LOHC Safety And Regulatory Considerations For Transport

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LOHC Technology Background and Objectives

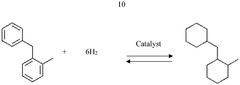

Liquid Organic Hydrogen Carriers (LOHC) represent a promising technology for hydrogen storage and transportation, emerging as a potential solution to the challenges associated with conventional hydrogen handling methods. The concept of LOHC involves chemically binding hydrogen to organic liquid compounds through hydrogenation reactions, allowing hydrogen to be stored and transported in liquid form under ambient conditions, which significantly enhances safety and practicality compared to compressed or liquefied hydrogen.

The evolution of LOHC technology can be traced back to the early 2000s when researchers began exploring alternative hydrogen storage methods to address the limitations of physical storage approaches. Over the past two decades, significant advancements have been made in catalyst development, carrier molecule design, and process optimization, leading to improved efficiency and economic viability of LOHC systems.

The primary technical objective of LOHC technology in transportation applications is to develop a safe, efficient, and economically viable method for hydrogen delivery that complies with existing regulatory frameworks while minimizing infrastructure modifications. This includes achieving high gravimetric and volumetric hydrogen storage capacities, reducing energy requirements for hydrogenation and dehydrogenation processes, and ensuring compatibility with existing liquid fuel infrastructure.

From a safety perspective, LOHC technology aims to mitigate risks associated with hydrogen transport by eliminating the need for high-pressure or cryogenic conditions. The technology seeks to develop carrier molecules with favorable safety profiles, including high flash points, low toxicity, and minimal environmental impact, thereby addressing regulatory concerns related to hazardous material transportation.

The regulatory landscape for hydrogen transport varies significantly across regions, with frameworks still evolving to accommodate emerging technologies like LOHC. A key technical objective is to develop LOHC systems that align with existing regulations for liquid fuel transport while establishing new standards specifically tailored to LOHC characteristics and handling requirements.

Current technical trends in LOHC development focus on enhancing energy efficiency, reducing catalyst costs, and optimizing carrier molecules for specific application scenarios. Research is increasingly directed toward addressing the full lifecycle of LOHC systems, including production, transportation, storage, and end-use considerations, with particular emphasis on safety and regulatory compliance throughout the value chain.

The ultimate goal of LOHC technology development for transport applications is to establish a hydrogen delivery system that offers comparable or superior safety, cost-effectiveness, and convenience to conventional fuel transport methods, thereby facilitating the broader adoption of hydrogen as an energy carrier in the transition toward a low-carbon economy.

The evolution of LOHC technology can be traced back to the early 2000s when researchers began exploring alternative hydrogen storage methods to address the limitations of physical storage approaches. Over the past two decades, significant advancements have been made in catalyst development, carrier molecule design, and process optimization, leading to improved efficiency and economic viability of LOHC systems.

The primary technical objective of LOHC technology in transportation applications is to develop a safe, efficient, and economically viable method for hydrogen delivery that complies with existing regulatory frameworks while minimizing infrastructure modifications. This includes achieving high gravimetric and volumetric hydrogen storage capacities, reducing energy requirements for hydrogenation and dehydrogenation processes, and ensuring compatibility with existing liquid fuel infrastructure.

From a safety perspective, LOHC technology aims to mitigate risks associated with hydrogen transport by eliminating the need for high-pressure or cryogenic conditions. The technology seeks to develop carrier molecules with favorable safety profiles, including high flash points, low toxicity, and minimal environmental impact, thereby addressing regulatory concerns related to hazardous material transportation.

The regulatory landscape for hydrogen transport varies significantly across regions, with frameworks still evolving to accommodate emerging technologies like LOHC. A key technical objective is to develop LOHC systems that align with existing regulations for liquid fuel transport while establishing new standards specifically tailored to LOHC characteristics and handling requirements.

Current technical trends in LOHC development focus on enhancing energy efficiency, reducing catalyst costs, and optimizing carrier molecules for specific application scenarios. Research is increasingly directed toward addressing the full lifecycle of LOHC systems, including production, transportation, storage, and end-use considerations, with particular emphasis on safety and regulatory compliance throughout the value chain.

The ultimate goal of LOHC technology development for transport applications is to establish a hydrogen delivery system that offers comparable or superior safety, cost-effectiveness, and convenience to conventional fuel transport methods, thereby facilitating the broader adoption of hydrogen as an energy carrier in the transition toward a low-carbon economy.

Market Demand Analysis for LOHC Transport Solutions

The global market for Liquid Organic Hydrogen Carrier (LOHC) transport solutions is experiencing significant growth driven by the increasing focus on hydrogen as a clean energy vector. Current market assessments indicate that the hydrogen economy could reach $700 billion by 2050, with transportation and storage solutions comprising approximately $150 billion of this market. LOHC technology specifically addresses critical challenges in hydrogen logistics that conventional methods cannot resolve effectively.

Market research reveals that industrial sectors including chemical manufacturing, refining, and metallurgy represent the primary current demand drivers, collectively consuming over 70 million tons of hydrogen annually. These established industries require safer hydrogen transport solutions that can integrate with existing infrastructure while meeting increasingly stringent safety regulations.

The emerging transportation sector presents substantial growth potential for LOHC solutions. Major automotive manufacturers and public transportation authorities in Europe, Japan, and South Korea are actively developing hydrogen fuel cell vehicles, creating demand for safe hydrogen distribution networks. Market projections suggest that hydrogen-powered vehicles could represent 15-20% of the global fleet by 2040, necessitating robust transport solutions.

Maritime shipping represents another significant market opportunity. The International Maritime Organization's emissions reduction targets are driving interest in hydrogen as an alternative fuel. LOHC technology offers particular advantages in this sector due to its compatibility with existing liquid fuel infrastructure and enhanced safety profile compared to compressed or liquefied hydrogen.

Regional analysis indicates that Europe leads LOHC adoption, supported by the European Hydrogen Strategy and substantial public investment. Japan follows closely with its hydrogen society vision, while China is rapidly scaling up hydrogen infrastructure investments. North America shows growing interest, particularly in industrial applications and long-haul transportation.

Market surveys indicate that safety considerations rank as the top priority for potential LOHC adopters, with 78% of industrial users citing regulatory compliance and accident prevention as critical decision factors. The ability to leverage existing infrastructure ranks second (65%), followed by total cost of ownership (58%).

Demand forecasts suggest the LOHC transport market could grow at a compound annual rate of 25-30% through 2030 as hydrogen production scales and distribution networks expand. This growth trajectory is contingent upon continued regulatory support, technological improvements in carrier efficiency, and successful demonstration projects that validate safety protocols and economic viability across different use cases.

Market research reveals that industrial sectors including chemical manufacturing, refining, and metallurgy represent the primary current demand drivers, collectively consuming over 70 million tons of hydrogen annually. These established industries require safer hydrogen transport solutions that can integrate with existing infrastructure while meeting increasingly stringent safety regulations.

The emerging transportation sector presents substantial growth potential for LOHC solutions. Major automotive manufacturers and public transportation authorities in Europe, Japan, and South Korea are actively developing hydrogen fuel cell vehicles, creating demand for safe hydrogen distribution networks. Market projections suggest that hydrogen-powered vehicles could represent 15-20% of the global fleet by 2040, necessitating robust transport solutions.

Maritime shipping represents another significant market opportunity. The International Maritime Organization's emissions reduction targets are driving interest in hydrogen as an alternative fuel. LOHC technology offers particular advantages in this sector due to its compatibility with existing liquid fuel infrastructure and enhanced safety profile compared to compressed or liquefied hydrogen.

Regional analysis indicates that Europe leads LOHC adoption, supported by the European Hydrogen Strategy and substantial public investment. Japan follows closely with its hydrogen society vision, while China is rapidly scaling up hydrogen infrastructure investments. North America shows growing interest, particularly in industrial applications and long-haul transportation.

Market surveys indicate that safety considerations rank as the top priority for potential LOHC adopters, with 78% of industrial users citing regulatory compliance and accident prevention as critical decision factors. The ability to leverage existing infrastructure ranks second (65%), followed by total cost of ownership (58%).

Demand forecasts suggest the LOHC transport market could grow at a compound annual rate of 25-30% through 2030 as hydrogen production scales and distribution networks expand. This growth trajectory is contingent upon continued regulatory support, technological improvements in carrier efficiency, and successful demonstration projects that validate safety protocols and economic viability across different use cases.

Current Safety Challenges in LOHC Transportation

Liquid Organic Hydrogen Carriers (LOHCs) represent a promising technology for hydrogen storage and transportation, yet they face significant safety challenges that must be addressed before widespread adoption. The primary concern stems from the chemical properties of these carriers, which often involve complex organic compounds that can pose flammability and toxicity risks. During transportation, these carriers may be exposed to varying environmental conditions, mechanical stresses, and potential accident scenarios that could compromise their integrity.

Temperature management presents a critical challenge in LOHC transportation. Most LOHCs require specific temperature ranges to maintain stability, with deviations potentially leading to unwanted chemical reactions or accelerated degradation. Current transportation infrastructure lacks sophisticated temperature control systems capable of maintaining these precise conditions across long distances and varying climates, particularly during intermodal transfers.

Pressure management similarly poses significant technical difficulties. While LOHCs generally operate at lower pressures than compressed hydrogen, they still require careful pressure monitoring and control, especially during loading, unloading, and in response to ambient temperature fluctuations. Existing pressure relief systems and monitoring technologies have not been fully optimized for the specific characteristics of different LOHC compounds.

Material compatibility issues further complicate safe transportation. LOHCs can interact with certain container materials, gaskets, and valves, potentially causing degradation, leakage, or contamination. The industry currently lacks comprehensive compatibility data for the full range of potential LOHC compounds across different transportation scenarios and container materials, creating uncertainty in container design and material selection.

Leak detection and containment represent another major safety challenge. Current detection systems are primarily designed for conventional fuels and may not adequately detect LOHC leaks, which can have different volatility and dispersion characteristics. Secondary containment systems also require adaptation to address the specific physical and chemical properties of various LOHC compounds.

Emergency response protocols present additional concerns, as first responders generally lack training and equipment specific to LOHC incidents. The unique fire suppression requirements, toxicity profiles, and chemical behaviors of these carriers necessitate specialized response procedures that have not yet been widely developed or implemented across transportation networks.

Regulatory frameworks remain underdeveloped for LOHC transportation, creating uncertainty regarding classification, handling requirements, and safety standards. This regulatory gap complicates cross-border transportation and creates inconsistent safety practices across different regions, further hindering the development of standardized safety protocols and equipment specifications.

Temperature management presents a critical challenge in LOHC transportation. Most LOHCs require specific temperature ranges to maintain stability, with deviations potentially leading to unwanted chemical reactions or accelerated degradation. Current transportation infrastructure lacks sophisticated temperature control systems capable of maintaining these precise conditions across long distances and varying climates, particularly during intermodal transfers.

Pressure management similarly poses significant technical difficulties. While LOHCs generally operate at lower pressures than compressed hydrogen, they still require careful pressure monitoring and control, especially during loading, unloading, and in response to ambient temperature fluctuations. Existing pressure relief systems and monitoring technologies have not been fully optimized for the specific characteristics of different LOHC compounds.

Material compatibility issues further complicate safe transportation. LOHCs can interact with certain container materials, gaskets, and valves, potentially causing degradation, leakage, or contamination. The industry currently lacks comprehensive compatibility data for the full range of potential LOHC compounds across different transportation scenarios and container materials, creating uncertainty in container design and material selection.

Leak detection and containment represent another major safety challenge. Current detection systems are primarily designed for conventional fuels and may not adequately detect LOHC leaks, which can have different volatility and dispersion characteristics. Secondary containment systems also require adaptation to address the specific physical and chemical properties of various LOHC compounds.

Emergency response protocols present additional concerns, as first responders generally lack training and equipment specific to LOHC incidents. The unique fire suppression requirements, toxicity profiles, and chemical behaviors of these carriers necessitate specialized response procedures that have not yet been widely developed or implemented across transportation networks.

Regulatory frameworks remain underdeveloped for LOHC transportation, creating uncertainty regarding classification, handling requirements, and safety standards. This regulatory gap complicates cross-border transportation and creates inconsistent safety practices across different regions, further hindering the development of standardized safety protocols and equipment specifications.

Existing LOHC Transport Safety Protocols

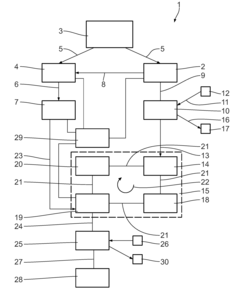

01 Safety features in LOHC storage and transportation systems

Liquid Organic Hydrogen Carriers (LOHC) systems incorporate various safety features to mitigate risks during storage and transportation. These include specialized containment vessels, pressure relief systems, and monitoring technologies that detect leaks or abnormal conditions. Advanced safety designs focus on preventing hydrogen release during transit and storage, with redundant safety mechanisms to handle emergency situations. These systems are engineered to maintain stability across various environmental conditions, reducing the risk of accidents.- Safety features in LOHC storage and transportation systems: Liquid Organic Hydrogen Carriers (LOHC) systems incorporate various safety features to mitigate risks during storage and transportation. These include pressure relief systems, leak detection mechanisms, and specialized containment designs that prevent hydrogen release during accidents. Advanced monitoring systems continuously track temperature, pressure, and hydrogen content to prevent dangerous conditions. These safety features are essential for the commercial viability of LOHC technology in hydrogen logistics.

- Fire and explosion prevention in LOHC handling: LOHC systems require specific fire and explosion prevention measures due to the flammable nature of hydrogen. This includes the use of flame arrestors, inert gas blanketing systems, and specialized electrical equipment designed for potentially explosive atmospheres. The carrier molecules themselves are selected for their high flash points and low volatility to minimize fire risks. Emergency shutdown systems are implemented to rapidly isolate hydrogen in case of detected abnormalities, preventing potential fire or explosion hazards.

- Toxicity management and environmental safety of LOHC compounds: The selection and handling of LOHC compounds must address potential toxicity concerns and environmental impacts. Modern LOHC systems utilize carrier molecules with minimal toxicity profiles and low environmental persistence. Containment systems are designed to prevent spills and leaks, while detection systems monitor for any release of carrier compounds. Biodegradable alternatives are being developed to further enhance environmental safety. Proper disposal and recycling protocols are established to manage spent or contaminated carrier materials.

- Thermal management and stability of LOHC systems: LOHC systems require effective thermal management to maintain safety during hydrogenation and dehydrogenation processes, which involve significant heat exchange. Cooling systems prevent overheating during exothermic hydrogenation, while heat supply systems for endothermic dehydrogenation are designed with multiple safety redundancies. Thermal stability of carrier molecules is crucial to prevent degradation that could lead to system failure or safety hazards. Temperature monitoring and control systems maintain optimal operating conditions to ensure both safety and efficiency.

- Regulatory compliance and safety standards for LOHC technology: LOHC systems must comply with various international and regional safety regulations and standards. This includes adherence to hydrogen handling codes, chemical storage regulations, and transportation safety requirements. Safety certification processes involve rigorous testing of containment systems, pressure management, and emergency response capabilities. Risk assessment methodologies specific to LOHC technology have been developed to identify and mitigate potential hazards. Regular safety audits and inspections are required to maintain compliance throughout the operational lifecycle of LOHC systems.

02 Risk assessment and hazard mitigation for LOHC handling

Comprehensive risk assessment methodologies have been developed specifically for LOHC systems to identify potential hazards and implement appropriate mitigation strategies. These approaches evaluate factors such as flammability, toxicity, reactivity, and environmental impact of different LOHC compounds. Safety protocols include proper handling procedures, emergency response plans, and operator training requirements. Advanced modeling techniques are used to predict behavior under various failure scenarios, allowing for the development of targeted safety measures that address specific risks associated with hydrogen carrier materials.Expand Specific Solutions03 Chemical stability and reactivity control in LOHC systems

Innovations in LOHC chemistry focus on enhancing the inherent safety of carrier molecules by improving their thermal and chemical stability. These developments include modified molecular structures that resist degradation and reduce unwanted side reactions during hydrogenation and dehydrogenation cycles. Stabilizing additives and catalysts are employed to control reaction rates and prevent runaway conditions. Research has led to carrier compounds with higher decomposition temperatures and reduced flammability, significantly improving the safety profile of LOHC systems under both normal operating conditions and potential accident scenarios.Expand Specific Solutions04 Safety-oriented LOHC system design and engineering

Engineering approaches to LOHC safety incorporate inherently safer design principles throughout the system lifecycle. These include modular construction that limits the quantity of material at risk, process intensification to reduce operational hazards, and fail-safe mechanisms that default to secure states during malfunctions. Safety considerations are integrated from the conceptual design phase through to decommissioning, with particular attention to material compatibility, thermal management, and pressure control. Advanced engineering controls include automated shutdown systems, fire suppression technologies, and specialized ventilation designs tailored to hydrogen-related risks.Expand Specific Solutions05 Regulatory compliance and safety standards for LOHC technology

Emerging regulatory frameworks and industry standards specifically address the unique safety challenges of LOHC technology. These include requirements for safety certification, periodic inspection protocols, and performance criteria for safety-critical components. Standardized testing methodologies have been developed to evaluate the safety performance of different LOHC materials and systems under various conditions. Compliance approaches incorporate risk-based methodologies that consider the full lifecycle of LOHC systems, from manufacturing through to disposal, ensuring comprehensive safety management across all operational phases.Expand Specific Solutions

Key Industry Players in LOHC Development

The LOHC (Liquid Organic Hydrogen Carrier) transport safety landscape is currently in a developing phase, with the market showing promising growth potential as hydrogen gains importance in clean energy transitions. The regulatory framework is still evolving, with companies like Hydrogenious LOHC Technologies pioneering commercial applications while established players such as Mercedes-Benz Group and Volkswagen AG explore integration into transportation systems. Technical maturity varies significantly across the ecosystem - research institutions like Fraunhofer-Gesellschaft and CEA are advancing fundamental safety protocols, while maritime entities including Japan Marine United and Shanghai Maritime University focus on specialized shipping regulations. The technology is progressing from laboratory to commercial deployment, with safety standards being developed collaboratively between automotive manufacturers, chemical companies, and regulatory authorities to address the unique challenges of hydrogen transport in liquid carrier form.

Hydrogenious Lohc Technologies GmbH

Technical Solution: Hydrogenious LOHC Technologies has developed a proprietary Liquid Organic Hydrogen Carrier (LOHC) system using dibenzyltoluene (DBT) as the carrier medium. Their technology enables hydrogen to be chemically bound to the liquid carrier at ambient conditions, transforming it into a conventional liquid fuel for safe transport and storage. The company's LOHC technology addresses key safety concerns by eliminating the need for pressurized or cryogenic hydrogen transport. Their system operates at atmospheric pressure and ambient temperature during transportation, significantly reducing explosion and fire risks associated with compressed or liquefied hydrogen. Hydrogenious has also developed specialized release units that can extract hydrogen from the carrier at the point of use, with their StorageBOX and ReleaseBOX systems designed to comply with international safety standards including ADR, RID, and IMDG codes for dangerous goods transport. The company has worked extensively with regulatory bodies to establish appropriate classification for LOHC materials within existing frameworks.

Strengths: Industry-leading expertise specifically in LOHC technology; established safety protocols already accepted by multiple regulatory bodies; eliminates high-pressure and cryogenic risks. Weaknesses: Release process requires thermal energy input; potential for carrier degradation over multiple cycles; relatively new technology with limited long-term operational data in commercial settings.

Mercedes-Benz Group AG

Technical Solution: Mercedes-Benz Group has developed an integrated approach to LOHC safety for transport applications, focusing on automotive implementations. Their technical solution incorporates LOHC systems into vehicle architectures with specialized storage tanks designed to withstand crash scenarios while maintaining structural integrity. The company has engineered thermal management systems that control the temperature of LOHC materials during loading/unloading operations, addressing the exothermic nature of hydrogenation and endothermic dehydrogenation processes. Mercedes-Benz has also developed proprietary safety protocols for LOHC handling in their service centers, including specialized training programs and equipment for technicians. Their approach includes vehicle-specific risk assessments that account for the unique characteristics of LOHC materials compared to conventional fuels, with particular attention to material compatibility with existing automotive components. The company has engaged with international regulatory bodies to establish appropriate standards for LOHC implementation in passenger and commercial vehicles, contributing to the development of ISO standards for hydrogen carriers in automotive applications.

Strengths: Extensive automotive safety engineering expertise; integrated approach that considers the entire vehicle ecosystem; established relationships with regulatory bodies worldwide. Weaknesses: Solutions primarily focused on automotive applications rather than broader transport modes; relatively early in commercial implementation compared to conventional fuel systems.

Critical Safety Innovations for LOHC Systems

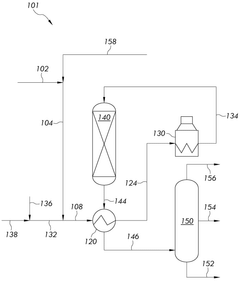

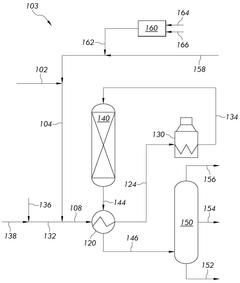

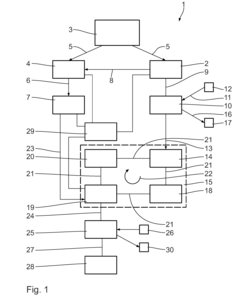

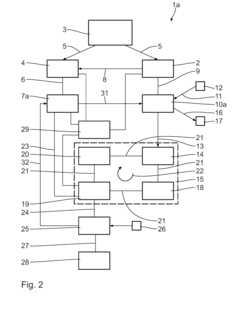

Methods for processing liquid organic hydrogen carriers

PatentWO2025128463A1

Innovation

- The use of liquid organic hydrogen carriers (LOHCs) that can store and transport hydrogen, releasing it through chemical processes, integrated with naphtha hydrotreating, allowing for co-feeding to the same reactor and efficient separation of products.

System and method for storing and releasing energy

PatentActiveUS20160301093A1

Innovation

- A system comprising a hydrogen production unit, a hydrogen storage device, a heat generation unit, and a heat storage unit, where hydrogen is stored chemically bound with a carrier medium, allowing for efficient storage and release of energy using heat from the heat storage unit during energy-rich and energy-poor periods.

International Regulatory Framework for LOHC Transport

The international regulatory landscape for Liquid Organic Hydrogen Carrier (LOHC) transport remains in development as this technology emerges as a promising hydrogen storage and transportation solution. Currently, LOHC systems fall under multiple regulatory frameworks depending on the specific carrier molecule, transportation mode, and jurisdictional boundaries.

The United Nations' Recommendations on the Transport of Dangerous Goods serves as the foundation for most international regulations, with specific provisions implemented through modal agreements such as the International Maritime Dangerous Goods (IMDG) Code for sea transport and the European Agreement concerning the International Carriage of Dangerous Goods by Road (ADR) for land transport. These frameworks classify substances based on their hazard properties, with most LOHC compounds potentially falling under Class 3 (flammable liquids) or Class 9 (miscellaneous dangerous goods).

The International Maritime Organization (IMO) has begun addressing hydrogen carriers specifically through the International Code for the Construction and Equipment of Ships Carrying Liquefied Gases in Bulk (IGC Code), though amendments may be necessary to fully accommodate LOHC technology. Similarly, the International Civil Aviation Organization (ICAO) Technical Instructions govern air transport of potentially hazardous materials.

Regional regulatory bodies have also started developing specific provisions for hydrogen transport technologies. The European Union, through regulations such as the Alternative Fuels Infrastructure Directive (AFID) and the European Hydrogen Strategy, is creating frameworks that may impact LOHC transport. In North America, both the U.S. Department of Transportation's Pipeline and Hazardous Materials Safety Administration (PHMSA) and Transport Canada have begun evaluating regulatory approaches for hydrogen carriers.

A significant challenge in the regulatory landscape is the classification of "spent" or "unloaded" LOHC materials, which may have different hazard profiles than their hydrogen-loaded counterparts. This distinction is not yet clearly addressed in most regulatory frameworks, creating potential compliance uncertainties for operators.

International standardization efforts through organizations like the International Organization for Standardization (ISO) and the International Electrotechnical Commission (IEC) are working to develop technical standards for hydrogen technologies, including TC 197 focusing on hydrogen technologies. These standards will likely influence future regulatory developments for LOHC transport across international boundaries.

The United Nations' Recommendations on the Transport of Dangerous Goods serves as the foundation for most international regulations, with specific provisions implemented through modal agreements such as the International Maritime Dangerous Goods (IMDG) Code for sea transport and the European Agreement concerning the International Carriage of Dangerous Goods by Road (ADR) for land transport. These frameworks classify substances based on their hazard properties, with most LOHC compounds potentially falling under Class 3 (flammable liquids) or Class 9 (miscellaneous dangerous goods).

The International Maritime Organization (IMO) has begun addressing hydrogen carriers specifically through the International Code for the Construction and Equipment of Ships Carrying Liquefied Gases in Bulk (IGC Code), though amendments may be necessary to fully accommodate LOHC technology. Similarly, the International Civil Aviation Organization (ICAO) Technical Instructions govern air transport of potentially hazardous materials.

Regional regulatory bodies have also started developing specific provisions for hydrogen transport technologies. The European Union, through regulations such as the Alternative Fuels Infrastructure Directive (AFID) and the European Hydrogen Strategy, is creating frameworks that may impact LOHC transport. In North America, both the U.S. Department of Transportation's Pipeline and Hazardous Materials Safety Administration (PHMSA) and Transport Canada have begun evaluating regulatory approaches for hydrogen carriers.

A significant challenge in the regulatory landscape is the classification of "spent" or "unloaded" LOHC materials, which may have different hazard profiles than their hydrogen-loaded counterparts. This distinction is not yet clearly addressed in most regulatory frameworks, creating potential compliance uncertainties for operators.

International standardization efforts through organizations like the International Organization for Standardization (ISO) and the International Electrotechnical Commission (IEC) are working to develop technical standards for hydrogen technologies, including TC 197 focusing on hydrogen technologies. These standards will likely influence future regulatory developments for LOHC transport across international boundaries.

Environmental Impact Assessment of LOHC Transport Systems

The environmental impact assessment of LOHC (Liquid Organic Hydrogen Carrier) transport systems reveals both significant advantages and potential concerns compared to conventional hydrogen transport methods. LOHC technology demonstrates a notably reduced carbon footprint across its lifecycle when renewable energy sources power the hydrogenation process. Studies indicate that LOHC systems can achieve up to 70-85% lower greenhouse gas emissions compared to compressed or liquefied hydrogen transport, primarily due to reduced energy requirements for maintaining hydrogen in transportable form.

Water consumption represents another critical environmental consideration, as LOHC systems typically require water for cooling during dehydrogenation processes. However, this consumption is substantially lower than that required for hydrogen production through electrolysis. Recent technological improvements have reduced water requirements by approximately 30% through advanced heat exchange systems and process optimization.

Land use impacts of LOHC transport infrastructure are minimal compared to alternatives like hydrogen pipelines or cryogenic transport systems. The ability to utilize existing liquid fuel infrastructure significantly reduces the need for new construction and associated habitat disruption. Environmental assessments conducted in Europe and Asia demonstrate that LOHC transport can reduce land footprint by 40-60% compared to developing dedicated hydrogen transport networks.

Regarding air quality impacts, LOHC systems exhibit mixed results. While they eliminate direct hydrogen emissions during transport, certain carrier materials may release volatile organic compounds (VOCs) during handling and dehydrogenation. Advanced catalytic systems and improved carrier formulations have reduced these emissions by up to 85% in newer systems, though regulatory monitoring remains essential.

Risk assessment studies highlight the reduced explosion and fire hazards of LOHC compared to pressurized or liquefied hydrogen, translating to lower environmental disaster risk. The stability of LOHC materials at ambient conditions significantly reduces the probability and potential severity of accidental releases that could impact ecosystems.

Life cycle assessments indicate that the environmental sustainability of LOHC systems heavily depends on carrier material selection and recycling protocols. Carriers with longer usable lifespans (exceeding 100 hydrogenation-dehydrogenation cycles) demonstrate superior environmental performance. Current research focuses on developing biodegradable carrier alternatives that maintain performance while reducing end-of-life environmental impacts.

Noise pollution from LOHC transport operations remains comparable to conventional liquid fuel transport, presenting no significant additional environmental burden. This represents an advantage over some alternative hydrogen transport methods that require specialized compression or refrigeration equipment generating higher noise levels.

Water consumption represents another critical environmental consideration, as LOHC systems typically require water for cooling during dehydrogenation processes. However, this consumption is substantially lower than that required for hydrogen production through electrolysis. Recent technological improvements have reduced water requirements by approximately 30% through advanced heat exchange systems and process optimization.

Land use impacts of LOHC transport infrastructure are minimal compared to alternatives like hydrogen pipelines or cryogenic transport systems. The ability to utilize existing liquid fuel infrastructure significantly reduces the need for new construction and associated habitat disruption. Environmental assessments conducted in Europe and Asia demonstrate that LOHC transport can reduce land footprint by 40-60% compared to developing dedicated hydrogen transport networks.

Regarding air quality impacts, LOHC systems exhibit mixed results. While they eliminate direct hydrogen emissions during transport, certain carrier materials may release volatile organic compounds (VOCs) during handling and dehydrogenation. Advanced catalytic systems and improved carrier formulations have reduced these emissions by up to 85% in newer systems, though regulatory monitoring remains essential.

Risk assessment studies highlight the reduced explosion and fire hazards of LOHC compared to pressurized or liquefied hydrogen, translating to lower environmental disaster risk. The stability of LOHC materials at ambient conditions significantly reduces the probability and potential severity of accidental releases that could impact ecosystems.

Life cycle assessments indicate that the environmental sustainability of LOHC systems heavily depends on carrier material selection and recycling protocols. Carriers with longer usable lifespans (exceeding 100 hydrogenation-dehydrogenation cycles) demonstrate superior environmental performance. Current research focuses on developing biodegradable carrier alternatives that maintain performance while reducing end-of-life environmental impacts.

Noise pollution from LOHC transport operations remains comparable to conventional liquid fuel transport, presenting no significant additional environmental burden. This represents an advantage over some alternative hydrogen transport methods that require specialized compression or refrigeration equipment generating higher noise levels.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!