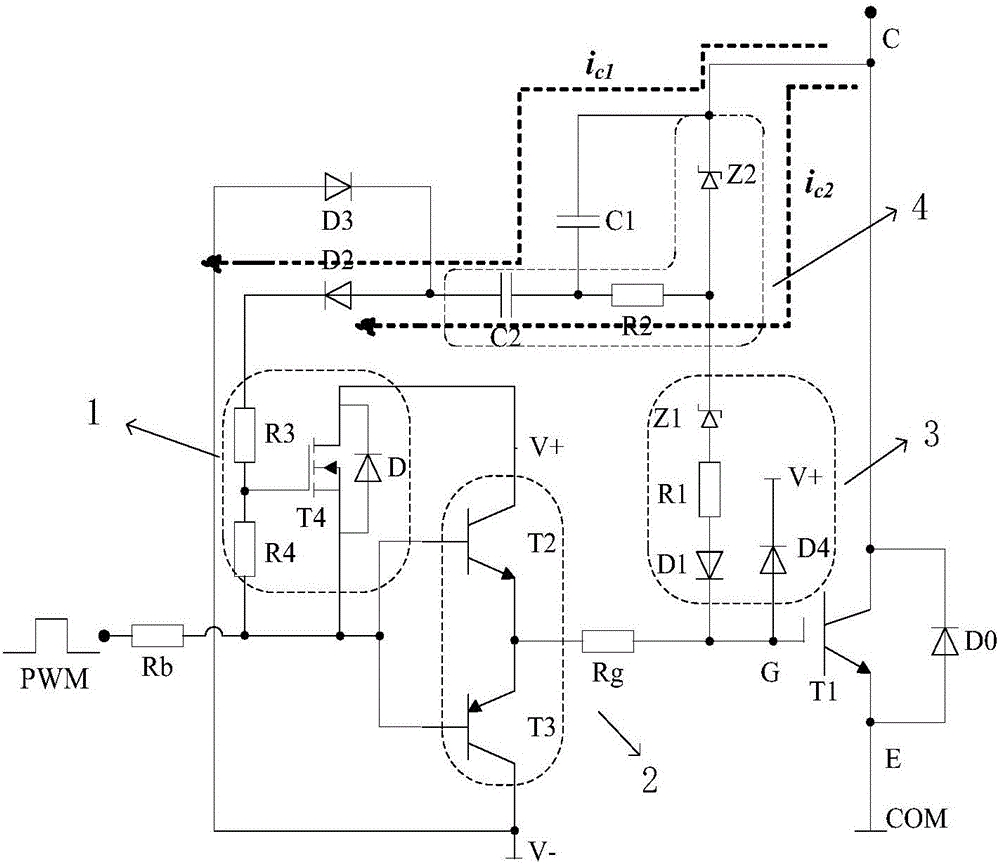

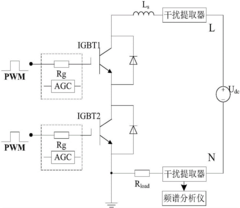

Active gate control circuit and IGBT electromagnetic interference inhibition method thereof

PatentActiveCN106452404A

Innovation

- An active gate control circuit is used to limit the voltage overshoot through the voltage VCE feedback network between the collector and emitter, including a PWM unit, resistor, high-speed high-gain amplifier unit and gate drive power amplifier unit, using voltage feedback control The circuit structure composed of transient suppression diodes and charge and discharge capacitors suppresses the electromagnetic interference of IGBT.

Global Regulatory Compliance Requirements

Supercapacitor safety testing is subject to various regulatory frameworks across different regions, creating a complex compliance landscape for manufacturers and engineers. The global regulatory environment for supercapacitors encompasses multiple standards bodies, each with distinct requirements and testing protocols that must be adhered to for market access.

In North America, UL (Underwriters Laboratories) standards predominate, with UL 810A specifically addressing electrochemical capacitors. The Automotive Electronics Council (AEC) standards are particularly influential for automotive applications, with AEC-Q200 providing rigorous qualification requirements for passive components including supercapacitors used in automotive environments.

The European Union enforces compliance with IEC (International Electrotechnical Commission) standards, particularly IEC 62391 for fixed electric double-layer capacitors, and IEC 62576 for hybrid electric vehicle applications. Additionally, products must meet CE marking requirements under applicable directives such as the Low Voltage Directive (LVD) and Electromagnetic Compatibility (EMC) Directive.

In Asia, Japan follows JIS (Japanese Industrial Standards) with specific provisions for supercapacitors, while China implements GB/T standards that often mirror IEC requirements but may include country-specific modifications. South Korea enforces KC certification requirements for electronic components including energy storage devices.

Globally, the transportation of supercapacitors must comply with UN regulations for dangerous goods transport, particularly UN 3499 classification for capacitors with energy storage capacity greater than 0.3Wh. These regulations impact shipping, packaging, and labeling requirements across international borders.

Military and aerospace applications face additional compliance hurdles, with standards such as MIL-STD-810 for environmental testing and NASA's EEE-INST-002 for space applications imposing stringent reliability and safety requirements beyond commercial standards.

The divergence between AEC and IEC standards presents significant challenges for manufacturers targeting multiple markets. While AEC standards emphasize automotive reliability with focus on temperature cycling, vibration resistance, and long-term durability, IEC standards provide broader coverage for general applications with detailed specifications for electrical performance and safety parameters.

Engineers must navigate these overlapping yet distinct regulatory frameworks, often necessitating multiple certification processes for global market access. Compliance strategies typically involve designing to meet the most stringent requirements across all applicable standards, though this approach may increase development costs and time-to-market.

In North America, UL (Underwriters Laboratories) standards predominate, with UL 810A specifically addressing electrochemical capacitors. The Automotive Electronics Council (AEC) standards are particularly influential for automotive applications, with AEC-Q200 providing rigorous qualification requirements for passive components including supercapacitors used in automotive environments.

The European Union enforces compliance with IEC (International Electrotechnical Commission) standards, particularly IEC 62391 for fixed electric double-layer capacitors, and IEC 62576 for hybrid electric vehicle applications. Additionally, products must meet CE marking requirements under applicable directives such as the Low Voltage Directive (LVD) and Electromagnetic Compatibility (EMC) Directive.

In Asia, Japan follows JIS (Japanese Industrial Standards) with specific provisions for supercapacitors, while China implements GB/T standards that often mirror IEC requirements but may include country-specific modifications. South Korea enforces KC certification requirements for electronic components including energy storage devices.

Globally, the transportation of supercapacitors must comply with UN regulations for dangerous goods transport, particularly UN 3499 classification for capacitors with energy storage capacity greater than 0.3Wh. These regulations impact shipping, packaging, and labeling requirements across international borders.

Military and aerospace applications face additional compliance hurdles, with standards such as MIL-STD-810 for environmental testing and NASA's EEE-INST-002 for space applications imposing stringent reliability and safety requirements beyond commercial standards.

The divergence between AEC and IEC standards presents significant challenges for manufacturers targeting multiple markets. While AEC standards emphasize automotive reliability with focus on temperature cycling, vibration resistance, and long-term durability, IEC standards provide broader coverage for general applications with detailed specifications for electrical performance and safety parameters.

Engineers must navigate these overlapping yet distinct regulatory frameworks, often necessitating multiple certification processes for global market access. Compliance strategies typically involve designing to meet the most stringent requirements across all applicable standards, though this approach may increase development costs and time-to-market.

Implementation Costs and Engineering Considerations

Implementing supercapacitor safety testing according to either AEC or IEC standards involves significant cost considerations and engineering requirements that organizations must carefully evaluate. The initial investment for AEC Q200 compliance typically ranges from $75,000 to $150,000, encompassing specialized testing equipment, environmental chambers, and precision measurement instruments. IEC 62391 implementation generally costs between $50,000 and $120,000, with variations depending on existing infrastructure and the scope of testing required.

Laboratory setup represents a substantial portion of these expenses. Both standards necessitate controlled environments with precise temperature and humidity regulation. AEC standards demand more rigorous environmental simulation capabilities, including thermal cycling chambers capable of extreme temperature ranges (-55°C to +125°C) and vibration testing equipment that can withstand automotive-grade mechanical stress testing. These specialized requirements can increase facility preparation costs by 30-40% compared to basic IEC compliance setups.

Personnel training constitutes another significant investment factor. Engineering teams require specialized knowledge in both the technical aspects of supercapacitor testing and the procedural requirements of the respective standards. AEC compliance typically demands 25-40 hours of specialized training per engineer, while IEC implementation requires approximately 15-30 hours. Organizations must account for both direct training costs and productivity losses during this transition period.

Ongoing compliance maintenance presents recurring expenses that vary between standards. AEC Q200 requires more frequent recalibration of equipment (typically quarterly) and more extensive documentation processes, resulting in annual maintenance costs of approximately $30,000-$50,000. IEC standards generally entail lower maintenance costs, averaging $20,000-$35,000 annually, primarily due to less stringent documentation requirements and semi-annual calibration schedules.

Time-to-market implications differ significantly between the two standards. AEC certification processes typically extend development cycles by 3-6 months due to more comprehensive testing requirements and stricter qualification criteria. IEC compliance generally adds 1-3 months to development timelines. Organizations must weigh these timeline impacts against market opportunities and competitive positioning when selecting their compliance approach.

Cross-compatibility considerations can potentially reduce implementation costs. Approximately 60% of testing procedures overlap between AEC and IEC standards, creating opportunities for efficient resource allocation. Organizations targeting multiple markets can design testing protocols that satisfy both standards simultaneously for these overlapping requirements, potentially reducing overall implementation costs by 20-30% compared to separate compliance programs.

Laboratory setup represents a substantial portion of these expenses. Both standards necessitate controlled environments with precise temperature and humidity regulation. AEC standards demand more rigorous environmental simulation capabilities, including thermal cycling chambers capable of extreme temperature ranges (-55°C to +125°C) and vibration testing equipment that can withstand automotive-grade mechanical stress testing. These specialized requirements can increase facility preparation costs by 30-40% compared to basic IEC compliance setups.

Personnel training constitutes another significant investment factor. Engineering teams require specialized knowledge in both the technical aspects of supercapacitor testing and the procedural requirements of the respective standards. AEC compliance typically demands 25-40 hours of specialized training per engineer, while IEC implementation requires approximately 15-30 hours. Organizations must account for both direct training costs and productivity losses during this transition period.

Ongoing compliance maintenance presents recurring expenses that vary between standards. AEC Q200 requires more frequent recalibration of equipment (typically quarterly) and more extensive documentation processes, resulting in annual maintenance costs of approximately $30,000-$50,000. IEC standards generally entail lower maintenance costs, averaging $20,000-$35,000 annually, primarily due to less stringent documentation requirements and semi-annual calibration schedules.

Time-to-market implications differ significantly between the two standards. AEC certification processes typically extend development cycles by 3-6 months due to more comprehensive testing requirements and stricter qualification criteria. IEC compliance generally adds 1-3 months to development timelines. Organizations must weigh these timeline impacts against market opportunities and competitive positioning when selecting their compliance approach.

Cross-compatibility considerations can potentially reduce implementation costs. Approximately 60% of testing procedures overlap between AEC and IEC standards, creating opportunities for efficient resource allocation. Organizations targeting multiple markets can design testing protocols that satisfy both standards simultaneously for these overlapping requirements, potentially reducing overall implementation costs by 20-30% compared to separate compliance programs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!