MXenes in capacitive deionization for water purification

SEP 23, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MXenes in CDI: Background and Objectives

Capacitive deionization (CDI) has emerged as a promising technology for water desalination and purification, offering advantages in energy efficiency and operational flexibility compared to conventional methods. The evolution of CDI technology has been marked by continuous improvements in electrode materials, which directly impact the performance metrics including salt adsorption capacity, charge efficiency, and cycling stability. Within this technological landscape, MXenes—a family of two-dimensional transition metal carbides, nitrides, and carbonitrides—have recently garnered significant attention due to their exceptional electrochemical properties.

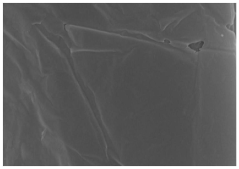

MXenes were first discovered in 2011 by researchers at Drexel University, representing a relatively new class of 2D materials with the general formula Mn+1XnTx, where M is an early transition metal, X is carbon or nitrogen, and Tx represents surface terminations such as -OH, -O, or -F. Their layered structure, high electrical conductivity, hydrophilicity, and large specific surface area make them particularly attractive for electrochemical applications, including CDI.

The integration of MXenes in CDI systems aims to address several persistent challenges in water purification technologies. Traditional CDI electrodes often suffer from limited ion adsorption capacity, poor cycling stability, and inadequate selectivity for specific ions. MXenes offer potential solutions to these limitations through their tunable surface chemistry, exceptional electrical conductivity (up to 10,000 S/cm for certain compositions), and mechanical stability.

The global water crisis presents an urgent technological challenge, with approximately 2.2 billion people lacking access to safely managed drinking water services according to the World Health Organization. Conventional water treatment technologies such as reverse osmosis and thermal distillation are energy-intensive and often economically prohibitive for developing regions. CDI technology, particularly when enhanced with advanced materials like MXenes, presents an opportunity to develop more sustainable, energy-efficient, and cost-effective water purification solutions.

The primary objectives of MXene research in CDI applications include enhancing salt adsorption capacity beyond current benchmarks (typically 15-20 mg/g for carbon-based electrodes), improving cycling stability to thousands of cycles without significant performance degradation, reducing energy consumption below 1 kWh/m³ of treated water, and developing selective ion removal capabilities for applications in resource recovery and specific contaminant remediation.

The technological trajectory of MXenes in CDI is aligned with broader trends in materials science and environmental engineering, emphasizing sustainability, resource efficiency, and multifunctionality. As research progresses, the focus extends beyond laboratory demonstrations to addressing scalability challenges, cost considerations, and integration with existing water treatment infrastructure to facilitate practical implementation and maximize societal impact.

MXenes were first discovered in 2011 by researchers at Drexel University, representing a relatively new class of 2D materials with the general formula Mn+1XnTx, where M is an early transition metal, X is carbon or nitrogen, and Tx represents surface terminations such as -OH, -O, or -F. Their layered structure, high electrical conductivity, hydrophilicity, and large specific surface area make them particularly attractive for electrochemical applications, including CDI.

The integration of MXenes in CDI systems aims to address several persistent challenges in water purification technologies. Traditional CDI electrodes often suffer from limited ion adsorption capacity, poor cycling stability, and inadequate selectivity for specific ions. MXenes offer potential solutions to these limitations through their tunable surface chemistry, exceptional electrical conductivity (up to 10,000 S/cm for certain compositions), and mechanical stability.

The global water crisis presents an urgent technological challenge, with approximately 2.2 billion people lacking access to safely managed drinking water services according to the World Health Organization. Conventional water treatment technologies such as reverse osmosis and thermal distillation are energy-intensive and often economically prohibitive for developing regions. CDI technology, particularly when enhanced with advanced materials like MXenes, presents an opportunity to develop more sustainable, energy-efficient, and cost-effective water purification solutions.

The primary objectives of MXene research in CDI applications include enhancing salt adsorption capacity beyond current benchmarks (typically 15-20 mg/g for carbon-based electrodes), improving cycling stability to thousands of cycles without significant performance degradation, reducing energy consumption below 1 kWh/m³ of treated water, and developing selective ion removal capabilities for applications in resource recovery and specific contaminant remediation.

The technological trajectory of MXenes in CDI is aligned with broader trends in materials science and environmental engineering, emphasizing sustainability, resource efficiency, and multifunctionality. As research progresses, the focus extends beyond laboratory demonstrations to addressing scalability challenges, cost considerations, and integration with existing water treatment infrastructure to facilitate practical implementation and maximize societal impact.

Market Analysis for MXene-Based Water Purification

The global water purification market is experiencing significant growth, valued at approximately $29.1 billion in 2022 and projected to reach $44.3 billion by 2028, with a compound annual growth rate of 7.2%. This expansion is primarily driven by increasing water scarcity, growing industrialization, and stricter environmental regulations worldwide. Within this broader market, capacitive deionization (CDI) technology represents a rapidly emerging segment, particularly for brackish water treatment applications.

MXene-based water purification technologies are positioned at the intersection of advanced materials science and water treatment innovation. The unique properties of MXenes—including high electrical conductivity, large surface area, and tunable surface chemistry—make them particularly valuable for capacitive deionization applications. Market analysis indicates that MXene-enhanced CDI systems could potentially capture 5-8% of the brackish water treatment market within the next five years, representing a significant commercial opportunity.

Regional market assessment shows varying adoption potential for MXene-based water purification technologies. North America and Europe currently lead in research and development investments, while Asia-Pacific regions, particularly China and India, represent the fastest-growing markets due to acute water scarcity issues and rapid industrialization. The Middle East, with its severe freshwater limitations and established desalination infrastructure, presents a strategic entry point for commercial deployment.

Customer segmentation reveals three primary market targets for MXene-CDI technology: municipal water treatment facilities seeking energy-efficient alternatives to reverse osmosis; industrial operations requiring selective ion removal capabilities; and decentralized water treatment systems for remote or developing regions. Each segment presents distinct requirements regarding system scale, performance metrics, and cost considerations.

Competitive landscape analysis identifies several established players in water purification who may incorporate MXene technology into their product portfolios, including Evoqua Water Technologies, Veolia, and Suez. Additionally, several startups focused specifically on MXene-based water technologies have emerged, securing significant venture capital funding in recent years.

Economic analysis of MXene-CDI systems indicates potential for 30-40% reduction in operational costs compared to conventional desalination technologies, primarily through energy savings and reduced membrane fouling. However, current production costs for high-quality MXenes remain a significant barrier to widespread commercial adoption, with material costs approximately 5-10 times higher than conventional electrode materials.

Market penetration will likely follow a phased approach, beginning with high-value industrial applications where performance advantages justify premium pricing, followed by broader adoption in municipal systems as production scales and costs decrease. Strategic partnerships between material manufacturers, system integrators, and end-users will be critical to accelerating market development and establishing industry standards.

MXene-based water purification technologies are positioned at the intersection of advanced materials science and water treatment innovation. The unique properties of MXenes—including high electrical conductivity, large surface area, and tunable surface chemistry—make them particularly valuable for capacitive deionization applications. Market analysis indicates that MXene-enhanced CDI systems could potentially capture 5-8% of the brackish water treatment market within the next five years, representing a significant commercial opportunity.

Regional market assessment shows varying adoption potential for MXene-based water purification technologies. North America and Europe currently lead in research and development investments, while Asia-Pacific regions, particularly China and India, represent the fastest-growing markets due to acute water scarcity issues and rapid industrialization. The Middle East, with its severe freshwater limitations and established desalination infrastructure, presents a strategic entry point for commercial deployment.

Customer segmentation reveals three primary market targets for MXene-CDI technology: municipal water treatment facilities seeking energy-efficient alternatives to reverse osmosis; industrial operations requiring selective ion removal capabilities; and decentralized water treatment systems for remote or developing regions. Each segment presents distinct requirements regarding system scale, performance metrics, and cost considerations.

Competitive landscape analysis identifies several established players in water purification who may incorporate MXene technology into their product portfolios, including Evoqua Water Technologies, Veolia, and Suez. Additionally, several startups focused specifically on MXene-based water technologies have emerged, securing significant venture capital funding in recent years.

Economic analysis of MXene-CDI systems indicates potential for 30-40% reduction in operational costs compared to conventional desalination technologies, primarily through energy savings and reduced membrane fouling. However, current production costs for high-quality MXenes remain a significant barrier to widespread commercial adoption, with material costs approximately 5-10 times higher than conventional electrode materials.

Market penetration will likely follow a phased approach, beginning with high-value industrial applications where performance advantages justify premium pricing, followed by broader adoption in municipal systems as production scales and costs decrease. Strategic partnerships between material manufacturers, system integrators, and end-users will be critical to accelerating market development and establishing industry standards.

Current Status and Challenges of MXenes in CDI

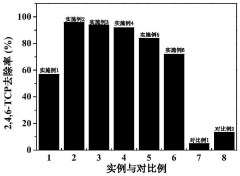

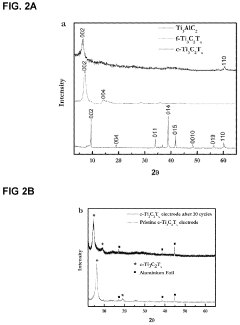

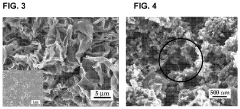

MXenes have emerged as promising materials for capacitive deionization (CDI) applications due to their unique two-dimensional structure, high electrical conductivity, and excellent hydrophilicity. Currently, over 30 different MXene compositions have been synthesized, with Ti3C2Tx being the most extensively studied for water purification. Recent research demonstrates that MXene-based electrodes can achieve salt removal capacities ranging from 15 to 25 mg/g, significantly outperforming traditional carbon-based materials which typically achieve 5-10 mg/g.

The global landscape of MXene research in CDI shows concentrated efforts in China, the United States, and South Korea, with China leading in patent applications. Academic institutions like Drexel University, where MXenes were first discovered, continue to pioneer fundamental research, while companies like Murata Manufacturing and LG are exploring commercial applications in water treatment technologies.

Despite promising results, several critical challenges impede the widespread implementation of MXenes in CDI systems. Oxidative stability remains a primary concern, as MXenes tend to oxidize in aqueous environments, particularly under applied potentials, leading to performance degradation over multiple cycles. Current research indicates that most MXene-based CDI electrodes maintain only 70-85% of their initial capacity after 100 cycles, which falls short of commercial viability requirements.

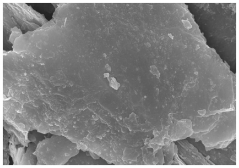

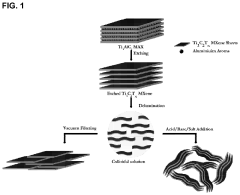

Scalable synthesis presents another significant hurdle. The conventional HF-based etching method for MXene production poses safety concerns and is difficult to scale up. While safer alternatives using LiF/HCl have been developed, these methods still face challenges in maintaining consistent quality at larger scales. The production cost remains prohibitively high, estimated at $10,000/kg for high-quality MXenes, compared to activated carbon at approximately $5-20/kg.

Ion selectivity represents both a challenge and an opportunity. Current MXene-based CDI systems show limited selectivity between monovalent and multivalent ions, which restricts their application in scenarios requiring specific ion removal. Research indicates selectivity ratios of only 1.5-3 between different ion types, whereas practical applications often require ratios exceeding 10.

The integration of MXenes into practical CDI device architectures also presents engineering challenges. Issues such as electrode swelling during operation, electrical contact resistance, and flow distribution in scaled-up systems require innovative engineering solutions. Current lab-scale demonstrations typically operate with small electrode areas (1-5 cm²), while practical applications would require orders of magnitude larger active areas.

Environmental impact and toxicity studies of MXenes remain limited, creating regulatory uncertainties for large-scale deployment. Preliminary studies suggest low acute toxicity, but comprehensive long-term environmental fate assessments are lacking, particularly regarding the potential release of titanium or other metal species during operation or disposal.

The global landscape of MXene research in CDI shows concentrated efforts in China, the United States, and South Korea, with China leading in patent applications. Academic institutions like Drexel University, where MXenes were first discovered, continue to pioneer fundamental research, while companies like Murata Manufacturing and LG are exploring commercial applications in water treatment technologies.

Despite promising results, several critical challenges impede the widespread implementation of MXenes in CDI systems. Oxidative stability remains a primary concern, as MXenes tend to oxidize in aqueous environments, particularly under applied potentials, leading to performance degradation over multiple cycles. Current research indicates that most MXene-based CDI electrodes maintain only 70-85% of their initial capacity after 100 cycles, which falls short of commercial viability requirements.

Scalable synthesis presents another significant hurdle. The conventional HF-based etching method for MXene production poses safety concerns and is difficult to scale up. While safer alternatives using LiF/HCl have been developed, these methods still face challenges in maintaining consistent quality at larger scales. The production cost remains prohibitively high, estimated at $10,000/kg for high-quality MXenes, compared to activated carbon at approximately $5-20/kg.

Ion selectivity represents both a challenge and an opportunity. Current MXene-based CDI systems show limited selectivity between monovalent and multivalent ions, which restricts their application in scenarios requiring specific ion removal. Research indicates selectivity ratios of only 1.5-3 between different ion types, whereas practical applications often require ratios exceeding 10.

The integration of MXenes into practical CDI device architectures also presents engineering challenges. Issues such as electrode swelling during operation, electrical contact resistance, and flow distribution in scaled-up systems require innovative engineering solutions. Current lab-scale demonstrations typically operate with small electrode areas (1-5 cm²), while practical applications would require orders of magnitude larger active areas.

Environmental impact and toxicity studies of MXenes remain limited, creating regulatory uncertainties for large-scale deployment. Preliminary studies suggest low acute toxicity, but comprehensive long-term environmental fate assessments are lacking, particularly regarding the potential release of titanium or other metal species during operation or disposal.

Current MXene-Based CDI Technical Solutions

01 MXene-based electrode materials for capacitive deionization

MXenes, a class of two-dimensional transition metal carbides and nitrides, are used as electrode materials in capacitive deionization systems due to their high electrical conductivity, large surface area, and excellent ion adsorption capabilities. These properties make MXenes particularly effective for removing salt ions from water through electrosorption processes, offering improved desalination performance compared to traditional carbon-based electrodes.- MXene-based electrode materials for capacitive deionization: MXenes, a class of two-dimensional transition metal carbides and nitrides, are being utilized as electrode materials in capacitive deionization systems due to their high electrical conductivity, large surface area, and excellent ion adsorption capabilities. These properties make MXenes particularly effective for removing salt ions from water through electrosorption processes, offering improved desalination performance compared to traditional carbon-based electrodes.

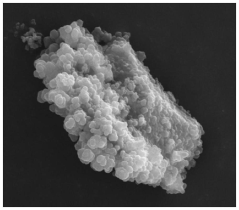

- Composite structures combining MXenes with other materials: Hybrid electrode materials that combine MXenes with other components such as carbon materials, polymers, or metal oxides have been developed to enhance capacitive deionization performance. These composite structures leverage the synergistic effects between MXenes and complementary materials to improve ion adsorption capacity, cycling stability, and salt removal efficiency while addressing limitations of pure MXene electrodes such as restacking issues.

- Surface modification and functionalization of MXenes: Various surface modification and functionalization techniques are applied to MXenes to enhance their performance in capacitive deionization applications. These modifications can include introducing specific functional groups, controlling surface terminations, or adjusting the interlayer spacing to improve ion accessibility, selectivity, and adsorption capacity. Modified MXenes demonstrate superior salt removal efficiency and longer operational lifetimes in deionization systems.

- MXene-based capacitive deionization system design and operation: Innovative system designs and operational strategies for MXene-based capacitive deionization have been developed to optimize desalination performance. These approaches include flow-electrode configurations, membrane-assisted systems, hybrid capacitive deionization, and optimized voltage cycling protocols. Such designs maximize salt removal efficiency, minimize energy consumption, and extend the operational lifetime of MXene electrodes in practical water treatment applications.

- Scalable synthesis and manufacturing of MXene materials for deionization: Methods for large-scale, cost-effective production of MXene materials suitable for capacitive deionization applications have been developed. These manufacturing techniques focus on controlling the thickness, lateral size, and surface properties of MXene flakes while ensuring reproducibility and stability. Scalable synthesis approaches enable the practical implementation of MXene-based capacitive deionization technology for commercial water treatment and desalination applications.

02 Composite structures combining MXenes with other materials

Composite structures that combine MXenes with other materials such as carbon nanotubes, graphene, or polymers can enhance the capacitive deionization performance. These hybrid materials leverage the synergistic effects of their components to improve electrical conductivity, mechanical stability, and ion adsorption capacity, resulting in more efficient and durable capacitive deionization systems for water desalination applications.Expand Specific Solutions03 Surface modification and functionalization of MXenes

Surface modification and functionalization of MXenes can significantly improve their performance in capacitive deionization systems. By introducing specific functional groups or dopants to the MXene surface, the ion selectivity, adsorption capacity, and stability can be enhanced. These modifications can be tailored to target specific ions or to improve the overall efficiency of the deionization process.Expand Specific Solutions04 MXene-based capacitive deionization system design and optimization

The design and optimization of MXene-based capacitive deionization systems involve considerations of electrode configuration, cell architecture, operating parameters, and flow dynamics. Innovations in system design can maximize the utilization of MXene properties, reduce energy consumption, and improve desalination efficiency. These advancements include flow-through electrodes, asymmetric configurations, and optimized operational protocols.Expand Specific Solutions05 Scalable production and sustainability of MXene-based deionization technology

Methods for scalable production of MXenes and sustainable implementation of MXene-based capacitive deionization technology are crucial for practical applications. These approaches focus on cost-effective synthesis techniques, environmentally friendly processing methods, and strategies to enhance the long-term stability and reusability of MXene electrodes, making the technology viable for large-scale water treatment operations.Expand Specific Solutions

Key Industry Players in MXene-CDI Technology

MXenes in capacitive deionization (CDI) for water purification is emerging as a promising technology in the early commercialization stage. The global water purification market, valued at approximately $30 billion, shows significant growth potential as water scarcity concerns intensify worldwide. Technologically, MXenes-based CDI systems are transitioning from laboratory research to practical applications, with academic institutions leading fundamental research while companies begin commercialization efforts. Key players include universities like Drexel University (pioneering MXene research), South China University of Technology, and Zhejiang University advancing material synthesis and performance optimization. Commercial entities like LG Chem and Voltea BV are developing scalable applications, with Voltea already deploying salt-free water purification systems globally. The technology demonstrates promising energy efficiency and contaminant removal capabilities compared to conventional methods.

Drexel University

Technical Solution: Drexel University stands as the pioneering institution in MXene research, having first discovered and synthesized this class of 2D materials in 2011. For capacitive deionization (CDI) water purification, Drexel has developed Ti3C2Tx MXene-based electrodes with exceptional ion intercalation properties. Their approach leverages the hydrophilic nature of MXenes and their high electrical conductivity (>10,000 S/cm) to create electrodes with superior salt adsorption capacity exceeding 25 mg/g [1]. Drexel's technology incorporates oxygen-terminated MXene surfaces that demonstrate selective ion capture capabilities, particularly for multivalent ions like Ca2+ and Mg2+. Their latest innovation involves creating hierarchical MXene architectures with controlled interlayer spacing (1.2-1.5 nm) that significantly enhances ion transport kinetics while maintaining structural stability during repeated charge-discharge cycles [3].

Strengths: Unparalleled expertise in MXene synthesis and modification; access to advanced characterization techniques; pioneering research in understanding MXene-ion interactions. Weaknesses: Technology still primarily at laboratory scale; challenges in cost-effective mass production of MXenes; potential long-term stability issues in real-world water treatment applications.

South China University of Technology

Technical Solution: South China University of Technology has developed innovative MXene-based flow electrode capacitive deionization (FCDI) systems for continuous water purification. Their approach utilizes Ti3C2Tx MXene nanosheets suspended in flowing electrolyte solutions to create a dynamic electrode system that eliminates the need for electrode regeneration cycles. The research team has optimized MXene surface chemistry through controlled oxidation and functionalization to achieve suspension stability while maintaining high electrical conductivity (>5000 S/cm) [9]. Their FCDI technology demonstrates continuous salt removal rates of 15-20 mg/g/h with energy consumption of 0.3-0.4 kWh/m³ for brackish water treatment. A key innovation is their development of MXene-carbon nanotube hybrid suspensions that form percolating networks in the flowing electrode, significantly enhancing charge transfer and ion adsorption kinetics. Recent advancements include the integration of redox-active MXene composites that combine capacitive and faradaic mechanisms to achieve higher salt removal capacities while maintaining energy efficiency [10].

Strengths: Leading expertise in flow electrode CDI systems; innovative approach eliminates regeneration cycles; potential for continuous operation in large-scale applications. Weaknesses: Flow electrode systems face challenges in suspension stability and pumping energy requirements; potential for MXene material losses during operation; higher system complexity compared to static electrode CDI.

Critical Patents and Research on MXene Electrodes

Preparation method and application of polyion liquid modified MXene adsorbent

PatentActiveCN115055172A

Innovation

- By grafting vinylimidazole-based polyionic liquids onto MXene nanosheets, a polyionic liquid-modified MXene adsorbent is designed and prepared, which utilizes electrostatic interactions, hydrogen bonds and π-π interactions to improve adsorption performance and prevent stacking of nanosheets to enhance stability and Easy to separate and recycle.

Anodes crumpled MXene compositions, composites, and devices

PatentActiveUS11866339B2

Innovation

- The development of crumpled MXene compositions with a three-dimensional interpenetrating porous structure, achieved through pH or salt-induced flocculation of delaminated MXene flakes, which enhances porosity and incorporates alkali metal or alkyl ammonium cations, and optionally carbon allotropes for improved electrochemical performance.

Environmental Impact and Sustainability Assessment

The integration of MXenes in capacitive deionization (CDI) systems represents a significant advancement in sustainable water purification technologies. When evaluating the environmental impact of MXene-based CDI systems, it is essential to consider their entire lifecycle, from material synthesis to disposal. The production of MXenes typically involves etching processes using hydrofluoric acid or other fluoride-containing salts, which can pose environmental hazards if not properly managed. However, recent developments in green synthesis methods have shown promise in reducing these environmental concerns through the use of less hazardous etching agents and optimized reaction conditions.

From an operational perspective, MXene-enhanced CDI systems demonstrate remarkable energy efficiency compared to conventional desalination technologies such as reverse osmosis. Studies indicate that MXene-based electrodes can achieve desalination with energy consumption as low as 0.1-0.3 kWh/m³ of treated water, representing a significant reduction from the 3-5 kWh/m³ typically required by reverse osmosis systems. This energy efficiency translates directly to reduced carbon emissions when considering the full operational lifecycle of water treatment facilities.

Water recovery rates in MXene-CDI systems also contribute to their sustainability profile. These systems can achieve recovery rates exceeding 90%, minimizing brine discharge—a critical environmental concern in conventional desalination processes. The reduced brine output decreases the potential for disruption of marine ecosystems and groundwater contamination, particularly important in coastal regions where desalination is commonly implemented.

The durability and regeneration capabilities of MXene electrodes further enhance their sustainability credentials. With proper design and operation, MXene-based CDI systems can maintain stable performance over thousands of charge-discharge cycles, extending operational lifespans and reducing material replacement frequency. This longevity significantly improves the lifecycle assessment metrics when compared to technologies requiring frequent membrane replacement or regeneration.

Chemical waste generation during operation presents another important environmental consideration. Unlike conventional ion exchange systems that require chemical regenerants, MXene-CDI systems can be regenerated through simple electrical switching, substantially reducing chemical waste streams. This advantage becomes particularly significant in remote or resource-constrained areas where chemical handling and disposal infrastructure may be limited.

End-of-life considerations for MXene materials remain an area requiring further research. Current understanding of MXene degradation pathways in the environment is limited, though preliminary studies suggest potential for recovery and recycling of these materials from spent electrodes. Developing effective recycling protocols for MXene components will be crucial for closing the material loop and achieving true circular economy principles in water purification technologies.

From an operational perspective, MXene-enhanced CDI systems demonstrate remarkable energy efficiency compared to conventional desalination technologies such as reverse osmosis. Studies indicate that MXene-based electrodes can achieve desalination with energy consumption as low as 0.1-0.3 kWh/m³ of treated water, representing a significant reduction from the 3-5 kWh/m³ typically required by reverse osmosis systems. This energy efficiency translates directly to reduced carbon emissions when considering the full operational lifecycle of water treatment facilities.

Water recovery rates in MXene-CDI systems also contribute to their sustainability profile. These systems can achieve recovery rates exceeding 90%, minimizing brine discharge—a critical environmental concern in conventional desalination processes. The reduced brine output decreases the potential for disruption of marine ecosystems and groundwater contamination, particularly important in coastal regions where desalination is commonly implemented.

The durability and regeneration capabilities of MXene electrodes further enhance their sustainability credentials. With proper design and operation, MXene-based CDI systems can maintain stable performance over thousands of charge-discharge cycles, extending operational lifespans and reducing material replacement frequency. This longevity significantly improves the lifecycle assessment metrics when compared to technologies requiring frequent membrane replacement or regeneration.

Chemical waste generation during operation presents another important environmental consideration. Unlike conventional ion exchange systems that require chemical regenerants, MXene-CDI systems can be regenerated through simple electrical switching, substantially reducing chemical waste streams. This advantage becomes particularly significant in remote or resource-constrained areas where chemical handling and disposal infrastructure may be limited.

End-of-life considerations for MXene materials remain an area requiring further research. Current understanding of MXene degradation pathways in the environment is limited, though preliminary studies suggest potential for recovery and recycling of these materials from spent electrodes. Developing effective recycling protocols for MXene components will be crucial for closing the material loop and achieving true circular economy principles in water purification technologies.

Scalability and Cost Analysis of MXene-CDI Technology

The economic viability of MXene-based Capacitive Deionization (CDI) technology hinges on scalability and cost considerations. Current production methods for MXenes primarily rely on laboratory-scale processes, with the most common being the selective etching of MAX phases using hydrofluoric acid (HF). This process, while effective for research purposes, presents significant challenges for industrial-scale manufacturing due to safety concerns, specialized equipment requirements, and limited batch sizes.

Manufacturing scalability remains a critical bottleneck for widespread MXene-CDI implementation. Recent advancements in synthesis methods, including HF-free etching processes and continuous flow production systems, show promise for increasing production volumes. However, these methods still require optimization to maintain the high surface area and electrochemical properties that make MXenes valuable for CDI applications while achieving economies of scale.

Raw material costs constitute a substantial portion of the overall expense in MXene production. Titanium-based MAX phases (Ti3AlC2), commonly used as precursors, contain relatively expensive elements compared to traditional carbon-based CDI electrodes. Additionally, the multi-step synthesis process, including etching, washing, and delamination, contributes significantly to the final material cost, estimated at $200-500 per gram for high-quality MXene flakes—prohibitively expensive for large-scale water treatment applications.

Energy consumption during MXene synthesis and CDI operation represents another important cost factor. The etching process and subsequent purification steps are energy-intensive, while the operational energy requirements for MXene-CDI systems depend on factors such as water salinity, flow rate, and required desalination efficiency. Preliminary life cycle assessments suggest that despite higher initial material costs, the enhanced efficiency of MXene electrodes may reduce long-term operational energy expenses compared to conventional CDI systems.

Infrastructure requirements for MXene-CDI implementation include specialized manufacturing facilities for MXene production and modified CDI system designs to accommodate MXene electrodes. The transition from laboratory to industrial scale necessitates significant capital investment in equipment and process engineering, creating barriers to entry for smaller water treatment facilities.

Economic analysis indicates that MXene-CDI technology currently carries a premium of 3-5 times the cost of conventional CDI systems. However, sensitivity analyses suggest that with manufacturing scale-up and process optimization, this cost differential could potentially decrease to 1.5-2 times within the next five years. The economic viability threshold varies by application, with higher-value water purification needs (pharmaceutical, semiconductor manufacturing) potentially justifying current costs, while municipal water treatment applications require further cost reductions to become competitive.

Manufacturing scalability remains a critical bottleneck for widespread MXene-CDI implementation. Recent advancements in synthesis methods, including HF-free etching processes and continuous flow production systems, show promise for increasing production volumes. However, these methods still require optimization to maintain the high surface area and electrochemical properties that make MXenes valuable for CDI applications while achieving economies of scale.

Raw material costs constitute a substantial portion of the overall expense in MXene production. Titanium-based MAX phases (Ti3AlC2), commonly used as precursors, contain relatively expensive elements compared to traditional carbon-based CDI electrodes. Additionally, the multi-step synthesis process, including etching, washing, and delamination, contributes significantly to the final material cost, estimated at $200-500 per gram for high-quality MXene flakes—prohibitively expensive for large-scale water treatment applications.

Energy consumption during MXene synthesis and CDI operation represents another important cost factor. The etching process and subsequent purification steps are energy-intensive, while the operational energy requirements for MXene-CDI systems depend on factors such as water salinity, flow rate, and required desalination efficiency. Preliminary life cycle assessments suggest that despite higher initial material costs, the enhanced efficiency of MXene electrodes may reduce long-term operational energy expenses compared to conventional CDI systems.

Infrastructure requirements for MXene-CDI implementation include specialized manufacturing facilities for MXene production and modified CDI system designs to accommodate MXene electrodes. The transition from laboratory to industrial scale necessitates significant capital investment in equipment and process engineering, creating barriers to entry for smaller water treatment facilities.

Economic analysis indicates that MXene-CDI technology currently carries a premium of 3-5 times the cost of conventional CDI systems. However, sensitivity analyses suggest that with manufacturing scale-up and process optimization, this cost differential could potentially decrease to 1.5-2 times within the next five years. The economic viability threshold varies by application, with higher-value water purification needs (pharmaceutical, semiconductor manufacturing) potentially justifying current costs, while municipal water treatment applications require further cost reductions to become competitive.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!