System Control And Monitoring For LOHC Refueling Stations

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LOHC Refueling Technology Background and Objectives

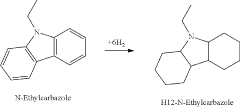

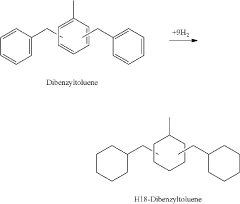

Liquid Organic Hydrogen Carriers (LOHC) technology represents a significant advancement in hydrogen storage and transportation, offering a safer and more efficient alternative to traditional methods. The evolution of LOHC technology began in the early 2000s with fundamental research on chemical hydrogen storage, progressing through laboratory demonstrations to the current phase of commercial implementation. This trajectory aligns with the global push towards hydrogen as a clean energy vector in the transition to low-carbon economies.

The development of LOHC refueling stations marks a critical milestone in hydrogen infrastructure deployment. These stations enable the storage of hydrogen in liquid organic carriers at ambient conditions, eliminating the need for cryogenic temperatures or high-pressure vessels associated with conventional hydrogen storage. The hydrogenation and dehydrogenation processes central to LOHC technology have seen significant improvements in catalyst efficiency and reaction kinetics over the past decade.

System control and monitoring technologies for LOHC refueling stations have evolved from basic manual operations to sophisticated automated systems incorporating advanced sensors, real-time analytics, and predictive maintenance capabilities. This evolution reflects the increasing maturity of the technology and its readiness for wider deployment in commercial and industrial applications.

The primary technical objectives for LOHC refueling station control systems include optimizing the efficiency of hydrogen release processes, ensuring operational safety through comprehensive monitoring, and developing scalable solutions adaptable to various deployment scenarios. Energy efficiency remains a paramount concern, with current research focused on minimizing the energy penalty associated with hydrogen release from the carrier molecules.

Integration with renewable energy sources represents another key objective, as fluctuating power availability necessitates intelligent control systems capable of adapting operation parameters in real-time. This integration is essential for maximizing the environmental benefits of hydrogen as an energy carrier and ensuring economic viability.

Standardization efforts are underway to establish common protocols for system control and monitoring, facilitating interoperability between equipment from different manufacturers and streamlining regulatory compliance. These standards will be crucial for the widespread adoption of LOHC technology across different markets and applications.

The technology trend indicates a movement toward more distributed hydrogen infrastructure, with smaller-scale LOHC refueling stations enabling hydrogen availability in areas previously considered impractical for hydrogen deployment. This decentralization trend necessitates robust remote monitoring capabilities and autonomous operation features in control systems.

The development of LOHC refueling stations marks a critical milestone in hydrogen infrastructure deployment. These stations enable the storage of hydrogen in liquid organic carriers at ambient conditions, eliminating the need for cryogenic temperatures or high-pressure vessels associated with conventional hydrogen storage. The hydrogenation and dehydrogenation processes central to LOHC technology have seen significant improvements in catalyst efficiency and reaction kinetics over the past decade.

System control and monitoring technologies for LOHC refueling stations have evolved from basic manual operations to sophisticated automated systems incorporating advanced sensors, real-time analytics, and predictive maintenance capabilities. This evolution reflects the increasing maturity of the technology and its readiness for wider deployment in commercial and industrial applications.

The primary technical objectives for LOHC refueling station control systems include optimizing the efficiency of hydrogen release processes, ensuring operational safety through comprehensive monitoring, and developing scalable solutions adaptable to various deployment scenarios. Energy efficiency remains a paramount concern, with current research focused on minimizing the energy penalty associated with hydrogen release from the carrier molecules.

Integration with renewable energy sources represents another key objective, as fluctuating power availability necessitates intelligent control systems capable of adapting operation parameters in real-time. This integration is essential for maximizing the environmental benefits of hydrogen as an energy carrier and ensuring economic viability.

Standardization efforts are underway to establish common protocols for system control and monitoring, facilitating interoperability between equipment from different manufacturers and streamlining regulatory compliance. These standards will be crucial for the widespread adoption of LOHC technology across different markets and applications.

The technology trend indicates a movement toward more distributed hydrogen infrastructure, with smaller-scale LOHC refueling stations enabling hydrogen availability in areas previously considered impractical for hydrogen deployment. This decentralization trend necessitates robust remote monitoring capabilities and autonomous operation features in control systems.

Market Analysis for LOHC Refueling Infrastructure

The global market for Liquid Organic Hydrogen Carrier (LOHC) refueling infrastructure is experiencing significant growth, driven by the increasing focus on hydrogen as a clean energy vector. Current market estimates value the hydrogen refueling station market at approximately $500 million, with projections indicating growth to reach $2 billion by 2030. Within this broader market, LOHC technology represents an emerging segment with distinctive advantages over compressed or liquefied hydrogen storage methods.

The demand for LOHC refueling infrastructure is primarily concentrated in regions with strong hydrogen economy initiatives, including Japan, Germany, South Korea, and parts of North America. Japan's strategic hydrogen roadmap has positioned the country as an early adopter, with substantial investments in LOHC technology through companies like Chiyoda Corporation. The European market, particularly Germany, has shown increasing interest, supported by the European Union's hydrogen strategy that allocates €470 billion for hydrogen infrastructure development through 2050.

Industrial sectors represent the most immediate market opportunity for LOHC refueling systems, with material handling, heavy-duty transport, and stationary power applications showing the strongest demand signals. The logistics and transportation sector is anticipated to be a major growth driver, with fleet operators seeking alternatives to battery electric solutions for long-haul operations.

Market penetration analysis reveals that LOHC refueling infrastructure faces competition from established hydrogen technologies, particularly compressed hydrogen (700 bar) stations. However, LOHC systems offer competitive advantages in storage density, safety profile, and compatibility with existing liquid fuel infrastructure, potentially lowering the barrier to market entry in regions with limited hydrogen pipeline networks.

Customer segmentation studies indicate three primary market segments: industrial hydrogen users seeking on-site hydrogen supply, transportation fleet operators requiring distributed refueling capabilities, and energy utilities exploring hydrogen as grid-scale energy storage. Each segment presents distinct requirements for control and monitoring systems, with industrial users prioritizing reliability, transportation operators focusing on refueling speed, and utilities emphasizing integration with existing energy management systems.

The market for LOHC refueling infrastructure exhibits regional variations in adoption patterns. Asia-Pacific leads in deployment volume, while European markets show greater emphasis on standardization and system interoperability. North American adoption has been more selective, focusing on specific use cases such as warehouse operations and port logistics.

Pricing trends suggest that while initial capital expenditure for LOHC refueling stations exceeds that of compressed hydrogen alternatives, the total cost of ownership over a 10-year operational period may be lower due to reduced maintenance requirements and simplified safety systems. This economic proposition strengthens as deployment scale increases, suggesting potential for accelerated market adoption as the technology matures.

The demand for LOHC refueling infrastructure is primarily concentrated in regions with strong hydrogen economy initiatives, including Japan, Germany, South Korea, and parts of North America. Japan's strategic hydrogen roadmap has positioned the country as an early adopter, with substantial investments in LOHC technology through companies like Chiyoda Corporation. The European market, particularly Germany, has shown increasing interest, supported by the European Union's hydrogen strategy that allocates €470 billion for hydrogen infrastructure development through 2050.

Industrial sectors represent the most immediate market opportunity for LOHC refueling systems, with material handling, heavy-duty transport, and stationary power applications showing the strongest demand signals. The logistics and transportation sector is anticipated to be a major growth driver, with fleet operators seeking alternatives to battery electric solutions for long-haul operations.

Market penetration analysis reveals that LOHC refueling infrastructure faces competition from established hydrogen technologies, particularly compressed hydrogen (700 bar) stations. However, LOHC systems offer competitive advantages in storage density, safety profile, and compatibility with existing liquid fuel infrastructure, potentially lowering the barrier to market entry in regions with limited hydrogen pipeline networks.

Customer segmentation studies indicate three primary market segments: industrial hydrogen users seeking on-site hydrogen supply, transportation fleet operators requiring distributed refueling capabilities, and energy utilities exploring hydrogen as grid-scale energy storage. Each segment presents distinct requirements for control and monitoring systems, with industrial users prioritizing reliability, transportation operators focusing on refueling speed, and utilities emphasizing integration with existing energy management systems.

The market for LOHC refueling infrastructure exhibits regional variations in adoption patterns. Asia-Pacific leads in deployment volume, while European markets show greater emphasis on standardization and system interoperability. North American adoption has been more selective, focusing on specific use cases such as warehouse operations and port logistics.

Pricing trends suggest that while initial capital expenditure for LOHC refueling stations exceeds that of compressed hydrogen alternatives, the total cost of ownership over a 10-year operational period may be lower due to reduced maintenance requirements and simplified safety systems. This economic proposition strengthens as deployment scale increases, suggesting potential for accelerated market adoption as the technology matures.

Current Challenges in LOHC System Control

Despite significant advancements in LOHC (Liquid Organic Hydrogen Carrier) technology, the control and monitoring systems for LOHC refueling stations face several critical challenges that impede widespread commercial deployment. The complexity of managing simultaneous hydrogenation and dehydrogenation processes creates substantial control engineering difficulties, particularly in maintaining optimal thermal management across different operational phases.

Temperature regulation represents one of the most significant hurdles, as dehydrogenation reactions require precise high-temperature conditions (typically 150-320°C depending on the carrier), while hydrogenation processes need different thermal profiles. Current control systems struggle to efficiently manage these divergent thermal requirements while minimizing energy consumption, often resulting in suboptimal system efficiency.

Pressure management across the system presents another major challenge. The control systems must precisely regulate pressure during hydrogen release from the carrier while simultaneously managing pressure during storage and transfer operations. Existing pressure control mechanisms lack the responsiveness needed for rapid load changes, creating potential safety concerns and operational inefficiencies during peak demand periods.

Real-time monitoring of hydrogen purity and carrier degradation remains problematic with current sensor technologies. The detection systems frequently experience drift and calibration issues in field conditions, leading to unreliable data for system control decisions. This challenge is particularly acute in detecting trace contaminants that can affect downstream fuel cell performance or catalyst poisoning in the LOHC system itself.

System integration challenges persist between control platforms and various subsystems. The lack of standardized communication protocols between hydrogen processing units, storage systems, and dispensing equipment creates significant interoperability issues. Current control architectures struggle to harmonize operations across these diverse components, resulting in suboptimal system performance and increased maintenance requirements.

Safety monitoring systems face limitations in detecting and responding to abnormal conditions. The current generation of control systems demonstrates inadequate predictive capabilities for identifying potential failure modes before they manifest as operational problems. This reactive rather than proactive approach increases operational risk and reduces system reliability.

Energy efficiency optimization remains a significant control challenge, with current systems unable to dynamically adjust operational parameters based on changing environmental conditions, varying hydrogen demand patterns, and fluctuating energy costs. The inability to implement advanced predictive control algorithms limits the economic viability of LOHC refueling stations in competitive energy markets.

Temperature regulation represents one of the most significant hurdles, as dehydrogenation reactions require precise high-temperature conditions (typically 150-320°C depending on the carrier), while hydrogenation processes need different thermal profiles. Current control systems struggle to efficiently manage these divergent thermal requirements while minimizing energy consumption, often resulting in suboptimal system efficiency.

Pressure management across the system presents another major challenge. The control systems must precisely regulate pressure during hydrogen release from the carrier while simultaneously managing pressure during storage and transfer operations. Existing pressure control mechanisms lack the responsiveness needed for rapid load changes, creating potential safety concerns and operational inefficiencies during peak demand periods.

Real-time monitoring of hydrogen purity and carrier degradation remains problematic with current sensor technologies. The detection systems frequently experience drift and calibration issues in field conditions, leading to unreliable data for system control decisions. This challenge is particularly acute in detecting trace contaminants that can affect downstream fuel cell performance or catalyst poisoning in the LOHC system itself.

System integration challenges persist between control platforms and various subsystems. The lack of standardized communication protocols between hydrogen processing units, storage systems, and dispensing equipment creates significant interoperability issues. Current control architectures struggle to harmonize operations across these diverse components, resulting in suboptimal system performance and increased maintenance requirements.

Safety monitoring systems face limitations in detecting and responding to abnormal conditions. The current generation of control systems demonstrates inadequate predictive capabilities for identifying potential failure modes before they manifest as operational problems. This reactive rather than proactive approach increases operational risk and reduces system reliability.

Energy efficiency optimization remains a significant control challenge, with current systems unable to dynamically adjust operational parameters based on changing environmental conditions, varying hydrogen demand patterns, and fluctuating energy costs. The inability to implement advanced predictive control algorithms limits the economic viability of LOHC refueling stations in competitive energy markets.

Existing Control Solutions for LOHC Stations

01 Industrial Control Systems and Automation

Industrial control systems involve the integration of hardware and software components to monitor and control industrial processes. These systems typically include programmable logic controllers (PLCs), distributed control systems, and SCADA (Supervisory Control and Data Acquisition) systems. They enable real-time monitoring, data collection, and automated control of manufacturing processes, improving efficiency and reducing human intervention in industrial environments.- Network-based control and monitoring systems: These systems utilize network infrastructure for remote control and monitoring of various devices and processes. They enable real-time data transmission across distributed systems, allowing for centralized management and oversight. The technology incorporates communication protocols that facilitate seamless interaction between different components of the system, enhancing operational efficiency and providing comprehensive monitoring capabilities across various industrial and commercial applications.

- Automated surveillance and security monitoring: Systems designed for automated surveillance and security monitoring incorporate video analytics, image processing, and pattern recognition technologies. These systems can detect unusual activities, track objects or individuals, and generate alerts for security breaches. They often include features for recording and storing surveillance data, enabling both real-time monitoring and retrospective analysis of security incidents.

- Industrial process control systems: These systems are specifically designed for monitoring and controlling industrial processes and manufacturing operations. They incorporate sensors, actuators, and control algorithms to maintain optimal operating conditions, ensure product quality, and enhance production efficiency. The technology enables automated responses to process variations, predictive maintenance capabilities, and integration with enterprise resource planning systems for comprehensive industrial management.

- Energy management and smart grid systems: Systems focused on monitoring and optimizing energy consumption across various applications, including smart grid technologies. These systems collect and analyze energy usage data, implement load balancing strategies, and enable automated control of energy-consuming devices. They incorporate features for demand response, renewable energy integration, and predictive analytics to enhance energy efficiency and reduce operational costs.

- Cloud-based monitoring and control platforms: These platforms leverage cloud computing technologies to provide scalable, flexible monitoring and control capabilities. They enable data storage, processing, and analysis in the cloud, facilitating access from multiple locations and devices. The technology incorporates features for data visualization, remote system management, and integration with various IoT devices, supporting applications ranging from building automation to distributed industrial control systems.

02 Network-based Monitoring and Control Systems

Network-based monitoring and control systems utilize communication networks to enable remote monitoring and control of various devices and processes. These systems typically employ protocols such as TCP/IP, wireless networks, or industrial Ethernet to facilitate data exchange between control centers and field devices. They allow for centralized management of distributed systems, real-time data collection, and remote diagnostics, making them particularly valuable for geographically dispersed operations.Expand Specific Solutions03 Smart Building Management Systems

Smart building management systems integrate various building functions such as HVAC (heating, ventilation, and air conditioning), lighting, security, and energy management into a unified control platform. These systems utilize sensors, controllers, and software to optimize building operations, enhance occupant comfort, and reduce energy consumption. They often incorporate features like automated scheduling, occupancy detection, and predictive maintenance to improve building efficiency and sustainability.Expand Specific Solutions04 Video Surveillance and Security Monitoring Systems

Video surveillance and security monitoring systems combine cameras, sensors, and software to provide comprehensive security solutions. These systems enable real-time monitoring of premises, automated threat detection, and recording of security events. Advanced implementations incorporate features such as facial recognition, motion detection, and integration with access control systems. They play a crucial role in protecting assets, ensuring safety, and providing forensic evidence when security incidents occur.Expand Specific Solutions05 Distributed Control Systems for Critical Infrastructure

Distributed control systems for critical infrastructure provide robust monitoring and control capabilities for essential services such as power grids, water treatment facilities, and transportation networks. These systems are designed with redundancy, fault tolerance, and security features to ensure continuous operation of vital services. They typically incorporate advanced analytics for predictive maintenance, anomaly detection, and optimization of resource allocation, helping to prevent service disruptions and improve overall reliability.Expand Specific Solutions

Key Industry Players in LOHC Refueling

The LOHC refueling station control and monitoring technology market is in its early growth phase, characterized by increasing investments as hydrogen gains traction as a clean energy carrier. The global market is projected to expand significantly with the hydrogen economy, estimated to reach several billion dollars by 2030. Technologically, the field shows varying maturity levels, with established energy companies like Sinopec, Air Liquide, and ENEOS developing advanced systems, while specialized firms such as Shanghai Sunwise, Changchun Jidian, and Korea Tatsuno focus on integration solutions. Major automotive players including Hyundai, Kia, and Boeing are investing in compatible technologies to support hydrogen mobility applications. The competitive landscape features collaboration between traditional energy infrastructure providers and emerging hydrogen specialists to overcome technical challenges in safe, efficient hydrogen handling.

China Petroleum & Chemical Corp.

Technical Solution: Sinopec (China Petroleum & Chemical Corp.) has engineered a comprehensive LOHC refueling station control system that leverages their extensive experience in conventional fuel distribution infrastructure. Their solution features a hierarchical control architecture with three distinct layers: field-level instrumentation, process control, and management supervision. The system implements advanced process control algorithms that optimize the hydrogenation and dehydrogenation cycles based on real-time catalyst performance monitoring, achieving hydrogen release efficiencies of up to 95%. Sinopec's platform incorporates dual redundant controllers with automatic failover capabilities and integrates with their enterprise resource planning systems for streamlined logistics management. The monitoring system employs fiber optic sensing technology for distributed temperature and strain measurements along LOHC storage tanks and transfer lines, providing early detection of potential integrity issues. Their solution also includes proprietary vapor recovery systems that minimize emissions during the refueling process, with reported recovery rates exceeding 99.5% of hydrogen compounds.

Strengths: Extensive experience in fuel distribution infrastructure; strong integration with existing supply chain systems; robust safety protocols developed from decades of handling hazardous materials. Weaknesses: System designed primarily for large-scale operations, potentially less cost-effective for smaller deployments; relatively new to hydrogen-specific technologies compared to specialized hydrogen companies.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai has developed an integrated control and monitoring system specifically for LOHC refueling stations that complements their hydrogen vehicle ecosystem. Their solution employs a centralized control architecture with distributed I/O modules that monitor over 200 process variables throughout the hydrogen release and dispensing process. The system features Hyundai's proprietary HydroLogic™ software that implements model predictive control algorithms to optimize the thermal management during dehydrogenation, reducing energy consumption by approximately 25% compared to conventional PID control methods. Hyundai's platform incorporates machine learning capabilities that adapt to changing environmental conditions and catalyst degradation patterns, maintaining optimal performance throughout equipment lifecycle. The monitoring system includes advanced leak detection using ultrasonic sensors with triangulation capabilities that can pinpoint hydrogen leaks with sub-centimeter accuracy. Their user interface provides intuitive visualization of system status with augmented reality capabilities for maintenance personnel, reducing diagnostic time by up to 40% according to field tests.

Strengths: Seamless integration with Hyundai's hydrogen vehicle ecosystem; advanced thermal management algorithms specifically optimized for automotive refueling applications; extensive field testing with actual hydrogen vehicles. Weaknesses: System optimized primarily for passenger vehicle refueling rather than industrial applications; relatively limited deployment experience compared to industrial gas specialists.

Core Monitoring Technologies for LOHC Systems

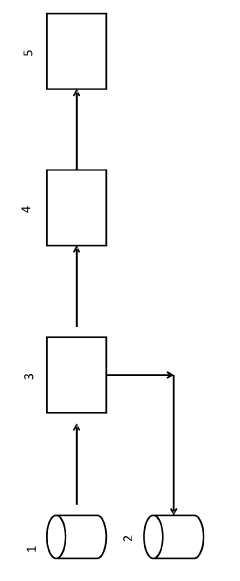

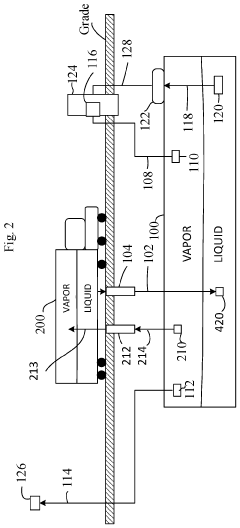

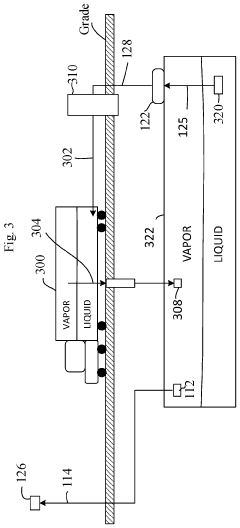

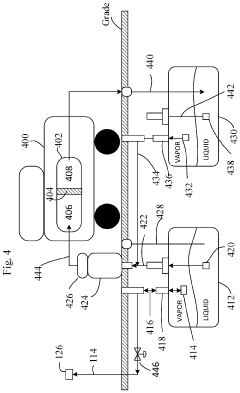

Arrangement and method for operating hydrogen filling stations

PatentActiveUS10260680B2

Innovation

- The use of Liquid Organic Hydrogen Carriers (LOHCs) for storing hydrogen, which are chemically bound and can be reversibly converted to release hydrogen at ambient temperatures and pressures, allowing for safe and efficient storage and delivery using existing infrastructure.

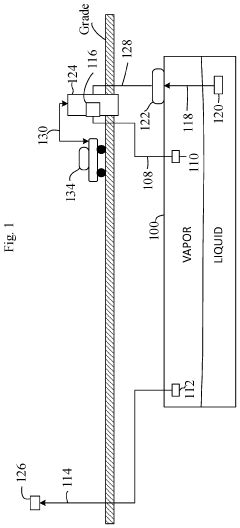

Fueling station for supply of liquid organic hydrogen carriers and method of operation

PatentInactiveUS20220349525A1

Innovation

- A modular fueling station system that supplies and recycles LOHC, featuring separate storage vessels for fresh and spent LOHC, a dehydrogenation reaction zone, hydrogen purification, and a vapor recovery system to manage vapor pressure and prevent fuel vapor release, enabling efficient and carbon-neutral transfer of LOHC between vehicles and fueling stations.

Safety Standards for Hydrogen Carrier Technologies

The safety standards for Liquid Organic Hydrogen Carrier (LOHC) technologies represent a critical framework for ensuring the safe operation of hydrogen refueling stations. These standards must address the unique characteristics of LOHC systems, which differ significantly from conventional hydrogen storage methods. International organizations such as ISO, IEC, and national regulatory bodies have established comprehensive guidelines that specifically target hydrogen carrier technologies.

For LOHC refueling stations, safety standards primarily focus on three key areas: material compatibility, operational procedures, and emergency response protocols. Material compatibility standards ensure that all components in contact with the hydrogen carrier can withstand the chemical properties of the specific LOHC being used, preventing degradation that could lead to leaks or system failures. These standards typically specify acceptable materials for pipes, valves, seals, and storage vessels.

Operational safety standards for LOHC systems address the thermal management requirements during hydrogen loading and unloading processes. Since these reactions involve significant heat exchange, standards specify temperature monitoring requirements, heat exchanger specifications, and cooling system parameters. Additionally, they establish limits for operating pressures, flow rates, and catalyst exposure conditions to prevent runaway reactions or system overloading.

Monitoring and control system standards for LOHC refueling stations mandate redundant safety systems, including hydrogen detection sensors, pressure relief mechanisms, and emergency shutdown capabilities. These standards typically require continuous monitoring of critical parameters such as temperature, pressure, flow rates, and hydrogen concentration levels in surrounding areas. The IEC 61508 functional safety standard is particularly relevant for the electronic control systems managing these safety functions.

Risk assessment methodologies specific to LOHC technologies have been developed, incorporating HAZOP (Hazard and Operability) studies and LOPA (Layer of Protection Analysis) approaches tailored to the unique characteristics of organic carrier systems. These methodologies help identify potential failure modes and establish appropriate safety integrity levels for critical control functions.

Certification requirements for LOHC refueling stations typically involve third-party verification of compliance with applicable standards. This includes inspection of design documentation, witnessing of factory acceptance tests, and on-site commissioning tests. Periodic recertification is generally required, with intervals determined by risk assessment outcomes and local regulatory requirements.

As LOHC technology continues to evolve, safety standards are being updated to address emerging concerns and incorporate lessons learned from early implementations. International harmonization efforts are underway to establish consistent global standards, facilitating wider adoption of this promising hydrogen storage and transport technology.

For LOHC refueling stations, safety standards primarily focus on three key areas: material compatibility, operational procedures, and emergency response protocols. Material compatibility standards ensure that all components in contact with the hydrogen carrier can withstand the chemical properties of the specific LOHC being used, preventing degradation that could lead to leaks or system failures. These standards typically specify acceptable materials for pipes, valves, seals, and storage vessels.

Operational safety standards for LOHC systems address the thermal management requirements during hydrogen loading and unloading processes. Since these reactions involve significant heat exchange, standards specify temperature monitoring requirements, heat exchanger specifications, and cooling system parameters. Additionally, they establish limits for operating pressures, flow rates, and catalyst exposure conditions to prevent runaway reactions or system overloading.

Monitoring and control system standards for LOHC refueling stations mandate redundant safety systems, including hydrogen detection sensors, pressure relief mechanisms, and emergency shutdown capabilities. These standards typically require continuous monitoring of critical parameters such as temperature, pressure, flow rates, and hydrogen concentration levels in surrounding areas. The IEC 61508 functional safety standard is particularly relevant for the electronic control systems managing these safety functions.

Risk assessment methodologies specific to LOHC technologies have been developed, incorporating HAZOP (Hazard and Operability) studies and LOPA (Layer of Protection Analysis) approaches tailored to the unique characteristics of organic carrier systems. These methodologies help identify potential failure modes and establish appropriate safety integrity levels for critical control functions.

Certification requirements for LOHC refueling stations typically involve third-party verification of compliance with applicable standards. This includes inspection of design documentation, witnessing of factory acceptance tests, and on-site commissioning tests. Periodic recertification is generally required, with intervals determined by risk assessment outcomes and local regulatory requirements.

As LOHC technology continues to evolve, safety standards are being updated to address emerging concerns and incorporate lessons learned from early implementations. International harmonization efforts are underway to establish consistent global standards, facilitating wider adoption of this promising hydrogen storage and transport technology.

Integration with Smart Grid Infrastructure

The integration of LOHC refueling stations with smart grid infrastructure represents a critical advancement in sustainable energy systems. Smart grids, characterized by their bidirectional communication capabilities and distributed intelligence, offer significant opportunities for optimizing the operation of LOHC facilities. By establishing seamless connectivity between refueling stations and the broader energy network, operators can achieve enhanced energy efficiency, cost reduction, and grid stability.

LOHC refueling stations can function as flexible loads within the smart grid ecosystem, adjusting their energy consumption patterns in response to grid conditions. During periods of excess renewable energy generation, these stations can increase their hydrogen production and LOHC hydrogenation activities, effectively serving as energy storage mechanisms. Conversely, during peak demand periods, operations can be scaled back to reduce strain on the grid, potentially even releasing stored energy back into the network.

Advanced metering infrastructure (AMI) serves as the foundation for this integration, providing real-time data exchange between refueling stations and grid operators. This enables participation in demand response programs, where stations receive financial incentives for adjusting their energy consumption based on grid requirements. The implementation of energy management systems (EMS) within LOHC facilities further enhances this capability by optimizing operational schedules according to electricity pricing signals and grid carbon intensity.

Cybersecurity considerations are paramount in this integration process. The increased connectivity between LOHC stations and grid infrastructure creates potential vulnerabilities that must be addressed through robust security protocols, encryption standards, and regular security audits. Industry standards such as IEC 62351 for power systems management and IEEE 2030 for smart grid interoperability provide essential frameworks for secure implementation.

The economic benefits of smart grid integration extend beyond operational efficiency. LOHC stations can generate additional revenue streams through grid services such as frequency regulation, voltage support, and capacity market participation. These value-stacking opportunities significantly improve the business case for LOHC technology deployment, accelerating market adoption and infrastructure development.

Future developments in this domain will likely focus on enhanced predictive capabilities through artificial intelligence and machine learning algorithms. These technologies will enable more sophisticated forecasting of energy availability, pricing fluctuations, and hydrogen demand patterns, further optimizing the symbiotic relationship between LOHC refueling stations and smart grid infrastructure.

LOHC refueling stations can function as flexible loads within the smart grid ecosystem, adjusting their energy consumption patterns in response to grid conditions. During periods of excess renewable energy generation, these stations can increase their hydrogen production and LOHC hydrogenation activities, effectively serving as energy storage mechanisms. Conversely, during peak demand periods, operations can be scaled back to reduce strain on the grid, potentially even releasing stored energy back into the network.

Advanced metering infrastructure (AMI) serves as the foundation for this integration, providing real-time data exchange between refueling stations and grid operators. This enables participation in demand response programs, where stations receive financial incentives for adjusting their energy consumption based on grid requirements. The implementation of energy management systems (EMS) within LOHC facilities further enhances this capability by optimizing operational schedules according to electricity pricing signals and grid carbon intensity.

Cybersecurity considerations are paramount in this integration process. The increased connectivity between LOHC stations and grid infrastructure creates potential vulnerabilities that must be addressed through robust security protocols, encryption standards, and regular security audits. Industry standards such as IEC 62351 for power systems management and IEEE 2030 for smart grid interoperability provide essential frameworks for secure implementation.

The economic benefits of smart grid integration extend beyond operational efficiency. LOHC stations can generate additional revenue streams through grid services such as frequency regulation, voltage support, and capacity market participation. These value-stacking opportunities significantly improve the business case for LOHC technology deployment, accelerating market adoption and infrastructure development.

Future developments in this domain will likely focus on enhanced predictive capabilities through artificial intelligence and machine learning algorithms. These technologies will enable more sophisticated forecasting of energy availability, pricing fluctuations, and hydrogen demand patterns, further optimizing the symbiotic relationship between LOHC refueling stations and smart grid infrastructure.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!