Comparing LOHC With Ammonia And LOX For Long-Distance Transport

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogen Transport Technologies Background and Objectives

Hydrogen has emerged as a promising energy carrier in the global transition towards sustainable energy systems. The evolution of hydrogen transport technologies has been marked by significant advancements over the past decades, transitioning from simple compressed gas cylinders to sophisticated carrier systems. This technological progression has been driven by the increasing recognition of hydrogen's potential as a clean energy vector capable of decarbonizing various sectors including transportation, industry, and power generation.

The development trajectory of hydrogen transport technologies has been shaped by fundamental challenges related to hydrogen's physical properties. With the lowest density among all elements and a boiling point of -252.8°C, hydrogen presents unique storage and transportation challenges. Early solutions focused on compression and liquefaction, while recent innovations have explored chemical carriers that can store hydrogen in more stable forms.

Current technological trends indicate a shift towards more efficient, safe, and economically viable methods for long-distance hydrogen transport. Three prominent technologies have emerged as frontrunners: Liquid Organic Hydrogen Carriers (LOHC), ammonia as a hydrogen carrier, and cryogenic systems involving Liquid Oxygen (LOX) for hydrogen-related applications. Each represents a distinct approach to addressing the hydrogen transport challenge, with varying levels of technological maturity and commercial readiness.

The primary objective of this technical research is to conduct a comprehensive comparative analysis of LOHC, ammonia, and LOX technologies for long-distance hydrogen transport. This analysis aims to evaluate these technologies across multiple dimensions including energy efficiency, safety profiles, infrastructure requirements, economic viability, and environmental impact. By establishing a clear understanding of the relative strengths and limitations of each approach, this research seeks to identify the most promising pathways for large-scale hydrogen deployment.

Additionally, this investigation intends to map the technological readiness levels of these transport methods and identify critical development milestones required for their widespread commercial adoption. The research will consider various use cases and geographic contexts, recognizing that optimal solutions may vary depending on specific application scenarios, distances, volumes, and regional factors.

Through this comprehensive assessment, we aim to provide strategic insights that can guide research priorities, infrastructure investments, and policy frameworks to accelerate the development of efficient hydrogen transport systems. This work is particularly timely as countries worldwide are formulating hydrogen strategies and making significant investments in hydrogen infrastructure as part of their energy transition plans.

The development trajectory of hydrogen transport technologies has been shaped by fundamental challenges related to hydrogen's physical properties. With the lowest density among all elements and a boiling point of -252.8°C, hydrogen presents unique storage and transportation challenges. Early solutions focused on compression and liquefaction, while recent innovations have explored chemical carriers that can store hydrogen in more stable forms.

Current technological trends indicate a shift towards more efficient, safe, and economically viable methods for long-distance hydrogen transport. Three prominent technologies have emerged as frontrunners: Liquid Organic Hydrogen Carriers (LOHC), ammonia as a hydrogen carrier, and cryogenic systems involving Liquid Oxygen (LOX) for hydrogen-related applications. Each represents a distinct approach to addressing the hydrogen transport challenge, with varying levels of technological maturity and commercial readiness.

The primary objective of this technical research is to conduct a comprehensive comparative analysis of LOHC, ammonia, and LOX technologies for long-distance hydrogen transport. This analysis aims to evaluate these technologies across multiple dimensions including energy efficiency, safety profiles, infrastructure requirements, economic viability, and environmental impact. By establishing a clear understanding of the relative strengths and limitations of each approach, this research seeks to identify the most promising pathways for large-scale hydrogen deployment.

Additionally, this investigation intends to map the technological readiness levels of these transport methods and identify critical development milestones required for their widespread commercial adoption. The research will consider various use cases and geographic contexts, recognizing that optimal solutions may vary depending on specific application scenarios, distances, volumes, and regional factors.

Through this comprehensive assessment, we aim to provide strategic insights that can guide research priorities, infrastructure investments, and policy frameworks to accelerate the development of efficient hydrogen transport systems. This work is particularly timely as countries worldwide are formulating hydrogen strategies and making significant investments in hydrogen infrastructure as part of their energy transition plans.

Market Analysis for Long-Distance Hydrogen Transport Solutions

The global hydrogen transport market is experiencing significant growth, driven by the increasing adoption of hydrogen as a clean energy carrier. Current market size estimates place the hydrogen transport sector at approximately $5 billion in 2023, with projections indicating growth to reach $20 billion by 2030, representing a compound annual growth rate of around 22%. This growth is primarily fueled by decarbonization initiatives across industrial sectors and the transportation industry.

When analyzing the market demand for long-distance hydrogen transport solutions, LOHC, ammonia, and LOX each address different market segments with varying requirements. The industrial sector currently dominates hydrogen consumption, accounting for roughly 70% of demand, particularly in refining and chemical production. However, emerging applications in power generation and transportation are expected to reshape market dynamics significantly over the next decade.

Regional market analysis reveals distinct patterns in hydrogen transport solution preferences. Asia-Pacific, particularly Japan and South Korea, has demonstrated strong interest in LOHC technology due to limited domestic energy resources and the need for stable import channels. The Middle East and Australia are positioning themselves as potential hydrogen export hubs, with significant investments in ammonia-based transport infrastructure to leverage existing shipping capabilities.

European markets show a balanced approach, with investments spread across all three technologies, though ammonia has gained particular traction for Mediterranean and North Sea transport routes. North America's market is currently more focused on domestic pipeline infrastructure, but coastal regions are increasingly exploring maritime transport options for international trade.

Cost sensitivity varies significantly across market segments. Industrial users prioritize reliability and volume capacity, while emerging green hydrogen applications place greater emphasis on carbon footprint considerations throughout the transport chain. This has created distinct market niches where each technology can potentially excel.

Market forecasts suggest that by 2030, ammonia will likely capture the largest share of the international hydrogen transport market at approximately 45%, followed by LOHC at 30% and various compressed or liquefied hydrogen solutions (including LOX systems) at 25%. These projections reflect the relative maturity of ammonia infrastructure and the ongoing technological developments in LOHC systems that are gradually improving their economic viability.

Customer requirements analysis indicates that safety considerations, energy efficiency, and integration with existing infrastructure are the primary decision factors for potential adopters of these technologies. The market increasingly demands solutions that offer flexibility in scaling and can adapt to the evolving regulatory landscape surrounding hydrogen transport.

When analyzing the market demand for long-distance hydrogen transport solutions, LOHC, ammonia, and LOX each address different market segments with varying requirements. The industrial sector currently dominates hydrogen consumption, accounting for roughly 70% of demand, particularly in refining and chemical production. However, emerging applications in power generation and transportation are expected to reshape market dynamics significantly over the next decade.

Regional market analysis reveals distinct patterns in hydrogen transport solution preferences. Asia-Pacific, particularly Japan and South Korea, has demonstrated strong interest in LOHC technology due to limited domestic energy resources and the need for stable import channels. The Middle East and Australia are positioning themselves as potential hydrogen export hubs, with significant investments in ammonia-based transport infrastructure to leverage existing shipping capabilities.

European markets show a balanced approach, with investments spread across all three technologies, though ammonia has gained particular traction for Mediterranean and North Sea transport routes. North America's market is currently more focused on domestic pipeline infrastructure, but coastal regions are increasingly exploring maritime transport options for international trade.

Cost sensitivity varies significantly across market segments. Industrial users prioritize reliability and volume capacity, while emerging green hydrogen applications place greater emphasis on carbon footprint considerations throughout the transport chain. This has created distinct market niches where each technology can potentially excel.

Market forecasts suggest that by 2030, ammonia will likely capture the largest share of the international hydrogen transport market at approximately 45%, followed by LOHC at 30% and various compressed or liquefied hydrogen solutions (including LOX systems) at 25%. These projections reflect the relative maturity of ammonia infrastructure and the ongoing technological developments in LOHC systems that are gradually improving their economic viability.

Customer requirements analysis indicates that safety considerations, energy efficiency, and integration with existing infrastructure are the primary decision factors for potential adopters of these technologies. The market increasingly demands solutions that offer flexibility in scaling and can adapt to the evolving regulatory landscape surrounding hydrogen transport.

Current Status and Challenges of LOHC, Ammonia, and LOX

The global landscape for hydrogen transport technologies shows varying levels of development across LOHC, ammonia, and LOX systems. LOHC technology has progressed significantly in recent years with several demonstration projects operational in Europe and Japan. Companies like Hydrogenious LOHC Technologies have established commercial-scale facilities capable of binding and releasing hydrogen from carrier substances. However, LOHC systems still face efficiency challenges with energy losses of 30-35% during the dehydrogenation process, requiring temperatures of 150-320°C and specialized catalysts that contain precious metals.

Ammonia as a hydrogen carrier has reached industrial maturity for production and transport, with over 180 million tonnes produced annually worldwide. The Haber-Bosch process is well-established, and ammonia transport infrastructure exists globally through pipelines, ships, and trucks. Despite this advantage, ammonia faces significant challenges in its use as an energy carrier, particularly in the development of efficient cracking technologies to release hydrogen. Current cracking processes require temperatures of 400-700°C and consume approximately 15-30% of the energy content of the stored hydrogen.

LOX technology, while not directly a hydrogen carrier, plays a crucial role in hydrogen-related applications, particularly in fuel cells and certain industrial processes. The liquefaction and transport of oxygen is a mature technology with established infrastructure globally. The primary challenge for LOX in hydrogen transport applications is the high energy requirement for liquefaction, consuming approximately 30% of the energy content.

Geographically, LOHC research and development is concentrated in Germany, Japan, and Australia, with emerging activities in South Korea and China. Ammonia infrastructure is globally distributed but particularly developed in regions with significant fertilizer production such as the Middle East, Russia, and North America. LOX production facilities are widely distributed across industrialized nations, with major capacity in the United States, Europe, and East Asia.

Technical constraints limiting widespread adoption include catalyst degradation and thermal management for LOHC systems, safety concerns and nitrogen oxide emissions for ammonia, and high energy consumption for LOX production. All three technologies face challenges related to scaling up infrastructure for hydrogen economy applications, with LOHC requiring the most significant new infrastructure development.

Regulatory frameworks present additional challenges, particularly for ammonia due to its toxicity and for LOHC due to the novelty of large-scale implementation. Both technologies require standardization of safety protocols and handling procedures before widespread commercial deployment can be achieved.

Ammonia as a hydrogen carrier has reached industrial maturity for production and transport, with over 180 million tonnes produced annually worldwide. The Haber-Bosch process is well-established, and ammonia transport infrastructure exists globally through pipelines, ships, and trucks. Despite this advantage, ammonia faces significant challenges in its use as an energy carrier, particularly in the development of efficient cracking technologies to release hydrogen. Current cracking processes require temperatures of 400-700°C and consume approximately 15-30% of the energy content of the stored hydrogen.

LOX technology, while not directly a hydrogen carrier, plays a crucial role in hydrogen-related applications, particularly in fuel cells and certain industrial processes. The liquefaction and transport of oxygen is a mature technology with established infrastructure globally. The primary challenge for LOX in hydrogen transport applications is the high energy requirement for liquefaction, consuming approximately 30% of the energy content.

Geographically, LOHC research and development is concentrated in Germany, Japan, and Australia, with emerging activities in South Korea and China. Ammonia infrastructure is globally distributed but particularly developed in regions with significant fertilizer production such as the Middle East, Russia, and North America. LOX production facilities are widely distributed across industrialized nations, with major capacity in the United States, Europe, and East Asia.

Technical constraints limiting widespread adoption include catalyst degradation and thermal management for LOHC systems, safety concerns and nitrogen oxide emissions for ammonia, and high energy consumption for LOX production. All three technologies face challenges related to scaling up infrastructure for hydrogen economy applications, with LOHC requiring the most significant new infrastructure development.

Regulatory frameworks present additional challenges, particularly for ammonia due to its toxicity and for LOHC due to the novelty of large-scale implementation. Both technologies require standardization of safety protocols and handling procedures before widespread commercial deployment can be achieved.

Technical Comparison of LOHC, Ammonia, and LOX Solutions

01 LOHC (Liquid Organic Hydrogen Carriers) transport systems

LOHC technology enables efficient hydrogen storage and transport through reversible hydrogenation of organic compounds. These systems allow hydrogen to be stored in liquid form at ambient conditions, eliminating the need for cryogenic or high-pressure storage. The carrier molecules can be loaded with hydrogen at production sites and then transported using existing infrastructure for liquid fuels, significantly improving transport efficiency and safety compared to compressed hydrogen gas.- LOHC (Liquid Organic Hydrogen Carrier) transport systems: LOHC technology enables efficient hydrogen storage and transport by binding hydrogen to organic carrier molecules. These systems allow hydrogen to be stored in liquid form at ambient conditions, eliminating the need for cryogenic or high-pressure storage. The carrier molecules can be loaded with hydrogen at production sites and then transported using existing infrastructure for liquid fuels. After delivery, hydrogen can be released through a dehydrogenation process. This approach significantly improves transport efficiency compared to compressed hydrogen gas.

- Ammonia as hydrogen carrier for energy transport: Ammonia serves as an efficient hydrogen carrier for energy transport due to its high hydrogen content (17.6% by weight) and established handling infrastructure. It can be liquefied at moderate pressure (10 bar) or low temperature (-33°C), making it more energy-efficient to transport than compressed or liquefied hydrogen. The transport efficiency is enhanced through advanced catalytic systems for ammonia synthesis and cracking. Various technologies have been developed to improve ammonia transport safety and reduce energy losses during conversion processes.

- LOX (Liquid Oxygen) storage and transport technologies: Liquid oxygen (LOX) transport systems utilize cryogenic technologies to maintain oxygen in liquid state at -183°C, significantly increasing transport efficiency by reducing volume. Advanced insulation techniques, including vacuum-insulated vessels and multi-layer insulation systems, minimize boil-off during transport. The efficiency of LOX transport is further enhanced through optimized loading/unloading systems and specialized cryogenic pumps. These technologies enable the safe and efficient transport of large quantities of oxygen for industrial, medical, and aerospace applications.

- Comparative efficiency of hydrogen carrier systems: Different hydrogen carrier systems (LOHC, ammonia, and LOX) offer varying transport efficiencies based on energy density, conversion losses, and infrastructure requirements. Ammonia provides high volumetric hydrogen density but requires energy for synthesis and cracking. LOHC systems offer ambient condition transport but have lower gravimetric hydrogen capacity and energy-intensive dehydrogenation. LOX systems, while not directly hydrogen carriers, are essential for hydrogen combustion and fuel cell applications. The selection of optimal transport method depends on distance, scale, end-use application, and existing infrastructure.

- Novel container and vessel designs for energy carrier transport: Innovative container and vessel designs have been developed to enhance the transport efficiency of energy carriers like LOHC, ammonia, and LOX. These designs incorporate advanced materials for improved insulation, specialized pressure management systems, and optimized geometries to maximize cargo capacity while ensuring safety. Multi-modal transport containers enable seamless transfers between ships, trains, and trucks without requiring cargo transfers. Smart monitoring systems integrated into these containers provide real-time tracking of temperature, pressure, and carrier status, further improving transport efficiency and safety.

02 Ammonia as hydrogen carrier for energy transport

Ammonia serves as an efficient hydrogen carrier with higher volumetric hydrogen density than compressed hydrogen. It can be transported using existing infrastructure and converted back to hydrogen at the point of use. Innovations in catalytic systems for ammonia synthesis and decomposition have improved the energy efficiency of the ammonia-based hydrogen transport chain. Advanced storage and handling technologies address safety concerns while maximizing transport efficiency.Expand Specific Solutions03 LOX (Liquid Oxygen) storage and transport technologies

Liquid oxygen transport systems utilize cryogenic technologies to maintain oxygen in liquid state at extremely low temperatures. Advanced insulation materials and vacuum-jacketed containers minimize boil-off during transport. Innovations in liquefaction processes have reduced the energy requirements for LOX production, while specialized handling equipment and safety protocols enable efficient loading, transport, and unloading operations.Expand Specific Solutions04 Integrated multi-carrier energy transport systems

Integrated systems combining multiple energy carriers (LOHC, ammonia, and LOX) optimize overall transport efficiency by leveraging the advantages of each carrier. These systems incorporate shared infrastructure elements and coordinated logistics to reduce costs and energy losses. Advanced monitoring and control technologies ensure optimal operation across different environmental conditions and transport distances, while modular designs allow for scalability and adaptation to specific application requirements.Expand Specific Solutions05 Energy-efficient carrier conversion technologies

Advanced catalytic and membrane technologies improve the efficiency of converting between different energy carriers. These innovations reduce energy losses during hydrogen loading/unloading from LOHC, ammonia synthesis/cracking, and oxygen liquefaction/regasification processes. Heat integration systems recover and utilize waste heat from conversion processes, while novel reactor designs optimize reaction conditions to maximize conversion efficiency and minimize energy consumption.Expand Specific Solutions

Key Industry Players in Hydrogen Transport Technologies

The hydrogen carrier market for long-distance transport is currently in its early growth phase, with an estimated global market size of $2-3 billion and projected CAGR of 30-35% through 2030. LOHC technology shows promising development with Hydrogenious LOHC Technologies leading commercialization efforts, while Saudi Aramco and Chevron are investing heavily in ammonia-based solutions due to existing infrastructure compatibility. LOX technology remains mature but faces efficiency challenges for hydrogen transport. The competitive landscape features strategic partnerships between energy majors (China Petroleum & Chemical Corp., Korea Gas) and research institutions (Commissariat à l'énergie atomique, Tsinghua University), with Asian players increasingly gaining technological ground against Western incumbents. Regulatory support and infrastructure development will determine which carrier technology achieves market dominance.

Saudi Arabian Oil Co.

Technical Solution: Saudi Aramco has developed a comprehensive hydrogen transport strategy focusing on LOHC technology and ammonia as hydrogen carriers. For LOHC, they've invested in toluene-based carrier systems that can be hydrogenated to methylcyclohexane (MCH), achieving hydrogen densities of approximately 6 wt%. Their process operates at moderate temperatures (150-200°C) and pressures (20-50 bar) during hydrogenation, with dehydrogenation occurring at 300-400°C. Aramco has also pioneered ammonia-based hydrogen transport, leveraging their existing LPG shipping infrastructure and expertise. Their ammonia pathway achieves 17.8 wt% hydrogen content and utilizes advanced catalysts to improve conversion efficiency. Aramco has established pilot facilities demonstrating both technologies and is developing large-scale export terminals specifically designed for hydrogen carrier shipment to key markets in Asia and Europe, with particular focus on Japan through their partnership in the Japan-Saudi Arabia hydrogen supply chain demonstration project.

Strengths: Extensive existing global logistics infrastructure that can be adapted for hydrogen carriers; significant financial resources for scaling technology; established relationships with major energy importers; and integrated approach covering production through end-use. Weaknesses: LOHC technology requires substantial energy for dehydrogenation; ammonia cracking for hydrogen recovery remains technically challenging at scale; and both pathways face efficiency losses in the conversion chain.

Aramco Services Co.

Technical Solution: Aramco Services Company has developed an integrated hydrogen transport solution centered on a dual-pathway approach using both LOHC and ammonia carriers. Their LOHC system employs a proprietary catalyst formulation that enhances hydrogenation efficiency, achieving loading rates up to 97% of theoretical capacity with reduced energy requirements. The technology operates within a moderate temperature range (180-220°C) and pressures below 50 bar, making it compatible with existing petrochemical infrastructure. For ammonia transport, they've engineered specialized handling systems that address safety concerns through advanced monitoring and containment technologies. Their approach includes purpose-designed vessels with cryogenic capabilities that can be reconfigured to transport either ammonia or conventional LNG, providing flexibility in hydrogen delivery options. The company has established demonstration facilities in Houston that showcase both carrier technologies, with particular emphasis on integration with existing refinery and petrochemical operations.

Strengths: Flexible dual-carrier approach allows optimization based on distance and end-use requirements; leverages extensive experience in global hydrocarbon logistics; and offers integration with existing energy infrastructure. Weaknesses: Requires significant capital investment for new specialized vessels and terminal facilities; faces regulatory hurdles in multiple jurisdictions; and both carrier technologies still face efficiency challenges in the full hydrogen value chain.

Critical Patents and Innovations in Hydrogen Carrier Technologies

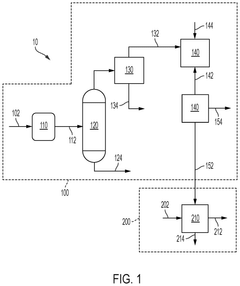

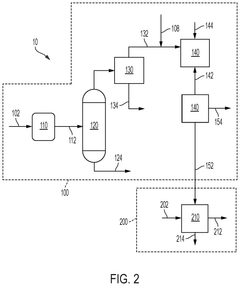

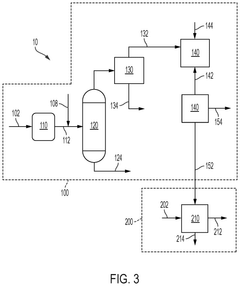

Methods for producing liquid organic hydrogen carriers (LOHC)

PatentPendingUS20250197200A1

Innovation

- The production of Liquid Organic Hydrogen Carriers (LOHCs) through hydrogenation and dehydrogenation cycles, where hydrocarbon streams are processed in thermal treatment, fractionation, and hydrogenation units to generate saturated compounds that can store and release hydrogen.

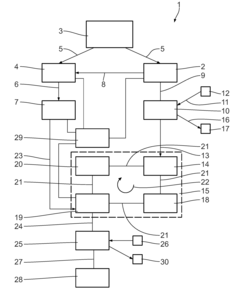

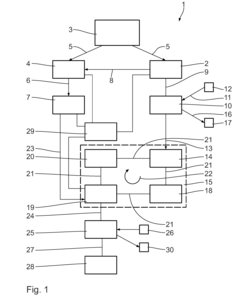

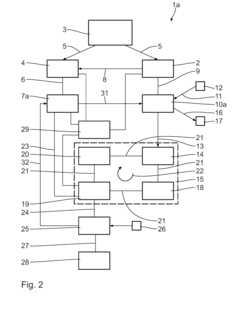

System and method for storing and releasing energy

PatentActiveUS20160301093A1

Innovation

- A system comprising a hydrogen production unit, a hydrogen storage device, a heat generation unit, and a heat storage unit, where hydrogen is stored chemically bound with a carrier medium, allowing for efficient storage and release of energy using heat from the heat storage unit during energy-rich and energy-poor periods.

Safety and Risk Assessment of Hydrogen Carrier Systems

Safety considerations are paramount when evaluating hydrogen carrier systems for long-distance transport. LOHC systems present moderate safety risks compared to other carriers. These organic compounds typically have high flash points and low volatility, reducing fire and explosion hazards. However, they often contain toxic components that require careful handling protocols and specialized containment systems. The release of hydrogen from LOHCs involves high-temperature catalytic processes, introducing thermal management challenges that necessitate robust engineering controls.

Ammonia presents significant toxicity concerns as it is corrosive to human tissue and harmful when inhaled even at low concentrations (>25 ppm). Its narrow flammability range (16-25% in air) offers some safety advantages, but its toxicity requires extensive safety measures including sophisticated leak detection systems, emergency response protocols, and specialized training for personnel. The established ammonia handling infrastructure provides well-documented safety procedures, though incidents can have severe consequences for human health and the environment.

LOX systems face distinct safety challenges related to cryogenic hazards. Operating at -183°C, LOX requires specialized insulated containers and handling equipment. Contact with organic materials can create explosive conditions, necessitating strict material compatibility protocols. Oxygen-enriched environments significantly increase fire risks, requiring specialized fire suppression systems and safety protocols. While not toxic, the extreme cold of LOX can cause severe tissue damage upon contact.

Risk assessment frameworks for these carriers must consider the entire transport chain, including loading/unloading operations, storage conditions, and emergency response capabilities. Quantitative risk assessment methodologies reveal that LOHC systems generally present lower catastrophic failure risks but higher chronic exposure concerns. Ammonia systems show moderate acute risk profiles with established mitigation strategies. LOX systems demonstrate low toxicity risks but higher potential for catastrophic incidents due to material compatibility issues.

Regulatory frameworks vary significantly by region, with European regulations typically imposing stricter safety requirements than those in North America or Asia. These disparities create compliance challenges for international transport operations. The implementation of harmonized international standards would substantially improve safety management across global supply chains.

Recent technological developments in monitoring systems, including distributed fiber optic sensing and IoT-enabled leak detection, are enhancing safety profiles across all carrier types. These innovations enable real-time risk assessment and automated emergency response protocols, potentially reducing incident severity and improving overall safety performance in hydrogen transport systems.

Ammonia presents significant toxicity concerns as it is corrosive to human tissue and harmful when inhaled even at low concentrations (>25 ppm). Its narrow flammability range (16-25% in air) offers some safety advantages, but its toxicity requires extensive safety measures including sophisticated leak detection systems, emergency response protocols, and specialized training for personnel. The established ammonia handling infrastructure provides well-documented safety procedures, though incidents can have severe consequences for human health and the environment.

LOX systems face distinct safety challenges related to cryogenic hazards. Operating at -183°C, LOX requires specialized insulated containers and handling equipment. Contact with organic materials can create explosive conditions, necessitating strict material compatibility protocols. Oxygen-enriched environments significantly increase fire risks, requiring specialized fire suppression systems and safety protocols. While not toxic, the extreme cold of LOX can cause severe tissue damage upon contact.

Risk assessment frameworks for these carriers must consider the entire transport chain, including loading/unloading operations, storage conditions, and emergency response capabilities. Quantitative risk assessment methodologies reveal that LOHC systems generally present lower catastrophic failure risks but higher chronic exposure concerns. Ammonia systems show moderate acute risk profiles with established mitigation strategies. LOX systems demonstrate low toxicity risks but higher potential for catastrophic incidents due to material compatibility issues.

Regulatory frameworks vary significantly by region, with European regulations typically imposing stricter safety requirements than those in North America or Asia. These disparities create compliance challenges for international transport operations. The implementation of harmonized international standards would substantially improve safety management across global supply chains.

Recent technological developments in monitoring systems, including distributed fiber optic sensing and IoT-enabled leak detection, are enhancing safety profiles across all carrier types. These innovations enable real-time risk assessment and automated emergency response protocols, potentially reducing incident severity and improving overall safety performance in hydrogen transport systems.

Environmental Impact and Sustainability Considerations

The environmental impact of hydrogen carrier systems represents a critical dimension in evaluating their viability for long-distance transport. LOHC systems demonstrate promising sustainability credentials through their closed-loop operation, where the carrier molecule is continuously recycled between hydrogenated and dehydrogenated states. This circularity significantly reduces waste generation compared to single-use alternatives. However, the energy intensity of the hydrogenation and dehydrogenation processes remains a concern, with current systems requiring substantial thermal energy inputs that often derive from fossil fuel sources.

Ammonia as a hydrogen carrier presents a mixed environmental profile. While it offers zero-carbon emissions at point of use when combusted directly or used in fuel cells, its production via conventional Haber-Bosch processes is highly carbon-intensive, accounting for approximately 1-2% of global CO2 emissions. Green ammonia production using renewable electricity represents a promising pathway but remains limited in scale. Additionally, ammonia poses significant toxicity risks to aquatic ecosystems in case of leakage events during transport or storage.

LOX systems, while not carrying hydrogen directly, enable oxygen-enriched combustion that can improve efficiency in various applications. The cryogenic liquefaction process for oxygen is extremely energy-intensive, requiring approximately 0.7 kWh/kg, which translates to substantial carbon emissions unless powered by renewable sources. However, LOX systems benefit from minimal direct environmental toxicity concerns compared to ammonia.

Life cycle assessment (LCA) studies comparing these carriers indicate that LOHC systems generally demonstrate lower cumulative environmental impacts when renewable energy powers the hydrogenation process. The carbon intensity of electricity used throughout the value chain emerges as the dominant factor in determining overall environmental performance for all three carrier systems.

Water consumption represents another critical environmental consideration, particularly for ammonia production, which requires approximately 1.5-3 gallons of water per kilogram of hydrogen equivalent. This raises sustainability concerns in water-stressed regions where hydrogen infrastructure might be developed.

Land use impacts vary significantly, with LOHC systems requiring more extensive storage infrastructure due to their lower volumetric hydrogen density, while ammonia's higher density allows for more compact facilities. The infrastructure footprint for LOX systems falls between these extremes but requires additional safety buffer zones due to oxygen's role as a combustion accelerant.

Ammonia as a hydrogen carrier presents a mixed environmental profile. While it offers zero-carbon emissions at point of use when combusted directly or used in fuel cells, its production via conventional Haber-Bosch processes is highly carbon-intensive, accounting for approximately 1-2% of global CO2 emissions. Green ammonia production using renewable electricity represents a promising pathway but remains limited in scale. Additionally, ammonia poses significant toxicity risks to aquatic ecosystems in case of leakage events during transport or storage.

LOX systems, while not carrying hydrogen directly, enable oxygen-enriched combustion that can improve efficiency in various applications. The cryogenic liquefaction process for oxygen is extremely energy-intensive, requiring approximately 0.7 kWh/kg, which translates to substantial carbon emissions unless powered by renewable sources. However, LOX systems benefit from minimal direct environmental toxicity concerns compared to ammonia.

Life cycle assessment (LCA) studies comparing these carriers indicate that LOHC systems generally demonstrate lower cumulative environmental impacts when renewable energy powers the hydrogenation process. The carbon intensity of electricity used throughout the value chain emerges as the dominant factor in determining overall environmental performance for all three carrier systems.

Water consumption represents another critical environmental consideration, particularly for ammonia production, which requires approximately 1.5-3 gallons of water per kilogram of hydrogen equivalent. This raises sustainability concerns in water-stressed regions where hydrogen infrastructure might be developed.

Land use impacts vary significantly, with LOHC systems requiring more extensive storage infrastructure due to their lower volumetric hydrogen density, while ammonia's higher density allows for more compact facilities. The infrastructure footprint for LOX systems falls between these extremes but requires additional safety buffer zones due to oxygen's role as a combustion accelerant.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!