Liquid Organic Hydrogen Carriers: System Principles And Use Cases

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LOHC Technology Background and Objectives

Liquid Organic Hydrogen Carriers (LOHCs) represent a transformative approach to hydrogen storage and transportation that has evolved significantly over the past decades. The concept originated in the 1980s but gained substantial momentum in the early 2000s as the global focus on decarbonization intensified. LOHCs function through reversible hydrogenation-dehydrogenation reactions of organic compounds, enabling hydrogen to be chemically bound to liquid carriers under ambient conditions, thus overcoming the traditional challenges of hydrogen's low volumetric energy density.

The technological evolution of LOHCs has progressed through several distinct phases. Initially, research focused on identifying suitable carrier molecules with optimal hydrogen storage capacity and favorable thermodynamic properties. This was followed by developments in catalytic systems to enhance the efficiency of hydrogenation and dehydrogenation processes. Recent advancements have concentrated on system integration and process optimization to improve energy efficiency and economic viability.

Current LOHC systems typically employ aromatic compounds such as toluene/methylcyclohexane, dibenzyltoluene, or N-ethylcarbazole as carrier molecules. These carriers can store approximately 5-7 weight percent hydrogen, representing a significant improvement over compressed or liquefied hydrogen in terms of volumetric energy density and safety. The technology's appeal lies in its compatibility with existing liquid fuel infrastructure, potentially enabling a smoother transition to hydrogen-based energy systems.

The primary objective of LOHC technology development is to establish a cost-effective, safe, and efficient hydrogen vector that facilitates the integration of hydrogen into the global energy landscape. Specific technical goals include improving the energy efficiency of the dehydrogenation process, which currently represents a significant energy penalty, developing more selective and durable catalysts, and optimizing system components for various application scenarios.

Looking forward, the technology trajectory for LOHCs is expected to focus on several key areas: enhancing catalyst performance to reduce operating temperatures and improve reaction kinetics; developing novel carrier molecules with superior thermodynamic properties; advancing system integration for specific use cases such as maritime applications, grid-scale energy storage, and hydrogen distribution networks; and improving overall system economics through process intensification and scale-up.

The ultimate aim is to position LOHCs as a cornerstone technology in the hydrogen economy, bridging renewable energy production with diverse end-use applications while addressing the critical challenges of hydrogen storage and transportation that have historically limited widespread hydrogen adoption.

The technological evolution of LOHCs has progressed through several distinct phases. Initially, research focused on identifying suitable carrier molecules with optimal hydrogen storage capacity and favorable thermodynamic properties. This was followed by developments in catalytic systems to enhance the efficiency of hydrogenation and dehydrogenation processes. Recent advancements have concentrated on system integration and process optimization to improve energy efficiency and economic viability.

Current LOHC systems typically employ aromatic compounds such as toluene/methylcyclohexane, dibenzyltoluene, or N-ethylcarbazole as carrier molecules. These carriers can store approximately 5-7 weight percent hydrogen, representing a significant improvement over compressed or liquefied hydrogen in terms of volumetric energy density and safety. The technology's appeal lies in its compatibility with existing liquid fuel infrastructure, potentially enabling a smoother transition to hydrogen-based energy systems.

The primary objective of LOHC technology development is to establish a cost-effective, safe, and efficient hydrogen vector that facilitates the integration of hydrogen into the global energy landscape. Specific technical goals include improving the energy efficiency of the dehydrogenation process, which currently represents a significant energy penalty, developing more selective and durable catalysts, and optimizing system components for various application scenarios.

Looking forward, the technology trajectory for LOHCs is expected to focus on several key areas: enhancing catalyst performance to reduce operating temperatures and improve reaction kinetics; developing novel carrier molecules with superior thermodynamic properties; advancing system integration for specific use cases such as maritime applications, grid-scale energy storage, and hydrogen distribution networks; and improving overall system economics through process intensification and scale-up.

The ultimate aim is to position LOHCs as a cornerstone technology in the hydrogen economy, bridging renewable energy production with diverse end-use applications while addressing the critical challenges of hydrogen storage and transportation that have historically limited widespread hydrogen adoption.

Market Demand Analysis for Hydrogen Storage Solutions

The global hydrogen storage market is experiencing significant growth, driven by the increasing focus on clean energy solutions and the transition away from fossil fuels. Current market valuations place the hydrogen storage sector at approximately 250 billion USD, with projections indicating a compound annual growth rate of 11-13% through 2030. This growth trajectory is primarily fueled by governmental commitments to carbon neutrality and substantial investments in hydrogen infrastructure across Europe, Asia, and North America.

Liquid Organic Hydrogen Carriers (LOHCs) represent a particularly promising segment within this market, addressing critical limitations of conventional hydrogen storage methods. Traditional compressed or liquefied hydrogen storage faces challenges including high energy requirements, safety concerns, and infrastructure limitations. LOHCs offer solutions to these issues by enabling hydrogen to be stored in ambient conditions, significantly reducing both storage costs and safety risks.

Industrial sectors demonstrate the strongest demand for advanced hydrogen storage solutions, with heavy manufacturing, steel production, and chemical processing leading adoption. These industries require large-scale, reliable hydrogen storage systems that can integrate with existing infrastructure while minimizing operational disruptions. The transportation sector follows closely, with maritime shipping, long-haul trucking, and aviation exploring hydrogen as an alternative fuel source, creating substantial demand for efficient storage technologies like LOHCs.

Regional analysis reveals varying market dynamics. Europe leads in LOHC technology adoption, supported by aggressive decarbonization policies and substantial research funding. Japan and South Korea demonstrate strong market potential due to their limited domestic energy resources and strategic hydrogen roadmaps. China is rapidly expanding its hydrogen infrastructure, creating significant opportunities for storage solutions that can scale efficiently.

End-user surveys indicate that cost efficiency remains the primary consideration in hydrogen storage technology adoption, followed by safety features and integration capabilities with existing systems. LOHCs address these concerns effectively, positioning them favorably against competing technologies such as metal hydrides and underground storage.

Market forecasts suggest that the LOHC segment specifically could capture 20-25% of the overall hydrogen storage market by 2030, representing a substantial opportunity for technology developers and implementers. This growth is contingent upon continued improvements in carrier efficiency, catalyst development, and system integration capabilities.

The market landscape is further shaped by emerging applications in grid-scale energy storage, where hydrogen serves as a medium for long-duration storage to complement intermittent renewable energy sources. This application alone could drive significant demand for LOHC systems capable of efficient energy storage and release cycles.

Liquid Organic Hydrogen Carriers (LOHCs) represent a particularly promising segment within this market, addressing critical limitations of conventional hydrogen storage methods. Traditional compressed or liquefied hydrogen storage faces challenges including high energy requirements, safety concerns, and infrastructure limitations. LOHCs offer solutions to these issues by enabling hydrogen to be stored in ambient conditions, significantly reducing both storage costs and safety risks.

Industrial sectors demonstrate the strongest demand for advanced hydrogen storage solutions, with heavy manufacturing, steel production, and chemical processing leading adoption. These industries require large-scale, reliable hydrogen storage systems that can integrate with existing infrastructure while minimizing operational disruptions. The transportation sector follows closely, with maritime shipping, long-haul trucking, and aviation exploring hydrogen as an alternative fuel source, creating substantial demand for efficient storage technologies like LOHCs.

Regional analysis reveals varying market dynamics. Europe leads in LOHC technology adoption, supported by aggressive decarbonization policies and substantial research funding. Japan and South Korea demonstrate strong market potential due to their limited domestic energy resources and strategic hydrogen roadmaps. China is rapidly expanding its hydrogen infrastructure, creating significant opportunities for storage solutions that can scale efficiently.

End-user surveys indicate that cost efficiency remains the primary consideration in hydrogen storage technology adoption, followed by safety features and integration capabilities with existing systems. LOHCs address these concerns effectively, positioning them favorably against competing technologies such as metal hydrides and underground storage.

Market forecasts suggest that the LOHC segment specifically could capture 20-25% of the overall hydrogen storage market by 2030, representing a substantial opportunity for technology developers and implementers. This growth is contingent upon continued improvements in carrier efficiency, catalyst development, and system integration capabilities.

The market landscape is further shaped by emerging applications in grid-scale energy storage, where hydrogen serves as a medium for long-duration storage to complement intermittent renewable energy sources. This application alone could drive significant demand for LOHC systems capable of efficient energy storage and release cycles.

LOHC Technical Status and Challenges

Liquid Organic Hydrogen Carriers (LOHCs) represent a promising technology for hydrogen storage and transportation, yet face significant technical challenges across the global landscape. Currently, the technology readiness level (TRL) of LOHC systems varies between 6-8, with commercial demonstrations emerging but widespread adoption still limited. The most advanced implementations can be found in Germany, Japan, and Australia, where pilot projects have demonstrated the feasibility of LOHC-based hydrogen logistics chains.

A primary technical challenge lies in the energy efficiency of the overall LOHC cycle. The hydrogenation process is exothermic and relatively efficient, but dehydrogenation requires substantial energy input, typically demanding temperatures between 150-320°C depending on the carrier molecule. This thermal energy requirement significantly impacts the round-trip efficiency, which currently ranges from 30-65% depending on system configuration and heat recovery implementation.

Catalyst development represents another critical challenge. While hydrogenation catalysts (typically based on ruthenium or nickel) have reached reasonable maturity, dehydrogenation catalysts still struggle with longevity issues under industrial conditions. Catalyst poisoning, thermal degradation, and coking remain persistent problems that reduce operational lifetimes and increase system costs.

The carrier molecules themselves present technical limitations. Current commercial carriers like dibenzyl toluene, methylcyclohexane, and decalin offer hydrogen capacities of 5-7 wt%, but theoretical analysis suggests capacities up to 8-9 wt% might be achievable with novel carrier designs. Additionally, carrier stability over multiple cycles needs improvement, as degradation products accumulate and reduce system performance after 100-500 cycles in real-world conditions.

Infrastructure compatibility presents significant integration challenges. Most existing LOHC systems require specialized handling equipment and are not fully compatible with current liquid fuel infrastructure. Material compatibility issues with certain elastomers and metals in conventional fuel systems necessitate modifications or alternative materials for long-term deployment.

Geographically, LOHC research centers are concentrated in Germany (Erlangen-Nuremberg), Japan (led by Chiyoda Corporation), and Australia (CSIRO), with emerging activities in South Korea and China. The technology distribution reflects strategic national interests in hydrogen economies, with countries lacking natural gas infrastructure showing particular interest in LOHC as an alternative hydrogen vector.

Regulatory frameworks and safety standards for large-scale LOHC deployment remain underdeveloped in most jurisdictions, creating uncertainty for commercial implementation and international transport applications.

A primary technical challenge lies in the energy efficiency of the overall LOHC cycle. The hydrogenation process is exothermic and relatively efficient, but dehydrogenation requires substantial energy input, typically demanding temperatures between 150-320°C depending on the carrier molecule. This thermal energy requirement significantly impacts the round-trip efficiency, which currently ranges from 30-65% depending on system configuration and heat recovery implementation.

Catalyst development represents another critical challenge. While hydrogenation catalysts (typically based on ruthenium or nickel) have reached reasonable maturity, dehydrogenation catalysts still struggle with longevity issues under industrial conditions. Catalyst poisoning, thermal degradation, and coking remain persistent problems that reduce operational lifetimes and increase system costs.

The carrier molecules themselves present technical limitations. Current commercial carriers like dibenzyl toluene, methylcyclohexane, and decalin offer hydrogen capacities of 5-7 wt%, but theoretical analysis suggests capacities up to 8-9 wt% might be achievable with novel carrier designs. Additionally, carrier stability over multiple cycles needs improvement, as degradation products accumulate and reduce system performance after 100-500 cycles in real-world conditions.

Infrastructure compatibility presents significant integration challenges. Most existing LOHC systems require specialized handling equipment and are not fully compatible with current liquid fuel infrastructure. Material compatibility issues with certain elastomers and metals in conventional fuel systems necessitate modifications or alternative materials for long-term deployment.

Geographically, LOHC research centers are concentrated in Germany (Erlangen-Nuremberg), Japan (led by Chiyoda Corporation), and Australia (CSIRO), with emerging activities in South Korea and China. The technology distribution reflects strategic national interests in hydrogen economies, with countries lacking natural gas infrastructure showing particular interest in LOHC as an alternative hydrogen vector.

Regulatory frameworks and safety standards for large-scale LOHC deployment remain underdeveloped in most jurisdictions, creating uncertainty for commercial implementation and international transport applications.

Current LOHC System Implementation Solutions

01 LOHC synthesis and composition

Liquid Organic Hydrogen Carriers (LOHCs) are compounds specifically designed for hydrogen storage and transport. These carriers typically consist of organic molecules that can reversibly bind and release hydrogen through hydrogenation and dehydrogenation reactions. Various chemical compositions are used as LOHCs, including aromatic compounds, heterocyclic compounds, and nitrogen-containing organic molecules. The synthesis methods focus on creating carriers with high hydrogen storage capacity, stability, and favorable thermodynamic properties.- LOHC synthesis and composition: Liquid Organic Hydrogen Carriers (LOHCs) are compounds specifically designed for hydrogen storage and transport. These carriers typically consist of organic molecules that can reversibly bind and release hydrogen through hydrogenation and dehydrogenation reactions. Various chemical compositions have been developed, including aromatic compounds, heterocyclic compounds, and nitrogen-containing organic molecules, each offering different hydrogen storage capacities and operating conditions.

- Hydrogen loading and unloading systems: Systems for efficient hydrogen loading (hydrogenation) and unloading (dehydrogenation) are critical components of LOHC technology. These systems typically involve catalytic reactors operating under specific temperature and pressure conditions. Advanced catalyst designs enhance reaction kinetics and selectivity, while heat management systems optimize energy efficiency during the endothermic dehydrogenation process. Innovations in reactor design and process integration have improved the overall efficiency of hydrogen release from LOHCs.

- LOHC transportation and storage infrastructure: Infrastructure for LOHC transportation and storage leverages existing liquid fuel logistics networks, offering advantages over compressed or liquefied hydrogen. These systems include specialized containers, pumping equipment, and safety mechanisms designed for handling hydrogen-loaded organic carriers. Innovations focus on minimizing carrier losses, preventing contamination, and ensuring long-term stability during storage periods. Integration with existing fuel distribution networks enables cost-effective hydrogen delivery across various distances.

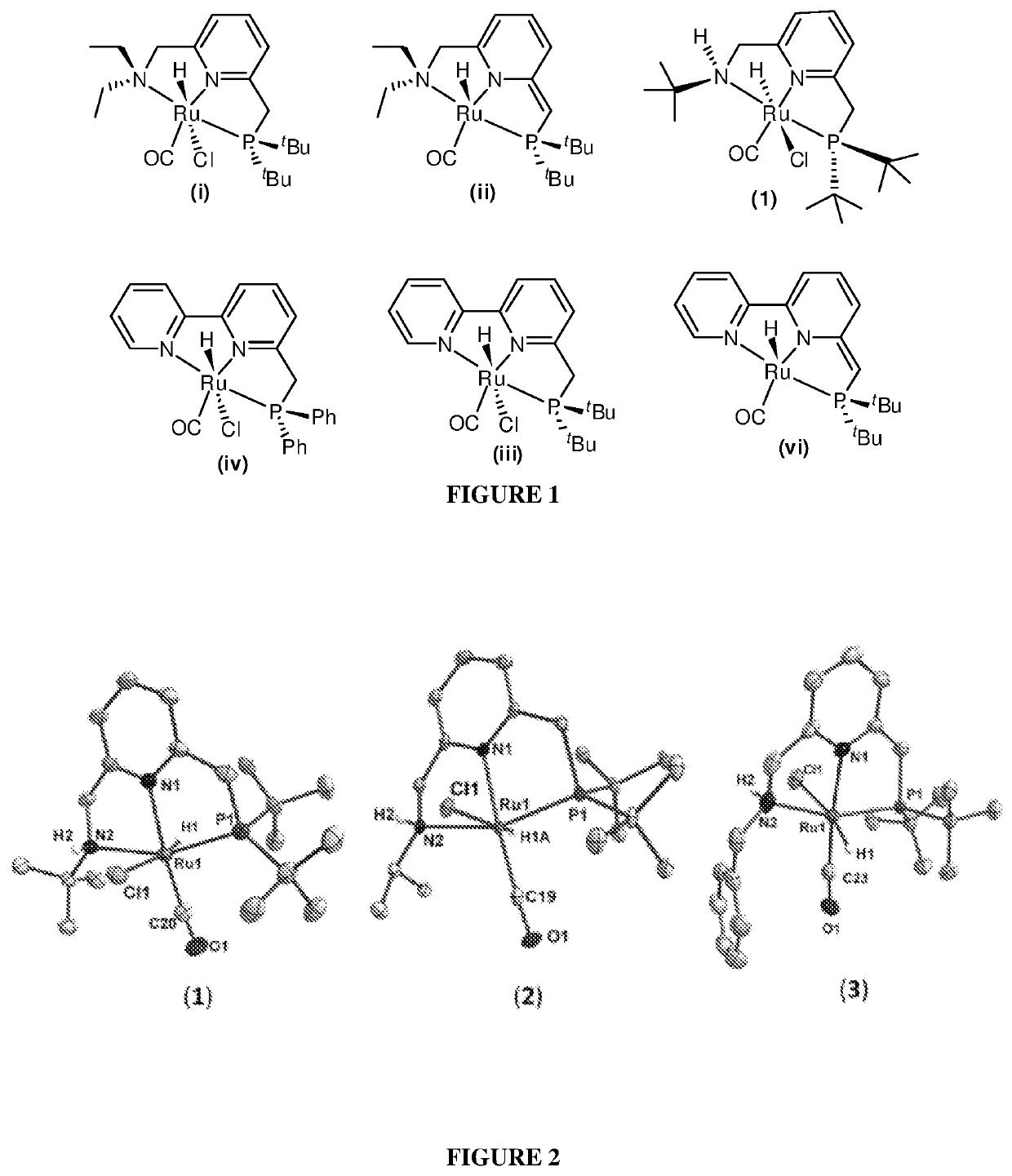

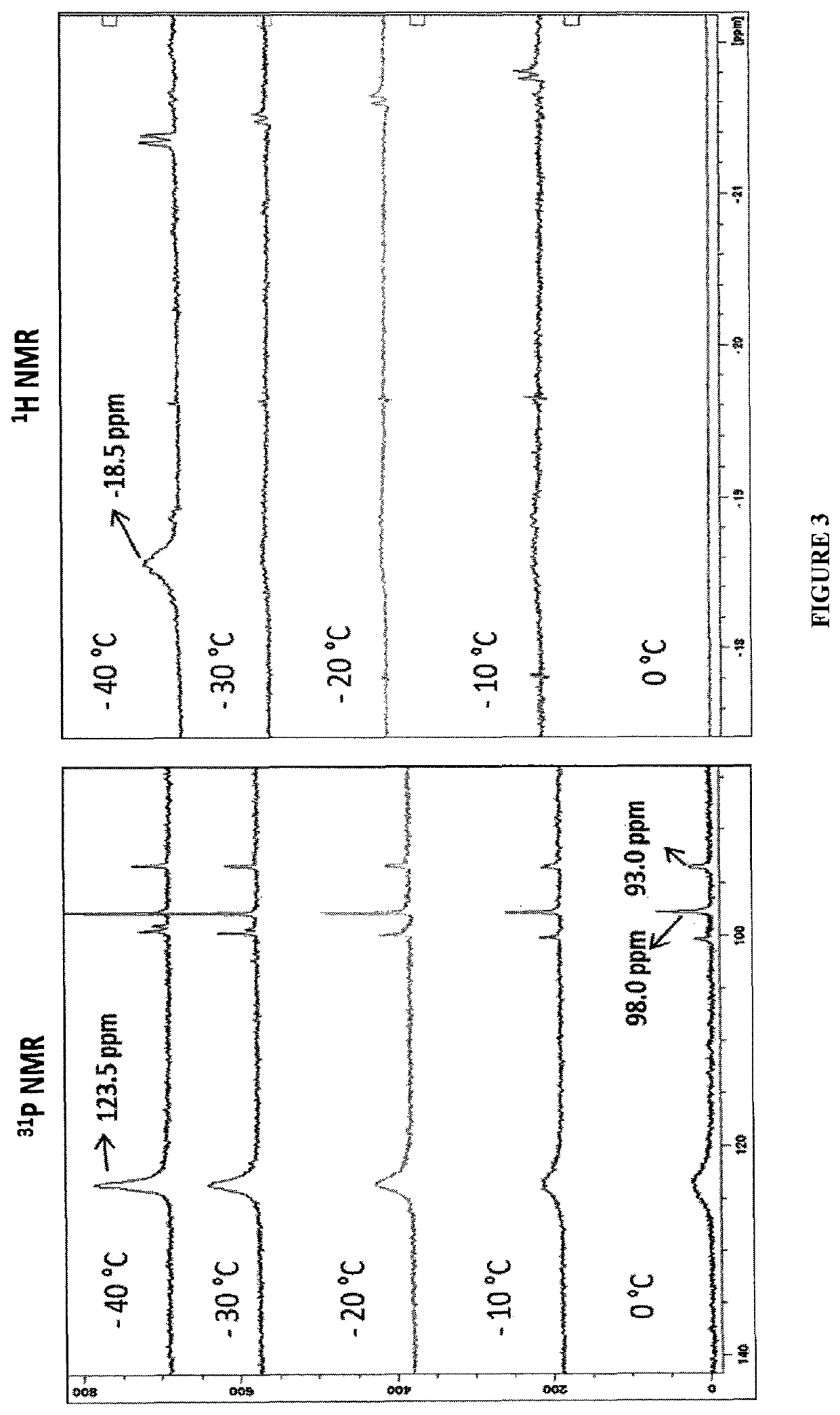

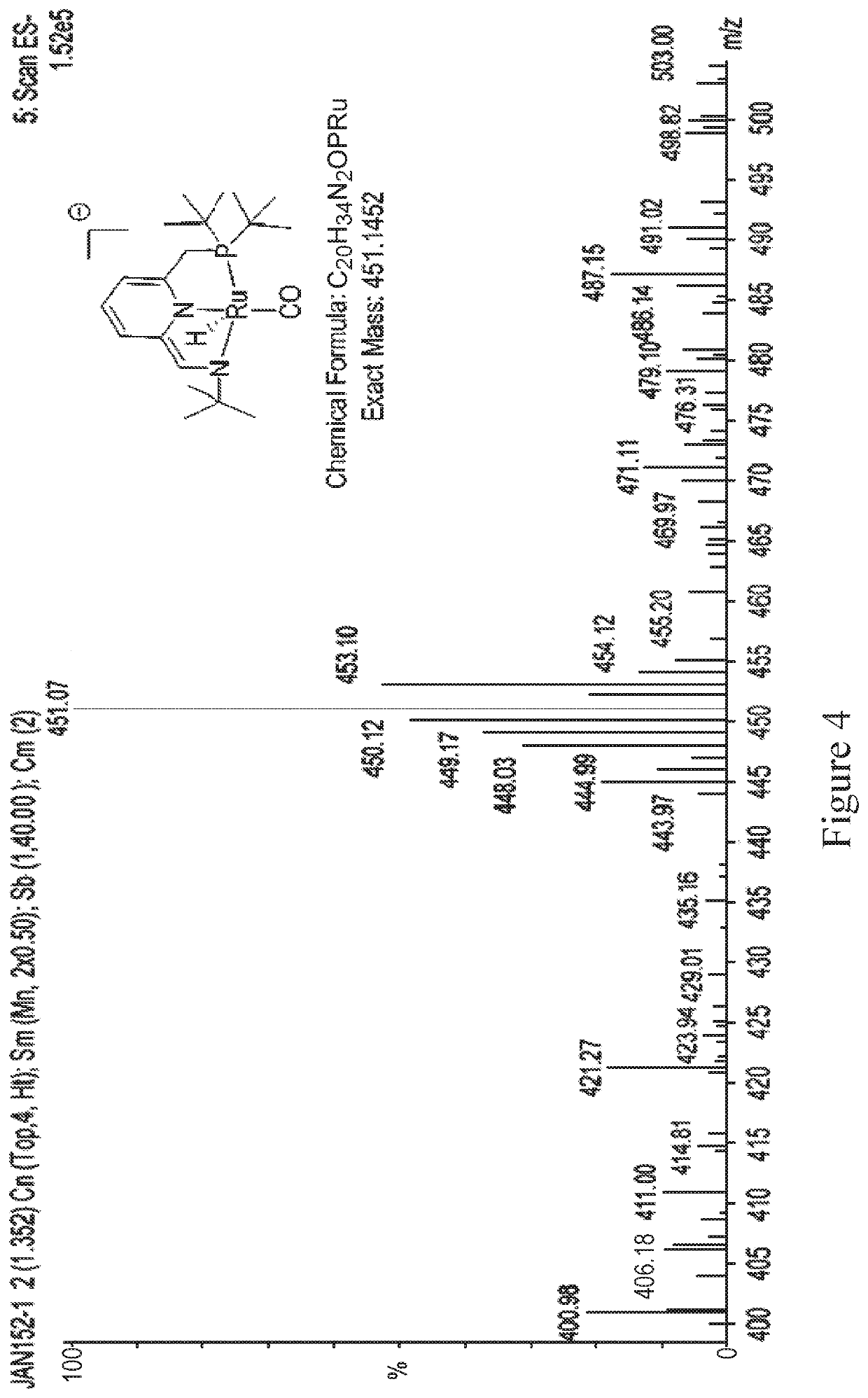

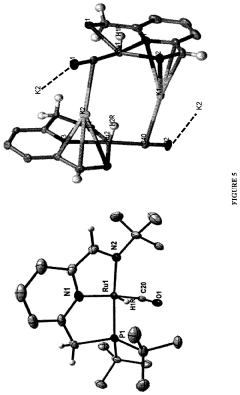

- Catalytic systems for LOHC dehydrogenation: Advanced catalytic systems are essential for efficient hydrogen release from LOHCs. These catalysts typically contain noble metals or transition metal compounds supported on various substrates. Research focuses on developing catalysts with high activity, selectivity, and durability while minimizing precious metal content. Novel support materials and preparation methods enhance catalyst performance and longevity under the demanding conditions of repeated hydrogenation-dehydrogenation cycles.

- LOHC integration with renewable energy systems: Integration of LOHC technology with renewable energy systems enables effective energy storage and utilization. Excess renewable electricity can be used for hydrogen production via electrolysis, which is then stored in LOHCs. This approach addresses intermittency issues of renewable sources and enables sector coupling between electricity, transportation, and industrial applications. Complete systems include electrolyzers, hydrogenation units, storage facilities, dehydrogenation reactors, and hydrogen utilization technologies such as fuel cells or turbines.

02 Hydrogen loading and unloading systems

Systems and methods for the efficient loading (hydrogenation) and unloading (dehydrogenation) of hydrogen from LOHCs are critical for practical hydrogen storage applications. These systems typically include catalytic reactors, heat exchangers, and separation units. Advanced catalysts are employed to facilitate the hydrogenation and dehydrogenation reactions at lower temperatures and pressures. The design of these systems focuses on energy efficiency, reaction kinetics, and the purity of the released hydrogen for downstream applications.Expand Specific Solutions03 LOHC integration with renewable energy systems

LOHCs can be integrated with renewable energy systems to store excess energy in the form of hydrogen. This integration enables the conversion of intermittent renewable energy into a storable and transportable form. The hydrogen stored in LOHCs can later be released and used for power generation, heating, or as a feedstock for industrial processes. This approach addresses the challenges of energy storage and transportation associated with renewable energy sources, contributing to a more sustainable energy ecosystem.Expand Specific Solutions04 Transportation and storage infrastructure for LOHCs

The development of infrastructure for the transportation and storage of LOHCs is essential for the hydrogen economy. This includes specialized containers, pipelines, and storage facilities designed to handle the physical and chemical properties of LOHCs. The infrastructure must ensure safety, minimize losses, and maintain the quality of the carrier during transportation and storage. Additionally, the compatibility of LOHCs with existing fuel infrastructure is considered to facilitate the transition to hydrogen-based energy systems.Expand Specific Solutions05 LOHC applications in mobility and industry

LOHCs have diverse applications in mobility and industrial sectors. In mobility, they can serve as hydrogen carriers for fuel cell vehicles, providing a safer and more convenient alternative to compressed or liquefied hydrogen. In industry, LOHCs can be used for hydrogen delivery to various processes, including chemical manufacturing, metallurgy, and power generation. The versatility of LOHCs makes them suitable for both centralized and decentralized hydrogen supply chains, addressing different market needs and infrastructure constraints.Expand Specific Solutions

Key Industry Players in LOHC Development

The Liquid Organic Hydrogen Carriers (LOHC) market is in an early growth phase, with increasing momentum as hydrogen gains prominence in clean energy transitions. The global LOHC market is projected to expand significantly, driven by the need for efficient hydrogen storage and transportation solutions. Technologically, the field shows promising developments but remains in early commercial stages. Leading players include Hydrogenious LOHC Technologies, pioneering commercial applications, alongside major energy corporations like Saudi Aramco and research-focused entities such as KAIST, Ulsan National Institute of Science & Technology, and the Commissariat à l'énergie atomique. Industrial players including Samsung Heavy Industries and LG Cable are exploring maritime and infrastructure applications, while Chinese entities like Wuhan Hynertech and Foshan Qingde are rapidly developing capabilities in this emerging sector.

Saudi Arabian Oil Co.

Technical Solution: Saudi Aramco has developed an advanced LOHC system leveraging their extensive hydrocarbon processing expertise. Their technology utilizes toluene-methylcyclohexane (MCH-TOL) as the primary carrier pair, achieving hydrogen storage capacities of 6.2 wt%. The company's approach integrates LOHC technology with their existing global petroleum infrastructure, enabling hydrogen transport through conventional oil tankers and storage facilities. Their system employs proprietary platinum-rhenium catalysts that achieve dehydrogenation at temperatures of 300-350°C with improved stability, maintaining over 95% selectivity after 2,000 hours of operation. A key innovation is their heat integration system that utilizes waste heat from other industrial processes to drive the endothermic dehydrogenation reaction, improving overall system efficiency by approximately 30%. Saudi Aramco's LOHC technology is designed for large-scale applications, with demonstration projects showing capacities exceeding 50 tons of hydrogen per day, positioning it as a solution for intercontinental hydrogen transport from regions with low-cost production potential to major demand centers.

Strengths: Massive existing global infrastructure that can be leveraged for LOHC distribution; substantial financial resources for technology scaling; integration with existing refinery operations; established global logistics network. Weaknesses: Primary focus on fossil-based hydrogen rather than renewable pathways; relatively high dehydrogenation temperatures increasing energy requirements; toluene carrier has higher toxicity concerns than some alternative carriers; technology still in demonstration rather than full commercial deployment.

Aramco Services Co.

Technical Solution: Aramco Services Company has developed an integrated LOHC system leveraging their extensive hydrocarbon expertise. Their approach focuses on utilizing existing oil and gas infrastructure for hydrogen transport and storage through specially designed carrier molecules derived from petroleum feedstocks. The company's LOHC technology employs a proprietary catalyst system that enables hydrogenation at lower temperatures (120-140°C) and pressures (15-25 bar) compared to industry standards, improving energy efficiency. Their system architecture incorporates modular units that can be deployed at various scales, from distributed hydrogen generation sites to centralized hubs. A key innovation is their heat management system that recovers approximately 40% of the thermal energy from the hydrogenation process to support dehydrogenation, reducing the overall energy penalty. Aramco's LOHC solution is designed to integrate with their existing global logistics network, potentially enabling hydrogen export from regions with low-cost production to demand centers worldwide.

Strengths: Extensive existing global infrastructure that can be repurposed for LOHC distribution; significant R&D resources and capital for technology scaling; integration potential with existing refinery operations; proprietary catalyst technology with improved efficiency. Weaknesses: Primary focus on fossil-based hydrogen production rather than green hydrogen; relatively new entrant to the LOHC-specific technology space; technology still in demonstration phase rather than full commercial deployment.

Critical LOHC Catalytic and Material Innovations

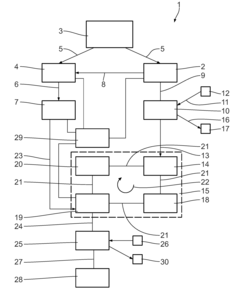

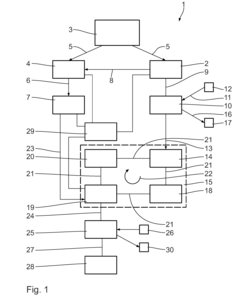

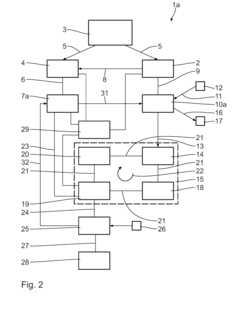

System and method for storing and releasing energy

PatentActiveUS20160301093A1

Innovation

- A system comprising a hydrogen production unit, a hydrogen storage device, a heat generation unit, and a heat storage unit, where hydrogen is stored chemically bound with a carrier medium, allowing for efficient storage and release of energy using heat from the heat storage unit during energy-rich and energy-poor periods.

Liquid-organic hydrogen carrier systems based on catalytic peptide formation and hydrogenation

PatentActiveUS10562767B2

Innovation

- The development of a system using aminoalcohol and diaminoalkane liquid-organic hydrogen carriers (LOHCs) that undergo dehydrogenative coupling and hydrogenation reactions catalyzed by Ruthenium complexes, allowing for efficient storage and release of hydrogen with high capacity and low catalyst loading.

Environmental Impact Assessment of LOHC Systems

The environmental impact assessment of LOHC systems reveals both promising advantages and notable challenges in the hydrogen energy landscape. LOHC technology offers significant environmental benefits compared to conventional hydrogen storage methods, particularly in reducing greenhouse gas emissions during the transportation and storage phases. Studies indicate that LOHC systems can achieve up to 30-40% lower carbon footprint compared to compressed or liquefied hydrogen when renewable energy sources power the hydrogenation and dehydrogenation processes.

Water consumption represents another critical environmental parameter. LOHC systems generally require less cooling water than alternative hydrogen carriers, with estimates suggesting 20-25% reduction compared to ammonia-based systems. However, the production of carrier molecules may involve water-intensive processes that partially offset these advantages, particularly in water-stressed regions.

Land use considerations reveal mixed outcomes. While LOHC infrastructure can largely utilize existing liquid fuel infrastructure, reducing the need for new construction, the cultivation of bio-based carrier molecules could potentially compete with food production or natural habitats if scaled significantly. Current assessments suggest that synthetic carrier production pathways may offer more sustainable land use profiles.

Toxicity and ecological risk assessments of various carrier molecules show substantial variation. Certain carriers like N-ethylcarbazole demonstrate relatively low aquatic toxicity, while others present more significant ecological concerns. The development of biodegradable carrier molecules represents an active research direction to mitigate potential environmental contamination risks from accidental releases.

Life cycle assessment (LCA) studies highlight that the environmental performance of LOHC systems depends heavily on several factors: the energy source for hydrogen production, the specific carrier molecule employed, transportation distances, and end-use applications. When powered by renewable electricity, well-designed LOHC systems can achieve carbon intensity reductions of 60-85% compared to fossil fuel alternatives across their full lifecycle.

Regulatory frameworks for environmental protection are still evolving for LOHC technologies. Current gaps in environmental standards specifically addressing these systems create uncertainty for deployment. Industry stakeholders and environmental agencies are collaborating to develop appropriate protocols for environmental monitoring and risk management tailored to the unique characteristics of LOHC systems.

Water consumption represents another critical environmental parameter. LOHC systems generally require less cooling water than alternative hydrogen carriers, with estimates suggesting 20-25% reduction compared to ammonia-based systems. However, the production of carrier molecules may involve water-intensive processes that partially offset these advantages, particularly in water-stressed regions.

Land use considerations reveal mixed outcomes. While LOHC infrastructure can largely utilize existing liquid fuel infrastructure, reducing the need for new construction, the cultivation of bio-based carrier molecules could potentially compete with food production or natural habitats if scaled significantly. Current assessments suggest that synthetic carrier production pathways may offer more sustainable land use profiles.

Toxicity and ecological risk assessments of various carrier molecules show substantial variation. Certain carriers like N-ethylcarbazole demonstrate relatively low aquatic toxicity, while others present more significant ecological concerns. The development of biodegradable carrier molecules represents an active research direction to mitigate potential environmental contamination risks from accidental releases.

Life cycle assessment (LCA) studies highlight that the environmental performance of LOHC systems depends heavily on several factors: the energy source for hydrogen production, the specific carrier molecule employed, transportation distances, and end-use applications. When powered by renewable electricity, well-designed LOHC systems can achieve carbon intensity reductions of 60-85% compared to fossil fuel alternatives across their full lifecycle.

Regulatory frameworks for environmental protection are still evolving for LOHC technologies. Current gaps in environmental standards specifically addressing these systems create uncertainty for deployment. Industry stakeholders and environmental agencies are collaborating to develop appropriate protocols for environmental monitoring and risk management tailored to the unique characteristics of LOHC systems.

Economic Viability and Commercialization Roadmap

The economic viability of Liquid Organic Hydrogen Carriers (LOHCs) is currently at a critical juncture. Cost analyses indicate that LOHC systems require significant capital investment, with estimates ranging from $2-5 million for small-scale installations to over $50 million for industrial-scale facilities. The levelized cost of hydrogen delivery via LOHCs currently stands at approximately $4-7 per kilogram, which remains higher than conventional fossil fuel-based hydrogen production methods ($1-2/kg).

Key economic drivers include the cost of carrier materials, energy requirements for hydrogenation and dehydrogenation processes, and infrastructure development expenses. The most promising carrier materials such as dibenzyl toluene and N-ethylcarbazole have seen production cost reductions of approximately 15% over the past three years, suggesting improving economics with scale.

Energy efficiency represents a significant challenge, with current LOHC systems requiring 30-40% of the hydrogen's energy content for the dehydrogenation process. Technological improvements targeting catalyst efficiency could potentially reduce this to 20-25% by 2025, substantially improving the economic equation.

The commercialization roadmap for LOHC technology follows a three-phase approach. The initial phase (2022-2025) focuses on demonstration projects and niche applications where conventional hydrogen storage faces limitations. Several pilot projects are already operational in Germany, Japan, and Australia, with capacities ranging from 50-200 kg H₂/day.

The mid-term phase (2026-2030) will likely see expanded commercial deployment in targeted sectors such as industrial hydrogen supply, maritime applications, and grid-scale energy storage. Industry projections suggest LOHC costs could decrease by 30-40% during this period through economies of scale and technological learning.

The long-term phase (2031-2040) envisions full commercial integration into hydrogen infrastructure networks, potentially enabling intercontinental hydrogen trade. The economic viability will depend heavily on carbon pricing mechanisms, renewable energy costs, and policy frameworks supporting hydrogen as an energy vector.

Strategic partnerships between technology developers, energy companies, and end-users are emerging as a critical factor in commercialization success. Notable examples include collaborations between Hydrogenious LOHC Technologies and Hyundai, and between Chiyoda Corporation and Mitsubishi Corporation, which have accelerated market entry through shared investment and risk mitigation.

Key economic drivers include the cost of carrier materials, energy requirements for hydrogenation and dehydrogenation processes, and infrastructure development expenses. The most promising carrier materials such as dibenzyl toluene and N-ethylcarbazole have seen production cost reductions of approximately 15% over the past three years, suggesting improving economics with scale.

Energy efficiency represents a significant challenge, with current LOHC systems requiring 30-40% of the hydrogen's energy content for the dehydrogenation process. Technological improvements targeting catalyst efficiency could potentially reduce this to 20-25% by 2025, substantially improving the economic equation.

The commercialization roadmap for LOHC technology follows a three-phase approach. The initial phase (2022-2025) focuses on demonstration projects and niche applications where conventional hydrogen storage faces limitations. Several pilot projects are already operational in Germany, Japan, and Australia, with capacities ranging from 50-200 kg H₂/day.

The mid-term phase (2026-2030) will likely see expanded commercial deployment in targeted sectors such as industrial hydrogen supply, maritime applications, and grid-scale energy storage. Industry projections suggest LOHC costs could decrease by 30-40% during this period through economies of scale and technological learning.

The long-term phase (2031-2040) envisions full commercial integration into hydrogen infrastructure networks, potentially enabling intercontinental hydrogen trade. The economic viability will depend heavily on carbon pricing mechanisms, renewable energy costs, and policy frameworks supporting hydrogen as an energy vector.

Strategic partnerships between technology developers, energy companies, and end-users are emerging as a critical factor in commercialization success. Notable examples include collaborations between Hydrogenious LOHC Technologies and Hyundai, and between Chiyoda Corporation and Mitsubishi Corporation, which have accelerated market entry through shared investment and risk mitigation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!