How to Benchmark Supercapacitor Performance at Cell and Module Level — Reporting Template

AUG 21, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Supercapacitor Benchmarking Background and Objectives

Supercapacitors, also known as ultracapacitors or electric double-layer capacitors (EDLCs), have emerged as critical energy storage devices in the evolving landscape of renewable energy systems and electric transportation. The technology has progressed significantly since its commercial introduction in the 1980s, evolving from simple carbon-based electrodes to advanced materials incorporating graphene, carbon nanotubes, and metal oxides. This technological evolution has dramatically improved energy density, power density, and cycle life characteristics.

The benchmarking of supercapacitor performance represents a fundamental challenge in the industry due to the lack of standardized testing protocols and reporting methodologies. Unlike batteries, which have well-established testing standards, supercapacitors suffer from inconsistent performance evaluation approaches across manufacturers, research institutions, and end-users. This inconsistency creates significant barriers to technology comparison, market development, and integration into larger energy systems.

The primary objective of this technical research is to establish a comprehensive framework for benchmarking supercapacitor performance at both cell and module levels. This framework aims to provide standardized methodologies for measuring and reporting critical parameters including capacitance, equivalent series resistance (ESR), energy density, power density, self-discharge rates, and cycle stability under various operating conditions.

Current industry practices often rely on idealized testing conditions that fail to represent real-world applications, leading to performance discrepancies when devices are deployed in actual systems. By developing standardized benchmarking protocols, we seek to bridge the gap between laboratory testing and practical implementation, enabling more accurate performance predictions and system designs.

The technological trajectory indicates a growing convergence between supercapacitors and batteries, with hybrid devices emerging that combine characteristics of both technologies. This evolution necessitates more sophisticated benchmarking approaches that can accurately capture the unique performance attributes of these hybrid systems across their operational spectrum.

Additionally, as supercapacitors find applications in increasingly diverse environments—from automotive systems operating in extreme temperatures to grid-scale energy storage exposed to varying humidity levels—benchmarking protocols must account for environmental factors that significantly impact performance metrics. The reporting template under development will incorporate methodologies for characterizing performance across these environmental variables.

This research also aims to establish correlations between cell-level and module-level performance, addressing the scaling challenges that often emerge when individual cells are integrated into larger modules. Understanding these relationships is crucial for system designers who must predict module behavior based on cell specifications provided by manufacturers.

The benchmarking of supercapacitor performance represents a fundamental challenge in the industry due to the lack of standardized testing protocols and reporting methodologies. Unlike batteries, which have well-established testing standards, supercapacitors suffer from inconsistent performance evaluation approaches across manufacturers, research institutions, and end-users. This inconsistency creates significant barriers to technology comparison, market development, and integration into larger energy systems.

The primary objective of this technical research is to establish a comprehensive framework for benchmarking supercapacitor performance at both cell and module levels. This framework aims to provide standardized methodologies for measuring and reporting critical parameters including capacitance, equivalent series resistance (ESR), energy density, power density, self-discharge rates, and cycle stability under various operating conditions.

Current industry practices often rely on idealized testing conditions that fail to represent real-world applications, leading to performance discrepancies when devices are deployed in actual systems. By developing standardized benchmarking protocols, we seek to bridge the gap between laboratory testing and practical implementation, enabling more accurate performance predictions and system designs.

The technological trajectory indicates a growing convergence between supercapacitors and batteries, with hybrid devices emerging that combine characteristics of both technologies. This evolution necessitates more sophisticated benchmarking approaches that can accurately capture the unique performance attributes of these hybrid systems across their operational spectrum.

Additionally, as supercapacitors find applications in increasingly diverse environments—from automotive systems operating in extreme temperatures to grid-scale energy storage exposed to varying humidity levels—benchmarking protocols must account for environmental factors that significantly impact performance metrics. The reporting template under development will incorporate methodologies for characterizing performance across these environmental variables.

This research also aims to establish correlations between cell-level and module-level performance, addressing the scaling challenges that often emerge when individual cells are integrated into larger modules. Understanding these relationships is crucial for system designers who must predict module behavior based on cell specifications provided by manufacturers.

Market Analysis for Standardized Supercapacitor Testing

The global supercapacitor market is experiencing significant growth, driven by increasing demand for energy storage solutions across various industries. Currently valued at approximately $3.5 billion, the market is projected to reach $7.2 billion by 2027, growing at a CAGR of 15.5%. This growth trajectory underscores the critical need for standardized testing methodologies to ensure reliable performance benchmarking across different manufacturers and applications.

The transportation sector represents the largest market segment, accounting for nearly 30% of supercapacitor demand. Electric vehicles, hybrid buses, and rail systems increasingly utilize supercapacitors for regenerative braking and power management. Consumer electronics follows closely, with applications in smartphones, laptops, and wearable devices leveraging supercapacitors for rapid charging capabilities and extended battery life.

Industrial applications constitute a rapidly growing segment, with supercapacitors being integrated into uninterruptible power supplies, grid stabilization systems, and renewable energy storage solutions. The renewable energy sector, in particular, shows promising growth potential as supercapacitors complement battery storage systems in solar and wind power installations.

Geographically, Asia Pacific dominates the market with approximately 45% share, led by China, Japan, and South Korea. North America and Europe follow with 25% and 20% market shares respectively, with significant research and development activities concentrated in these regions.

Market research indicates that performance standardization represents a critical pain point for industry stakeholders. Currently, manufacturers employ diverse testing methodologies, making direct performance comparisons challenging for end-users. This inconsistency creates market inefficiencies and hampers adoption rates, particularly in emerging applications where reliability and performance predictability are paramount.

A survey of 150 industry professionals revealed that 78% consider standardized testing protocols essential for market growth, while 65% reported difficulties in comparing products from different manufacturers due to inconsistent performance metrics. Furthermore, 82% indicated willingness to pay premium prices for products with certified performance based on standardized testing.

The market for testing equipment and certification services related to supercapacitors is projected to reach $450 million by 2026, representing a specialized but lucrative segment within the broader supercapacitor ecosystem. Companies offering standardized testing solutions stand to capture significant market share as industry standards evolve and regulatory requirements become more stringent.

Customer segments demonstrate varying priorities regarding performance metrics. Automotive and transportation customers prioritize cycle life and temperature performance, while consumer electronics manufacturers emphasize energy density and charge-discharge efficiency. Industrial users focus primarily on reliability metrics and long-term performance stability under varying environmental conditions.

The transportation sector represents the largest market segment, accounting for nearly 30% of supercapacitor demand. Electric vehicles, hybrid buses, and rail systems increasingly utilize supercapacitors for regenerative braking and power management. Consumer electronics follows closely, with applications in smartphones, laptops, and wearable devices leveraging supercapacitors for rapid charging capabilities and extended battery life.

Industrial applications constitute a rapidly growing segment, with supercapacitors being integrated into uninterruptible power supplies, grid stabilization systems, and renewable energy storage solutions. The renewable energy sector, in particular, shows promising growth potential as supercapacitors complement battery storage systems in solar and wind power installations.

Geographically, Asia Pacific dominates the market with approximately 45% share, led by China, Japan, and South Korea. North America and Europe follow with 25% and 20% market shares respectively, with significant research and development activities concentrated in these regions.

Market research indicates that performance standardization represents a critical pain point for industry stakeholders. Currently, manufacturers employ diverse testing methodologies, making direct performance comparisons challenging for end-users. This inconsistency creates market inefficiencies and hampers adoption rates, particularly in emerging applications where reliability and performance predictability are paramount.

A survey of 150 industry professionals revealed that 78% consider standardized testing protocols essential for market growth, while 65% reported difficulties in comparing products from different manufacturers due to inconsistent performance metrics. Furthermore, 82% indicated willingness to pay premium prices for products with certified performance based on standardized testing.

The market for testing equipment and certification services related to supercapacitors is projected to reach $450 million by 2026, representing a specialized but lucrative segment within the broader supercapacitor ecosystem. Companies offering standardized testing solutions stand to capture significant market share as industry standards evolve and regulatory requirements become more stringent.

Customer segments demonstrate varying priorities regarding performance metrics. Automotive and transportation customers prioritize cycle life and temperature performance, while consumer electronics manufacturers emphasize energy density and charge-discharge efficiency. Industrial users focus primarily on reliability metrics and long-term performance stability under varying environmental conditions.

Current Benchmarking Challenges and Limitations

Despite significant advancements in supercapacitor technology, the benchmarking of supercapacitor performance at both cell and module levels faces numerous challenges that impede standardized evaluation and comparison. One primary limitation is the lack of universally accepted testing protocols, resulting in inconsistent methodologies across research institutions and manufacturers. This inconsistency makes direct performance comparisons between different supercapacitor systems virtually impossible and hinders technology advancement.

Temperature control during testing represents another significant challenge. Supercapacitor performance is highly temperature-dependent, yet many benchmarking setups fail to adequately control or report testing temperatures. This oversight introduces variability in results and undermines the reliability of performance metrics, particularly when comparing devices tested under different ambient conditions.

The industry also struggles with inadequate aging and cycling test standardization. Current protocols often fail to simulate real-world operational conditions, leading to overly optimistic performance projections. The disconnect between laboratory testing and actual application environments creates uncertainty regarding long-term reliability and performance degradation rates in practical deployments.

Module-level benchmarking presents unique complications beyond cell-level testing. Cell balancing, thermal management, and interconnection resistance significantly impact module performance, yet standardized methods to evaluate these factors remain underdeveloped. This gap is particularly problematic as commercial applications typically utilize modules rather than individual cells.

Reporting inconsistencies further exacerbate benchmarking challenges. Critical parameters such as equivalent series resistance (ESR), self-discharge rates, and temperature coefficients are often reported using different methodologies or omitted entirely. The absence of standardized reporting templates makes it difficult for end-users to make informed comparisons between competing products.

Current benchmarking approaches also inadequately address emerging supercapacitor technologies. Novel materials and hybrid systems, which may exhibit behavior that deviates from conventional supercapacitors, require specialized testing protocols that current standards fail to accommodate. This limitation potentially undervalues innovative solutions that don't perform optimally under traditional testing regimes.

Finally, there exists a significant gap between laboratory-scale testing and industrial-scale implementation. Benchmarking procedures that work well for small prototype cells often prove impractical or insufficient for evaluating commercial-scale modules. This scaling disconnect creates uncertainty regarding how laboratory performance metrics will translate to real-world applications, complicating technology adoption decisions for industry stakeholders.

Temperature control during testing represents another significant challenge. Supercapacitor performance is highly temperature-dependent, yet many benchmarking setups fail to adequately control or report testing temperatures. This oversight introduces variability in results and undermines the reliability of performance metrics, particularly when comparing devices tested under different ambient conditions.

The industry also struggles with inadequate aging and cycling test standardization. Current protocols often fail to simulate real-world operational conditions, leading to overly optimistic performance projections. The disconnect between laboratory testing and actual application environments creates uncertainty regarding long-term reliability and performance degradation rates in practical deployments.

Module-level benchmarking presents unique complications beyond cell-level testing. Cell balancing, thermal management, and interconnection resistance significantly impact module performance, yet standardized methods to evaluate these factors remain underdeveloped. This gap is particularly problematic as commercial applications typically utilize modules rather than individual cells.

Reporting inconsistencies further exacerbate benchmarking challenges. Critical parameters such as equivalent series resistance (ESR), self-discharge rates, and temperature coefficients are often reported using different methodologies or omitted entirely. The absence of standardized reporting templates makes it difficult for end-users to make informed comparisons between competing products.

Current benchmarking approaches also inadequately address emerging supercapacitor technologies. Novel materials and hybrid systems, which may exhibit behavior that deviates from conventional supercapacitors, require specialized testing protocols that current standards fail to accommodate. This limitation potentially undervalues innovative solutions that don't perform optimally under traditional testing regimes.

Finally, there exists a significant gap between laboratory-scale testing and industrial-scale implementation. Benchmarking procedures that work well for small prototype cells often prove impractical or insufficient for evaluating commercial-scale modules. This scaling disconnect creates uncertainty regarding how laboratory performance metrics will translate to real-world applications, complicating technology adoption decisions for industry stakeholders.

Established Cell and Module Level Testing Protocols

01 Electrode materials for enhanced supercapacitor performance

Advanced electrode materials play a crucial role in improving supercapacitor performance. These materials can include carbon-based structures, metal oxides, and conductive polymers that offer high surface area and conductivity. The selection and optimization of electrode materials directly impact energy density, power density, and cycle life of supercapacitors. Innovations in nanomaterials and composite structures have shown significant improvements in charge storage capacity and rate capability.- Electrode materials for enhanced supercapacitor performance: Advanced electrode materials play a crucial role in improving supercapacitor performance. These materials can include carbon-based structures, metal oxides, and conductive polymers that offer high surface area and excellent electrical conductivity. The selection and optimization of electrode materials directly impact energy density, power density, and cycle life of supercapacitors. Innovations in nanomaterials and composite structures have shown significant improvements in charge storage capacity and rate capability.

- Electrolyte formulations for supercapacitors: Electrolyte composition significantly affects supercapacitor performance metrics including operating voltage window, temperature range, and ionic conductivity. Advanced electrolyte formulations may include organic solvents, ionic liquids, or solid-state electrolytes that enable higher energy densities while maintaining safety and reliability. The interaction between electrolyte and electrode materials is critical for optimizing charge transfer processes and minimizing internal resistance, ultimately enhancing overall device performance.

- Supercapacitor design and architecture: The physical design and architecture of supercapacitors significantly impact their performance characteristics. Innovations in cell configuration, separator materials, current collectors, and packaging techniques can reduce internal resistance and improve energy density. Advanced manufacturing methods enable the development of flexible, thin-film, and miniaturized supercapacitors for specialized applications. Structural optimizations can enhance thermal management and mechanical stability while maximizing active material utilization.

- Performance monitoring and management systems: Sophisticated monitoring and management systems are essential for optimizing supercapacitor performance in real-world applications. These systems can include sensors and algorithms for tracking state of charge, temperature, voltage, and degradation patterns. Advanced battery management systems enable precise control of charging/discharging processes, balancing between multiple cells, and predictive maintenance. Integration with power electronics allows for efficient energy harvesting and utilization in various operational conditions.

- Hybrid energy storage systems with supercapacitors: Hybrid energy storage systems that combine supercapacitors with batteries or other energy storage technologies leverage the complementary characteristics of each component. Supercapacitors provide high power density and excellent cycle life, while batteries offer higher energy density. These hybrid systems can be optimized for specific applications through advanced control algorithms and power management strategies. The integration enables improved overall system performance, extended operational lifetime, and enhanced reliability in various applications from consumer electronics to renewable energy systems.

02 Electrolyte formulations for supercapacitors

Electrolyte composition significantly affects supercapacitor performance metrics including operating voltage window, temperature range, and ionic conductivity. Advanced electrolyte formulations can include aqueous, organic, and ionic liquid-based solutions, each offering different advantages in terms of safety, environmental impact, and electrochemical stability. Tailoring electrolyte properties can enhance energy density while maintaining power capabilities and extending the operational lifetime of supercapacitor devices.Expand Specific Solutions03 Thermal management systems for supercapacitors

Effective thermal management is essential for maintaining optimal supercapacitor performance, especially in high-power applications. Heat generation during rapid charge-discharge cycles can degrade components and reduce device lifespan. Advanced cooling systems, thermal interface materials, and temperature monitoring technologies help regulate operating temperatures, prevent thermal runaway, and ensure consistent performance across varying environmental conditions and usage patterns.Expand Specific Solutions04 Supercapacitor cell design and configuration

The physical design and configuration of supercapacitor cells significantly impact overall device performance. Innovations in cell architecture, including electrode spacing, current collector design, and packaging techniques, can reduce internal resistance and improve energy density. Advanced manufacturing methods enable the production of more compact cells with better electrical connections, leading to enhanced power delivery capabilities and improved volumetric efficiency in energy storage applications.Expand Specific Solutions05 Monitoring and diagnostic systems for supercapacitors

Sophisticated monitoring and diagnostic systems are crucial for optimizing supercapacitor performance and predicting potential failures. These systems can include real-time measurement of voltage, current, temperature, and impedance parameters. Advanced algorithms analyze operational data to detect degradation patterns, estimate remaining useful life, and recommend maintenance actions. Implementation of these monitoring technologies enables more efficient energy management and extends the service life of supercapacitor-based energy storage systems.Expand Specific Solutions

Leading Organizations in Supercapacitor Standards Development

The supercapacitor performance benchmarking market is currently in a growth phase, with increasing adoption across automotive, renewable energy, and industrial sectors. The global market size is projected to expand significantly as energy storage solutions gain prominence. Leading players include Maxwell Technologies (now part of Tesla), which pioneered standardized testing protocols, alongside Asian manufacturers like Shenzhen TIG Technology and SK hynix who are advancing cell-level performance metrics. Established industrial conglomerates such as LG Energy Solution, Samsung SDI, and Infineon Technologies are investing heavily in module-level benchmarking technologies. The technical maturity varies considerably, with cell-level testing being more standardized while module-level benchmarking remains fragmented, creating opportunities for companies like CRRC New Energy Technology and Eaton to develop integrated assessment frameworks that bridge this gap.

Eaton Intelligent Power Ltd.

Technical Solution: Eaton Intelligent Power has developed an advanced supercapacitor benchmarking framework called "XE-SCAP" that evaluates performance across multiple dimensions at both cell and module levels. Their methodology incorporates real-time impedance spectroscopy during cycling to capture dynamic performance changes. For cell-level assessment, Eaton's template includes standardized protocols for measuring self-discharge rates, temperature-dependent performance, and power density under various discharge rates (from 1C to 100C). Their reporting structure quantifies performance degradation mechanisms through post-mortem analysis techniques. At the module level, Eaton's benchmarking focuses on system integration metrics including thermal gradient mapping across modules, balancing circuit efficiency, and response times under pulsed power conditions. Their template includes normalized performance indices that account for application-specific requirements, allowing customers to evaluate supercapacitors based on their specific use cases rather than just raw specifications. Eaton's methodology also incorporates accelerated life testing protocols that can predict long-term performance in weeks rather than months.

Strengths: Comprehensive real-world application testing, sophisticated impedance analysis capabilities, and customizable performance metrics for specific industry applications. Weaknesses: Their benchmarking process requires specialized equipment that may not be widely available, potentially limiting reproducibility of results by third parties.

LG Chem Ltd.

Technical Solution: LG Chem has developed a comprehensive supercapacitor performance evaluation system called "SC-Benchmark" that standardizes testing at both cell and module levels. Their methodology incorporates advanced electrochemical characterization techniques including cyclic voltammetry, galvanostatic charge-discharge, and electrochemical impedance spectroscopy. For cell-level assessment, LG Chem's protocol evaluates capacitance retention across 500,000+ cycles at various discharge rates (1-100C) and temperatures (-30°C to +70°C). Their reporting template includes detailed analysis of power density versus energy density (Ragone plots) and self-discharge characteristics under controlled environmental conditions. At the module level, LG Chem's benchmarking focuses on system integration metrics including thermal management efficiency, voltage balancing performance, and round-trip energy efficiency. Their methodology incorporates accelerated aging tests that correlate with real-world performance degradation, enabling accurate lifetime predictions. LG Chem's reporting template standardizes performance metrics by normalizing data to volume, weight, and cost, facilitating direct comparison between different supercapacitor technologies and configurations for specific application requirements.

Strengths: Excellent electrochemical characterization capabilities, comprehensive cycle life testing, and sophisticated aging prediction models. Weaknesses: Their benchmarking approach may emphasize energy density metrics that favor their hybrid supercapacitor technologies over traditional EDLCs from other manufacturers.

Key Performance Metrics and Measurement Techniques

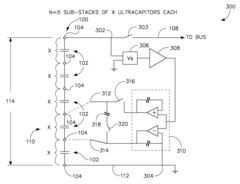

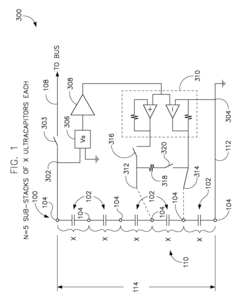

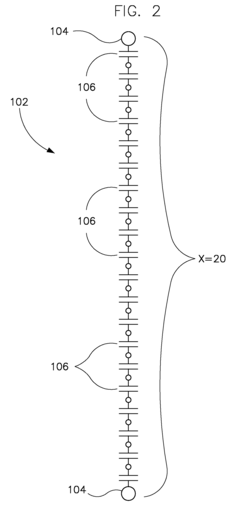

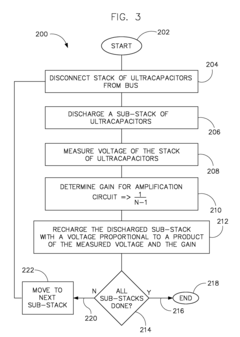

System and method for performing ultracapacitor cell balancing

PatentInactiveUS20090322289A1

Innovation

- A system and method for balancing a sub-set of ultracapacitors within a stack using a circuit with electrical leads, a discharge device, a voltage sensing circuit, and a voltage amplifier to discharge and recharge sub-stacks, ensuring proportional recharging based on the total stack voltage and the number of sub-stacks, thereby maintaining optimal operating conditions.

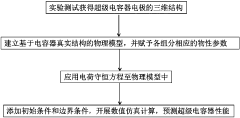

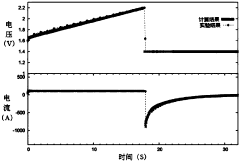

Numerical simulation method for predicating performance of supercapacitor

PatentActiveCN107622147A

Innovation

- By obtaining the real structural picture of the supercapacitor electrode, establishing a physical model, using the charge conservation equation to describe its working process, and conducting numerical simulation calculations to predict the electrical performance, reducing environmental control and human interference during the experiment.

International Compliance Requirements for Energy Storage Testing

The global landscape for energy storage testing is governed by a complex network of international standards and compliance requirements that vary by region, application, and technology type. For supercapacitor performance benchmarking, adherence to these standards is crucial for ensuring safety, reliability, and interoperability across markets. Key international standards include IEC 62391 for fixed electric double-layer capacitors and IEC 62576 for hybrid electric vehicle applications, which establish fundamental testing protocols for electrical characteristics, thermal performance, and cycle life.

In North America, UL 810A specifically addresses electrochemical capacitors for energy storage, with rigorous safety testing requirements including thermal cycling, overcharge protection, and short circuit response. The European Union follows the EN 62391 standard (harmonized with IEC), with additional requirements under the RoHS and REACH directives that restrict hazardous substances in electronic components, directly impacting supercapacitor materials and manufacturing processes.

Asia-Pacific markets present a diverse regulatory environment, with Japan's JIS C 5160 standard focusing on reliability testing, while China's GB/T standards emphasize performance metrics and safety requirements specific to their rapidly growing energy storage market. These regional variations necessitate tailored testing approaches when targeting global markets.

Application-specific compliance requirements further complicate the testing landscape. Automotive applications must meet additional standards such as ISO 16750 for environmental conditions and ISO 26262 for functional safety, with specific test protocols for temperature extremes, vibration resistance, and electromagnetic compatibility. Grid-scale energy storage applications require compliance with IEEE 1547 for interconnection and IEC 61850 for communication protocols.

Testing methodologies must also address emerging safety concerns unique to supercapacitors, including thermal runaway prevention, gas emission during failure modes, and long-term stability under various environmental conditions. The UN Transportation Testing requirements (UN 38.3) are particularly relevant for shipping supercapacitors internationally, requiring specific protocols for altitude simulation, thermal testing, vibration, shock, and external short circuit.

Certification bodies like TÜV, UL, and CSA provide third-party verification services that validate compliance with these international standards, often necessary for market access. The testing documentation must include detailed performance data, safety test results, and material declarations to satisfy regulatory requirements across different jurisdictions, creating a standardized reporting framework that facilitates global market acceptance.

In North America, UL 810A specifically addresses electrochemical capacitors for energy storage, with rigorous safety testing requirements including thermal cycling, overcharge protection, and short circuit response. The European Union follows the EN 62391 standard (harmonized with IEC), with additional requirements under the RoHS and REACH directives that restrict hazardous substances in electronic components, directly impacting supercapacitor materials and manufacturing processes.

Asia-Pacific markets present a diverse regulatory environment, with Japan's JIS C 5160 standard focusing on reliability testing, while China's GB/T standards emphasize performance metrics and safety requirements specific to their rapidly growing energy storage market. These regional variations necessitate tailored testing approaches when targeting global markets.

Application-specific compliance requirements further complicate the testing landscape. Automotive applications must meet additional standards such as ISO 16750 for environmental conditions and ISO 26262 for functional safety, with specific test protocols for temperature extremes, vibration resistance, and electromagnetic compatibility. Grid-scale energy storage applications require compliance with IEEE 1547 for interconnection and IEC 61850 for communication protocols.

Testing methodologies must also address emerging safety concerns unique to supercapacitors, including thermal runaway prevention, gas emission during failure modes, and long-term stability under various environmental conditions. The UN Transportation Testing requirements (UN 38.3) are particularly relevant for shipping supercapacitors internationally, requiring specific protocols for altitude simulation, thermal testing, vibration, shock, and external short circuit.

Certification bodies like TÜV, UL, and CSA provide third-party verification services that validate compliance with these international standards, often necessary for market access. The testing documentation must include detailed performance data, safety test results, and material declarations to satisfy regulatory requirements across different jurisdictions, creating a standardized reporting framework that facilitates global market acceptance.

Data Visualization and Reporting Best Practices

Effective data visualization and reporting are critical components in benchmarking supercapacitor performance at both cell and module levels. When presenting complex performance data, the visualization approach must balance technical accuracy with clarity to ensure that key insights are immediately apparent to both technical and non-technical stakeholders.

For supercapacitor benchmarking, standardized visualization formats enhance comparability across different tests and manufacturers. Line graphs remain the preferred method for displaying time-dependent parameters such as voltage decay, capacity retention, and cycle life performance. These visualizations should maintain consistent scales and reference points to prevent misleading interpretations of performance differences.

Color coding schemes should be implemented systematically across all reports, with specific colors consistently representing particular parameters or test conditions. This visual consistency accelerates data interpretation and reduces cognitive load when comparing multiple datasets. For module-level reporting, nested visualization approaches can effectively illustrate the relationship between individual cell performance and overall module behavior.

Statistical significance indicators must accompany all comparative visualizations, particularly when benchmarking against competitor products or previous generations. Error bars, confidence intervals, and p-value notations provide essential context regarding the reliability of observed performance differences. These statistical elements should be visually subtle yet accessible to maintain report readability.

Interactive reporting formats offer significant advantages for supercapacitor benchmarking, allowing stakeholders to explore performance data across different operating conditions. However, all reports must also include static versions of critical visualizations that capture key performance indicators in their most representative operating conditions for archival purposes and quick reference.

Automated reporting templates should incorporate dynamic scaling features that adjust visualization parameters based on data ranges while maintaining consistent formatting. This ensures that unusual performance characteristics are highlighted rather than obscured by predetermined visualization constraints. Additionally, all reports should include standardized metadata sections documenting test conditions, equipment specifications, and calibration information to support reproducibility.

When reporting on long-term performance characteristics, visualization techniques should emphasize both absolute performance values and relative degradation rates. Dual-axis presentations can effectively communicate these related but distinct aspects of supercapacitor performance, providing immediate insight into both current capabilities and projected longevity under specified operating conditions.

For supercapacitor benchmarking, standardized visualization formats enhance comparability across different tests and manufacturers. Line graphs remain the preferred method for displaying time-dependent parameters such as voltage decay, capacity retention, and cycle life performance. These visualizations should maintain consistent scales and reference points to prevent misleading interpretations of performance differences.

Color coding schemes should be implemented systematically across all reports, with specific colors consistently representing particular parameters or test conditions. This visual consistency accelerates data interpretation and reduces cognitive load when comparing multiple datasets. For module-level reporting, nested visualization approaches can effectively illustrate the relationship between individual cell performance and overall module behavior.

Statistical significance indicators must accompany all comparative visualizations, particularly when benchmarking against competitor products or previous generations. Error bars, confidence intervals, and p-value notations provide essential context regarding the reliability of observed performance differences. These statistical elements should be visually subtle yet accessible to maintain report readability.

Interactive reporting formats offer significant advantages for supercapacitor benchmarking, allowing stakeholders to explore performance data across different operating conditions. However, all reports must also include static versions of critical visualizations that capture key performance indicators in their most representative operating conditions for archival purposes and quick reference.

Automated reporting templates should incorporate dynamic scaling features that adjust visualization parameters based on data ranges while maintaining consistent formatting. This ensures that unusual performance characteristics are highlighted rather than obscured by predetermined visualization constraints. Additionally, all reports should include standardized metadata sections documenting test conditions, equipment specifications, and calibration information to support reproducibility.

When reporting on long-term performance characteristics, visualization techniques should emphasize both absolute performance values and relative degradation rates. Dual-axis presentations can effectively communicate these related but distinct aspects of supercapacitor performance, providing immediate insight into both current capabilities and projected longevity under specified operating conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!