Research on MXenes in lithium sulfur battery applications

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MXenes in Li-S Batteries: Background and Objectives

MXenes represent a revolutionary class of two-dimensional (2D) transition metal carbides, nitrides, and carbonitrides that have emerged as promising materials for energy storage applications. First discovered in 2011 by researchers at Drexel University, MXenes have rapidly gained attention due to their unique layered structure, excellent electrical conductivity, hydrophilic surfaces, and tunable chemistry. The general formula for MXenes is Mn+1XnTx, where M represents a transition metal, X is carbon or nitrogen, and Tx denotes surface functional groups such as -OH, -O, or -F.

The development trajectory of MXenes has been characterized by continuous expansion in synthesis methods, compositional diversity, and application domains. Initially limited to a few compositions, the MXene family now encompasses over 30 different variants with customizable properties, enabling their integration into various energy storage systems, including lithium-sulfur (Li-S) batteries.

Lithium-sulfur batteries have emerged as a promising next-generation energy storage technology due to their theoretical energy density of 2600 Wh/kg, which significantly exceeds that of conventional lithium-ion batteries (500-700 Wh/kg). Additionally, sulfur is abundant, environmentally friendly, and cost-effective compared to traditional cathode materials. However, Li-S batteries face critical challenges that have hindered their commercial viability.

The primary technical obstacles include the insulating nature of sulfur, significant volume expansion during cycling, and the notorious "shuttle effect" caused by soluble lithium polysulfide intermediates. These challenges lead to rapid capacity fading, poor rate capability, and limited cycle life. The integration of MXenes into Li-S battery systems aims to address these fundamental issues by leveraging their unique physicochemical properties.

The technical objectives of MXene research in Li-S batteries encompass several dimensions. First, researchers aim to utilize the high electrical conductivity of MXenes to enhance the overall conductivity of sulfur cathodes. Second, the abundant functional groups on MXene surfaces offer strong chemical interactions with polysulfides, potentially mitigating the shuttle effect. Third, the two-dimensional morphology of MXenes provides structural stability to accommodate volume changes during cycling.

Recent technological evolution indicates a shift from using MXenes as simple conductive additives to developing more sophisticated architectures where MXenes serve multiple functions simultaneously. These include acting as sulfur hosts, interlayer barriers, separator modifiers, and even components in composite electrolytes. The versatility of MXenes in addressing multiple challenges simultaneously represents a significant advantage over other materials being explored for Li-S batteries.

The ultimate goal of this research direction is to develop commercially viable Li-S batteries with energy densities exceeding 500 Wh/kg at the cell level, cycle life of over 1000 cycles, and cost-effectiveness suitable for both electric vehicle and grid storage applications.

The development trajectory of MXenes has been characterized by continuous expansion in synthesis methods, compositional diversity, and application domains. Initially limited to a few compositions, the MXene family now encompasses over 30 different variants with customizable properties, enabling their integration into various energy storage systems, including lithium-sulfur (Li-S) batteries.

Lithium-sulfur batteries have emerged as a promising next-generation energy storage technology due to their theoretical energy density of 2600 Wh/kg, which significantly exceeds that of conventional lithium-ion batteries (500-700 Wh/kg). Additionally, sulfur is abundant, environmentally friendly, and cost-effective compared to traditional cathode materials. However, Li-S batteries face critical challenges that have hindered their commercial viability.

The primary technical obstacles include the insulating nature of sulfur, significant volume expansion during cycling, and the notorious "shuttle effect" caused by soluble lithium polysulfide intermediates. These challenges lead to rapid capacity fading, poor rate capability, and limited cycle life. The integration of MXenes into Li-S battery systems aims to address these fundamental issues by leveraging their unique physicochemical properties.

The technical objectives of MXene research in Li-S batteries encompass several dimensions. First, researchers aim to utilize the high electrical conductivity of MXenes to enhance the overall conductivity of sulfur cathodes. Second, the abundant functional groups on MXene surfaces offer strong chemical interactions with polysulfides, potentially mitigating the shuttle effect. Third, the two-dimensional morphology of MXenes provides structural stability to accommodate volume changes during cycling.

Recent technological evolution indicates a shift from using MXenes as simple conductive additives to developing more sophisticated architectures where MXenes serve multiple functions simultaneously. These include acting as sulfur hosts, interlayer barriers, separator modifiers, and even components in composite electrolytes. The versatility of MXenes in addressing multiple challenges simultaneously represents a significant advantage over other materials being explored for Li-S batteries.

The ultimate goal of this research direction is to develop commercially viable Li-S batteries with energy densities exceeding 500 Wh/kg at the cell level, cycle life of over 1000 cycles, and cost-effectiveness suitable for both electric vehicle and grid storage applications.

Market Analysis for Li-S Battery Technology

The lithium-sulfur (Li-S) battery market is experiencing significant growth potential due to its theoretical energy density advantages over conventional lithium-ion batteries. Current market projections indicate the global Li-S battery market could reach $2.1 billion by 2030, with a compound annual growth rate of approximately 35% from 2023 to 2030. This growth is primarily driven by increasing demand for high-energy-density storage solutions in electric vehicles, aerospace applications, and portable electronics.

The integration of MXenes into Li-S battery technology represents a specialized segment within this emerging market. While still predominantly in the research phase, industry analysts anticipate MXene-enhanced Li-S batteries could capture 15-20% of the premium battery market within the next decade if current technical challenges are overcome.

Market demand for Li-S batteries is particularly strong in sectors requiring lightweight, high-capacity energy storage. The electric vehicle industry represents the largest potential market, with manufacturers actively seeking alternatives to traditional lithium-ion technology to extend driving range and reduce battery weight. Aerospace and defense sectors follow closely, valuing the potential weight reduction of up to 70% compared to conventional batteries.

Consumer electronics manufacturers have also expressed interest in Li-S technology, particularly for applications requiring extended operation between charges. However, this market segment remains more price-sensitive and may adopt the technology more gradually as manufacturing costs decrease.

Geographically, North America and East Asia (particularly China, Japan, and South Korea) dominate research and development investments in Li-S battery technology. China has positioned itself as the leading market for both production and consumption, with substantial government backing for advanced battery technologies as part of its strategic industrial policies.

Market barriers include current high production costs, with MXene-enhanced Li-S batteries estimated to cost 3-4 times more than conventional lithium-ion batteries at present. Additionally, concerns regarding cycle life stability and large-scale manufacturing feasibility have tempered immediate commercial adoption.

Industry partnerships between material science companies, battery manufacturers, and end-users are accelerating, with over 30 significant research collaborations announced in the past three years. These partnerships aim to bridge the gap between laboratory success and commercial viability, focusing on scalable production methods for MXene materials and their integration into practical battery designs.

The integration of MXenes into Li-S battery technology represents a specialized segment within this emerging market. While still predominantly in the research phase, industry analysts anticipate MXene-enhanced Li-S batteries could capture 15-20% of the premium battery market within the next decade if current technical challenges are overcome.

Market demand for Li-S batteries is particularly strong in sectors requiring lightweight, high-capacity energy storage. The electric vehicle industry represents the largest potential market, with manufacturers actively seeking alternatives to traditional lithium-ion technology to extend driving range and reduce battery weight. Aerospace and defense sectors follow closely, valuing the potential weight reduction of up to 70% compared to conventional batteries.

Consumer electronics manufacturers have also expressed interest in Li-S technology, particularly for applications requiring extended operation between charges. However, this market segment remains more price-sensitive and may adopt the technology more gradually as manufacturing costs decrease.

Geographically, North America and East Asia (particularly China, Japan, and South Korea) dominate research and development investments in Li-S battery technology. China has positioned itself as the leading market for both production and consumption, with substantial government backing for advanced battery technologies as part of its strategic industrial policies.

Market barriers include current high production costs, with MXene-enhanced Li-S batteries estimated to cost 3-4 times more than conventional lithium-ion batteries at present. Additionally, concerns regarding cycle life stability and large-scale manufacturing feasibility have tempered immediate commercial adoption.

Industry partnerships between material science companies, battery manufacturers, and end-users are accelerating, with over 30 significant research collaborations announced in the past three years. These partnerships aim to bridge the gap between laboratory success and commercial viability, focusing on scalable production methods for MXene materials and their integration into practical battery designs.

Current Status and Challenges of MXenes in Li-S Batteries

MXenes have emerged as promising materials for lithium-sulfur (Li-S) batteries due to their unique two-dimensional structure and excellent electrical conductivity. Currently, MXenes are being extensively investigated as sulfur hosts, interlayer materials, and separator modifiers in Li-S battery systems. The integration of MXenes has shown significant improvements in addressing the key challenges of Li-S batteries, particularly the shuttle effect of polysulfides and the poor electrical conductivity of sulfur.

Globally, research on MXenes in Li-S batteries has gained momentum, with major contributions from research institutions in China, the United States, and Europe. The number of publications in this field has increased exponentially over the past five years, indicating growing interest and investment in this technology. However, despite the promising results, several critical challenges remain unresolved.

One of the primary technical challenges is the limited understanding of the interaction mechanisms between MXenes and polysulfides. While it has been observed that MXenes can effectively trap polysulfides through chemical and physical adsorption, the exact nature of these interactions and their long-term stability are not fully understood. This knowledge gap hinders the rational design of optimized MXene structures for Li-S batteries.

Another significant challenge is the scalable synthesis of high-quality MXenes with controlled properties. Current synthesis methods often result in variations in flake size, thickness, and surface termination, which directly impact the performance of MXenes in Li-S batteries. The development of standardized, large-scale production methods remains a bottleneck for commercial applications.

The stability of MXenes in the harsh electrochemical environment of Li-S batteries also presents a major concern. MXenes can undergo oxidation and structural degradation during cycling, leading to performance deterioration over time. Research efforts are needed to enhance the chemical stability of MXenes without compromising their beneficial properties.

Furthermore, the integration of MXenes into practical battery designs faces engineering challenges. Issues such as electrode thickness, sulfur loading, and electrolyte optimization need to be addressed to translate the promising laboratory results into commercially viable products. The trade-off between high sulfur content and battery performance remains a critical consideration.

From a geographical perspective, research on MXenes for Li-S batteries shows interesting patterns. While China leads in terms of publication volume, pioneering work on MXene synthesis and fundamental properties has been predominantly conducted in the United States, particularly at Drexel University. European institutions have made significant contributions to understanding the electrochemical behavior of MXenes in battery systems.

Globally, research on MXenes in Li-S batteries has gained momentum, with major contributions from research institutions in China, the United States, and Europe. The number of publications in this field has increased exponentially over the past five years, indicating growing interest and investment in this technology. However, despite the promising results, several critical challenges remain unresolved.

One of the primary technical challenges is the limited understanding of the interaction mechanisms between MXenes and polysulfides. While it has been observed that MXenes can effectively trap polysulfides through chemical and physical adsorption, the exact nature of these interactions and their long-term stability are not fully understood. This knowledge gap hinders the rational design of optimized MXene structures for Li-S batteries.

Another significant challenge is the scalable synthesis of high-quality MXenes with controlled properties. Current synthesis methods often result in variations in flake size, thickness, and surface termination, which directly impact the performance of MXenes in Li-S batteries. The development of standardized, large-scale production methods remains a bottleneck for commercial applications.

The stability of MXenes in the harsh electrochemical environment of Li-S batteries also presents a major concern. MXenes can undergo oxidation and structural degradation during cycling, leading to performance deterioration over time. Research efforts are needed to enhance the chemical stability of MXenes without compromising their beneficial properties.

Furthermore, the integration of MXenes into practical battery designs faces engineering challenges. Issues such as electrode thickness, sulfur loading, and electrolyte optimization need to be addressed to translate the promising laboratory results into commercially viable products. The trade-off between high sulfur content and battery performance remains a critical consideration.

From a geographical perspective, research on MXenes for Li-S batteries shows interesting patterns. While China leads in terms of publication volume, pioneering work on MXene synthesis and fundamental properties has been predominantly conducted in the United States, particularly at Drexel University. European institutions have made significant contributions to understanding the electrochemical behavior of MXenes in battery systems.

Current MXene Integration Strategies for Li-S Batteries

01 Synthesis and preparation methods of MXenes

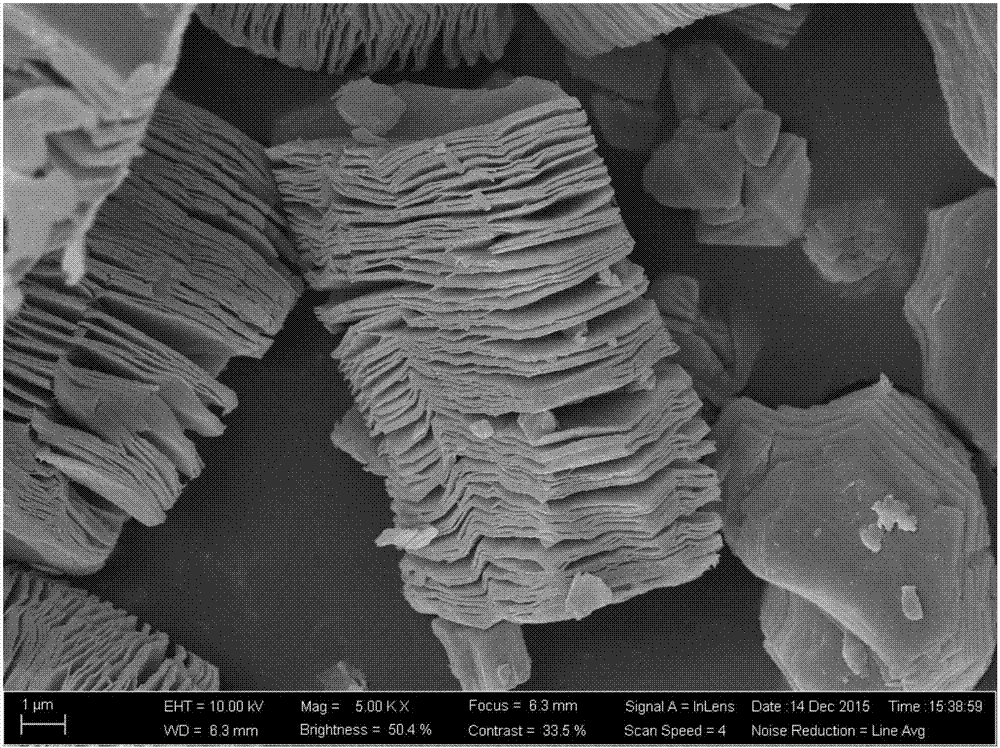

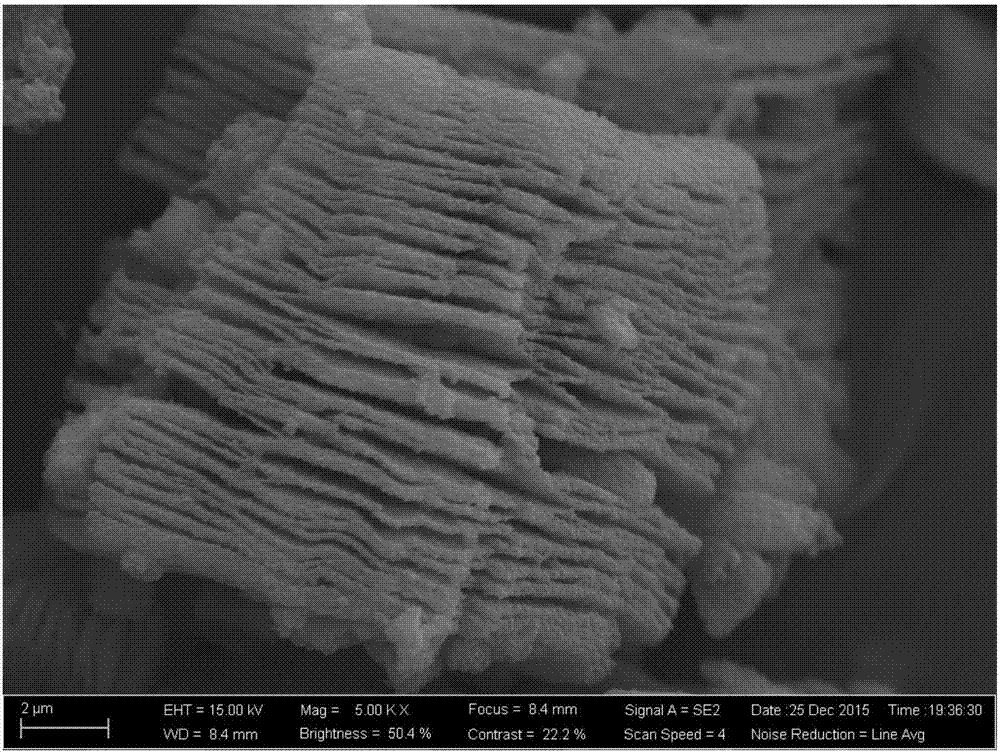

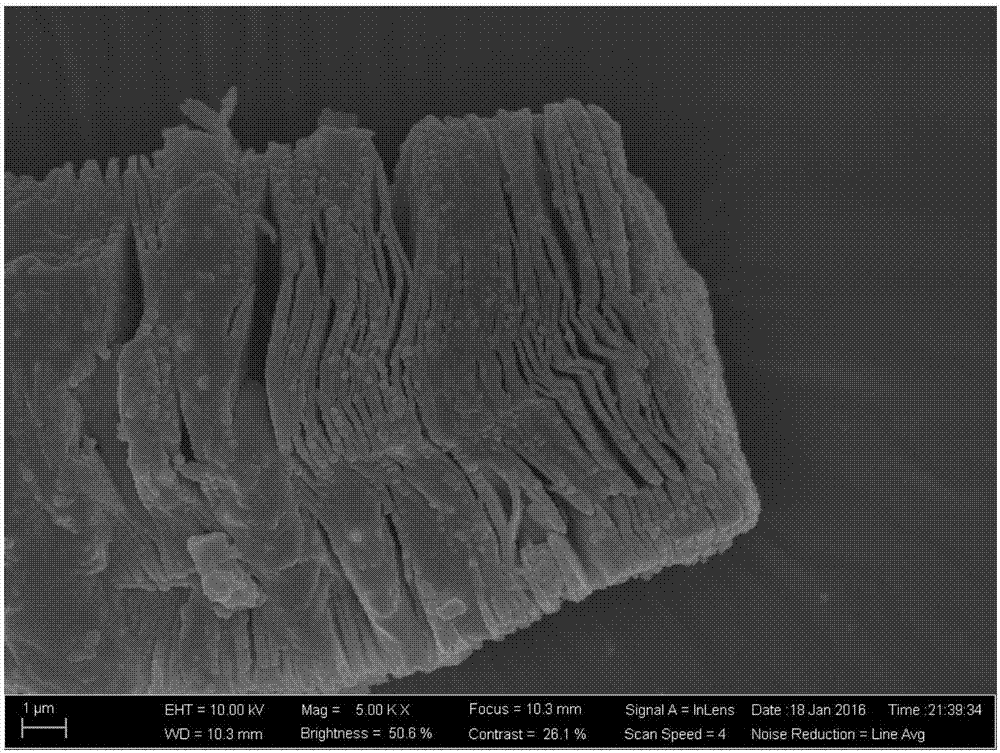

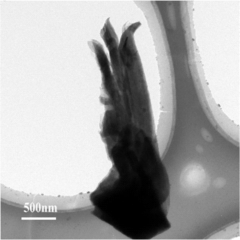

Various methods for synthesizing and preparing MXenes, which are two-dimensional transition metal carbides and nitrides. These methods include selective etching of MAX phases, chemical exfoliation, and other novel approaches to produce high-quality MXene sheets with controlled thickness and properties. The synthesis processes often involve the removal of A-layer atoms from MAX phases using different etchants and post-treatment techniques to optimize the structure and performance of the resulting MXenes.- Synthesis and preparation methods of MXenes: Various methods for synthesizing and preparing MXenes, which are two-dimensional transition metal carbides and nitrides. These methods include selective etching of MAX phases, chemical exfoliation techniques, and other novel approaches to produce high-quality MXene sheets with controlled thickness and properties. The synthesis processes often involve the removal of A-layer atoms from MAX phases using acids or other chemical treatments.

- MXenes for energy storage applications: Application of MXenes in energy storage devices such as supercapacitors, batteries, and other electrochemical systems. MXenes exhibit high electrical conductivity, large surface area, and excellent ion intercalation properties, making them promising materials for improving energy density, power density, and cycling stability in various energy storage technologies.

- MXenes in composite materials: Integration of MXenes into composite materials to enhance mechanical, electrical, thermal, and other functional properties. MXenes can be combined with polymers, metals, ceramics, and other nanomaterials to create composites with synergistic effects. These composites find applications in structural materials, flexible electronics, electromagnetic shielding, and thermal management systems.

- MXenes for environmental applications: Utilization of MXenes in environmental remediation, water purification, gas separation, and sensing applications. MXenes' unique surface chemistry, high adsorption capacity, and catalytic properties make them effective for removing pollutants, heavy metals, and organic contaminants from water and air. They can also be used as sensors for detecting environmental pollutants and hazardous substances.

- Functionalization and modification of MXenes: Methods for functionalizing and modifying MXenes to tailor their properties for specific applications. Surface modification techniques include chemical functionalization, doping, intercalation, and hybridization with other nanomaterials. These modifications can enhance stability, dispersibility, and performance of MXenes in various environments and applications, while also enabling new functionalities and properties.

02 MXene-based energy storage applications

Applications of MXenes in energy storage devices such as supercapacitors, batteries, and other electrochemical systems. MXenes exhibit excellent electrical conductivity, high surface area, and unique intercalation properties, making them promising materials for improving energy density, power density, and cycling stability in various energy storage technologies. Their two-dimensional structure facilitates ion transport and storage, enhancing the overall performance of energy storage devices.Expand Specific Solutions03 MXene composites with other nanomaterials

Development of composite materials combining MXenes with other nanomaterials such as graphene, carbon nanotubes, metal oxides, and polymers. These composites leverage the synergistic effects between MXenes and other materials to enhance mechanical, electrical, thermal, and electrochemical properties. The resulting hybrid materials demonstrate improved performance in various applications including sensors, catalysts, electromagnetic shielding, and environmental remediation.Expand Specific Solutions04 MXenes for environmental applications

Utilization of MXenes in environmental applications such as water purification, pollutant removal, and environmental sensing. MXenes' large surface area, abundant functional groups, and tunable surface chemistry make them effective adsorbents for heavy metals, organic pollutants, and other contaminants. They can be incorporated into membranes, filters, and other separation technologies to improve efficiency and selectivity in environmental remediation processes.Expand Specific Solutions05 MXenes in biomedical and healthcare applications

Applications of MXenes in biomedical fields including drug delivery, biosensing, tissue engineering, and therapeutic treatments. MXenes exhibit biocompatibility, photothermal properties, and ability to be functionalized with various biomolecules, making them suitable for targeted drug delivery, bioimaging, cancer therapy, and antimicrobial applications. Their two-dimensional structure allows for high drug loading capacity and controlled release mechanisms in biomedical systems.Expand Specific Solutions

Key Industry Players in MXene-Based Battery Research

The lithium-sulfur battery market utilizing MXenes is currently in an early growth phase, characterized by intensive research and development activities primarily led by academic institutions. With the global lithium-sulfur battery market projected to reach $1.4 billion by 2028, MXene applications represent a promising segment due to their exceptional conductivity and sulfur-trapping capabilities. Research leadership is concentrated among Chinese universities including Guangdong University of Technology, Zhejiang University, and Sichuan University, with significant contributions from international institutions like Drexel University (where MXenes were first discovered) and Korea Advanced Institute of Science & Technology. Commercial development remains limited, with companies like Guangdong Dongdao New Energy and Zhanjiang Juxin New Energy beginning to explore industrial applications, indicating the technology is approaching the transition from laboratory to commercial viability.

Shandong University

Technical Solution: Shandong University has developed a distinctive approach to MXene-based lithium-sulfur batteries focusing on rational interface engineering. Their research team has created novel MXene/sulfur composites using a hydrothermal-assisted method that enables precise control over the MXene's surface chemistry. By modifying Ti3C2Tx MXenes with transition metal ions (particularly Fe, Co, and Ni), they have enhanced the material's polysulfide adsorption capabilities through coordination chemistry principles. Their most significant innovation involves creating "polar-polar" interfaces between functionalized MXenes and sulfur species, which demonstrate substantially stronger binding energies (calculated at 2.3-3.8 eV) compared to conventional carbon hosts. This approach effectively suppresses the shuttle effect while maintaining excellent electrical conductivity. Shandong researchers have also pioneered the development of free-standing MXene films as both sulfur hosts and interlayers, eliminating the need for traditional binders and conductive additives. Their recent work demonstrates batteries with areal sulfur loadings exceeding 5 mg/cm² while maintaining high capacity (initial discharge capacity >1200 mAh/g) and impressive cycling stability (capacity retention >75% after 300 cycles at 1C rate).

Strengths: Shandong University's approach excels in interface engineering and surface chemistry modification, resulting in materials with exceptional polysulfide trapping abilities. Their free-standing electrode designs eliminate several traditional components, potentially simplifying manufacturing processes. Weaknesses: The surface modification techniques may introduce additional processing steps and costs, and the long-term stability of the modified interfaces under extended cycling needs further validation for commercial applications.

Drexel University

Technical Solution: Drexel University is a pioneer in MXene research for lithium-sulfur batteries, having discovered MXenes in 2011. Their approach focuses on using two-dimensional titanium carbide MXene (Ti3C2Tx) as a multifunctional host material for sulfur cathodes. The university's research team has developed a method where Ti3C2Tx MXene nanosheets are used to encapsulate sulfur particles, creating a conductive network that effectively traps polysulfides through strong chemical interactions between the sulfur species and the MXene's surface functional groups. This design addresses the "shuttle effect" problem in Li-S batteries by preventing polysulfide dissolution. Additionally, Drexel researchers have demonstrated that MXene's high electrical conductivity (up to 6000 S/cm) facilitates rapid electron transfer during charge-discharge cycles, significantly improving the battery's rate capability and cycling stability. Their latest advancements include creating hierarchical MXene/sulfur composites with controlled pore structures that achieve sulfur loadings exceeding 70 wt% while maintaining high capacity retention over extended cycling.

Strengths: Drexel possesses unparalleled expertise in MXene synthesis and characterization as the original discoverer of the material. Their research benefits from direct access to specialized equipment and established protocols for creating high-quality MXenes with controlled properties. Weaknesses: Some of their approaches may face scalability challenges for industrial production, and the cost of high-purity MXene production remains relatively high compared to conventional battery materials.

Critical Patents and Literature on MXene-Sulfur Interfaces

Preparation method of oxidized Mxene/S compound applied to lithium-sulphur battery cathode

PatentInactiveCN107579235A

Innovation

- Oxidized Mxene is used as a carrier and combined with sulfur through a water bath method to prepare an oxidized Mxene/S composite with high conductivity, large surface area, and effective adsorption of lithium polysulfide, thereby improving the conductivity and cycle stability of the material.

A kind of lithium-sulfur battery cathode material

PatentActiveCN115000410B

Innovation

- Carbon nanotube-titanium carbide composite porous microspheres are used as sulfur carriers. The carbon nanotubes prevent the lamellar structure of the MXene material from collapsing and stacking, enhance the conductivity and physical barrier capabilities of the composite material, and reduce the dissolution and migration of polysulfides.

Environmental Impact and Sustainability Assessment

The integration of MXenes in lithium-sulfur (Li-S) battery applications presents significant environmental implications that warrant comprehensive assessment. MXenes, as two-dimensional transition metal carbides and nitrides, offer potential advantages in terms of sustainability compared to conventional battery materials. Their synthesis typically requires less energy-intensive processes than traditional electrode materials, potentially reducing the carbon footprint associated with battery production.

When evaluating the environmental impact of MXene-enhanced Li-S batteries, the entire lifecycle must be considered. The raw material acquisition phase shows promising aspects, as MXenes can be synthesized from abundant elements like titanium, which has lower environmental extraction costs compared to cobalt or nickel used in conventional lithium-ion batteries. This reduced dependence on rare earth elements and critical minerals represents a significant sustainability advantage.

Manufacturing processes for MXene-based components currently involve the use of hydrofluoric acid, which poses environmental and safety concerns. However, recent research has demonstrated progress in developing greener synthesis routes using less hazardous etchants. These alternative methods could substantially reduce the environmental burden associated with MXene production while maintaining their exceptional electrochemical properties for Li-S battery applications.

The operational phase of MXene-enhanced Li-S batteries demonstrates environmental benefits through improved energy density and cycle life. By enabling more efficient sulfur utilization and mitigating polysulfide shuttling, MXenes contribute to batteries with longer service lives and higher capacity. This translates to fewer replacement cycles and reduced material consumption over time, decreasing the overall environmental footprint of energy storage systems.

End-of-life considerations reveal both challenges and opportunities. While the recycling infrastructure for Li-S batteries incorporating MXenes is still developing, these materials show promising recoverability characteristics. The two-dimensional structure of MXenes facilitates their separation from other battery components, potentially enabling more efficient recycling processes compared to conventional battery materials. Additionally, the lower toxicity profile of many MXene compositions could reduce environmental risks associated with improper disposal.

Water usage and emissions during manufacturing remain areas requiring further optimization. Current synthesis methods can be water-intensive, and scaling up production will necessitate closed-loop water recycling systems to minimize environmental impact. Similarly, emissions control during high-temperature processing steps will be essential to ensure MXene-enhanced Li-S batteries truly represent a more sustainable energy storage solution.

When evaluating the environmental impact of MXene-enhanced Li-S batteries, the entire lifecycle must be considered. The raw material acquisition phase shows promising aspects, as MXenes can be synthesized from abundant elements like titanium, which has lower environmental extraction costs compared to cobalt or nickel used in conventional lithium-ion batteries. This reduced dependence on rare earth elements and critical minerals represents a significant sustainability advantage.

Manufacturing processes for MXene-based components currently involve the use of hydrofluoric acid, which poses environmental and safety concerns. However, recent research has demonstrated progress in developing greener synthesis routes using less hazardous etchants. These alternative methods could substantially reduce the environmental burden associated with MXene production while maintaining their exceptional electrochemical properties for Li-S battery applications.

The operational phase of MXene-enhanced Li-S batteries demonstrates environmental benefits through improved energy density and cycle life. By enabling more efficient sulfur utilization and mitigating polysulfide shuttling, MXenes contribute to batteries with longer service lives and higher capacity. This translates to fewer replacement cycles and reduced material consumption over time, decreasing the overall environmental footprint of energy storage systems.

End-of-life considerations reveal both challenges and opportunities. While the recycling infrastructure for Li-S batteries incorporating MXenes is still developing, these materials show promising recoverability characteristics. The two-dimensional structure of MXenes facilitates their separation from other battery components, potentially enabling more efficient recycling processes compared to conventional battery materials. Additionally, the lower toxicity profile of many MXene compositions could reduce environmental risks associated with improper disposal.

Water usage and emissions during manufacturing remain areas requiring further optimization. Current synthesis methods can be water-intensive, and scaling up production will necessitate closed-loop water recycling systems to minimize environmental impact. Similarly, emissions control during high-temperature processing steps will be essential to ensure MXene-enhanced Li-S batteries truly represent a more sustainable energy storage solution.

Scalability and Manufacturing Considerations

The scalability of MXene production represents a critical challenge for their widespread application in lithium-sulfur batteries. Current laboratory-scale synthesis methods, primarily based on selective etching of MAX phases, face significant barriers when transitioning to industrial-scale manufacturing. The most common synthesis route involving hydrofluoric acid etching presents safety concerns and environmental risks that complicate large-scale implementation. Alternative etching methods using fluoride salts in acidic media show promise for safer scale-up but still require optimization for consistent quality control.

Manufacturing considerations for MXene-based components in lithium-sulfur batteries must address several key factors. The production of MXene films and coatings with uniform thickness and consistent properties demands precise control over processing parameters. Current coating technologies, including spray coating, doctor blade, and vacuum filtration methods, each present different scalability profiles and quality control challenges. Spray coating offers good scalability but may result in less uniform MXene distribution, while vacuum filtration produces high-quality films but faces throughput limitations.

Cost analysis reveals that raw material sourcing represents a significant portion of MXene production expenses. The precursor MAX phases require high-purity transition metals and precise synthesis conditions, contributing substantially to overall costs. Process optimization focusing on reducing material waste and improving etching efficiency could significantly lower production costs, making MXene-enhanced lithium-sulfur batteries more commercially viable.

Quality control systems for scaled MXene production must evolve beyond current laboratory characterization methods. In-line monitoring techniques for assessing surface functionality, layer number, and defect density are essential for maintaining consistent performance in battery applications. Automated quality assessment using spectroscopic methods shows promise for integration into manufacturing workflows.

Environmental considerations and regulatory compliance present additional challenges for industrial-scale MXene production. Waste management strategies for spent etching solutions require development, with potential for recycling fluoride compounds to improve sustainability metrics. Closed-loop manufacturing systems that minimize chemical waste and maximize resource efficiency represent the ideal approach for environmentally responsible scale-up.

Strategic partnerships between academic institutions developing novel MXene synthesis routes and industrial manufacturers with battery production expertise will likely accelerate commercialization timelines. Several pilot-scale production facilities have demonstrated MXene synthesis at kilogram scales, but further engineering solutions are needed to reach the multi-ton production volumes required for commercial battery applications.

Manufacturing considerations for MXene-based components in lithium-sulfur batteries must address several key factors. The production of MXene films and coatings with uniform thickness and consistent properties demands precise control over processing parameters. Current coating technologies, including spray coating, doctor blade, and vacuum filtration methods, each present different scalability profiles and quality control challenges. Spray coating offers good scalability but may result in less uniform MXene distribution, while vacuum filtration produces high-quality films but faces throughput limitations.

Cost analysis reveals that raw material sourcing represents a significant portion of MXene production expenses. The precursor MAX phases require high-purity transition metals and precise synthesis conditions, contributing substantially to overall costs. Process optimization focusing on reducing material waste and improving etching efficiency could significantly lower production costs, making MXene-enhanced lithium-sulfur batteries more commercially viable.

Quality control systems for scaled MXene production must evolve beyond current laboratory characterization methods. In-line monitoring techniques for assessing surface functionality, layer number, and defect density are essential for maintaining consistent performance in battery applications. Automated quality assessment using spectroscopic methods shows promise for integration into manufacturing workflows.

Environmental considerations and regulatory compliance present additional challenges for industrial-scale MXene production. Waste management strategies for spent etching solutions require development, with potential for recycling fluoride compounds to improve sustainability metrics. Closed-loop manufacturing systems that minimize chemical waste and maximize resource efficiency represent the ideal approach for environmentally responsible scale-up.

Strategic partnerships between academic institutions developing novel MXene synthesis routes and industrial manufacturers with battery production expertise will likely accelerate commercialization timelines. Several pilot-scale production facilities have demonstrated MXene synthesis at kilogram scales, but further engineering solutions are needed to reach the multi-ton production volumes required for commercial battery applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!