Cellophane Advances in the Electronics Industry

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cellophane in Electronics: Background and Objectives

Cellophane, a thin, transparent sheet made from regenerated cellulose, has a rich history dating back to its invention in 1908. Initially developed for packaging and food preservation, cellophane has undergone significant advancements over the years, finding its way into various industries, including electronics. The evolution of cellophane in the electronics sector represents a fascinating intersection of materials science and technological innovation.

In recent years, the electronics industry has been exploring novel applications for cellophane due to its unique properties. The material's transparency, flexibility, and biodegradability make it an attractive option for developing eco-friendly electronic components. As the demand for sustainable and recyclable materials in electronics grows, cellophane has emerged as a potential solution to address environmental concerns while meeting the industry's performance requirements.

The primary objective of cellophane research in electronics is to harness its inherent characteristics to create innovative products and improve existing technologies. One key area of focus is the development of flexible and transparent electronic devices, such as displays, sensors, and wearable technology. Cellophane's ability to be easily molded and shaped while maintaining its optical properties opens up new possibilities for designing sleek, lightweight electronic products.

Another significant goal is to leverage cellophane's biodegradability to address the growing issue of electronic waste. As the global community becomes increasingly aware of the environmental impact of discarded electronic devices, there is a pressing need for materials that can decompose naturally without leaving harmful residues. Cellophane's potential in this area could revolutionize the way electronic components are manufactured and disposed of, leading to more sustainable practices in the industry.

Researchers are also exploring cellophane's potential as a substrate for printed electronics. The material's smooth surface and compatibility with various printing techniques make it an ideal candidate for creating flexible circuits and conductive patterns. This application could pave the way for cost-effective production of large-area electronics and disposable electronic devices.

As the electronics industry continues to evolve, the role of cellophane is expected to expand further. The ongoing research aims to enhance the material's properties, such as improving its heat resistance and electrical conductivity, to broaden its applications in electronic devices. By combining cellophane with other advanced materials and technologies, scientists and engineers are working towards creating a new generation of electronics that are not only high-performing but also environmentally friendly.

In recent years, the electronics industry has been exploring novel applications for cellophane due to its unique properties. The material's transparency, flexibility, and biodegradability make it an attractive option for developing eco-friendly electronic components. As the demand for sustainable and recyclable materials in electronics grows, cellophane has emerged as a potential solution to address environmental concerns while meeting the industry's performance requirements.

The primary objective of cellophane research in electronics is to harness its inherent characteristics to create innovative products and improve existing technologies. One key area of focus is the development of flexible and transparent electronic devices, such as displays, sensors, and wearable technology. Cellophane's ability to be easily molded and shaped while maintaining its optical properties opens up new possibilities for designing sleek, lightweight electronic products.

Another significant goal is to leverage cellophane's biodegradability to address the growing issue of electronic waste. As the global community becomes increasingly aware of the environmental impact of discarded electronic devices, there is a pressing need for materials that can decompose naturally without leaving harmful residues. Cellophane's potential in this area could revolutionize the way electronic components are manufactured and disposed of, leading to more sustainable practices in the industry.

Researchers are also exploring cellophane's potential as a substrate for printed electronics. The material's smooth surface and compatibility with various printing techniques make it an ideal candidate for creating flexible circuits and conductive patterns. This application could pave the way for cost-effective production of large-area electronics and disposable electronic devices.

As the electronics industry continues to evolve, the role of cellophane is expected to expand further. The ongoing research aims to enhance the material's properties, such as improving its heat resistance and electrical conductivity, to broaden its applications in electronic devices. By combining cellophane with other advanced materials and technologies, scientists and engineers are working towards creating a new generation of electronics that are not only high-performing but also environmentally friendly.

Market Demand Analysis for Cellophane in Electronics

The market demand for cellophane in the electronics industry has been experiencing significant growth in recent years, driven by the material's unique properties and the evolving needs of electronic devices. Cellophane, a thin, transparent film made from regenerated cellulose, offers excellent barrier properties against moisture and gases, making it particularly valuable in electronic applications.

One of the primary drivers of market demand is the increasing use of cellophane in flexible electronics. As consumer electronics trend towards thinner, lighter, and more flexible designs, cellophane's ability to provide a protective barrier while maintaining flexibility has become highly sought after. This is particularly evident in the production of flexible displays, wearable devices, and foldable smartphones, where cellophane serves as a crucial component in protecting sensitive electronic components.

The growing emphasis on sustainability in the electronics industry has also contributed to the rising demand for cellophane. As a biodegradable and renewable material, cellophane aligns well with the industry's efforts to reduce environmental impact. This has led to its increased adoption in packaging for electronic components and devices, replacing traditional petroleum-based plastics in many applications.

In the semiconductor industry, cellophane has found applications in the manufacturing process of integrated circuits. Its use as a temporary protective layer during wafer processing and as a carrier film for delicate components has expanded the market for high-purity, specialized cellophane products. This segment of the market is expected to grow as semiconductor manufacturing becomes more advanced and requires increasingly precise materials.

The automotive electronics sector represents another significant area of market growth for cellophane. With the rise of electric vehicles and advanced driver assistance systems, there is an increasing need for reliable, moisture-resistant materials to protect sensitive electronic components. Cellophane's properties make it an excellent choice for insulation and protection in automotive electronic systems.

Market analysis indicates that the Asia-Pacific region, particularly countries like China, Japan, and South Korea, dominates the demand for cellophane in electronics due to their strong electronics manufacturing base. However, North America and Europe are also showing increased adoption, driven by innovations in flexible electronics and sustainable packaging solutions.

Looking ahead, the market for cellophane in electronics is projected to continue its upward trajectory. Factors such as the expansion of 5G networks, the Internet of Things (IoT), and advancements in flexible and printed electronics are expected to create new opportunities for cellophane applications. Additionally, ongoing research into enhancing cellophane's properties, such as improving its heat resistance and electrical insulation capabilities, is likely to further broaden its market potential in the electronics industry.

One of the primary drivers of market demand is the increasing use of cellophane in flexible electronics. As consumer electronics trend towards thinner, lighter, and more flexible designs, cellophane's ability to provide a protective barrier while maintaining flexibility has become highly sought after. This is particularly evident in the production of flexible displays, wearable devices, and foldable smartphones, where cellophane serves as a crucial component in protecting sensitive electronic components.

The growing emphasis on sustainability in the electronics industry has also contributed to the rising demand for cellophane. As a biodegradable and renewable material, cellophane aligns well with the industry's efforts to reduce environmental impact. This has led to its increased adoption in packaging for electronic components and devices, replacing traditional petroleum-based plastics in many applications.

In the semiconductor industry, cellophane has found applications in the manufacturing process of integrated circuits. Its use as a temporary protective layer during wafer processing and as a carrier film for delicate components has expanded the market for high-purity, specialized cellophane products. This segment of the market is expected to grow as semiconductor manufacturing becomes more advanced and requires increasingly precise materials.

The automotive electronics sector represents another significant area of market growth for cellophane. With the rise of electric vehicles and advanced driver assistance systems, there is an increasing need for reliable, moisture-resistant materials to protect sensitive electronic components. Cellophane's properties make it an excellent choice for insulation and protection in automotive electronic systems.

Market analysis indicates that the Asia-Pacific region, particularly countries like China, Japan, and South Korea, dominates the demand for cellophane in electronics due to their strong electronics manufacturing base. However, North America and Europe are also showing increased adoption, driven by innovations in flexible electronics and sustainable packaging solutions.

Looking ahead, the market for cellophane in electronics is projected to continue its upward trajectory. Factors such as the expansion of 5G networks, the Internet of Things (IoT), and advancements in flexible and printed electronics are expected to create new opportunities for cellophane applications. Additionally, ongoing research into enhancing cellophane's properties, such as improving its heat resistance and electrical insulation capabilities, is likely to further broaden its market potential in the electronics industry.

Current State and Challenges of Cellophane in Electronics

Cellophane, a transparent and flexible material, has made significant strides in the electronics industry, yet it faces several challenges in its current state of application. The material's unique properties, including its transparency, flexibility, and biodegradability, have positioned it as a potential alternative to traditional plastics in electronic components and packaging.

In recent years, cellophane has found increasing use in flexible electronics, particularly in the development of bendable displays and wearable devices. Its ability to withstand repeated bending and folding without losing structural integrity has made it an attractive option for manufacturers seeking to create more durable and versatile electronic products. However, the integration of cellophane into complex electronic systems remains a significant challenge, primarily due to its limited conductivity and heat resistance.

One of the primary obstacles in the widespread adoption of cellophane in electronics is its inherent lack of electrical conductivity. While this property makes it an excellent insulator, it also limits its application in circuits and conductive pathways. Researchers are actively exploring methods to enhance cellophane's conductivity through various surface treatments and the incorporation of conductive nanoparticles, but these solutions often come at the cost of reduced transparency or flexibility.

Another critical challenge lies in cellophane's thermal properties. Electronic devices generate heat during operation, and the material's relatively low heat resistance can lead to degradation and performance issues in high-temperature environments. This limitation restricts its use in applications where heat dissipation is crucial, such as in power electronics or high-performance computing devices.

The manufacturing process for integrating cellophane into electronic components also presents significant hurdles. Traditional electronics manufacturing techniques are often incompatible with cellophane's properties, necessitating the development of new production methods and equipment. This adaptation requires substantial investment in research and development, as well as retooling of existing manufacturing facilities.

Despite these challenges, the potential benefits of cellophane in electronics continue to drive innovation. Its biodegradability offers a promising solution to the growing problem of electronic waste, aligning with the industry's push towards more sustainable practices. Additionally, the material's flexibility opens up new possibilities for form factors in electronic devices, potentially revolutionizing product design and user interaction.

As the electronics industry continues to evolve, addressing these challenges will be crucial for realizing the full potential of cellophane. Collaborative efforts between material scientists, electrical engineers, and manufacturing experts are essential to overcome the current limitations and develop novel applications that leverage cellophane's unique properties.

In recent years, cellophane has found increasing use in flexible electronics, particularly in the development of bendable displays and wearable devices. Its ability to withstand repeated bending and folding without losing structural integrity has made it an attractive option for manufacturers seeking to create more durable and versatile electronic products. However, the integration of cellophane into complex electronic systems remains a significant challenge, primarily due to its limited conductivity and heat resistance.

One of the primary obstacles in the widespread adoption of cellophane in electronics is its inherent lack of electrical conductivity. While this property makes it an excellent insulator, it also limits its application in circuits and conductive pathways. Researchers are actively exploring methods to enhance cellophane's conductivity through various surface treatments and the incorporation of conductive nanoparticles, but these solutions often come at the cost of reduced transparency or flexibility.

Another critical challenge lies in cellophane's thermal properties. Electronic devices generate heat during operation, and the material's relatively low heat resistance can lead to degradation and performance issues in high-temperature environments. This limitation restricts its use in applications where heat dissipation is crucial, such as in power electronics or high-performance computing devices.

The manufacturing process for integrating cellophane into electronic components also presents significant hurdles. Traditional electronics manufacturing techniques are often incompatible with cellophane's properties, necessitating the development of new production methods and equipment. This adaptation requires substantial investment in research and development, as well as retooling of existing manufacturing facilities.

Despite these challenges, the potential benefits of cellophane in electronics continue to drive innovation. Its biodegradability offers a promising solution to the growing problem of electronic waste, aligning with the industry's push towards more sustainable practices. Additionally, the material's flexibility opens up new possibilities for form factors in electronic devices, potentially revolutionizing product design and user interaction.

As the electronics industry continues to evolve, addressing these challenges will be crucial for realizing the full potential of cellophane. Collaborative efforts between material scientists, electrical engineers, and manufacturing experts are essential to overcome the current limitations and develop novel applications that leverage cellophane's unique properties.

Existing Applications of Cellophane in Electronics

01 Cellophane in packaging applications

Cellophane is widely used in packaging applications due to its transparency, flexibility, and barrier properties. It is particularly useful for food packaging, where it can help preserve freshness and extend shelf life. Cellophane can be used alone or in combination with other materials to create various packaging solutions.- Cellophane production and modification: Various methods and processes for producing and modifying cellophane are described. These include techniques for improving the properties of cellophane, such as its strength, flexibility, and barrier characteristics. The production processes may involve chemical treatments, physical modifications, or the incorporation of additives to enhance the performance of cellophane for specific applications.

- Packaging applications of cellophane: Cellophane is widely used in packaging applications due to its transparency, flexibility, and barrier properties. The patents describe various packaging solutions utilizing cellophane, including food packaging, consumer product packaging, and industrial packaging. Some innovations focus on improving the sealing properties, printability, and environmental sustainability of cellophane-based packaging materials.

- Cellophane-based composite materials: The development of composite materials incorporating cellophane is discussed in several patents. These composites may combine cellophane with other materials such as polymers, fibers, or nanoparticles to create materials with enhanced properties. Applications for these composites include packaging, textiles, and various industrial uses.

- Biodegradable and eco-friendly cellophane: Innovations in making cellophane more environmentally friendly are described. These include developing biodegradable cellophane formulations, improving the recyclability of cellophane products, and creating cellophane alternatives from sustainable sources. The patents also cover methods for reducing the environmental impact of cellophane production and disposal.

- Cellophane in medical and pharmaceutical applications: The use of cellophane in medical and pharmaceutical applications is explored in several patents. These applications include drug delivery systems, wound dressings, and medical packaging. The patents describe methods for modifying cellophane to improve its biocompatibility, sterilizability, and controlled release properties for medical use.

02 Cellophane production and processing

The production and processing of cellophane involve various techniques to improve its properties and performance. This includes methods for enhancing its strength, flexibility, and barrier properties. Innovations in cellophane production focus on improving manufacturing efficiency and developing new formulations to meet specific application requirements.Expand Specific Solutions03 Cellophane in medical and pharmaceutical applications

Cellophane finds applications in the medical and pharmaceutical industries due to its biocompatibility and barrier properties. It can be used in wound dressings, drug delivery systems, and as a protective layer for medical devices. Research in this area focuses on enhancing cellophane's properties for specific medical applications.Expand Specific Solutions04 Cellophane in electronic and optical applications

Cellophane has potential applications in electronic and optical devices due to its transparency and flexibility. It can be used as a substrate or protective layer in flexible electronics, displays, and optical films. Research in this area explores ways to modify cellophane to enhance its electrical and optical properties for these advanced applications.Expand Specific Solutions05 Biodegradable and sustainable cellophane alternatives

With increasing environmental concerns, there is growing interest in developing biodegradable and sustainable alternatives to traditional cellophane. This includes research into bio-based materials that can mimic cellophane's properties while offering improved environmental performance. These alternatives aim to reduce plastic waste and promote circular economy principles in packaging and other applications.Expand Specific Solutions

Key Players in Cellophane and Electronics Industries

The cellophane advances in the electronics industry are in a nascent stage, with the market still developing and relatively small. The technology's maturity is low, but growing interest from major players indicates potential. Companies like LG Energy Solution, Texas Instruments, and Huawei are exploring applications in flexible electronics and displays. Samsung and LG Display are leveraging their expertise in screen technologies to incorporate cellophane innovations. While not yet mainstream, cellophane's unique properties are attracting R&D efforts from electronics giants, suggesting a competitive landscape forming around this emerging technology for next-generation devices.

Texas Instruments Incorporated

Technical Solution: Texas Instruments has been exploring the use of cellophane-derived materials in various electronic components. They have developed a process to create cellophane-based dielectrics for use in high-frequency circuits, offering improved performance in wireless communication devices. TI is also investigating the potential of cellophane in thermal management solutions for power electronics, leveraging its natural heat dissipation properties. Their research extends to the use of cellophane-based materials in flexible sensors for IoT applications, combining biodegradability with advanced sensing capabilities[8][10].

Strengths: Extensive experience in semiconductor manufacturing, diverse product portfolio, and strong presence in multiple electronics markets. Weaknesses: Potential resistance to adoption of new materials in established product lines and competition from specialized materials companies.

Huawei Technologies Co., Ltd.

Technical Solution: Huawei has been investing in cellophane-based technologies for various applications in the electronics industry. They have developed a novel cellophane-derived material with enhanced conductivity for use in flexible antennas and sensors. Huawei's research also includes the use of cellophane in advanced packaging solutions for 5G components, offering improved signal integrity and thermal management. Additionally, they are exploring the potential of cellophane-based materials in energy storage devices, such as supercapacitors, for next-generation mobile devices[4][6].

Strengths: Strong expertise in telecommunications technology, extensive global research network, and ability to rapidly commercialize innovations. Weaknesses: Potential regulatory challenges in some markets and competition from established materials suppliers.

Innovative Cellophane Technologies for Electronics

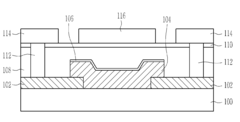

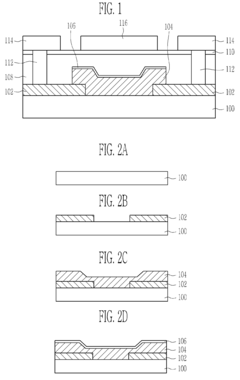

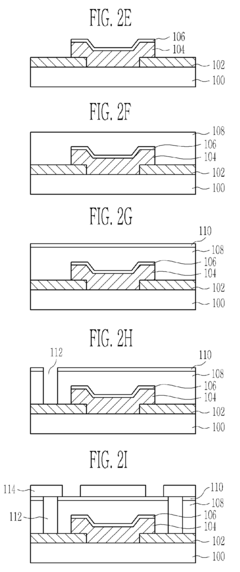

Transparent nonvolatile memory thin film transistor and method of manufacturing the same

PatentActiveUS8198625B2

Innovation

- A transparent nonvolatile memory TFT structure using an organic ferroelectric thin layer and an oxide semiconductor thin layer, with auxiliary insulating layers to reduce processing temperature and operating voltage, and prevent leakage currents, enabling low-temperature processing and reliable operations.

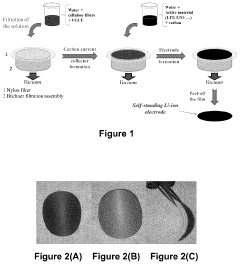

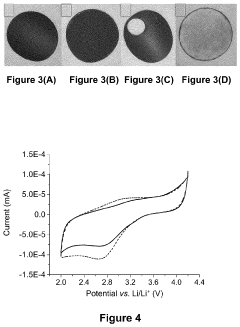

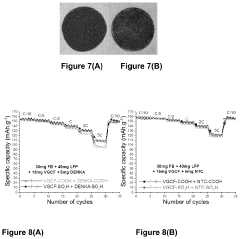

Cellulose-based self-standing films for use in Li-ion batteries

PatentActiveUS11811068B2

Innovation

- A self-standing electrode composed of a first electronically conductive material with grafted aryl groups, cellulose fibers as a binder, and an electrochemically active material, where the concentration of conductive material and active material increases from one surface to the other, eliminating the need for metal current collectors and using a water-based filtration process inspired by the paper industry.

Environmental Impact of Cellophane in Electronics

The environmental impact of cellophane in the electronics industry is a complex issue that requires careful consideration. Cellophane, a thin, transparent sheet made from regenerated cellulose, has found various applications in electronic packaging and components. However, its widespread use raises concerns about its ecological footprint throughout its lifecycle.

In the production phase, cellophane manufacturing involves chemical processes that can generate harmful byproducts. The use of carbon disulfide and other chemicals in the viscose process may lead to air and water pollution if not properly managed. Additionally, the energy-intensive nature of cellophane production contributes to greenhouse gas emissions, further impacting the environment.

During the use phase in electronics, cellophane's environmental impact is relatively low. Its lightweight and flexible properties can contribute to reduced material usage and energy consumption in electronic devices. However, the durability of cellophane in certain applications may be limited, potentially leading to more frequent replacement and increased waste generation.

The end-of-life stage presents significant environmental challenges. While cellophane is biodegradable under certain conditions, its disposal in electronic waste streams often prevents proper decomposition. When incinerated with other electronic waste, cellophane may release harmful emissions. In landfills, it may take years to degrade, contributing to long-term waste accumulation.

Recycling cellophane from electronic products poses difficulties due to contamination and the complex nature of electronic waste. The material is often mixed with other components, making separation and recovery challenging. This limitation in recycling options further exacerbates the environmental burden of cellophane in electronics.

To mitigate these environmental impacts, the industry is exploring several avenues. Research into more sustainable production methods, such as using alternative solvents or bio-based raw materials, aims to reduce the ecological footprint of cellophane manufacturing. Efforts to improve the material's durability and recyclability are also underway, with the goal of extending product lifespans and facilitating easier recovery at end-of-life.

Furthermore, the development of biodegradable electronics and eco-friendly packaging solutions incorporating cellophane derivatives shows promise in reducing environmental impact. These innovations seek to address the challenges of electronic waste management while maintaining the beneficial properties of cellophane in electronic applications.

In the production phase, cellophane manufacturing involves chemical processes that can generate harmful byproducts. The use of carbon disulfide and other chemicals in the viscose process may lead to air and water pollution if not properly managed. Additionally, the energy-intensive nature of cellophane production contributes to greenhouse gas emissions, further impacting the environment.

During the use phase in electronics, cellophane's environmental impact is relatively low. Its lightweight and flexible properties can contribute to reduced material usage and energy consumption in electronic devices. However, the durability of cellophane in certain applications may be limited, potentially leading to more frequent replacement and increased waste generation.

The end-of-life stage presents significant environmental challenges. While cellophane is biodegradable under certain conditions, its disposal in electronic waste streams often prevents proper decomposition. When incinerated with other electronic waste, cellophane may release harmful emissions. In landfills, it may take years to degrade, contributing to long-term waste accumulation.

Recycling cellophane from electronic products poses difficulties due to contamination and the complex nature of electronic waste. The material is often mixed with other components, making separation and recovery challenging. This limitation in recycling options further exacerbates the environmental burden of cellophane in electronics.

To mitigate these environmental impacts, the industry is exploring several avenues. Research into more sustainable production methods, such as using alternative solvents or bio-based raw materials, aims to reduce the ecological footprint of cellophane manufacturing. Efforts to improve the material's durability and recyclability are also underway, with the goal of extending product lifespans and facilitating easier recovery at end-of-life.

Furthermore, the development of biodegradable electronics and eco-friendly packaging solutions incorporating cellophane derivatives shows promise in reducing environmental impact. These innovations seek to address the challenges of electronic waste management while maintaining the beneficial properties of cellophane in electronic applications.

Regulatory Landscape for Cellophane in Electronics

The regulatory landscape for cellophane in the electronics industry is complex and evolving, reflecting the increasing importance of this material in advanced electronic applications. Regulatory bodies across major markets have implemented stringent guidelines to ensure the safe and sustainable use of cellophane in electronic products.

In the United States, the Environmental Protection Agency (EPA) and the Food and Drug Administration (FDA) play crucial roles in regulating cellophane use. The EPA focuses on the environmental impact of cellophane production and disposal, while the FDA oversees its application in consumer electronics, particularly those that may come into contact with food or skin.

The European Union has implemented the Restriction of Hazardous Substances (RoHS) directive, which limits the use of certain hazardous materials in electrical and electronic equipment. While cellophane itself is not directly restricted, manufacturers must ensure that any additives or treatments applied to cellophane comply with RoHS standards.

In Asia, countries like Japan and South Korea have established their own regulatory frameworks. Japan's Ministry of Economy, Trade and Industry (METI) has set guidelines for the use of bio-based materials, including cellophane, in electronics. South Korea's regulatory approach focuses on the recyclability and environmental impact of electronic components.

Globally, the International Electrotechnical Commission (IEC) has developed standards for the use of bioplastics in electronics, which indirectly affect cellophane applications. These standards address issues such as thermal stability, electrical properties, and long-term reliability of bio-based materials in electronic devices.

Recent regulatory trends indicate a growing emphasis on sustainability and circular economy principles. This has led to increased scrutiny of the entire lifecycle of cellophane in electronics, from raw material sourcing to end-of-life disposal. Manufacturers are now required to consider the recyclability and biodegradability of cellophane components in their product designs.

Emerging regulations are also addressing the potential health impacts of cellophane in electronics. This includes assessing the release of volatile organic compounds (VOCs) from cellophane-based components and the potential for allergen exposure in wearable electronics.

As the use of cellophane in electronics continues to expand, regulatory bodies are likely to develop more specific guidelines. Industry stakeholders are actively participating in the development of these regulations, aiming to balance innovation with safety and environmental concerns. This collaborative approach is expected to shape the future regulatory landscape for cellophane in the electronics industry.

In the United States, the Environmental Protection Agency (EPA) and the Food and Drug Administration (FDA) play crucial roles in regulating cellophane use. The EPA focuses on the environmental impact of cellophane production and disposal, while the FDA oversees its application in consumer electronics, particularly those that may come into contact with food or skin.

The European Union has implemented the Restriction of Hazardous Substances (RoHS) directive, which limits the use of certain hazardous materials in electrical and electronic equipment. While cellophane itself is not directly restricted, manufacturers must ensure that any additives or treatments applied to cellophane comply with RoHS standards.

In Asia, countries like Japan and South Korea have established their own regulatory frameworks. Japan's Ministry of Economy, Trade and Industry (METI) has set guidelines for the use of bio-based materials, including cellophane, in electronics. South Korea's regulatory approach focuses on the recyclability and environmental impact of electronic components.

Globally, the International Electrotechnical Commission (IEC) has developed standards for the use of bioplastics in electronics, which indirectly affect cellophane applications. These standards address issues such as thermal stability, electrical properties, and long-term reliability of bio-based materials in electronic devices.

Recent regulatory trends indicate a growing emphasis on sustainability and circular economy principles. This has led to increased scrutiny of the entire lifecycle of cellophane in electronics, from raw material sourcing to end-of-life disposal. Manufacturers are now required to consider the recyclability and biodegradability of cellophane components in their product designs.

Emerging regulations are also addressing the potential health impacts of cellophane in electronics. This includes assessing the release of volatile organic compounds (VOCs) from cellophane-based components and the potential for allergen exposure in wearable electronics.

As the use of cellophane in electronics continues to expand, regulatory bodies are likely to develop more specific guidelines. Industry stakeholders are actively participating in the development of these regulations, aiming to balance innovation with safety and environmental concerns. This collaborative approach is expected to shape the future regulatory landscape for cellophane in the electronics industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!