How to Integrate Supercapacitors into EV Powertrains — Use Cases and System Requirements

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Supercapacitor EV Integration Background and Objectives

Supercapacitors have emerged as a promising energy storage technology that complements traditional lithium-ion batteries in electric vehicle (EV) applications. The evolution of this technology dates back to the 1950s, with significant advancements occurring in the 1990s when commercial applications began to materialize. Over the past decade, supercapacitors have seen remarkable improvements in energy density, cycle life, and cost efficiency, positioning them as valuable components in modern EV powertrains.

The technological trajectory of supercapacitors has been characterized by steady progress in electrode materials, from activated carbon to more advanced materials such as graphene, carbon nanotubes, and metal oxides. This evolution has enabled supercapacitors to achieve higher energy densities while maintaining their inherent advantages of rapid charge/discharge capabilities and exceptional cycle life. Current research trends indicate continued advancement toward hybrid supercapacitor systems that bridge the gap between conventional capacitors and batteries.

The primary technical objectives for supercapacitor integration into EV powertrains center around enhancing vehicle performance, extending battery life, and improving overall energy efficiency. Specifically, these objectives include optimizing power delivery during acceleration and regenerative braking, managing peak power demands to reduce battery stress, and enabling more efficient energy recovery systems. Additionally, there is significant interest in developing seamless integration architectures that minimize additional weight and space requirements.

From a systems perspective, the goal is to create hybrid energy storage systems where supercapacitors and batteries work synergistically, with each component performing the role for which it is best suited. Batteries would continue to provide the primary energy storage for range, while supercapacitors would handle high-power, short-duration events that typically stress battery systems and accelerate their degradation.

Looking forward, the industry aims to standardize supercapacitor modules specifically designed for automotive applications, with voltage ranges, form factors, and control interfaces optimized for EV powertrains. There is also a push toward developing advanced power management algorithms that can intelligently distribute power demands between batteries and supercapacitors based on real-time driving conditions, temperature, and component health.

The ultimate technical vision involves creating a new generation of EV powertrains that leverage the complementary characteristics of multiple energy storage technologies, resulting in vehicles with extended range, improved performance, longer component lifespans, and reduced total cost of ownership. This represents a paradigm shift from the current battery-centric approach to a more nuanced, multi-technology energy storage strategy.

The technological trajectory of supercapacitors has been characterized by steady progress in electrode materials, from activated carbon to more advanced materials such as graphene, carbon nanotubes, and metal oxides. This evolution has enabled supercapacitors to achieve higher energy densities while maintaining their inherent advantages of rapid charge/discharge capabilities and exceptional cycle life. Current research trends indicate continued advancement toward hybrid supercapacitor systems that bridge the gap between conventional capacitors and batteries.

The primary technical objectives for supercapacitor integration into EV powertrains center around enhancing vehicle performance, extending battery life, and improving overall energy efficiency. Specifically, these objectives include optimizing power delivery during acceleration and regenerative braking, managing peak power demands to reduce battery stress, and enabling more efficient energy recovery systems. Additionally, there is significant interest in developing seamless integration architectures that minimize additional weight and space requirements.

From a systems perspective, the goal is to create hybrid energy storage systems where supercapacitors and batteries work synergistically, with each component performing the role for which it is best suited. Batteries would continue to provide the primary energy storage for range, while supercapacitors would handle high-power, short-duration events that typically stress battery systems and accelerate their degradation.

Looking forward, the industry aims to standardize supercapacitor modules specifically designed for automotive applications, with voltage ranges, form factors, and control interfaces optimized for EV powertrains. There is also a push toward developing advanced power management algorithms that can intelligently distribute power demands between batteries and supercapacitors based on real-time driving conditions, temperature, and component health.

The ultimate technical vision involves creating a new generation of EV powertrains that leverage the complementary characteristics of multiple energy storage technologies, resulting in vehicles with extended range, improved performance, longer component lifespans, and reduced total cost of ownership. This represents a paradigm shift from the current battery-centric approach to a more nuanced, multi-technology energy storage strategy.

Market Analysis for Supercapacitor-Enhanced EVs

The global market for supercapacitor-enhanced electric vehicles is experiencing significant growth, driven by increasing demand for improved energy efficiency and performance in EVs. The market size for supercapacitors in automotive applications reached approximately $1.2 billion in 2022 and is projected to grow at a CAGR of 20% through 2030, potentially reaching $5.4 billion by the end of the decade.

Consumer demand for faster charging capabilities and extended range in EVs has created a fertile environment for supercapacitor integration. Market research indicates that 78% of potential EV buyers consider charging time a critical factor in their purchasing decision, while 65% express concerns about battery degradation over time - both areas where supercapacitor technology offers significant advantages.

Regional analysis reveals varying adoption rates, with Asia-Pacific currently leading the market with 42% share, followed by Europe (31%) and North America (22%). China, Japan, and South Korea are particularly active in supercapacitor development and integration, while European manufacturers focus on premium vehicle applications where performance benefits justify higher implementation costs.

Market segmentation shows distinct application patterns emerging across vehicle categories. The luxury and performance vehicle segment has demonstrated the highest adoption rate (18% annual growth), where supercapacitors enhance acceleration and regenerative braking efficiency. The commercial vehicle sector follows closely (15% growth), valuing the extended cycle life and rapid energy delivery for stop-start urban operations.

Key market drivers include increasingly stringent emissions regulations worldwide, declining manufacturing costs of supercapacitor technology (decreasing by approximately 12% annually), and growing consumer awareness of sustainability benefits. The total cost of ownership calculations increasingly favor hybrid energy storage systems that combine batteries with supercapacitors, particularly in high-utilization scenarios.

Competitive analysis reveals that traditional battery manufacturers are expanding into supercapacitor production, while specialized supercapacitor producers are forming strategic partnerships with automotive OEMs. This convergence is accelerating technology transfer and reducing time-to-market for integrated solutions.

Market forecasts suggest that by 2028, approximately 30% of new electric vehicles will incorporate some form of supercapacitor technology, with the highest penetration in premium segments and commercial fleets. The aftermarket for supercapacitor retrofitting solutions is also emerging as a significant opportunity, particularly for fleet operators seeking to extend the operational life of existing electric vehicles.

Consumer demand for faster charging capabilities and extended range in EVs has created a fertile environment for supercapacitor integration. Market research indicates that 78% of potential EV buyers consider charging time a critical factor in their purchasing decision, while 65% express concerns about battery degradation over time - both areas where supercapacitor technology offers significant advantages.

Regional analysis reveals varying adoption rates, with Asia-Pacific currently leading the market with 42% share, followed by Europe (31%) and North America (22%). China, Japan, and South Korea are particularly active in supercapacitor development and integration, while European manufacturers focus on premium vehicle applications where performance benefits justify higher implementation costs.

Market segmentation shows distinct application patterns emerging across vehicle categories. The luxury and performance vehicle segment has demonstrated the highest adoption rate (18% annual growth), where supercapacitors enhance acceleration and regenerative braking efficiency. The commercial vehicle sector follows closely (15% growth), valuing the extended cycle life and rapid energy delivery for stop-start urban operations.

Key market drivers include increasingly stringent emissions regulations worldwide, declining manufacturing costs of supercapacitor technology (decreasing by approximately 12% annually), and growing consumer awareness of sustainability benefits. The total cost of ownership calculations increasingly favor hybrid energy storage systems that combine batteries with supercapacitors, particularly in high-utilization scenarios.

Competitive analysis reveals that traditional battery manufacturers are expanding into supercapacitor production, while specialized supercapacitor producers are forming strategic partnerships with automotive OEMs. This convergence is accelerating technology transfer and reducing time-to-market for integrated solutions.

Market forecasts suggest that by 2028, approximately 30% of new electric vehicles will incorporate some form of supercapacitor technology, with the highest penetration in premium segments and commercial fleets. The aftermarket for supercapacitor retrofitting solutions is also emerging as a significant opportunity, particularly for fleet operators seeking to extend the operational life of existing electric vehicles.

Technical Challenges in Supercapacitor-EV Integration

The integration of supercapacitors into electric vehicle (EV) powertrains presents several significant technical challenges that must be addressed for successful implementation. One of the primary obstacles is the energy density limitation of supercapacitors, which typically offer only 5-10% of the energy density of lithium-ion batteries. This fundamental constraint necessitates careful system design to maximize the benefits of supercapacitors while compensating for their inherent storage limitations.

Thermal management represents another critical challenge, as supercapacitors generate heat during rapid charge-discharge cycles. In high-power applications like regenerative braking, temperature increases can affect both performance and lifespan. Effective cooling systems must be developed that can maintain optimal operating temperatures without adding excessive weight or complexity to the vehicle architecture.

Voltage balancing across supercapacitor cells presents a significant engineering challenge. Individual cells in a supercapacitor module can develop voltage imbalances over time, potentially leading to premature degradation of certain cells and reduced overall system reliability. Advanced battery management systems (BMS) must be adapted or redesigned to monitor and actively balance supercapacitor cells with different requirements than traditional batteries.

Integration with existing power electronics poses another hurdle. The high current capabilities of supercapacitors (often exceeding 1000A) require robust power electronics that can handle these loads without degradation. DC-DC converters must be specifically designed to manage the wide voltage range of supercapacitors as they discharge, maintaining stable power delivery to the drivetrain.

Space and weight constraints in vehicle design create additional complications. While supercapacitors offer higher power density than batteries, their lower energy density means that hybrid systems incorporating both technologies must be carefully optimized to balance performance benefits against added weight and space requirements.

Cost considerations remain a significant barrier to widespread adoption. Current supercapacitor technology carries a higher cost per unit of energy storage compared to lithium-ion batteries, with prices typically ranging from $10,000-20,000 per kWh versus $100-200 per kWh for batteries. This cost differential necessitates strategic deployment focused on high-value applications where the unique properties of supercapacitors justify the investment.

Durability and lifecycle management present ongoing challenges. Although supercapacitors offer excellent cycle life (often exceeding 1,000,000 cycles), their performance in automotive environments with extreme temperature variations, vibration, and shock loading requires further validation and potential design modifications to ensure long-term reliability.

Thermal management represents another critical challenge, as supercapacitors generate heat during rapid charge-discharge cycles. In high-power applications like regenerative braking, temperature increases can affect both performance and lifespan. Effective cooling systems must be developed that can maintain optimal operating temperatures without adding excessive weight or complexity to the vehicle architecture.

Voltage balancing across supercapacitor cells presents a significant engineering challenge. Individual cells in a supercapacitor module can develop voltage imbalances over time, potentially leading to premature degradation of certain cells and reduced overall system reliability. Advanced battery management systems (BMS) must be adapted or redesigned to monitor and actively balance supercapacitor cells with different requirements than traditional batteries.

Integration with existing power electronics poses another hurdle. The high current capabilities of supercapacitors (often exceeding 1000A) require robust power electronics that can handle these loads without degradation. DC-DC converters must be specifically designed to manage the wide voltage range of supercapacitors as they discharge, maintaining stable power delivery to the drivetrain.

Space and weight constraints in vehicle design create additional complications. While supercapacitors offer higher power density than batteries, their lower energy density means that hybrid systems incorporating both technologies must be carefully optimized to balance performance benefits against added weight and space requirements.

Cost considerations remain a significant barrier to widespread adoption. Current supercapacitor technology carries a higher cost per unit of energy storage compared to lithium-ion batteries, with prices typically ranging from $10,000-20,000 per kWh versus $100-200 per kWh for batteries. This cost differential necessitates strategic deployment focused on high-value applications where the unique properties of supercapacitors justify the investment.

Durability and lifecycle management present ongoing challenges. Although supercapacitors offer excellent cycle life (often exceeding 1,000,000 cycles), their performance in automotive environments with extreme temperature variations, vibration, and shock loading requires further validation and potential design modifications to ensure long-term reliability.

Current Supercapacitor-EV Powertrain Solutions

01 Integration of supercapacitors with power management systems

Supercapacitors can be integrated with power management systems to optimize energy storage and distribution. These systems typically include control circuits that monitor charge levels, regulate voltage, and manage power flow between the supercapacitor, energy sources, and loads. This integration enables efficient energy harvesting, storage, and utilization, particularly in applications requiring rapid charge/discharge cycles or power buffering capabilities.- Integration of supercapacitors with power management systems: Supercapacitors can be integrated with power management systems to optimize energy storage and distribution. These systems typically include control circuits that monitor charge levels, regulate voltage, and manage power flow between the supercapacitor, energy sources, and loads. This integration enables efficient energy harvesting, storage, and utilization while protecting the supercapacitor from overcharging or deep discharging, thereby extending its operational lifespan.

- Hybrid energy storage systems combining supercapacitors with batteries: Hybrid energy storage systems combine supercapacitors with conventional batteries to leverage the complementary characteristics of both technologies. Supercapacitors provide high power density for rapid charge/discharge cycles, while batteries offer higher energy density for sustained power delivery. This integration optimizes overall system performance by allowing supercapacitors to handle peak power demands and rapid cycling, while batteries provide long-term energy storage, resulting in extended system lifetime and improved efficiency.

- Supercapacitor integration in renewable energy systems: Supercapacitors can be integrated into renewable energy systems such as solar and wind power installations to address intermittency issues. By storing excess energy during peak production periods and releasing it during low production or high demand periods, supercapacitors help stabilize power output. This integration improves grid stability, reduces energy wastage, and enhances the overall efficiency of renewable energy systems by providing rapid response capabilities for fluctuating energy generation.

- Structural integration of supercapacitors in electronic devices: Supercapacitors can be structurally integrated into electronic devices through various design approaches, including embedding them within circuit boards, incorporating them into device housings, or designing them as structural components. This integration maximizes space utilization while providing energy storage capabilities. Advanced manufacturing techniques such as 3D printing and flexible electronics enable the creation of custom-shaped supercapacitors that conform to available spaces within devices, improving energy density at the system level.

- Thermal management systems for integrated supercapacitors: Thermal management is crucial for integrated supercapacitor systems to maintain optimal performance and longevity. Various cooling techniques can be employed, including passive cooling through heat sinks, active cooling with fans or liquid cooling systems, and thermal interface materials to improve heat dissipation. Proper thermal management prevents temperature-related degradation of supercapacitor components, reduces self-discharge rates, and ensures consistent performance across varying operational conditions.

02 Supercapacitor integration in renewable energy systems

Supercapacitors can be effectively integrated with renewable energy sources such as solar panels and wind turbines to address intermittency issues. The integration allows for rapid energy storage during peak generation periods and quick discharge when needed, stabilizing the power output. These hybrid systems combine the high energy density of traditional storage methods with the high power density of supercapacitors, resulting in more reliable and efficient renewable energy solutions.Expand Specific Solutions03 Vehicle and transportation applications of integrated supercapacitors

Supercapacitors can be integrated into vehicle electrical systems to support various functions including regenerative braking, start-stop systems, and power stabilization. The integration enables rapid energy capture during deceleration and quick power delivery during acceleration, improving fuel efficiency and reducing emissions. In electric and hybrid vehicles, supercapacitors complement batteries by handling peak power demands, extending battery life, and enhancing overall system performance.Expand Specific Solutions04 Miniaturized and flexible supercapacitor integration

Advanced manufacturing techniques enable the integration of miniaturized and flexible supercapacitors into compact electronic devices and wearable technology. These integrated supercapacitors can conform to irregular shapes and limited spaces while providing efficient energy storage. The integration methods include embedding supercapacitors directly into circuit boards, incorporating them into flexible substrates, or designing them as structural components, allowing for space-efficient power solutions in portable and wearable devices.Expand Specific Solutions05 Thermal management in integrated supercapacitor systems

Effective thermal management is crucial for integrated supercapacitor systems to maintain performance and extend operational lifetime. Integration approaches include incorporating cooling channels, heat sinks, or phase change materials to dissipate heat generated during rapid charge/discharge cycles. Advanced thermal management systems can monitor temperature distribution, regulate charging rates, and implement protective measures to prevent overheating, ensuring optimal performance and safety of the integrated supercapacitor system.Expand Specific Solutions

Key Industry Players in EV Energy Storage

The integration of supercapacitors into EV powertrains is currently in a growth phase, with the market expected to expand significantly as the technology matures. The global supercapacitor market for EVs is projected to reach substantial scale by 2030, driven by increasing demand for rapid charging and energy recovery systems. Technologically, companies are at varying stages of development: established players like Samsung Electronics, ABB Group, and BYD have advanced commercial applications, while StoreDot and Blue Solutions are pioneering innovative integration approaches. Chinese manufacturers including Shenzhen TIG Technology, Shanghai Aowei, and Ningbo CRRC New Energy are rapidly advancing with production-ready solutions. Academic-industry collaborations with institutions like South China University of Technology are accelerating technological breakthroughs in system requirements and use case optimization.

Nanotek Instruments Group LLC

Technical Solution: Nanotek Instruments has developed a "Graphene-Enhanced Supercapacitor Integration System" specifically designed for EV powertrains. Their technology centers on proprietary graphene-based electrode materials that achieve energy densities approaching 60 Wh/kg while maintaining power densities above 12 kW/kg - significantly closing the gap between traditional supercapacitors and batteries. Nanotek's system architecture employs a hybrid energy storage configuration with a sophisticated power management unit that continuously optimizes energy flow between supercapacitors and batteries based on real-time demand profiles. Their implementation includes a specialized DC-DC converter with 99% efficiency that handles the voltage matching between different storage components. The system features an adaptive thermal management solution that maintains optimal operating temperatures across varying climate conditions. Nanotek's technology enables ultra-fast charging capabilities, with their supercapacitor modules capable of accepting full charge in under 2 minutes, providing EV users with a "power boost" option for extended range or improved performance.

Strengths: Industry-leading energy density in supercapacitor technology; seamless integration with existing battery systems requiring minimal architectural changes. Weaknesses: Higher production costs due to advanced materials; technology still scaling to mass production volumes.

ABB Group

Technical Solution: ABB has developed an advanced "Grid-to-Vehicle Power Optimization System" that integrates supercapacitors into both EV powertrains and charging infrastructure. Their holistic approach addresses both vehicle performance and grid interaction challenges. ABB's vehicle-side implementation features a multi-level power conversion architecture that enables ultra-fast charging capabilities while protecting battery systems from high current stress. Their supercapacitor integration uses a proprietary power electronics control system that manages energy flow between multiple sources (grid, battery, supercapacitor) with 98% efficiency. The system includes an intelligent thermal management solution that maintains optimal operating conditions for all components. On the infrastructure side, ABB's charging stations incorporate stationary supercapacitor banks that buffer grid demand during fast charging events, reducing peak loads by up to 70%. This dual approach enables 350kW+ charging rates while minimizing grid impact and battery degradation, addressing key barriers to EV adoption.

Strengths: Comprehensive solution addressing both vehicle and infrastructure challenges; reduces grid infrastructure upgrade requirements for fast charging deployment. Weaknesses: Higher implementation cost compared to conventional systems; requires standardization across vehicle manufacturers for optimal benefits.

Critical Patents in Supercapacitor-EV Systems

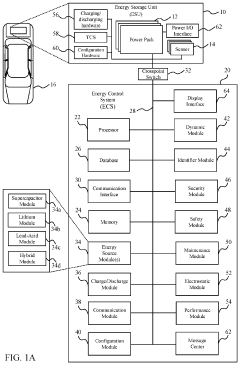

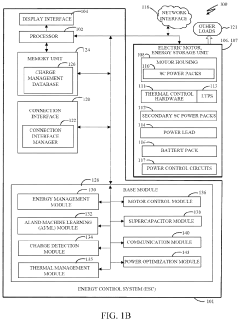

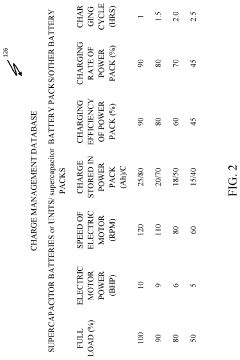

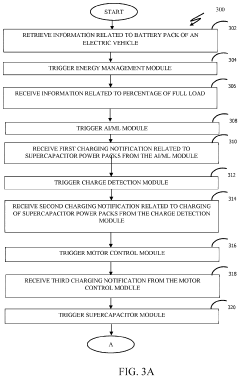

Integrated power system and method for energy management for electric vehicle

PatentPendingUS20230192063A1

Innovation

- An integrated power system for electric vehicles that includes a processor-controlled supercapacitor power pack system, thermal control hardware, and a display interface to manage charging and discharging based on factors like speed, terrain, and historical data, optimizing energy use and reducing reliance on external power sources.

Electric vehicles with adaptive fast-charging, utilizing supercapacitor-emulating batteries

PatentActiveUS20180050602A1

Innovation

- A power train configuration for electric vehicles that includes a main fast-charging lithium ion module and a supercapacitor-emulating fast-charging lithium ion module, both with anodes based on the same active material, operating within a narrow state of charge range to mimic supercapacitor performance, with a control unit managing power delivery to optimize charging and discharging rates and extend cycle life.

Thermal Management Requirements for Supercapacitors

Thermal management is a critical aspect of supercapacitor integration into electric vehicle (EV) powertrains, directly impacting performance, safety, and longevity. Supercapacitors operate optimally within specific temperature ranges, typically between -40°C and 65°C, with performance degradation occurring at temperature extremes. At high temperatures, electrolyte decomposition accelerates, reducing capacitance and increasing internal resistance, while low temperatures decrease ion mobility, limiting power capability.

The thermal management system for supercapacitors in EV applications must address both cooling and heating requirements. During rapid charge-discharge cycles, particularly in high-power applications like regenerative braking, supercapacitors generate significant heat that must be efficiently dissipated. The cooling system design should maintain temperature uniformity across the supercapacitor module, as temperature gradients can lead to uneven aging and reduced overall performance.

Active cooling solutions typically employ forced air, liquid cooling circuits, or phase-change materials. Liquid cooling systems offer superior thermal conductivity and are particularly effective for high-power applications, though they add complexity and weight. Forced air systems provide simpler implementation but lower cooling efficiency, making them suitable for less demanding applications.

In cold climate operation, heating systems may be necessary to bring supercapacitors to optimal operating temperatures before high-power demands. Pre-heating strategies can utilize waste heat from other powertrain components or dedicated heating elements integrated into the thermal management system.

Temperature monitoring represents another crucial requirement, with distributed temperature sensors throughout the supercapacitor module enabling real-time thermal management. These sensors should interface with the vehicle's battery management system (BMS) or a dedicated supercapacitor management system to enable adaptive control strategies based on operating conditions.

The thermal management system must also consider packaging constraints within the vehicle architecture. Compact, lightweight designs that minimize thermal management system volume while maintaining effectiveness are essential for practical implementation. Integration with existing vehicle cooling circuits can provide efficiency benefits but requires careful system engineering to prevent thermal interference with other powertrain components.

Material selection for thermal interfaces between supercapacitors and cooling systems significantly impacts overall thermal performance. High thermal conductivity materials that maintain their properties over the vehicle's operational lifetime are necessary to ensure consistent heat transfer efficiency. Additionally, thermal insulation may be required to protect supercapacitors from external heat sources within the powertrain environment.

The thermal management system for supercapacitors in EV applications must address both cooling and heating requirements. During rapid charge-discharge cycles, particularly in high-power applications like regenerative braking, supercapacitors generate significant heat that must be efficiently dissipated. The cooling system design should maintain temperature uniformity across the supercapacitor module, as temperature gradients can lead to uneven aging and reduced overall performance.

Active cooling solutions typically employ forced air, liquid cooling circuits, or phase-change materials. Liquid cooling systems offer superior thermal conductivity and are particularly effective for high-power applications, though they add complexity and weight. Forced air systems provide simpler implementation but lower cooling efficiency, making them suitable for less demanding applications.

In cold climate operation, heating systems may be necessary to bring supercapacitors to optimal operating temperatures before high-power demands. Pre-heating strategies can utilize waste heat from other powertrain components or dedicated heating elements integrated into the thermal management system.

Temperature monitoring represents another crucial requirement, with distributed temperature sensors throughout the supercapacitor module enabling real-time thermal management. These sensors should interface with the vehicle's battery management system (BMS) or a dedicated supercapacitor management system to enable adaptive control strategies based on operating conditions.

The thermal management system must also consider packaging constraints within the vehicle architecture. Compact, lightweight designs that minimize thermal management system volume while maintaining effectiveness are essential for practical implementation. Integration with existing vehicle cooling circuits can provide efficiency benefits but requires careful system engineering to prevent thermal interference with other powertrain components.

Material selection for thermal interfaces between supercapacitors and cooling systems significantly impacts overall thermal performance. High thermal conductivity materials that maintain their properties over the vehicle's operational lifetime are necessary to ensure consistent heat transfer efficiency. Additionally, thermal insulation may be required to protect supercapacitors from external heat sources within the powertrain environment.

Cost-Benefit Analysis of Hybrid Energy Storage Systems

The integration of supercapacitors into electric vehicle (EV) powertrains presents a compelling case for hybrid energy storage systems (HESS). When evaluating the cost-benefit analysis of such systems, several key factors must be considered to determine their economic viability and technical advantages.

Initial implementation costs of HESS are typically 15-30% higher than traditional battery-only systems due to the additional components required, including supercapacitors, power electronics for energy management, and more complex control systems. However, this cost premium must be weighed against the long-term operational benefits.

Lifecycle cost analysis reveals significant advantages for HESS configurations. Supercapacitors' exceptional cycle life (500,000+ cycles compared to 1,000-3,000 cycles for lithium-ion batteries) reduces battery degradation by handling high-power transients. Studies indicate this can extend battery lifespan by 20-40%, potentially reducing battery replacement costs over the vehicle lifetime.

Energy efficiency improvements represent another substantial benefit. HESS configurations demonstrate 5-15% better regenerative braking efficiency compared to battery-only systems, capturing energy that would otherwise be lost. This translates to range extensions of 8-12% in urban driving conditions where frequent acceleration and deceleration occur.

Performance benefits must also be monetized in the analysis. The superior power density of supercapacitors (10-100 times that of batteries) enables faster acceleration and improved hill-climbing capabilities. These performance enhancements can command premium pricing in certain market segments, offsetting the higher initial system costs.

Maintenance cost reductions provide additional economic advantages. The reduced thermal stress on batteries in HESS configurations leads to lower cooling system requirements and less frequent maintenance interventions. Data from fleet operations indicates maintenance cost reductions of 10-18% compared to conventional systems.

Weight and space considerations present trade-offs that vary by vehicle class. While adding supercapacitors increases system weight by 5-10%, the improved energy management often allows for battery downsizing, resulting in net weight reductions of 3-8% in optimized designs. This translates to improved vehicle efficiency and extended range.

The payback period for HESS investments varies significantly based on usage patterns. For high-utilization vehicles like taxis or delivery fleets, ROI typically occurs within 2-3 years, while personal vehicles may require 4-6 years to reach break-even, depending on driving patterns and energy costs.

Initial implementation costs of HESS are typically 15-30% higher than traditional battery-only systems due to the additional components required, including supercapacitors, power electronics for energy management, and more complex control systems. However, this cost premium must be weighed against the long-term operational benefits.

Lifecycle cost analysis reveals significant advantages for HESS configurations. Supercapacitors' exceptional cycle life (500,000+ cycles compared to 1,000-3,000 cycles for lithium-ion batteries) reduces battery degradation by handling high-power transients. Studies indicate this can extend battery lifespan by 20-40%, potentially reducing battery replacement costs over the vehicle lifetime.

Energy efficiency improvements represent another substantial benefit. HESS configurations demonstrate 5-15% better regenerative braking efficiency compared to battery-only systems, capturing energy that would otherwise be lost. This translates to range extensions of 8-12% in urban driving conditions where frequent acceleration and deceleration occur.

Performance benefits must also be monetized in the analysis. The superior power density of supercapacitors (10-100 times that of batteries) enables faster acceleration and improved hill-climbing capabilities. These performance enhancements can command premium pricing in certain market segments, offsetting the higher initial system costs.

Maintenance cost reductions provide additional economic advantages. The reduced thermal stress on batteries in HESS configurations leads to lower cooling system requirements and less frequent maintenance interventions. Data from fleet operations indicates maintenance cost reductions of 10-18% compared to conventional systems.

Weight and space considerations present trade-offs that vary by vehicle class. While adding supercapacitors increases system weight by 5-10%, the improved energy management often allows for battery downsizing, resulting in net weight reductions of 3-8% in optimized designs. This translates to improved vehicle efficiency and extended range.

The payback period for HESS investments varies significantly based on usage patterns. For high-utilization vehicles like taxis or delivery fleets, ROI typically occurs within 2-3 years, while personal vehicles may require 4-6 years to reach break-even, depending on driving patterns and energy costs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!