Supercapacitor Charging Protocols for Fast-charge Applications — Safety and Degradation Impacts

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Supercapacitor Fast-charging Background and Objectives

Supercapacitors have emerged as a revolutionary energy storage technology, offering exceptional power density, rapid charge-discharge capabilities, and extended cycle life compared to conventional batteries. The evolution of supercapacitor technology dates back to the 1950s, with significant advancements occurring in the 1990s through the development of novel electrode materials and electrolytes. Over the past decade, research has intensified on optimizing charging protocols specifically for fast-charging applications, driven by the growing demand for rapid energy storage solutions in various sectors.

The technological trajectory of supercapacitors has been characterized by continuous improvements in energy density, which historically has been their primary limitation compared to batteries. Recent innovations in electrode materials, including advanced carbon nanostructures, metal oxides, and conductive polymers, have substantially enhanced energy storage capabilities while maintaining the inherent fast-charging advantages of supercapacitors.

Current research trends are increasingly focused on the critical intersection of charging speed and device longevity. As applications demand ever-faster charging capabilities, understanding the fundamental mechanisms of degradation during rapid charging becomes paramount. The industry is witnessing a shift from purely performance-oriented research to safety-conscious protocol development that balances charging speed with device integrity and operational safety.

The primary technical objective of this investigation is to comprehensively evaluate existing and emerging supercapacitor charging protocols specifically designed for fast-charge applications. This includes identifying optimal voltage and current profiles that minimize degradation while maximizing charging speed, as well as establishing safety parameters to prevent thermal runaway, electrolyte decomposition, and electrode damage during rapid charging cycles.

Additionally, this research aims to quantify the relationship between charging rates and capacity retention over extended cycling, develop predictive models for supercapacitor aging under various fast-charging conditions, and establish standardized testing methodologies for evaluating fast-charging protocols across different supercapacitor technologies and form factors.

The ultimate goal is to establish a framework for designing application-specific charging protocols that optimize the trade-off between charging speed, operational safety, and device longevity. This framework will serve as a foundation for the next generation of supercapacitor-based energy storage systems in demanding applications such as electric vehicles, grid stabilization, consumer electronics, and industrial power management where rapid energy delivery and absorption are critical requirements.

The technological trajectory of supercapacitors has been characterized by continuous improvements in energy density, which historically has been their primary limitation compared to batteries. Recent innovations in electrode materials, including advanced carbon nanostructures, metal oxides, and conductive polymers, have substantially enhanced energy storage capabilities while maintaining the inherent fast-charging advantages of supercapacitors.

Current research trends are increasingly focused on the critical intersection of charging speed and device longevity. As applications demand ever-faster charging capabilities, understanding the fundamental mechanisms of degradation during rapid charging becomes paramount. The industry is witnessing a shift from purely performance-oriented research to safety-conscious protocol development that balances charging speed with device integrity and operational safety.

The primary technical objective of this investigation is to comprehensively evaluate existing and emerging supercapacitor charging protocols specifically designed for fast-charge applications. This includes identifying optimal voltage and current profiles that minimize degradation while maximizing charging speed, as well as establishing safety parameters to prevent thermal runaway, electrolyte decomposition, and electrode damage during rapid charging cycles.

Additionally, this research aims to quantify the relationship between charging rates and capacity retention over extended cycling, develop predictive models for supercapacitor aging under various fast-charging conditions, and establish standardized testing methodologies for evaluating fast-charging protocols across different supercapacitor technologies and form factors.

The ultimate goal is to establish a framework for designing application-specific charging protocols that optimize the trade-off between charging speed, operational safety, and device longevity. This framework will serve as a foundation for the next generation of supercapacitor-based energy storage systems in demanding applications such as electric vehicles, grid stabilization, consumer electronics, and industrial power management where rapid energy delivery and absorption are critical requirements.

Market Analysis for Fast-charge Supercapacitor Applications

The global market for fast-charge supercapacitor applications is experiencing robust growth, driven by increasing demand for rapid energy storage solutions across multiple sectors. The market size was valued at approximately $2.1 billion in 2022 and is projected to reach $5.8 billion by 2028, representing a compound annual growth rate (CAGR) of 18.4% during the forecast period.

Electric vehicles represent the largest application segment, accounting for nearly 35% of the market share. The automotive industry's shift toward electrification has created significant demand for supercapacitors that can handle fast charging while maintaining safety and longevity. Major automotive manufacturers are increasingly incorporating supercapacitors into their designs to complement traditional battery systems, particularly for regenerative braking and rapid acceleration functions.

Consumer electronics constitutes the second-largest market segment at 28%, with applications in smartphones, laptops, and wearable devices. The demand for devices that can charge in minutes rather than hours is driving innovation in this space. Market research indicates that consumers are willing to pay a premium of up to 15% for devices featuring fast-charge capabilities.

Industrial applications represent 20% of the market, with significant growth potential in grid stabilization, renewable energy integration, and industrial machinery. The remaining market share is distributed across public transportation, aerospace, and medical devices, each presenting unique requirements for fast-charge protocols.

Geographically, Asia-Pacific dominates the market with a 45% share, led by China, Japan, and South Korea. These countries have established robust manufacturing ecosystems for supercapacitors and related technologies. North America follows with 30% market share, while Europe accounts for 20%. The remaining 5% is distributed across other regions.

Market analysis reveals that safety concerns and degradation issues remain significant barriers to wider adoption. Approximately 65% of potential industrial users cite safety as their primary concern when considering fast-charge supercapacitor implementation. Additionally, 58% of surveyed companies indicated that uncertainty about long-term degradation impacts directly influences their purchasing decisions.

The competitive landscape features established players like Maxwell Technologies (now part of Tesla), Panasonic, and Skeleton Technologies, alongside emerging startups focusing on novel materials and charging protocols. Recent market consolidation through mergers and acquisitions suggests that industry players are positioning themselves strategically to address the growing demand for safer and more efficient fast-charge solutions.

Electric vehicles represent the largest application segment, accounting for nearly 35% of the market share. The automotive industry's shift toward electrification has created significant demand for supercapacitors that can handle fast charging while maintaining safety and longevity. Major automotive manufacturers are increasingly incorporating supercapacitors into their designs to complement traditional battery systems, particularly for regenerative braking and rapid acceleration functions.

Consumer electronics constitutes the second-largest market segment at 28%, with applications in smartphones, laptops, and wearable devices. The demand for devices that can charge in minutes rather than hours is driving innovation in this space. Market research indicates that consumers are willing to pay a premium of up to 15% for devices featuring fast-charge capabilities.

Industrial applications represent 20% of the market, with significant growth potential in grid stabilization, renewable energy integration, and industrial machinery. The remaining market share is distributed across public transportation, aerospace, and medical devices, each presenting unique requirements for fast-charge protocols.

Geographically, Asia-Pacific dominates the market with a 45% share, led by China, Japan, and South Korea. These countries have established robust manufacturing ecosystems for supercapacitors and related technologies. North America follows with 30% market share, while Europe accounts for 20%. The remaining 5% is distributed across other regions.

Market analysis reveals that safety concerns and degradation issues remain significant barriers to wider adoption. Approximately 65% of potential industrial users cite safety as their primary concern when considering fast-charge supercapacitor implementation. Additionally, 58% of surveyed companies indicated that uncertainty about long-term degradation impacts directly influences their purchasing decisions.

The competitive landscape features established players like Maxwell Technologies (now part of Tesla), Panasonic, and Skeleton Technologies, alongside emerging startups focusing on novel materials and charging protocols. Recent market consolidation through mergers and acquisitions suggests that industry players are positioning themselves strategically to address the growing demand for safer and more efficient fast-charge solutions.

Technical Challenges and Safety Constraints in Supercapacitor Charging

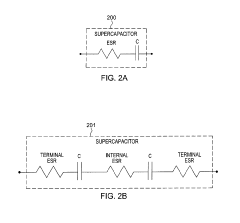

Supercapacitors present unique technical challenges in fast-charging applications that differ significantly from traditional battery systems. The primary challenge lies in managing the extremely high current rates during rapid charging, which can exceed hundreds of amperes. These high currents generate substantial heat through resistive losses in the electrode materials, current collectors, and electrolyte, potentially leading to thermal runaway if not properly managed.

Voltage balancing represents another critical challenge, particularly in series-connected supercapacitor modules. Individual cells can experience voltage imbalances due to manufacturing variations in capacitance and internal resistance. During fast charging, these imbalances become amplified, potentially causing some cells to exceed their rated voltage while others remain underutilized, significantly increasing safety risks.

The electrolyte stability window imposes strict safety constraints on charging protocols. Most commercial supercapacitors utilize organic electrolytes with decomposition voltages around 2.7-3.0V per cell. Fast charging that exceeds these voltage limits, even momentarily, can trigger electrolyte decomposition, generating gas and increasing internal pressure. This process not only accelerates degradation but also creates explosion hazards in sealed devices.

Temperature management during rapid charging presents substantial engineering challenges. The thermal conductivity of supercapacitor materials is relatively poor, creating potential for localized hotspots that can accelerate degradation mechanisms or trigger thermal runaway events. Safety constraints typically limit maximum operating temperatures to 65-70°C, requiring sophisticated thermal management systems for high-power applications.

Current distribution homogeneity across the electrode surface becomes increasingly problematic at high charging rates. Non-uniform current distribution leads to localized heating and stress concentrations that accelerate aging mechanisms. This phenomenon is particularly pronounced in larger form-factor supercapacitors where edge effects become significant.

Mechanical stress induced during rapid charging also presents safety concerns. The charging process involves ion migration into electrode pores, causing physical expansion of electrode materials. At extreme charging rates, this expansion occurs unevenly, generating mechanical stresses that can compromise structural integrity over time, potentially leading to internal short circuits or electrolyte leakage.

The interaction between charging rate and cycle life presents a fundamental technical trade-off. While supercapacitors are generally considered high-cycle-life devices, fast charging protocols significantly accelerate aging mechanisms including electrolyte degradation, electrode material breakdown, and collector corrosion. Establishing charging protocols that balance performance requirements with acceptable degradation rates remains a central challenge.

Voltage balancing represents another critical challenge, particularly in series-connected supercapacitor modules. Individual cells can experience voltage imbalances due to manufacturing variations in capacitance and internal resistance. During fast charging, these imbalances become amplified, potentially causing some cells to exceed their rated voltage while others remain underutilized, significantly increasing safety risks.

The electrolyte stability window imposes strict safety constraints on charging protocols. Most commercial supercapacitors utilize organic electrolytes with decomposition voltages around 2.7-3.0V per cell. Fast charging that exceeds these voltage limits, even momentarily, can trigger electrolyte decomposition, generating gas and increasing internal pressure. This process not only accelerates degradation but also creates explosion hazards in sealed devices.

Temperature management during rapid charging presents substantial engineering challenges. The thermal conductivity of supercapacitor materials is relatively poor, creating potential for localized hotspots that can accelerate degradation mechanisms or trigger thermal runaway events. Safety constraints typically limit maximum operating temperatures to 65-70°C, requiring sophisticated thermal management systems for high-power applications.

Current distribution homogeneity across the electrode surface becomes increasingly problematic at high charging rates. Non-uniform current distribution leads to localized heating and stress concentrations that accelerate aging mechanisms. This phenomenon is particularly pronounced in larger form-factor supercapacitors where edge effects become significant.

Mechanical stress induced during rapid charging also presents safety concerns. The charging process involves ion migration into electrode pores, causing physical expansion of electrode materials. At extreme charging rates, this expansion occurs unevenly, generating mechanical stresses that can compromise structural integrity over time, potentially leading to internal short circuits or electrolyte leakage.

The interaction between charging rate and cycle life presents a fundamental technical trade-off. While supercapacitors are generally considered high-cycle-life devices, fast charging protocols significantly accelerate aging mechanisms including electrolyte degradation, electrode material breakdown, and collector corrosion. Establishing charging protocols that balance performance requirements with acceptable degradation rates remains a central challenge.

Current Fast-charging Protocol Solutions and Implementations

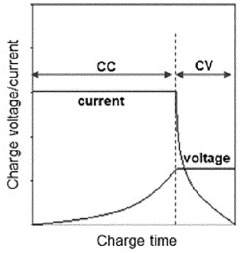

01 Constant Current-Constant Voltage (CC-CV) Charging Protocols

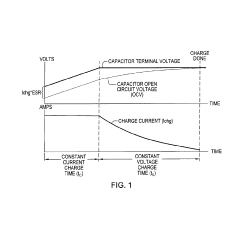

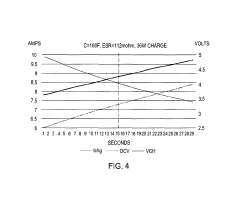

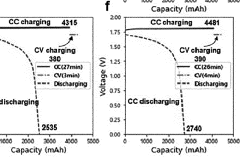

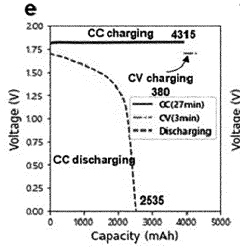

The CC-CV charging protocol is widely used for supercapacitors to ensure safety and minimize degradation. This method involves initially charging the supercapacitor at a constant current until it reaches a predetermined voltage threshold, then switching to constant voltage mode to complete the charging process. This approach prevents voltage spikes that could damage the supercapacitor and extends its operational lifespan by reducing stress on the internal components during charging.- Constant Current-Constant Voltage (CC-CV) Charging Protocols: The CC-CV charging protocol is widely used for supercapacitors to ensure safety and minimize degradation. This method involves initially charging at a constant current until reaching a predetermined voltage threshold, then switching to constant voltage mode to complete the charging process. This approach prevents voltage overshoots and reduces thermal stress on the supercapacitor, extending its operational lifetime while maintaining charging efficiency.

- Temperature-Controlled Charging Systems: Temperature monitoring and control during supercapacitor charging is critical for preventing degradation and ensuring safety. Advanced charging systems incorporate temperature sensors and adaptive algorithms that adjust charging parameters based on the supercapacitor's temperature. These systems can reduce charging current or implement cooling mechanisms when temperatures approach critical thresholds, preventing thermal runaway and extending the supercapacitor's lifespan.

- Pulse Charging Techniques: Pulse charging involves applying current in controlled pulses rather than continuously, allowing rest periods between charging cycles. This technique reduces heat generation and internal resistance buildup in supercapacitors, minimizing degradation mechanisms such as electrolyte decomposition. The rest periods enable ion redistribution within the electrolyte, resulting in more uniform charging and reduced stress on the supercapacitor structure.

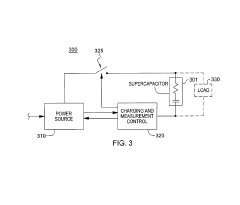

- State of Health Monitoring for Safe Charging: Advanced charging protocols incorporate real-time state of health monitoring to adapt charging parameters based on the supercapacitor's condition. These systems analyze parameters such as internal resistance, capacitance, and leakage current to detect early signs of degradation. By dynamically adjusting charging profiles according to the supercapacitor's health status, these systems can prevent overcharging and extend operational lifetime while maintaining safety.

- Balancing Circuits for Multi-cell Supercapacitor Systems: In multi-cell supercapacitor systems, voltage imbalances between cells can lead to accelerated degradation and safety risks. Specialized balancing circuits ensure uniform voltage distribution across all cells during charging. These circuits can employ passive or active balancing techniques to redistribute energy between cells, preventing individual cells from experiencing overvoltage conditions that could lead to premature failure or thermal events.

02 Temperature Management During Charging

Effective temperature management is crucial for safe supercapacitor charging and preventing accelerated degradation. Charging protocols that incorporate temperature monitoring and control mechanisms can adjust charging parameters based on the supercapacitor's temperature. This helps prevent thermal runaway conditions and reduces the risk of electrolyte decomposition, which can significantly impact the supercapacitor's lifespan and performance characteristics.Expand Specific Solutions03 Pulse Charging Techniques

Pulse charging techniques involve applying intermittent charging currents rather than continuous ones. This approach allows for thermal relaxation periods between charging pulses, which can reduce internal heating and minimize electrolyte degradation. Pulse charging protocols can be particularly beneficial for high-power applications where rapid charging is required while still maintaining safety and longevity of the supercapacitor.Expand Specific Solutions04 State of Health Monitoring Systems

Advanced charging protocols incorporate state of health monitoring systems that continuously assess the supercapacitor's condition during charging. These systems measure parameters such as internal resistance, capacitance, and leakage current to detect early signs of degradation. By adapting the charging profile based on the supercapacitor's current health status, these protocols can optimize the balance between charging speed and device longevity.Expand Specific Solutions05 Multi-stage Adaptive Charging Algorithms

Multi-stage adaptive charging algorithms dynamically adjust charging parameters based on the supercapacitor's response. These sophisticated protocols can incorporate multiple charging phases with different current and voltage profiles tailored to the specific characteristics of the supercapacitor. By analyzing the voltage response curve and other feedback parameters, these algorithms can optimize charging efficiency while minimizing stress factors that contribute to degradation.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Supercapacitor Technology

The supercapacitor fast-charging protocol market is in a growth phase, with increasing adoption across automotive, energy storage, and consumer electronics sectors. The global market is projected to expand significantly as demand for rapid energy storage solutions rises. Technologically, the field shows varying maturity levels, with companies at different development stages. Leaders like StoreDot and LG Energy Solution are advancing innovative fast-charging protocols with enhanced safety features, while Shenzhen TIG Technology and CATL (Ningde Amperex) focus on material optimization to reduce degradation impacts. Automotive manufacturers including BMW, Lamborghini, and Volvo are integrating these technologies, while research institutions like Argonne and Xi'an University contribute fundamental scientific advancements to address thermal management and longevity challenges.

StoreDot Ltd.

Technical Solution: StoreDot has pioneered XFC (Extreme Fast Charging) technology specifically designed for supercapacitor applications. Their silicon-dominant anode technology enables ultra-fast charging protocols that can deliver 100 miles of range in just 5 minutes. The company has developed specialized BMS (Battery Management Systems) that incorporate advanced charging algorithms to monitor temperature, voltage, and current in real-time during fast-charging events. These protocols dynamically adjust charging parameters based on supercapacitor state-of-health and environmental conditions to maximize charging speed while minimizing degradation. StoreDot's technology includes proprietary electrolyte formulations that enhance ion transport during high-current charging scenarios, effectively reducing internal resistance and heat generation that typically accelerate degradation in fast-charge applications.

Strengths: Industry-leading charging speeds (0-80% in under 10 minutes) with minimal degradation impact; proprietary materials science innovations specifically designed for extreme fast charging scenarios. Weaknesses: Higher manufacturing costs compared to conventional systems; requires specialized charging infrastructure to achieve optimal performance.

Uchicago Argonne LLC

Technical Solution: Argonne National Laboratory has developed advanced charging protocols for supercapacitor systems that focus on maximizing lifetime while enabling fast-charging capabilities. Their approach utilizes electrochemical impedance spectroscopy (EIS) in real-time to monitor supercapacitor health during charging events, allowing for dynamic adjustment of charging parameters. Argonne's protocols incorporate physics-based models that predict degradation mechanisms under various charging conditions, enabling preemptive adjustments to charging profiles. Their research has yielded multi-objective optimization algorithms that balance charging speed, thermal management, and long-term degradation effects. Particularly notable is their work on pulse charging techniques that reduce heat generation during fast-charging while maintaining high charging efficiency. Argonne has also pioneered safety-focused charging protocols that incorporate early detection systems for potential failure modes specific to supercapacitor technologies.

Strengths: Research-driven approach with strong scientific foundation; sophisticated modeling capabilities that accurately predict long-term degradation impacts of various charging protocols. Weaknesses: Solutions may require additional development for commercial implementation; higher computational requirements for real-time implementation of advanced models.

Critical Patents and Research on Supercapacitor Degradation Mechanisms

Charging control for supercapacitor(s)

PatentInactiveUS10461559B2

Innovation

- A method and system for dynamically determining the remaining charge time or overvoltage value to control the termination of constant charge charging, allowing the charging to continue until the supercapacitor is substantially fully charged, thereby optimizing energy delivery and preventing capacitor degradation.

Method for charging zinc-bromine supercapattery

PatentWO2024101735A1

Innovation

- A CCCV (Constant Current-Constant Voltage) charging protocol is applied, where a constant current is maintained for 24-29 hours and then switched to a constant voltage for 1-6 minutes, specifically at 1 V, to prevent overvoltage and concentration polarization, optimizing the charging process.

Standardization and Testing Methodologies for Fast-charging Protocols

The standardization of fast-charging protocols for supercapacitors represents a critical area requiring immediate attention from industry stakeholders and regulatory bodies. Currently, there exists a significant gap in unified testing methodologies specifically designed for supercapacitor fast-charging applications, unlike the more established standards for lithium-ion batteries.

International organizations such as IEC (International Electrotechnical Commission) and IEEE (Institute of Electrical and Electronics Engineers) have begun developing preliminary frameworks for supercapacitor testing, but these efforts remain fragmented and incomplete regarding fast-charging scenarios. The IEC 62391 standard addresses general supercapacitor performance metrics but lacks comprehensive protocols for evaluating fast-charging safety parameters.

Testing methodologies must evolve to encompass thermal behavior monitoring during rapid charge cycles, as temperature spikes represent a primary safety concern. Current approaches typically employ thermocouples and infrared imaging, but standardization of sensor placement, measurement frequency, and critical threshold values remains inconsistent across testing facilities.

Electrochemical stability assessment constitutes another crucial testing domain requiring standardization. Cyclic voltammetry and electrochemical impedance spectroscopy provide valuable insights into degradation mechanisms during fast charging, yet testing parameters vary significantly between laboratories, complicating cross-study comparisons and industry-wide benchmarking.

Safety certification protocols must establish clear pass/fail criteria specifically addressing the unique characteristics of supercapacitor fast-charging. These should include quantifiable metrics for thermal runaway resistance, gas evolution thresholds, and physical deformation limits under extreme charging conditions.

Accelerated aging tests represent perhaps the most challenging area for standardization. Current methodologies struggle to accurately simulate real-world degradation patterns within compressed timeframes. The development of universally accepted acceleration factors that maintain relevance to actual usage scenarios remains an ongoing challenge for the testing community.

Industry collaboration through consortia such as the Supercapacitor Materials and Technology Association (SMTA) has begun addressing these standardization gaps. Their proposed testing framework incorporates multi-parameter safety assessments and degradation metrics specifically calibrated for fast-charging applications, potentially serving as a foundation for future official standards.

The establishment of comprehensive, internationally recognized testing methodologies will ultimately accelerate market adoption of fast-charging supercapacitor technologies by providing manufacturers, regulators, and consumers with reliable safety and performance benchmarks.

International organizations such as IEC (International Electrotechnical Commission) and IEEE (Institute of Electrical and Electronics Engineers) have begun developing preliminary frameworks for supercapacitor testing, but these efforts remain fragmented and incomplete regarding fast-charging scenarios. The IEC 62391 standard addresses general supercapacitor performance metrics but lacks comprehensive protocols for evaluating fast-charging safety parameters.

Testing methodologies must evolve to encompass thermal behavior monitoring during rapid charge cycles, as temperature spikes represent a primary safety concern. Current approaches typically employ thermocouples and infrared imaging, but standardization of sensor placement, measurement frequency, and critical threshold values remains inconsistent across testing facilities.

Electrochemical stability assessment constitutes another crucial testing domain requiring standardization. Cyclic voltammetry and electrochemical impedance spectroscopy provide valuable insights into degradation mechanisms during fast charging, yet testing parameters vary significantly between laboratories, complicating cross-study comparisons and industry-wide benchmarking.

Safety certification protocols must establish clear pass/fail criteria specifically addressing the unique characteristics of supercapacitor fast-charging. These should include quantifiable metrics for thermal runaway resistance, gas evolution thresholds, and physical deformation limits under extreme charging conditions.

Accelerated aging tests represent perhaps the most challenging area for standardization. Current methodologies struggle to accurately simulate real-world degradation patterns within compressed timeframes. The development of universally accepted acceleration factors that maintain relevance to actual usage scenarios remains an ongoing challenge for the testing community.

Industry collaboration through consortia such as the Supercapacitor Materials and Technology Association (SMTA) has begun addressing these standardization gaps. Their proposed testing framework incorporates multi-parameter safety assessments and degradation metrics specifically calibrated for fast-charging applications, potentially serving as a foundation for future official standards.

The establishment of comprehensive, internationally recognized testing methodologies will ultimately accelerate market adoption of fast-charging supercapacitor technologies by providing manufacturers, regulators, and consumers with reliable safety and performance benchmarks.

Environmental Impact and Sustainability of Supercapacitor Technologies

The environmental impact of supercapacitor technologies is increasingly significant as fast-charging applications become more widespread. Unlike traditional batteries, supercapacitors generally contain fewer toxic materials, with most commercial devices utilizing activated carbon electrodes and organic or aqueous electrolytes. This composition presents a lower environmental hazard compared to lithium-ion batteries, which often contain cobalt, nickel, and other potentially harmful metals.

Fast-charging protocols, while beneficial for performance, can influence the sustainability profile of supercapacitor systems. Aggressive charging methods that prioritize speed may increase energy consumption during the charging process, reducing overall energy efficiency. Research indicates that optimized charging protocols can improve energy efficiency by 15-20% compared to basic constant current methods, directly reducing the carbon footprint associated with supercapacitor operation.

The manufacturing process of supercapacitors presents both challenges and opportunities for sustainability. Current production methods for activated carbon electrodes require high energy inputs, contributing to embodied carbon. However, recent innovations have focused on developing electrodes from sustainable biomass sources such as coconut shells, wood waste, and agricultural byproducts, potentially reducing manufacturing emissions by up to 40%.

Lifecycle assessment studies reveal that supercapacitors generally outperform batteries in terms of longevity, with typical lifespans exceeding 500,000 charge-discharge cycles when operated within optimal parameters. This extended operational life significantly reduces waste generation and resource consumption compared to technologies requiring frequent replacement.

End-of-life considerations for supercapacitors are increasingly important as deployment scales. Current recycling rates remain low, with less than 10% of commercial supercapacitors undergoing formal recycling processes. The development of dedicated recycling infrastructure represents a critical opportunity to recover valuable materials and further enhance sustainability credentials.

Water usage in supercapacitor manufacturing presents another environmental consideration, particularly for aqueous electrolyte systems. Production facilities typically consume 15-20 liters of water per kWh of storage capacity produced, highlighting the importance of water management strategies in manufacturing locations experiencing water stress.

Emerging research into biodegradable electrolytes and naturally derived separator materials offers promising pathways to reduce the environmental footprint of next-generation supercapacitors. These innovations could potentially address end-of-life concerns while maintaining or even enhancing performance characteristics for fast-charging applications.

Fast-charging protocols, while beneficial for performance, can influence the sustainability profile of supercapacitor systems. Aggressive charging methods that prioritize speed may increase energy consumption during the charging process, reducing overall energy efficiency. Research indicates that optimized charging protocols can improve energy efficiency by 15-20% compared to basic constant current methods, directly reducing the carbon footprint associated with supercapacitor operation.

The manufacturing process of supercapacitors presents both challenges and opportunities for sustainability. Current production methods for activated carbon electrodes require high energy inputs, contributing to embodied carbon. However, recent innovations have focused on developing electrodes from sustainable biomass sources such as coconut shells, wood waste, and agricultural byproducts, potentially reducing manufacturing emissions by up to 40%.

Lifecycle assessment studies reveal that supercapacitors generally outperform batteries in terms of longevity, with typical lifespans exceeding 500,000 charge-discharge cycles when operated within optimal parameters. This extended operational life significantly reduces waste generation and resource consumption compared to technologies requiring frequent replacement.

End-of-life considerations for supercapacitors are increasingly important as deployment scales. Current recycling rates remain low, with less than 10% of commercial supercapacitors undergoing formal recycling processes. The development of dedicated recycling infrastructure represents a critical opportunity to recover valuable materials and further enhance sustainability credentials.

Water usage in supercapacitor manufacturing presents another environmental consideration, particularly for aqueous electrolyte systems. Production facilities typically consume 15-20 liters of water per kWh of storage capacity produced, highlighting the importance of water management strategies in manufacturing locations experiencing water stress.

Emerging research into biodegradable electrolytes and naturally derived separator materials offers promising pathways to reduce the environmental footprint of next-generation supercapacitors. These innovations could potentially address end-of-life concerns while maintaining or even enhancing performance characteristics for fast-charging applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!