Comparative study of MXenes vs graphene in supercapacitors

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MXenes and Graphene Evolution in Energy Storage

The evolution of energy storage technologies has witnessed significant advancements in recent decades, with supercapacitors emerging as promising devices for high-power applications. Within this landscape, two-dimensional (2D) materials have revolutionized the field, with graphene initially dominating research attention since its isolation in 2004, and MXenes gaining substantial interest since their discovery in 2011.

Graphene's journey in energy storage began with its exceptional theoretical surface area (2630 m²/g) and electrical conductivity, which promised unprecedented energy storage capabilities. Early research focused on reduced graphene oxide (rGO) due to scalability advantages, though performance often fell short of theoretical predictions due to restacking issues. The evolution progressed through various structural modifications including 3D graphene architectures, holey graphene, and graphene composites to address these limitations.

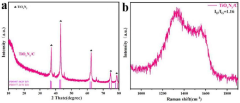

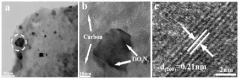

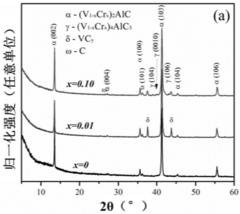

MXenes, representing a newer class of 2D transition metal carbides and nitrides, have followed a different evolutionary path. Initially synthesized through selective etching of MAX phases, early MXenes (primarily Ti3C2Tx) demonstrated promising capacitance values but faced stability challenges. Their evolution has been marked by rapid diversification, with over 30 compositions now synthesized and continuous improvements in synthesis methods moving from hydrofluoric acid to safer alternatives.

The comparative evolution reveals interesting convergence and divergence patterns. Both materials initially faced similar challenges regarding restacking and limited ion accessibility, but developed distinct solutions. Graphene research evolved toward hybrid structures and doping strategies, while MXenes development focused on interlayer spacing engineering and surface termination optimization.

Performance metrics have shown remarkable improvement trajectories. Graphene-based supercapacitors initially achieved specific capacitances of 100-200 F/g, evolving to 300-400 F/g with advanced architectures. MXenes demonstrated a steeper improvement curve, from initial values of ~200 F/g to recent reports exceeding 500 F/g, particularly in aqueous electrolytes.

The technological maturity differs significantly, with graphene-based solutions already commercialized in niche applications, while MXenes remain predominantly in laboratory research phases. This maturity gap is reflected in manufacturing scalability, with graphene production reaching ton-scale while MXene synthesis remains limited to gram-scale in most research settings.

Recent evolutionary trends show increasing convergence, with MXene-graphene hybrids emerging as a promising direction that combines the high conductivity of graphene with the pseudocapacitive properties of MXenes, potentially offering synergistic performance improvements that exceed the capabilities of either material alone.

Graphene's journey in energy storage began with its exceptional theoretical surface area (2630 m²/g) and electrical conductivity, which promised unprecedented energy storage capabilities. Early research focused on reduced graphene oxide (rGO) due to scalability advantages, though performance often fell short of theoretical predictions due to restacking issues. The evolution progressed through various structural modifications including 3D graphene architectures, holey graphene, and graphene composites to address these limitations.

MXenes, representing a newer class of 2D transition metal carbides and nitrides, have followed a different evolutionary path. Initially synthesized through selective etching of MAX phases, early MXenes (primarily Ti3C2Tx) demonstrated promising capacitance values but faced stability challenges. Their evolution has been marked by rapid diversification, with over 30 compositions now synthesized and continuous improvements in synthesis methods moving from hydrofluoric acid to safer alternatives.

The comparative evolution reveals interesting convergence and divergence patterns. Both materials initially faced similar challenges regarding restacking and limited ion accessibility, but developed distinct solutions. Graphene research evolved toward hybrid structures and doping strategies, while MXenes development focused on interlayer spacing engineering and surface termination optimization.

Performance metrics have shown remarkable improvement trajectories. Graphene-based supercapacitors initially achieved specific capacitances of 100-200 F/g, evolving to 300-400 F/g with advanced architectures. MXenes demonstrated a steeper improvement curve, from initial values of ~200 F/g to recent reports exceeding 500 F/g, particularly in aqueous electrolytes.

The technological maturity differs significantly, with graphene-based solutions already commercialized in niche applications, while MXenes remain predominantly in laboratory research phases. This maturity gap is reflected in manufacturing scalability, with graphene production reaching ton-scale while MXene synthesis remains limited to gram-scale in most research settings.

Recent evolutionary trends show increasing convergence, with MXene-graphene hybrids emerging as a promising direction that combines the high conductivity of graphene with the pseudocapacitive properties of MXenes, potentially offering synergistic performance improvements that exceed the capabilities of either material alone.

Market Analysis for Supercapacitor Materials

The global supercapacitor market is experiencing robust growth, projected to reach $5.4 billion by 2025 with a CAGR of 20.7% from 2020. This expansion is primarily driven by increasing demand for high-performance energy storage solutions across automotive, renewable energy, consumer electronics, and industrial sectors. The material composition of supercapacitors represents a critical factor in their performance characteristics and market adoption.

Graphene has dominated the premium supercapacitor materials market since its commercial introduction, capturing approximately 32% of the high-performance materials segment. Its market value within supercapacitor applications reached $720 million in 2022. Major manufacturers including Tesla, Samsung SDI, and Maxwell Technologies have integrated graphene-based supercapacitors into their product portfolios, particularly for rapid-charging applications.

MXenes, as relative newcomers to the commercial supercapacitor materials landscape, currently hold a smaller market share of approximately 8% in the high-performance segment. However, they demonstrate the fastest growth rate among all supercapacitor materials at 34.5% annually. This accelerated adoption is particularly evident in specialized applications requiring exceptional volumetric capacitance.

Regional analysis reveals distinct market patterns. North America leads in graphene supercapacitor adoption with 38% market share, driven by electric vehicle and grid storage applications. Asia-Pacific demonstrates the highest growth trajectory for both materials, with China, South Korea, and Japan collectively investing over $1.2 billion in MXene manufacturing infrastructure between 2020-2023.

End-user segmentation indicates automotive applications represent the largest market for both materials (41%), followed by consumer electronics (27%), renewable energy storage (18%), and industrial applications (14%). MXenes show particularly strong penetration in miniaturized electronics applications, where their volumetric efficiency provides significant advantages.

Price sensitivity analysis reveals MXenes currently command a 15-20% premium over graphene materials, primarily due to manufacturing scale limitations. However, this gap is narrowing as production technologies mature, with projections suggesting price parity could be achieved by 2026 if current scaling trends continue.

Market forecasts indicate the combined graphene and MXene supercapacitor materials market will grow to $3.8 billion by 2028, with MXenes potentially capturing up to 25% market share. This projection is contingent upon continued improvements in MXene manufacturing scalability and further demonstration of their performance advantages in commercial applications.

Graphene has dominated the premium supercapacitor materials market since its commercial introduction, capturing approximately 32% of the high-performance materials segment. Its market value within supercapacitor applications reached $720 million in 2022. Major manufacturers including Tesla, Samsung SDI, and Maxwell Technologies have integrated graphene-based supercapacitors into their product portfolios, particularly for rapid-charging applications.

MXenes, as relative newcomers to the commercial supercapacitor materials landscape, currently hold a smaller market share of approximately 8% in the high-performance segment. However, they demonstrate the fastest growth rate among all supercapacitor materials at 34.5% annually. This accelerated adoption is particularly evident in specialized applications requiring exceptional volumetric capacitance.

Regional analysis reveals distinct market patterns. North America leads in graphene supercapacitor adoption with 38% market share, driven by electric vehicle and grid storage applications. Asia-Pacific demonstrates the highest growth trajectory for both materials, with China, South Korea, and Japan collectively investing over $1.2 billion in MXene manufacturing infrastructure between 2020-2023.

End-user segmentation indicates automotive applications represent the largest market for both materials (41%), followed by consumer electronics (27%), renewable energy storage (18%), and industrial applications (14%). MXenes show particularly strong penetration in miniaturized electronics applications, where their volumetric efficiency provides significant advantages.

Price sensitivity analysis reveals MXenes currently command a 15-20% premium over graphene materials, primarily due to manufacturing scale limitations. However, this gap is narrowing as production technologies mature, with projections suggesting price parity could be achieved by 2026 if current scaling trends continue.

Market forecasts indicate the combined graphene and MXene supercapacitor materials market will grow to $3.8 billion by 2028, with MXenes potentially capturing up to 25% market share. This projection is contingent upon continued improvements in MXene manufacturing scalability and further demonstration of their performance advantages in commercial applications.

Technical Challenges in MXenes vs Graphene Implementation

Despite the promising properties of both MXenes and graphene for supercapacitor applications, significant technical challenges impede their widespread implementation. For MXenes, stability issues present a major obstacle as these materials are prone to oxidation when exposed to ambient conditions, resulting in degraded electrochemical performance over time. The synthesis of high-quality MXenes with consistent properties remains challenging, with current etching processes often introducing defects and impurities that affect performance reliability.

Manufacturing scalability represents another critical challenge for MXenes. While laboratory-scale production has demonstrated impressive results, translating these processes to industrial scales while maintaining quality and cost-effectiveness has proven difficult. The complex multi-step synthesis procedures, particularly the selective etching of the A-layer from MAX phases, are time-consuming and require precise control of reaction conditions.

Graphene faces its own set of implementation challenges. The production of high-quality, defect-free graphene sheets at commercial scales remains problematic. Methods like chemical vapor deposition (CVD) produce high-quality graphene but are expensive and difficult to scale, while chemical reduction of graphene oxide yields materials with significant defects that compromise electrical conductivity and capacitance.

The restacking of graphene sheets during electrode fabrication significantly reduces the effective surface area accessible to electrolyte ions, diminishing the theoretical performance advantages. Various approaches to prevent restacking, such as introducing spacers or creating 3D architectures, add complexity to manufacturing processes and may introduce new performance trade-offs.

For both materials, electrode fabrication presents technical hurdles. Creating uniform, stable electrodes with optimal thickness, porosity, and mechanical integrity requires sophisticated engineering. The interface between these nanomaterials and current collectors often suffers from contact resistance issues that limit device performance.

Electrolyte compatibility also poses challenges. Finding electrolyte systems that maximize the potential window while ensuring long-term stability with these carbon-based materials requires extensive optimization. For MXenes specifically, the interaction between surface functional groups and electrolyte ions is complex and highly dependent on synthesis conditions.

Cost considerations remain significant for both materials. While graphene production costs have decreased over time, high-quality material remains expensive for large-scale energy storage applications. MXenes, being newer materials with more complex synthesis requirements, currently face even higher production costs, limiting commercial viability despite their promising performance metrics.

Manufacturing scalability represents another critical challenge for MXenes. While laboratory-scale production has demonstrated impressive results, translating these processes to industrial scales while maintaining quality and cost-effectiveness has proven difficult. The complex multi-step synthesis procedures, particularly the selective etching of the A-layer from MAX phases, are time-consuming and require precise control of reaction conditions.

Graphene faces its own set of implementation challenges. The production of high-quality, defect-free graphene sheets at commercial scales remains problematic. Methods like chemical vapor deposition (CVD) produce high-quality graphene but are expensive and difficult to scale, while chemical reduction of graphene oxide yields materials with significant defects that compromise electrical conductivity and capacitance.

The restacking of graphene sheets during electrode fabrication significantly reduces the effective surface area accessible to electrolyte ions, diminishing the theoretical performance advantages. Various approaches to prevent restacking, such as introducing spacers or creating 3D architectures, add complexity to manufacturing processes and may introduce new performance trade-offs.

For both materials, electrode fabrication presents technical hurdles. Creating uniform, stable electrodes with optimal thickness, porosity, and mechanical integrity requires sophisticated engineering. The interface between these nanomaterials and current collectors often suffers from contact resistance issues that limit device performance.

Electrolyte compatibility also poses challenges. Finding electrolyte systems that maximize the potential window while ensuring long-term stability with these carbon-based materials requires extensive optimization. For MXenes specifically, the interaction between surface functional groups and electrolyte ions is complex and highly dependent on synthesis conditions.

Cost considerations remain significant for both materials. While graphene production costs have decreased over time, high-quality material remains expensive for large-scale energy storage applications. MXenes, being newer materials with more complex synthesis requirements, currently face even higher production costs, limiting commercial viability despite their promising performance metrics.

Current Electrode Design Solutions

01 Electrical conductivity comparison between MXenes and graphene

MXenes generally exhibit lower electrical conductivity compared to graphene due to their different atomic structure and composition. While graphene has a 2D sheet of carbon atoms with exceptional electron mobility, MXenes consist of transition metal carbides or nitrides with surface terminations that can affect electron transport. However, some MXene compositions can be engineered to achieve conductivity values approaching those of graphene, particularly when surface functional groups are optimized. The layered structure of both materials contributes to their conductive properties, though graphene remains superior in most electrical applications.- Electrical conductivity comparison between MXenes and graphene: MXenes generally exhibit lower electrical conductivity compared to graphene due to their different atomic structure and composition. While graphene has a 2D honeycomb lattice of carbon atoms with exceptional electron mobility, MXenes consist of transition metal carbides or nitrides with surface terminations that affect electron transport. However, some MXene compositions can be engineered to achieve conductivity values approaching those of graphene, particularly when surface functional groups are optimized.

- Mechanical properties and flexibility differences: Graphene demonstrates superior mechanical strength with a Young's modulus of approximately 1 TPa, making it one of the strongest materials known. MXenes typically show lower mechanical strength but often exhibit better flexibility and stretchability due to their layered structure and surface terminations. This makes MXenes particularly advantageous in flexible electronics and wearable devices where conformability is crucial, while graphene excels in applications requiring maximum mechanical reinforcement.

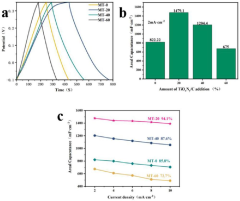

- Energy storage and electrochemical performance: MXenes generally outperform graphene in energy storage applications, particularly as electrode materials in supercapacitors and batteries. Their higher volumetric capacitance, better ion intercalation properties, and tunable interlayer spacing allow for superior charge storage capabilities. MXenes demonstrate faster ion transport and higher specific capacitance compared to graphene, though graphene often shows better cycling stability and electrical conductivity in these applications.

- Surface chemistry and functionalization capabilities: MXenes offer more diverse surface chemistry than graphene due to their inherent surface terminations (such as -O, -OH, -F) that form during synthesis. This makes MXenes easier to functionalize for specific applications without disrupting their core structure. Graphene, being primarily composed of carbon atoms, requires more extensive modification to achieve similar functional diversity. The rich surface chemistry of MXenes enables better interfacial interactions in composites and more tunable properties for sensing and catalytic applications.

- Optical and electromagnetic properties comparison: Graphene exhibits uniform and broadband optical absorption across the electromagnetic spectrum with high transparency, while MXenes show thickness-dependent and composition-dependent optical properties with typically higher absorption in the visible range. MXenes demonstrate superior electromagnetic interference (EMI) shielding effectiveness compared to graphene at equivalent thicknesses due to their higher electrical conductivity combined with dielectric losses. MXenes also show promising photothermal conversion efficiency that can exceed graphene in certain applications.

02 Mechanical properties and flexibility differences

Graphene demonstrates superior mechanical strength with a Young's modulus of approximately 1 TPa, making it one of the strongest materials known. MXenes, while still exhibiting good mechanical properties, typically show lower tensile strength but potentially better flexibility in certain compositions. The layered structure of MXenes allows for better deformation capabilities in some applications. The mechanical performance difference is attributed to the atomic bonding characteristics - graphene's strong carbon-carbon bonds versus MXenes' metal-carbon bonds with surface terminations. These differences make each material suitable for different mechanical applications.Expand Specific Solutions03 Electrochemical performance in energy storage applications

MXenes often outperform graphene in electrochemical energy storage applications, particularly as electrode materials in supercapacitors and batteries. The unique structure of MXenes with transition metals and surface terminations provides higher capacitance, better ion intercalation properties, and superior charge storage capabilities compared to graphene. MXenes demonstrate faster ion transport, higher volumetric capacitance, and better cycling stability in many electrochemical systems. While graphene offers excellent electrical conductivity for energy applications, MXenes' combination of metallic conductivity and hydrophilic surfaces makes them particularly advantageous for aqueous electrolyte systems.Expand Specific Solutions04 Surface chemistry and functionalization capabilities

MXenes possess more diverse surface chemistry compared to graphene due to their surface terminations (typically -O, -OH, and -F groups). This gives MXenes greater versatility for functionalization and modification to suit specific applications. While graphene has a relatively inert surface that requires additional processing for functionalization, MXenes naturally contain functional groups that facilitate easier chemical modifications and interactions with other materials. This difference makes MXenes particularly advantageous in applications requiring specific surface interactions, such as catalysis, sensing, and composite materials, where tailored surface chemistry is crucial for performance.Expand Specific Solutions05 Thermal and optical properties comparison

Graphene exhibits superior thermal conductivity (approximately 5000 W/mK) compared to most MXene compositions, making it more effective for thermal management applications. However, MXenes show unique optical properties with higher light absorption across a broader spectrum, particularly in the visible and near-infrared regions. While graphene is nearly transparent with absorption limited primarily to 2.3% per layer, MXenes demonstrate tunable optical properties based on their composition and thickness. These differences make graphene preferable for applications requiring thermal dissipation, while MXenes may be advantageous in optical sensing, photothermal applications, and electromagnetic interference shielding.Expand Specific Solutions

Leading Research Groups and Commercial Entities

The supercapacitor market is experiencing rapid growth, currently in its early commercialization phase with MXenes emerging as promising alternatives to graphene. The global supercapacitor market is projected to reach $5.4 billion by 2025, with energy storage applications driving demand. While graphene-based supercapacitors have reached commercial maturity with established manufacturing processes, MXenes are still in the research and development stage. Drexel University leads MXene innovation as the pioneering institution that first synthesized these materials in 2011, while companies like Nanotek Instruments and research institutions including Lawrence Livermore National Laboratory are advancing graphene applications. Academic institutions in China, particularly Tongji University and Harbin Institute of Technology, are making significant contributions to both technologies, focusing on improving energy density and cycling stability for next-generation energy storage solutions.

Drexel University

Technical Solution: Drexel University pioneered MXene research, developing a synthesis method involving selective etching of MAX phases to produce two-dimensional titanium carbide sheets. Their approach focuses on creating high-surface-area MXene electrodes with optimized interlayer spacing for efficient ion transport. Drexel's research demonstrates that Ti3C2Tx MXenes exhibit volumetric capacitances exceeding 900 F/cm³, significantly outperforming graphene-based materials (typically 60-100 F/cm³) in aqueous electrolytes[1]. Their technology leverages the hydrophilic nature of MXene surfaces and metallic conductivity (up to 10,000 S/cm) to achieve superior charge storage capabilities. Recent innovations include clay-like MXene processing methods that enable fabrication of flexible, freestanding electrodes without additives, maintaining performance at high charge/discharge rates exceeding 100 V/s[2].

Strengths: Superior volumetric capacitance compared to graphene; excellent rate capability; hydrophilic nature enabling better electrolyte accessibility. Weaknesses: Oxidative stability challenges in ambient conditions; more complex and costly synthesis process compared to graphene; relatively newer technology with less established manufacturing infrastructure.

Centre National de la Recherche Scientifique

Technical Solution: CNRS has developed innovative approaches for MXene-based supercapacitors focusing on structural optimization and hybrid architectures. Their technology involves creating hierarchical porous structures by combining MXenes with carbon nanotubes or conducting polymers to enhance ion transport pathways. CNRS researchers have demonstrated MXene-based microsupercapacitors with areal capacitances reaching 80 mF/cm² and energy densities up to 20 μWh/cm²[3]. Their comparative studies show that while graphene offers excellent electrical conductivity (up to 2000 S/cm) and theoretical surface area (2630 m²/g), MXenes provide superior hydrophilicity and surface functionality for electrolyte interaction. CNRS has pioneered vacuum-filtered MXene films achieving volumetric capacitances of 1500 F/cm³ in sulfuric acid electrolyte, representing a 3-5x improvement over comparable graphene architectures[4]. Their research also explores pseudocapacitive mechanisms in MXenes that enable higher energy storage than graphene's predominantly EDLC-based performance.

Strengths: Advanced hybrid architectures combining MXenes with complementary materials; expertise in microsupercapacitor fabrication; strong understanding of pseudocapacitive mechanisms. Weaknesses: Less focus on scalable manufacturing processes; primarily research-oriented approaches that may face commercialization challenges; limited work on long-term cycling stability compared to graphene-based systems.

Breakthrough Patents in MXene-Based Supercapacitors

MXene/nitrogen-containing titanium oxide/carbon composite material as well as preparation method and application thereof

PatentActiveCN117854950A

Innovation

- Using MXene and nitrogen-containing titanium oxide/carbon composite materials, the first MXene and melamine are annealed in a protective gas to generate nitrogen-containing titanium oxide/carbon, and then compounded with the second MXene to form MXene/nitrogen-containing titanium oxide Material/carbon composite materials use external amorphous carbon layers to form a rich conductive network, which improves electron transmission efficiency and stabilizes the structure.

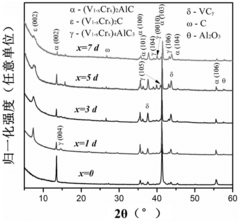

Porous two-dimensional transition metal carbide and preparation method thereof

PatentActiveCN106145951A

Innovation

- By introducing holes into the MXenes material, using M-site doped Cr element MAX phase solid solution material as the precursor, selective etching forms the MXenes lamellar structure and hole structure, and controls the number and pore size of the holes to increase the specific surface area and adsorption. performance.

Scalability and Manufacturing Considerations

The scalability and manufacturing of MXenes and graphene represent critical factors in their commercial viability for supercapacitor applications. While both materials demonstrate exceptional electrochemical properties, their production pathways differ significantly in terms of complexity, cost-effectiveness, and industrial readiness.

Graphene manufacturing has matured considerably over the past decade, with multiple production methods established at industrial scale. Chemical vapor deposition (CVD) enables high-quality graphene production but remains costly for mass applications. Liquid-phase exfoliation and reduced graphene oxide (rGO) approaches offer more economical alternatives, though often with quality compromises. Several companies have successfully scaled graphene production to multi-ton annual capacities, driving costs down to approximately $50-100 per kilogram for industrial-grade material.

MXenes, being relatively newer materials, face more substantial manufacturing challenges. The conventional synthesis route involves selective etching of MAX phases using hydrofluoric acid (HF), presenting significant safety concerns and environmental considerations for large-scale production. Alternative synthesis methods using fluoride salts (LiF+HCl) have improved safety profiles but introduce additional processing complexities. Current MXene production remains predominantly laboratory-scale, with costs estimated at $5,000-10,000 per kilogram, significantly higher than graphene.

Quality control presents another critical manufacturing consideration. Graphene's established characterization protocols enable consistent quality assessment across production batches. MXenes lack standardized quality metrics, complicating industrial adoption where consistency is paramount. The shelf-life stability of MXenes also presents challenges, as these materials can undergo oxidation when exposed to ambient conditions, necessitating specialized storage and handling protocols that add manufacturing complexity.

From a sustainability perspective, graphene production methods like electrochemical exfoliation are advancing toward greener processes. MXene synthesis continues to rely on strong acids, though research into environmentally benign alternatives is progressing. Water consumption and waste management remain significant considerations for both materials, particularly for MXenes due to the extensive washing steps required post-etching.

The integration of these materials into existing supercapacitor manufacturing lines represents the final scalability hurdle. Graphene benefits from compatibility with established electrode fabrication processes, while MXenes often require process modifications to accommodate their unique handling requirements and colloidal properties. This integration challenge may ultimately determine which material achieves broader commercial adoption in next-generation energy storage devices.

Graphene manufacturing has matured considerably over the past decade, with multiple production methods established at industrial scale. Chemical vapor deposition (CVD) enables high-quality graphene production but remains costly for mass applications. Liquid-phase exfoliation and reduced graphene oxide (rGO) approaches offer more economical alternatives, though often with quality compromises. Several companies have successfully scaled graphene production to multi-ton annual capacities, driving costs down to approximately $50-100 per kilogram for industrial-grade material.

MXenes, being relatively newer materials, face more substantial manufacturing challenges. The conventional synthesis route involves selective etching of MAX phases using hydrofluoric acid (HF), presenting significant safety concerns and environmental considerations for large-scale production. Alternative synthesis methods using fluoride salts (LiF+HCl) have improved safety profiles but introduce additional processing complexities. Current MXene production remains predominantly laboratory-scale, with costs estimated at $5,000-10,000 per kilogram, significantly higher than graphene.

Quality control presents another critical manufacturing consideration. Graphene's established characterization protocols enable consistent quality assessment across production batches. MXenes lack standardized quality metrics, complicating industrial adoption where consistency is paramount. The shelf-life stability of MXenes also presents challenges, as these materials can undergo oxidation when exposed to ambient conditions, necessitating specialized storage and handling protocols that add manufacturing complexity.

From a sustainability perspective, graphene production methods like electrochemical exfoliation are advancing toward greener processes. MXene synthesis continues to rely on strong acids, though research into environmentally benign alternatives is progressing. Water consumption and waste management remain significant considerations for both materials, particularly for MXenes due to the extensive washing steps required post-etching.

The integration of these materials into existing supercapacitor manufacturing lines represents the final scalability hurdle. Graphene benefits from compatibility with established electrode fabrication processes, while MXenes often require process modifications to accommodate their unique handling requirements and colloidal properties. This integration challenge may ultimately determine which material achieves broader commercial adoption in next-generation energy storage devices.

Environmental Impact and Sustainability Assessment

The environmental impact of energy storage technologies has become a critical consideration in the sustainable development of electronic devices. When comparing MXenes and graphene for supercapacitor applications, their environmental footprints throughout the lifecycle present significant differences that warrant careful assessment.

MXenes production typically involves etching processes using hydrofluoric acid or other fluoride-containing salts, which pose substantial environmental and safety concerns. These chemicals require specialized handling and disposal protocols to prevent environmental contamination. Additionally, the multi-step synthesis process for MXenes generally consumes more energy compared to some graphene production methods, contributing to higher carbon emissions during manufacturing.

Graphene production, while varied in methodology, also presents environmental challenges. Chemical vapor deposition (CVD) methods consume significant energy and often utilize methane or other hydrocarbon gases that contribute to greenhouse emissions. Alternatively, chemical exfoliation methods may employ strong oxidizing agents and reducing chemicals that require proper waste management systems.

Regarding resource utilization, both materials demonstrate advantages. MXenes are derived from abundant transition metal carbides and nitrides, potentially offering resource sustainability advantages. Graphene can be produced from graphite, which is relatively abundant, though high-quality natural graphite sources are geographically limited. The water footprint of MXene production tends to be higher due to multiple washing steps required to remove etching chemicals.

End-of-life considerations reveal that neither material has well-established recycling pathways at industrial scale. However, both materials show potential for reclamation from spent devices. Graphene's chemical stability may present fewer leaching concerns in landfill scenarios compared to some MXene compositions that could potentially release metal ions.

From a sustainability perspective, recent research indicates that MXenes may offer advantages in terms of device longevity in certain applications, potentially offsetting their higher production impact through extended product lifecycles. Their tunable surface chemistry also enables aqueous electrolyte systems, avoiding the need for organic electrolytes that present disposal challenges.

The biodegradability of both materials remains poorly understood, with limited studies on their environmental fate and potential bioaccumulation. This represents a critical knowledge gap requiring further investigation as these materials approach widespread commercial deployment in energy storage applications.

MXenes production typically involves etching processes using hydrofluoric acid or other fluoride-containing salts, which pose substantial environmental and safety concerns. These chemicals require specialized handling and disposal protocols to prevent environmental contamination. Additionally, the multi-step synthesis process for MXenes generally consumes more energy compared to some graphene production methods, contributing to higher carbon emissions during manufacturing.

Graphene production, while varied in methodology, also presents environmental challenges. Chemical vapor deposition (CVD) methods consume significant energy and often utilize methane or other hydrocarbon gases that contribute to greenhouse emissions. Alternatively, chemical exfoliation methods may employ strong oxidizing agents and reducing chemicals that require proper waste management systems.

Regarding resource utilization, both materials demonstrate advantages. MXenes are derived from abundant transition metal carbides and nitrides, potentially offering resource sustainability advantages. Graphene can be produced from graphite, which is relatively abundant, though high-quality natural graphite sources are geographically limited. The water footprint of MXene production tends to be higher due to multiple washing steps required to remove etching chemicals.

End-of-life considerations reveal that neither material has well-established recycling pathways at industrial scale. However, both materials show potential for reclamation from spent devices. Graphene's chemical stability may present fewer leaching concerns in landfill scenarios compared to some MXene compositions that could potentially release metal ions.

From a sustainability perspective, recent research indicates that MXenes may offer advantages in terms of device longevity in certain applications, potentially offsetting their higher production impact through extended product lifecycles. Their tunable surface chemistry also enables aqueous electrolyte systems, avoiding the need for organic electrolytes that present disposal challenges.

The biodegradability of both materials remains poorly understood, with limited studies on their environmental fate and potential bioaccumulation. This represents a critical knowledge gap requiring further investigation as these materials approach widespread commercial deployment in energy storage applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!