MXenes for next generation flexible and wearable sensors

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MXenes Technology Background and Objectives

MXenes represent a revolutionary class of two-dimensional (2D) transition metal carbides, nitrides, and carbonitrides that have emerged as promising materials for flexible and wearable sensing technologies. First discovered in 2011 by researchers at Drexel University, MXenes are derived from MAX phases through selective etching of the A-layer atoms. Their unique structure consists of few-atom-thick layers of transition metals with surface terminations such as -O, -OH, and -F groups, giving them exceptional electrical conductivity, hydrophilicity, and mechanical flexibility.

The evolution of MXenes technology has accelerated dramatically over the past decade, with significant breakthroughs in synthesis methods, property characterization, and application development. Initially limited to Ti3C2Tx compositions, the MXene family has expanded to include over 30 different compositions with tunable properties, enabling their integration into various sensing platforms. This rapid development has positioned MXenes as a cornerstone material for next-generation flexible electronics.

The primary technical objective in MXene-based flexible and wearable sensors is to leverage their inherent properties to create highly sensitive, mechanically robust, and biocompatible sensing devices. These sensors aim to monitor physiological parameters, environmental conditions, and biomechanical movements with unprecedented accuracy while maintaining comfort and durability during prolonged wear. Specific goals include achieving high sensitivity to stimuli such as strain, pressure, temperature, and various chemical analytes while maintaining stable performance under mechanical deformation.

Current technical trends in MXene research focus on enhancing their stability in ambient conditions, as oxidation remains a significant challenge limiting their long-term application. Researchers are exploring various encapsulation strategies, surface modifications, and composite formations to overcome this limitation. Additionally, scalable production methods are being developed to transition from laboratory-scale synthesis to industrial manufacturing, addressing the gap between academic research and commercial implementation.

Another emerging trend involves the integration of MXenes with other functional materials to create hybrid systems with synergistic properties. These include combinations with polymers for enhanced flexibility, graphene for improved electrical properties, and biomaterials for better biocompatibility. Such hybrid approaches are expected to overcome the inherent limitations of single-material systems and expand the application scope of MXene-based sensors.

The ultimate technical vision for MXene-based flexible sensors encompasses self-powered, wireless, and multifunctional devices capable of real-time health monitoring, environmental sensing, and human-machine interfacing. This vision aligns with the growing demand for personalized healthcare, smart textiles, and Internet of Things (IoT) technologies, positioning MXenes as a transformative material platform for the next generation of wearable electronics.

The evolution of MXenes technology has accelerated dramatically over the past decade, with significant breakthroughs in synthesis methods, property characterization, and application development. Initially limited to Ti3C2Tx compositions, the MXene family has expanded to include over 30 different compositions with tunable properties, enabling their integration into various sensing platforms. This rapid development has positioned MXenes as a cornerstone material for next-generation flexible electronics.

The primary technical objective in MXene-based flexible and wearable sensors is to leverage their inherent properties to create highly sensitive, mechanically robust, and biocompatible sensing devices. These sensors aim to monitor physiological parameters, environmental conditions, and biomechanical movements with unprecedented accuracy while maintaining comfort and durability during prolonged wear. Specific goals include achieving high sensitivity to stimuli such as strain, pressure, temperature, and various chemical analytes while maintaining stable performance under mechanical deformation.

Current technical trends in MXene research focus on enhancing their stability in ambient conditions, as oxidation remains a significant challenge limiting their long-term application. Researchers are exploring various encapsulation strategies, surface modifications, and composite formations to overcome this limitation. Additionally, scalable production methods are being developed to transition from laboratory-scale synthesis to industrial manufacturing, addressing the gap between academic research and commercial implementation.

Another emerging trend involves the integration of MXenes with other functional materials to create hybrid systems with synergistic properties. These include combinations with polymers for enhanced flexibility, graphene for improved electrical properties, and biomaterials for better biocompatibility. Such hybrid approaches are expected to overcome the inherent limitations of single-material systems and expand the application scope of MXene-based sensors.

The ultimate technical vision for MXene-based flexible sensors encompasses self-powered, wireless, and multifunctional devices capable of real-time health monitoring, environmental sensing, and human-machine interfacing. This vision aligns with the growing demand for personalized healthcare, smart textiles, and Internet of Things (IoT) technologies, positioning MXenes as a transformative material platform for the next generation of wearable electronics.

Market Analysis for Flexible and Wearable Sensors

The global market for flexible and wearable sensors is experiencing robust growth, driven by increasing consumer demand for health monitoring devices, fitness trackers, and smart clothing. The market was valued at approximately $2.9 billion in 2022 and is projected to reach $9.7 billion by 2028, representing a compound annual growth rate (CAGR) of 22.3% during the forecast period.

MXenes-based sensors are positioned to capture a significant portion of this expanding market due to their superior electrical conductivity, mechanical flexibility, and biocompatibility compared to traditional sensor materials. The healthcare segment currently dominates the application landscape, accounting for nearly 38% of the market share, followed by consumer electronics at 27% and sports/fitness at 21%.

Regional analysis indicates North America leads the market with approximately 35% share, attributed to early technology adoption and substantial R&D investments. Asia-Pacific is the fastest-growing region with a CAGR of 25.7%, driven by expanding manufacturing capabilities in China, South Korea, and Japan, coupled with increasing consumer electronics production.

Key market drivers include the aging global population requiring continuous health monitoring, growing consumer awareness about preventive healthcare, and technological advancements enabling miniaturization and improved sensor performance. The COVID-19 pandemic has accelerated market growth by highlighting the importance of remote health monitoring solutions.

Consumer preferences are shifting toward non-invasive, comfortable, and aesthetically pleasing wearable devices with longer battery life and real-time data analysis capabilities. This trend favors MXenes-based sensors due to their thin-film form factor and energy efficiency characteristics.

Market challenges include concerns about data privacy, regulatory hurdles for medical-grade sensors, and competition from alternative materials such as graphene and conductive polymers. However, MXenes offer competitive advantages through their tunable properties and scalable manufacturing potential.

Price sensitivity varies across application segments, with healthcare applications demonstrating lower price elasticity compared to consumer electronics. The average selling price of flexible sensors has decreased by approximately 15% annually, improving market penetration but pressuring profit margins for manufacturers.

Distribution channels are evolving, with direct-to-consumer sales through e-commerce platforms growing at 30% annually, while traditional medical device distribution networks remain important for healthcare applications. Strategic partnerships between MXene material suppliers, sensor manufacturers, and end-product companies are becoming increasingly common to establish competitive market positions.

MXenes-based sensors are positioned to capture a significant portion of this expanding market due to their superior electrical conductivity, mechanical flexibility, and biocompatibility compared to traditional sensor materials. The healthcare segment currently dominates the application landscape, accounting for nearly 38% of the market share, followed by consumer electronics at 27% and sports/fitness at 21%.

Regional analysis indicates North America leads the market with approximately 35% share, attributed to early technology adoption and substantial R&D investments. Asia-Pacific is the fastest-growing region with a CAGR of 25.7%, driven by expanding manufacturing capabilities in China, South Korea, and Japan, coupled with increasing consumer electronics production.

Key market drivers include the aging global population requiring continuous health monitoring, growing consumer awareness about preventive healthcare, and technological advancements enabling miniaturization and improved sensor performance. The COVID-19 pandemic has accelerated market growth by highlighting the importance of remote health monitoring solutions.

Consumer preferences are shifting toward non-invasive, comfortable, and aesthetically pleasing wearable devices with longer battery life and real-time data analysis capabilities. This trend favors MXenes-based sensors due to their thin-film form factor and energy efficiency characteristics.

Market challenges include concerns about data privacy, regulatory hurdles for medical-grade sensors, and competition from alternative materials such as graphene and conductive polymers. However, MXenes offer competitive advantages through their tunable properties and scalable manufacturing potential.

Price sensitivity varies across application segments, with healthcare applications demonstrating lower price elasticity compared to consumer electronics. The average selling price of flexible sensors has decreased by approximately 15% annually, improving market penetration but pressuring profit margins for manufacturers.

Distribution channels are evolving, with direct-to-consumer sales through e-commerce platforms growing at 30% annually, while traditional medical device distribution networks remain important for healthcare applications. Strategic partnerships between MXene material suppliers, sensor manufacturers, and end-product companies are becoming increasingly common to establish competitive market positions.

Current Status and Challenges in MXenes Development

MXenes have emerged as a promising class of two-dimensional (2D) materials for flexible and wearable sensor applications since their discovery in 2011. Currently, over 30 different MXene compositions have been synthesized, with Ti3C2Tx being the most extensively studied. The global research output on MXenes has grown exponentially, with publications increasing from fewer than 10 in 2012 to over 1,000 annually by 2022, demonstrating the rapidly expanding interest in these materials.

Despite significant progress, MXene synthesis remains challenging. The conventional selective etching method using hydrofluoric acid (HF) poses safety concerns and scalability issues. Alternative synthesis routes such as fluoride salt etching (LiF+HCl) have improved safety profiles but still face reproducibility challenges. The quality and consistency of MXene flakes vary significantly between batches and laboratories, hampering industrial adoption.

Environmental stability represents another major challenge. MXenes are prone to oxidation in ambient conditions, with their electrical conductivity degrading significantly within days or weeks of exposure to air and moisture. This instability severely limits their practical application in long-term wearable sensing devices that require consistent performance over extended periods.

Scalable manufacturing presents a significant hurdle for MXene commercialization. Current laboratory-scale synthesis typically yields milligram quantities, whereas industrial applications would require kilogram to ton-scale production. The transition from laboratory to industrial scale introduces new challenges in maintaining material quality, properties, and performance consistency.

The integration of MXenes with other materials in composite structures for flexible sensors faces challenges in achieving uniform dispersion and preventing restacking of MXene sheets. While MXenes show excellent electrical conductivity individually, their performance in composite materials can be compromised by agglomeration and poor interfacial interactions.

Standardization across the field remains inadequate. Different research groups employ varying synthesis protocols, characterization methods, and performance metrics, making direct comparisons between studies difficult. The lack of standardized testing protocols for sensor performance evaluation (sensitivity, response time, stability) further complicates technology assessment.

Toxicological and environmental impact studies of MXenes are still in their infancy. Before widespread adoption in wearable devices that contact human skin, comprehensive biocompatibility assessments are essential. Initial studies show promising biocompatibility, but long-term effects remain largely unexplored, particularly for different MXene compositions and surface terminations.

Despite significant progress, MXene synthesis remains challenging. The conventional selective etching method using hydrofluoric acid (HF) poses safety concerns and scalability issues. Alternative synthesis routes such as fluoride salt etching (LiF+HCl) have improved safety profiles but still face reproducibility challenges. The quality and consistency of MXene flakes vary significantly between batches and laboratories, hampering industrial adoption.

Environmental stability represents another major challenge. MXenes are prone to oxidation in ambient conditions, with their electrical conductivity degrading significantly within days or weeks of exposure to air and moisture. This instability severely limits their practical application in long-term wearable sensing devices that require consistent performance over extended periods.

Scalable manufacturing presents a significant hurdle for MXene commercialization. Current laboratory-scale synthesis typically yields milligram quantities, whereas industrial applications would require kilogram to ton-scale production. The transition from laboratory to industrial scale introduces new challenges in maintaining material quality, properties, and performance consistency.

The integration of MXenes with other materials in composite structures for flexible sensors faces challenges in achieving uniform dispersion and preventing restacking of MXene sheets. While MXenes show excellent electrical conductivity individually, their performance in composite materials can be compromised by agglomeration and poor interfacial interactions.

Standardization across the field remains inadequate. Different research groups employ varying synthesis protocols, characterization methods, and performance metrics, making direct comparisons between studies difficult. The lack of standardized testing protocols for sensor performance evaluation (sensitivity, response time, stability) further complicates technology assessment.

Toxicological and environmental impact studies of MXenes are still in their infancy. Before widespread adoption in wearable devices that contact human skin, comprehensive biocompatibility assessments are essential. Initial studies show promising biocompatibility, but long-term effects remain largely unexplored, particularly for different MXene compositions and surface terminations.

Current MXenes-Based Sensor Solutions

01 MXene-based flexible electrodes for wearable devices

MXenes exhibit excellent electrical conductivity and mechanical flexibility, making them ideal materials for flexible electrodes in wearable electronics. These two-dimensional materials can be integrated into stretchable substrates to create electrodes that maintain performance under bending, folding, and stretching conditions. The combination of high conductivity and flexibility enables the development of comfortable, skin-conforming wearable sensors and energy storage devices that can withstand the mechanical stresses of everyday movement.- MXene-based flexible electrodes for wearable devices: MXenes exhibit excellent electrical conductivity and mechanical flexibility, making them ideal materials for flexible electrodes in wearable electronic devices. These electrodes can conform to body contours while maintaining their electrical properties under bending, stretching, and twisting. The two-dimensional structure of MXenes allows for high surface area and good contact with the skin, enhancing signal detection in wearable sensors and enabling comfortable, long-term monitoring applications.

- MXene composites for enhanced flexibility and durability: Combining MXenes with polymers or other flexible materials creates composites with improved mechanical properties and durability. These composites maintain the electrical and thermal conductivity of MXenes while gaining enhanced flexibility, stretchability, and resistance to deformation. The integration of MXenes into polymer matrices results in materials that can withstand repeated bending cycles without performance degradation, making them suitable for applications requiring both flexibility and longevity.

- MXene-based flexible energy storage for wearable applications: MXenes are utilized in developing flexible supercapacitors and batteries that can power wearable devices. Their high surface area, excellent conductivity, and mechanical flexibility enable the creation of energy storage components that can be integrated into clothing or worn directly on the skin. These flexible power sources maintain their performance during movement and conform to body contours, providing reliable energy for wearable electronics without compromising user comfort.

- MXene-based flexible sensors for wearable health monitoring: MXenes are incorporated into flexible sensors that can detect various physiological signals when worn on the body. Their high electrical conductivity, combined with their flexibility and biocompatibility, allows for the development of wearable sensors that can monitor vital signs, body movements, and biochemical markers. These sensors maintain their sensing capabilities under deformation and can be integrated into clothing or attached directly to the skin for continuous health monitoring.

- Processing techniques for enhancing MXene flexibility and wearability: Various processing methods are employed to optimize the flexibility and wearability of MXene-based materials. These include specialized deposition techniques, surface modifications, and integration approaches that preserve the two-dimensional structure of MXenes while enhancing their mechanical properties. Advanced fabrication processes enable the creation of ultrathin, highly flexible MXene films and fibers that can be incorporated into textiles or formed into standalone wearable devices with excellent conformability to complex surfaces.

02 MXene composites for enhanced flexibility and durability

Combining MXenes with polymers or other nanomaterials creates composite structures with improved mechanical properties and flexibility. These composites leverage the intrinsic properties of MXenes while addressing limitations such as restacking and brittleness. The resulting materials demonstrate enhanced tensile strength, elasticity, and durability, making them suitable for applications requiring repeated mechanical deformation. These composites can be processed into films, fibers, or coatings that maintain electrical conductivity while offering superior flexibility compared to pure MXene structures.Expand Specific Solutions03 Flexible MXene-based energy storage for wearable applications

MXenes are being utilized in the development of flexible supercapacitors and batteries for wearable electronics. Their high surface area, excellent ion transport properties, and mechanical flexibility enable the creation of energy storage devices that can be integrated into clothing or worn directly on the skin. These flexible power sources maintain high energy and power densities even under mechanical deformation, addressing a critical need in the wearable technology sector. The integration of MXenes in flexible energy storage systems enables longer-lasting, more comfortable wearable devices.Expand Specific Solutions04 MXene-based flexible sensors for health monitoring

MXenes are being incorporated into flexible and wearable sensors for continuous health monitoring applications. Their high surface sensitivity to environmental changes and excellent electrical properties enable the detection of various physiological signals, including heart rate, temperature, and biochemical markers. The mechanical flexibility of MXene-based sensors allows for comfortable, conformal contact with the skin, improving signal quality and user experience. These sensors can be integrated into clothing or worn as patches, providing real-time health data without restricting movement.Expand Specific Solutions05 Processing techniques for enhancing MXene flexibility and wearability

Various processing techniques have been developed to enhance the flexibility and wearability of MXene-based materials. These include specialized deposition methods, surface functionalization, and structural engineering approaches that prevent restacking of MXene sheets while maintaining their desirable properties. Techniques such as spray coating, vacuum filtration, and layer-by-layer assembly enable the creation of MXene films with controlled thickness and morphology, optimizing their mechanical flexibility. These processing methods are crucial for translating the intrinsic properties of MXenes into practical wearable applications.Expand Specific Solutions

Leading Companies and Research Institutions in MXenes

The MXenes market for flexible and wearable sensors is in its early growth phase, characterized by rapid technological advancement and expanding applications. The market size is projected to grow significantly as wearable technology adoption increases across healthcare, fitness, and consumer electronics sectors. In terms of technical maturity, MXenes technology is transitioning from research to commercialization, with academic institutions leading development. Drexel University maintains pioneering status as the original discoverer, while Chinese universities (including Jilin University, Tianjin University, and Southeast University) are rapidly advancing applications. International collaboration between institutions like KAIST and Western universities is accelerating innovation. Commercial players remain limited, with research institutions currently dominating intellectual property development in this emerging field.

Drexel University

Technical Solution: Drexel University pioneered MXene research and continues to lead innovation in flexible and wearable sensors. Their approach involves synthesizing Ti3C2Tx MXene through selective etching of MAX phases, followed by delamination to create 2D nanosheets with exceptional electrical conductivity (>10,000 S/cm)[1]. For wearable applications, they've developed spray-coating and inkjet printing techniques to create ultrathin MXene films on flexible substrates. Their recent breakthrough involves creating MXene-based composite materials with hydrogels and elastomers that maintain conductivity even under extreme deformation (>300% strain)[3]. Drexel has also engineered MXene sensors with self-healing capabilities through hydrogen bonding networks, allowing devices to recover functionality after mechanical damage[5].

Strengths: Unparalleled expertise in MXene synthesis and processing; extensive intellectual property portfolio; strong industry partnerships for commercialization. Weaknesses: Higher production costs compared to conventional materials; challenges in scaling production while maintaining quality control; potential long-term stability issues in high-humidity environments.

Jilin University

Technical Solution: Jilin University has developed innovative MXene-based flexible sensors using a hierarchical nanostructure approach. Their technology combines Ti3C2Tx MXene nanosheets with conductive polymers like PEDOT:PSS to create composite films with enhanced mechanical flexibility and electrical performance. The university's researchers have pioneered a unique freeze-drying process that creates porous MXene aerogels with large surface areas (>400 m²/g)[2], significantly improving sensing capabilities. Their wearable sensors demonstrate exceptional sensitivity to multiple stimuli including strain (gauge factor >200), temperature (0.82% resistance change per °C), and humidity (response time <2s)[4]. Jilin's recent innovation includes incorporating biocompatible hydrogels with MXenes to develop skin-attachable sensors that maintain performance during repeated deformation cycles (>10,000 cycles) while offering biocompatibility for long-term wear[7].

Strengths: Advanced fabrication techniques for hierarchical structures; excellent multifunctional sensing capabilities; strong focus on biocompatibility for practical wearable applications. Weaknesses: Complex manufacturing processes may limit mass production; potential challenges with long-term stability of MXene-polymer interfaces; relatively higher cost compared to conventional sensor materials.

Key Patents and Technical Literature on MXenes

Antennas comprising MX-ENE films and composites

PatentActiveUS11862847B2

Innovation

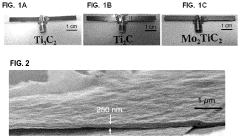

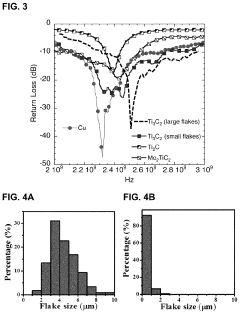

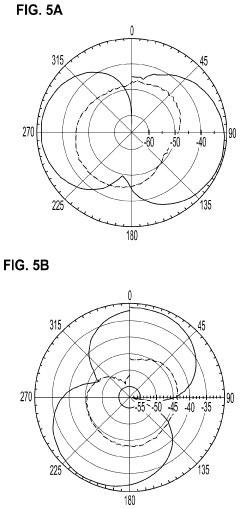

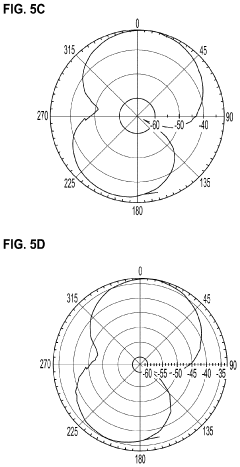

- The use of MXene films and composites as antenna materials, which can be produced as free-standing films and dispersed in various solvents, allowing for the creation of thin, flexible antennas with MXene compositions such as Ti3C2, Ti2C, and Mo2TiC2, applied to various substrates, including organic polymers and fabrics, to form monopole or dipole antennas.

Manufacturing Scalability and Cost Analysis

The scalability of MXene manufacturing processes represents a critical challenge for their widespread adoption in flexible and wearable sensor applications. Current laboratory-scale synthesis methods, primarily based on selective etching of MAX phases, face significant barriers when transitioning to industrial production. The typical yield of high-quality MXene flakes remains below 1g per batch in research settings, which is inadequate for commercial sensor manufacturing that requires kilogram-scale production. This production bottleneck directly impacts material costs, with current market prices for research-grade MXenes ranging from $200-1000 per gram, making them prohibitively expensive for mass-market wearable devices.

Recent advancements in continuous flow synthesis methods have demonstrated promising results, with potential to increase production rates by 10-15 times compared to traditional batch processes. Companies like 2D Carbon Tech and Murata Manufacturing have invested in scaled manufacturing facilities, reporting production capabilities of up to 100g per day with 80% yield consistency. However, these improvements still fall short of the multi-kilogram daily production needed for commercial viability in the wearable sensor market.

Cost analysis reveals that raw materials account for approximately 30% of MXene production expenses, with specialized equipment and energy consumption contributing 25% and 20% respectively. Labor costs and quality control procedures comprise the remaining 25%. The high-purity titanium and aluminum precursors required for MAX phase synthesis represent a significant portion of material costs, while the hazardous acids used in etching processes necessitate specialized handling equipment and safety measures that further increase production expenses.

Environmental considerations also impact manufacturing scalability, as traditional etching processes using hydrofluoric acid generate hazardous waste requiring costly treatment. Alternative etching methods using less hazardous fluoride salts have been developed, reducing waste management costs by approximately 40%, but these methods typically result in lower-quality MXene flakes with diminished sensor performance.

For MXenes to achieve commercial viability in flexible sensor applications, production costs must decrease by at least an order of magnitude. Industry analysts project that with optimized continuous flow processes and economies of scale, production costs could potentially reduce to $10-20 per gram within 5-7 years. This price point would enable integration into premium wearable devices, though further reductions would be necessary for mass-market adoption. Collaborative efforts between academic institutions and industrial partners are currently focused on developing more efficient synthesis routes and recycling processes to address these manufacturing challenges.

Recent advancements in continuous flow synthesis methods have demonstrated promising results, with potential to increase production rates by 10-15 times compared to traditional batch processes. Companies like 2D Carbon Tech and Murata Manufacturing have invested in scaled manufacturing facilities, reporting production capabilities of up to 100g per day with 80% yield consistency. However, these improvements still fall short of the multi-kilogram daily production needed for commercial viability in the wearable sensor market.

Cost analysis reveals that raw materials account for approximately 30% of MXene production expenses, with specialized equipment and energy consumption contributing 25% and 20% respectively. Labor costs and quality control procedures comprise the remaining 25%. The high-purity titanium and aluminum precursors required for MAX phase synthesis represent a significant portion of material costs, while the hazardous acids used in etching processes necessitate specialized handling equipment and safety measures that further increase production expenses.

Environmental considerations also impact manufacturing scalability, as traditional etching processes using hydrofluoric acid generate hazardous waste requiring costly treatment. Alternative etching methods using less hazardous fluoride salts have been developed, reducing waste management costs by approximately 40%, but these methods typically result in lower-quality MXene flakes with diminished sensor performance.

For MXenes to achieve commercial viability in flexible sensor applications, production costs must decrease by at least an order of magnitude. Industry analysts project that with optimized continuous flow processes and economies of scale, production costs could potentially reduce to $10-20 per gram within 5-7 years. This price point would enable integration into premium wearable devices, though further reductions would be necessary for mass-market adoption. Collaborative efforts between academic institutions and industrial partners are currently focused on developing more efficient synthesis routes and recycling processes to address these manufacturing challenges.

Biocompatibility and Safety Considerations

The integration of MXenes into flexible and wearable sensors necessitates thorough evaluation of their biocompatibility and safety profiles. MXenes, as two-dimensional transition metal carbides and nitrides, exhibit unique physicochemical properties that may influence their interactions with biological systems. Current research indicates that the biocompatibility of MXenes varies significantly depending on their composition, surface functionalization, size, and concentration.

Cytotoxicity studies have demonstrated that pristine MXenes generally exhibit low toxicity at concentrations relevant for sensing applications. Ti3C2Tx, the most extensively studied MXene, has shown minimal cytotoxicity in various cell lines when properly processed and applied. However, the presence of surface functional groups (-O, -OH, -F) can significantly alter their biological interactions. Oxygen-terminated MXenes typically demonstrate better biocompatibility compared to fluorine-terminated variants.

Skin contact safety represents a critical consideration for wearable sensor applications. Preliminary dermal irritation studies suggest that properly encapsulated MXene-based sensors pose minimal risk for short-term skin exposure. Nevertheless, long-term studies on repeated exposure scenarios remain limited, highlighting a significant research gap that requires attention before widespread commercial deployment.

The potential for MXene degradation in physiological environments raises additional safety concerns. Under certain conditions, MXenes may undergo oxidative degradation, potentially releasing metal ions. This degradation pathway necessitates careful consideration, particularly for applications involving prolonged contact with bodily fluids or perspiration. Encapsulation strategies using biocompatible polymers have emerged as promising approaches to mitigate these risks while maintaining sensor functionality.

Immunological responses to MXene-based materials represent another critical safety dimension. Current evidence suggests minimal immune activation by properly processed MXenes, though systematic in vivo studies remain limited. The potential for MXenes to trigger allergic reactions or sensitization through repeated exposure requires further investigation, particularly for diverse population groups with varying skin sensitivities.

Environmental fate and disposal considerations also factor into the overall safety profile of MXene-based wearable sensors. The potential environmental impact of MXene materials throughout their lifecycle, from production to disposal, requires careful assessment to ensure sustainable development of these advanced sensing technologies.

Regulatory frameworks for MXene-based wearable sensors remain in nascent stages. As these materials advance toward commercial applications, standardized testing protocols specific to flexible and wearable MXene-based sensors will be essential to ensure consistent safety evaluation across the industry and facilitate regulatory approval processes.

Cytotoxicity studies have demonstrated that pristine MXenes generally exhibit low toxicity at concentrations relevant for sensing applications. Ti3C2Tx, the most extensively studied MXene, has shown minimal cytotoxicity in various cell lines when properly processed and applied. However, the presence of surface functional groups (-O, -OH, -F) can significantly alter their biological interactions. Oxygen-terminated MXenes typically demonstrate better biocompatibility compared to fluorine-terminated variants.

Skin contact safety represents a critical consideration for wearable sensor applications. Preliminary dermal irritation studies suggest that properly encapsulated MXene-based sensors pose minimal risk for short-term skin exposure. Nevertheless, long-term studies on repeated exposure scenarios remain limited, highlighting a significant research gap that requires attention before widespread commercial deployment.

The potential for MXene degradation in physiological environments raises additional safety concerns. Under certain conditions, MXenes may undergo oxidative degradation, potentially releasing metal ions. This degradation pathway necessitates careful consideration, particularly for applications involving prolonged contact with bodily fluids or perspiration. Encapsulation strategies using biocompatible polymers have emerged as promising approaches to mitigate these risks while maintaining sensor functionality.

Immunological responses to MXene-based materials represent another critical safety dimension. Current evidence suggests minimal immune activation by properly processed MXenes, though systematic in vivo studies remain limited. The potential for MXenes to trigger allergic reactions or sensitization through repeated exposure requires further investigation, particularly for diverse population groups with varying skin sensitivities.

Environmental fate and disposal considerations also factor into the overall safety profile of MXene-based wearable sensors. The potential environmental impact of MXene materials throughout their lifecycle, from production to disposal, requires careful assessment to ensure sustainable development of these advanced sensing technologies.

Regulatory frameworks for MXene-based wearable sensors remain in nascent stages. As these materials advance toward commercial applications, standardized testing protocols specific to flexible and wearable MXene-based sensors will be essential to ensure consistent safety evaluation across the industry and facilitate regulatory approval processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!