Materials Compatibility And Corrosion In LOHC Systems

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LOHC Technology Background and Objectives

Liquid Organic Hydrogen Carriers (LOHC) technology has emerged as a promising solution for hydrogen storage and transportation, addressing key challenges in the hydrogen economy. The concept of LOHC dates back to the 1980s, but significant advancements have occurred in the past decade due to increasing interest in hydrogen as a clean energy vector. LOHCs function through reversible hydrogenation-dehydrogenation cycles, where hydrogen is chemically bound to organic compounds for storage and released when needed.

The evolution of LOHC technology has been marked by several milestone developments. Initially, research focused on cyclohexane-benzene systems, which despite their simplicity, required high temperatures for dehydrogenation. The field progressed with the introduction of N-heterocyclic compounds like N-ethylcarbazole in the 2000s, offering improved hydrogen storage capacities. Recent innovations have centered on dibenzyltoluene and other aromatic compounds that demonstrate enhanced stability and favorable physical properties.

Current technological trends indicate a shift toward developing LOHC systems with lower dehydrogenation temperatures, improved catalyst efficiency, and enhanced cycle stability. Research is increasingly focused on optimizing the entire LOHC value chain, from hydrogen loading to transportation logistics and release systems.

The primary technical objectives for LOHC systems include achieving higher gravimetric and volumetric hydrogen storage densities, reducing energy requirements for hydrogen release, extending the operational lifetime of carrier materials, and ensuring compatibility with existing infrastructure. Specifically for materials compatibility and corrosion challenges, objectives include identifying carrier materials and system components that maintain integrity over thousands of hydrogenation-dehydrogenation cycles.

Another critical goal is developing LOHC systems that minimize corrosion effects on storage tanks, pipelines, and handling equipment. This requires comprehensive understanding of the interaction mechanisms between LOHCs and various materials under different operating conditions, including temperature variations, pressure fluctuations, and exposure to impurities.

The technology aims to establish standardized testing protocols for evaluating material compatibility and corrosion resistance in LOHC environments. Additionally, there is a push toward developing predictive models that can anticipate material degradation over time, enabling proactive maintenance strategies and informing material selection decisions for LOHC infrastructure.

As hydrogen gains prominence in global decarbonization strategies, LOHC technology is positioned to play a crucial role in enabling hydrogen's integration into existing energy systems, particularly for long-duration storage and long-distance transportation applications where compressed or liquefied hydrogen faces significant challenges.

The evolution of LOHC technology has been marked by several milestone developments. Initially, research focused on cyclohexane-benzene systems, which despite their simplicity, required high temperatures for dehydrogenation. The field progressed with the introduction of N-heterocyclic compounds like N-ethylcarbazole in the 2000s, offering improved hydrogen storage capacities. Recent innovations have centered on dibenzyltoluene and other aromatic compounds that demonstrate enhanced stability and favorable physical properties.

Current technological trends indicate a shift toward developing LOHC systems with lower dehydrogenation temperatures, improved catalyst efficiency, and enhanced cycle stability. Research is increasingly focused on optimizing the entire LOHC value chain, from hydrogen loading to transportation logistics and release systems.

The primary technical objectives for LOHC systems include achieving higher gravimetric and volumetric hydrogen storage densities, reducing energy requirements for hydrogen release, extending the operational lifetime of carrier materials, and ensuring compatibility with existing infrastructure. Specifically for materials compatibility and corrosion challenges, objectives include identifying carrier materials and system components that maintain integrity over thousands of hydrogenation-dehydrogenation cycles.

Another critical goal is developing LOHC systems that minimize corrosion effects on storage tanks, pipelines, and handling equipment. This requires comprehensive understanding of the interaction mechanisms between LOHCs and various materials under different operating conditions, including temperature variations, pressure fluctuations, and exposure to impurities.

The technology aims to establish standardized testing protocols for evaluating material compatibility and corrosion resistance in LOHC environments. Additionally, there is a push toward developing predictive models that can anticipate material degradation over time, enabling proactive maintenance strategies and informing material selection decisions for LOHC infrastructure.

As hydrogen gains prominence in global decarbonization strategies, LOHC technology is positioned to play a crucial role in enabling hydrogen's integration into existing energy systems, particularly for long-duration storage and long-distance transportation applications where compressed or liquefied hydrogen faces significant challenges.

Market Analysis for LOHC Hydrogen Storage Solutions

The global market for Liquid Organic Hydrogen Carrier (LOHC) systems is experiencing significant growth, driven by the increasing demand for efficient hydrogen storage solutions. As of 2023, the hydrogen storage market is valued at approximately $15.4 billion, with LOHC technology representing a growing segment expected to reach $2.3 billion by 2030, reflecting a compound annual growth rate of 12.7%.

The primary market drivers for LOHC systems include the global push for decarbonization, government initiatives supporting hydrogen infrastructure, and the inherent advantages of LOHC technology over compressed or liquefied hydrogen storage methods. The European Union's Hydrogen Strategy, Japan's Basic Hydrogen Strategy, and similar initiatives in South Korea and China have created favorable market conditions for LOHC adoption.

Industrial sectors represent the largest current market for LOHC systems, particularly chemical manufacturing, refining, and metallurgy where hydrogen is already utilized as a feedstock or process gas. The transportation sector presents substantial growth potential, with maritime shipping emerging as a particularly promising application due to the high energy density of LOHC systems compared to compressed hydrogen or batteries.

Regional analysis indicates that Europe currently leads LOHC market development, with Germany, the Netherlands, and Nordic countries at the forefront. The Asia-Pacific region shows the highest growth potential, particularly Japan and South Korea, where significant investments in hydrogen infrastructure are underway. North America follows with moderate but steadily increasing adoption rates.

Market challenges include the relatively high initial capital costs of LOHC systems, with current estimates ranging from $1,500-2,200 per kilogram of hydrogen storage capacity. Additionally, the energy requirements for hydrogen release from the carrier compound remain a significant economic barrier, with dehydrogenation processes typically consuming 25-35% of the hydrogen's energy content.

Customer demand analysis reveals growing interest from energy utilities, industrial gas suppliers, and transportation companies seeking to establish hydrogen value chains. The market shows particular sensitivity to total cost of ownership rather than initial investment costs, with operational efficiency and system longevity being key decision factors.

Competitive landscape assessment identifies several established players including Hydrogenious LOHC Technologies, Chiyoda Corporation, and Hyundai, alongside emerging startups developing novel carrier compounds and catalyst systems. Strategic partnerships between technology developers and industrial end-users characterize the current market dynamics, with vertical integration becoming increasingly common.

The primary market drivers for LOHC systems include the global push for decarbonization, government initiatives supporting hydrogen infrastructure, and the inherent advantages of LOHC technology over compressed or liquefied hydrogen storage methods. The European Union's Hydrogen Strategy, Japan's Basic Hydrogen Strategy, and similar initiatives in South Korea and China have created favorable market conditions for LOHC adoption.

Industrial sectors represent the largest current market for LOHC systems, particularly chemical manufacturing, refining, and metallurgy where hydrogen is already utilized as a feedstock or process gas. The transportation sector presents substantial growth potential, with maritime shipping emerging as a particularly promising application due to the high energy density of LOHC systems compared to compressed hydrogen or batteries.

Regional analysis indicates that Europe currently leads LOHC market development, with Germany, the Netherlands, and Nordic countries at the forefront. The Asia-Pacific region shows the highest growth potential, particularly Japan and South Korea, where significant investments in hydrogen infrastructure are underway. North America follows with moderate but steadily increasing adoption rates.

Market challenges include the relatively high initial capital costs of LOHC systems, with current estimates ranging from $1,500-2,200 per kilogram of hydrogen storage capacity. Additionally, the energy requirements for hydrogen release from the carrier compound remain a significant economic barrier, with dehydrogenation processes typically consuming 25-35% of the hydrogen's energy content.

Customer demand analysis reveals growing interest from energy utilities, industrial gas suppliers, and transportation companies seeking to establish hydrogen value chains. The market shows particular sensitivity to total cost of ownership rather than initial investment costs, with operational efficiency and system longevity being key decision factors.

Competitive landscape assessment identifies several established players including Hydrogenious LOHC Technologies, Chiyoda Corporation, and Hyundai, alongside emerging startups developing novel carrier compounds and catalyst systems. Strategic partnerships between technology developers and industrial end-users characterize the current market dynamics, with vertical integration becoming increasingly common.

Current Challenges in LOHC Materials Compatibility

Liquid Organic Hydrogen Carriers (LOHC) systems face significant materials compatibility challenges that impede their widespread adoption. The primary concern is the corrosive nature of the hydrogenation and dehydrogenation processes, which operate under harsh conditions including high temperatures (150-300°C) and pressures (10-50 bar). These conditions accelerate material degradation and necessitate careful selection of system components.

Metal components in LOHC systems frequently experience hydrogen embrittlement, where hydrogen atoms diffuse into the metal lattice, reducing ductility and tensile strength. This phenomenon is particularly problematic in steel alloys commonly used in industrial applications, leading to premature failure of critical components such as reactors, valves, and pipelines.

Chemical compatibility presents another major challenge. Many LOHCs, such as dibenzyl toluene (DBT) and N-ethylcarbazole (NEC), contain aromatic compounds that can react with certain materials, especially at elevated temperatures. These reactions can lead to catalyst poisoning, reducing system efficiency and increasing operational costs. Additionally, impurities in the LOHC medium can accelerate corrosion processes, particularly in the presence of trace water or oxygen.

Sealing materials face unique challenges in LOHC environments. Conventional elastomers often experience swelling, shrinkage, or chemical degradation when exposed to aromatic LOHCs. This compromises the integrity of seals and gaskets, leading to hydrogen leakage—a critical safety concern given hydrogen's flammability and low ignition energy.

Thermal cycling effects compound these issues. The repeated heating and cooling cycles inherent in LOHC operation create thermal expansion stresses that can accelerate material fatigue and crack propagation. This is particularly problematic at interface points between different materials with varying thermal expansion coefficients.

Long-term stability remains inadequately characterized for many materials in LOHC environments. Most compatibility studies focus on short-term exposure, leaving significant uncertainty about system durability over the expected 10-20 year operational lifespan of industrial hydrogen storage facilities.

Cost considerations further complicate material selection. While specialized alloys like Inconel or Hastelloy demonstrate superior resistance to hydrogen embrittlement and chemical attack, their high cost prohibits widespread use in large-scale systems. This creates a challenging trade-off between system longevity and economic viability.

Standardized testing protocols for material compatibility in LOHC systems are still evolving, making it difficult to compare results across different research groups and hampering the development of industry-wide material selection guidelines. This lack of standardization represents a significant barrier to accelerating LOHC technology deployment.

Metal components in LOHC systems frequently experience hydrogen embrittlement, where hydrogen atoms diffuse into the metal lattice, reducing ductility and tensile strength. This phenomenon is particularly problematic in steel alloys commonly used in industrial applications, leading to premature failure of critical components such as reactors, valves, and pipelines.

Chemical compatibility presents another major challenge. Many LOHCs, such as dibenzyl toluene (DBT) and N-ethylcarbazole (NEC), contain aromatic compounds that can react with certain materials, especially at elevated temperatures. These reactions can lead to catalyst poisoning, reducing system efficiency and increasing operational costs. Additionally, impurities in the LOHC medium can accelerate corrosion processes, particularly in the presence of trace water or oxygen.

Sealing materials face unique challenges in LOHC environments. Conventional elastomers often experience swelling, shrinkage, or chemical degradation when exposed to aromatic LOHCs. This compromises the integrity of seals and gaskets, leading to hydrogen leakage—a critical safety concern given hydrogen's flammability and low ignition energy.

Thermal cycling effects compound these issues. The repeated heating and cooling cycles inherent in LOHC operation create thermal expansion stresses that can accelerate material fatigue and crack propagation. This is particularly problematic at interface points between different materials with varying thermal expansion coefficients.

Long-term stability remains inadequately characterized for many materials in LOHC environments. Most compatibility studies focus on short-term exposure, leaving significant uncertainty about system durability over the expected 10-20 year operational lifespan of industrial hydrogen storage facilities.

Cost considerations further complicate material selection. While specialized alloys like Inconel or Hastelloy demonstrate superior resistance to hydrogen embrittlement and chemical attack, their high cost prohibits widespread use in large-scale systems. This creates a challenging trade-off between system longevity and economic viability.

Standardized testing protocols for material compatibility in LOHC systems are still evolving, making it difficult to compare results across different research groups and hampering the development of industry-wide material selection guidelines. This lack of standardization represents a significant barrier to accelerating LOHC technology deployment.

Current Corrosion Mitigation Strategies for LOHC Systems

01 Material selection for LOHC systems

The selection of appropriate materials for Liquid Organic Hydrogen Carrier (LOHC) systems is crucial to prevent corrosion and ensure system longevity. Materials must be compatible with both the hydrogen carrier compounds and the operating conditions of the system. Certain metals and alloys demonstrate superior resistance to degradation when exposed to LOHC compounds under various temperature and pressure conditions. The proper selection of construction materials can significantly reduce maintenance requirements and extend the service life of LOHC infrastructure.- Material selection for LOHC systems: The selection of appropriate materials for Liquid Organic Hydrogen Carrier (LOHC) systems is crucial to prevent corrosion and ensure system longevity. Materials must be compatible with both the hydrogen carrier compounds and the operating conditions of the system. Certain metals and alloys show superior resistance to degradation when exposed to LOHC compounds under various temperature and pressure conditions. The proper selection of construction materials can significantly reduce maintenance requirements and extend the service life of LOHC storage and transportation systems.

- Corrosion inhibitors for LOHC applications: Specialized corrosion inhibitors can be incorporated into LOHC systems to protect metal components from degradation. These inhibitors form protective layers on metal surfaces or neutralize corrosive compounds within the hydrogen carrier medium. The effectiveness of corrosion inhibitors depends on the specific LOHC compound used, operating temperature, and system pressure. Proper formulation and concentration of these inhibitors are essential for maintaining system integrity during long-term hydrogen storage and transportation operations.

- Surface treatment and coating technologies: Various surface treatment and coating technologies can enhance the compatibility of materials with LOHC systems. These include specialized coatings that create barriers between the base material and the hydrogen carrier, preventing direct contact and subsequent corrosion. Surface modification techniques such as nitriding, carburizing, or the application of ceramic coatings can significantly improve corrosion resistance. These treatments must maintain their integrity under the cyclic loading and temperature variations typical in hydrogen dehydrogenation and hydrogenation processes.

- Monitoring and testing methods for corrosion: Advanced monitoring and testing methods are essential for evaluating material compatibility and detecting corrosion in LOHC systems. These include electrochemical impedance spectroscopy, weight loss measurements, and surface analysis techniques that can identify early signs of material degradation. Real-time monitoring systems can track changes in system parameters that might indicate corrosion processes. Accelerated testing protocols help predict long-term material behavior under various operating conditions, enabling better material selection and system design.

- System design considerations for corrosion prevention: Proper system design plays a crucial role in preventing corrosion in LOHC systems. This includes considerations such as avoiding galvanic coupling of dissimilar metals, ensuring appropriate flow rates to minimize erosion-corrosion, and implementing temperature control to keep the system within optimal operating ranges. Design elements such as sacrificial anodes, strategic placement of corrosion-resistant components at critical points, and provisions for regular inspection and maintenance can significantly extend system lifespan. Additionally, proper sealing and containment strategies prevent contamination that could accelerate corrosion processes.

02 Corrosion inhibitors for LOHC applications

Specialized corrosion inhibitors can be incorporated into LOHC systems to protect metal components from degradation. These additives form protective films on metal surfaces or neutralize corrosive compounds present in the hydrogen carrier medium. The effectiveness of corrosion inhibitors depends on their chemical composition, concentration, and compatibility with the specific LOHC compounds used. Implementing appropriate corrosion inhibition strategies can significantly extend the operational lifetime of LOHC storage and transport systems.Expand Specific Solutions03 Surface treatment and coating technologies

Various surface treatment and coating technologies can enhance the corrosion resistance of materials used in LOHC systems. These include passivation treatments, conversion coatings, and the application of specialized polymer or ceramic coatings. Such treatments create protective barriers that prevent direct contact between the base material and potentially corrosive LOHC compounds. The selection of appropriate coating technology depends on the specific operating conditions, including temperature ranges, pressure levels, and the chemical composition of the hydrogen carrier.Expand Specific Solutions04 Monitoring and testing methods for corrosion

Advanced monitoring and testing methods are essential for evaluating material compatibility and detecting corrosion in LOHC systems. These include electrochemical impedance spectroscopy, weight loss measurements, surface analysis techniques, and in-situ monitoring systems. Regular assessment of material degradation allows for timely maintenance interventions and helps optimize material selection for specific LOHC applications. Implementing comprehensive corrosion monitoring programs can prevent catastrophic failures and ensure the safe operation of hydrogen storage and transport infrastructure.Expand Specific Solutions05 System design considerations for corrosion prevention

The design of LOHC systems plays a crucial role in preventing corrosion and ensuring material compatibility. Key design considerations include minimizing dead zones where corrosive substances might accumulate, implementing proper drainage systems, selecting appropriate sealing materials, and designing for thermal expansion. Additionally, the integration of corrosion-resistant alloys at critical points and the use of sacrificial anodes in certain applications can significantly enhance system durability. Proper system design that accounts for material compatibility issues can substantially reduce maintenance costs and extend operational lifetimes.Expand Specific Solutions

Key Industry Players in LOHC Technology Development

The LOHC (Liquid Organic Hydrogen Carrier) systems market is in its early growth phase, characterized by increasing R&D investments but limited commercial deployment. The global market is projected to expand significantly as hydrogen economy develops, with current estimates around $300-500 million and potential to reach billions by 2030. Technical challenges in materials compatibility and corrosion remain critical barriers to widespread adoption. Leading players include BASF SE and Solvay SA developing specialized coating solutions, while automotive companies like BMW, Mazda, and Boeing are exploring LOHC applications for transportation. Research institutions such as Beihang University and Southwest Research Institute are advancing fundamental understanding of material-LOHC interactions, while oil companies like Saudi Aramco are investing in LOHC technology as part of their energy transition strategies.

Saudi Arabian Oil Co.

Technical Solution: Saudi Arabian Oil Co. (Saudi Aramco) has developed comprehensive materials compatibility solutions for LOHC systems tailored to large-scale hydrogen storage and transport applications. Their approach focuses on high-temperature resistant alloys specifically engineered to withstand the thermal cycling and chemical exposure in industrial-scale LOHC operations. Aramco's materials research has yielded specialized nickel-chromium alloys with molybdenum and tungsten additions that demonstrate superior resistance to sulfur-containing impurities often present in industrial hydrogen streams. The company has established extensive testing facilities that simulate accelerated aging under various LOHC operational conditions, including temperature fluctuations between ambient and 350°C and exposure to carrier fluids like toluene derivatives. Their corrosion mitigation strategy incorporates both passive protection through material selection and active protection through intelligent monitoring systems that detect early signs of material degradation. Aramco has also developed specialized ceramic-lined components for critical sections of LOHC systems where conventional metallic materials would experience accelerated degradation.

Strengths: Extensive experience with large-scale industrial operations provides insights into scaling challenges for LOHC systems. Significant R&D resources allow for comprehensive materials testing and validation. Weaknesses: Solutions may be optimized for petroleum industry applications rather than diverse energy storage scenarios. Some proprietary technologies may have limited availability outside Aramco's operations.

Robert Bosch GmbH

Technical Solution: Robert Bosch GmbH has pioneered materials engineering for LOHC systems with focus on hydrogen storage and transportation infrastructure. Their technology centers on specialized stainless steel alloys containing optimized chromium-nickel-molybdenum compositions that demonstrate exceptional resistance to hydrogen-induced stress corrosion cracking. Bosch has developed proprietary surface treatment processes that create nanoscale protective layers on metal components exposed to LOHC media, significantly reducing material degradation rates. Their engineering approach incorporates computational fluid dynamics to identify potential corrosion hotspots in LOHC handling systems, allowing for targeted material selection. Bosch's materials testing regimen includes electrochemical impedance spectroscopy to characterize corrosion mechanisms in real-time under operational conditions. The company has also developed specialized joining technologies that maintain material integrity at connection points between dissimilar metals in LOHC systems, addressing a common failure point in hydrogen infrastructure.

Strengths: Extensive experience in automotive and industrial applications provides practical insights into real-world implementation challenges. Comprehensive testing capabilities allow for validation under diverse operational scenarios. Weaknesses: Solutions may be optimized for automotive applications rather than stationary storage systems. Higher initial investment costs compared to conventional materials.

Critical Patents and Research on LOHC-Compatible Materials

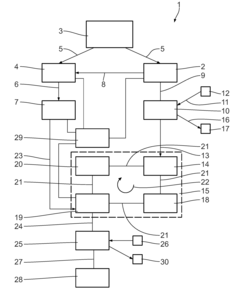

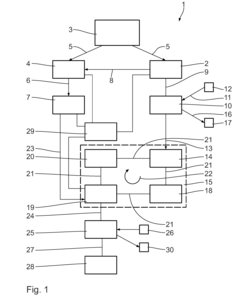

System and method for storing and releasing energy

PatentActiveUS20160301093A1

Innovation

- A system comprising a hydrogen production unit, a hydrogen storage device, a heat generation unit, and a heat storage unit, where hydrogen is stored chemically bound with a carrier medium, allowing for efficient storage and release of energy using heat from the heat storage unit during energy-rich and energy-poor periods.

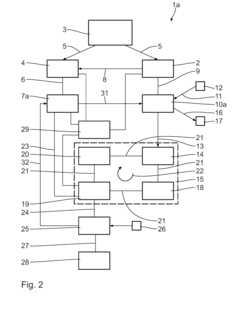

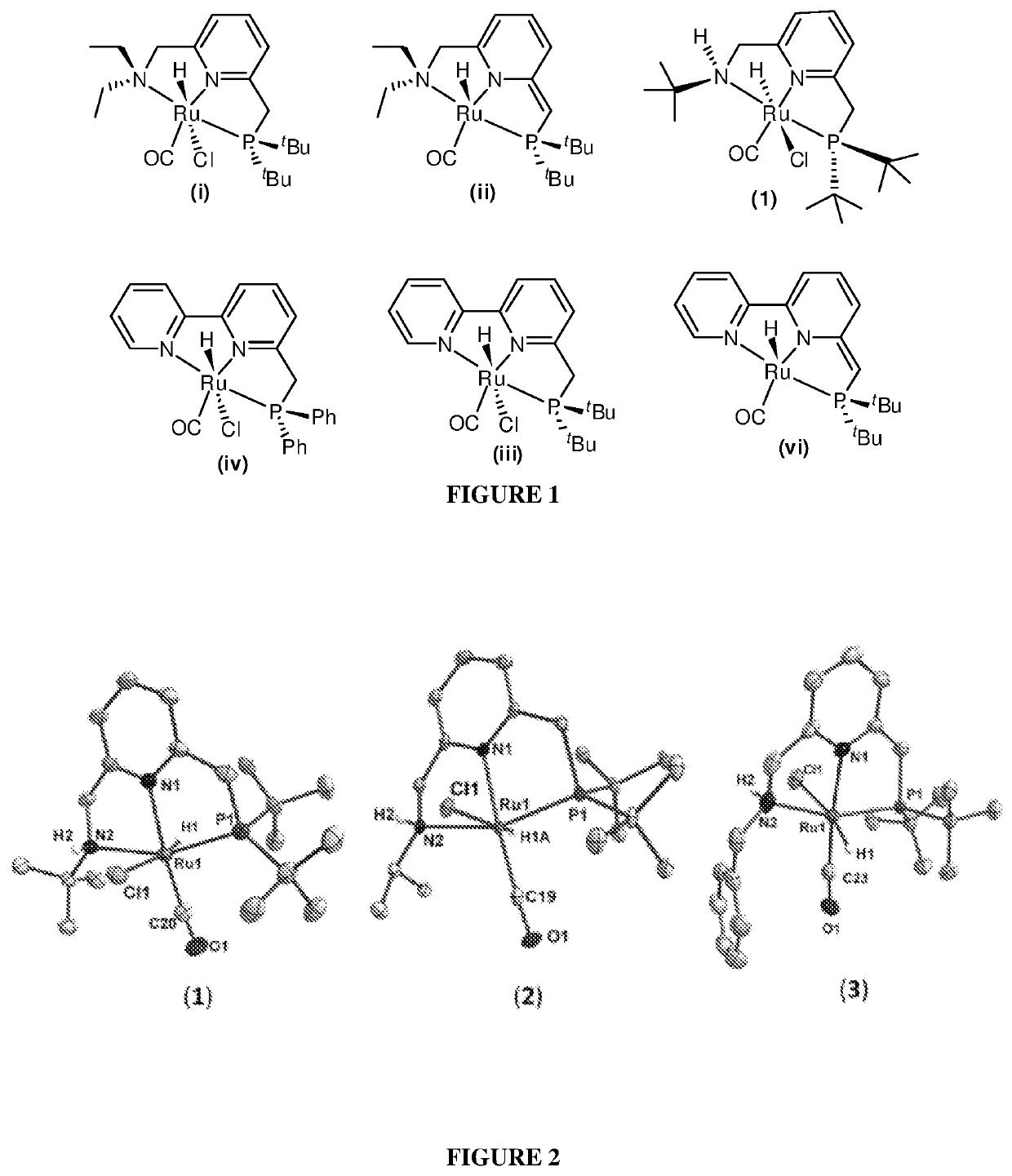

Liquid-organic hydrogen carrier systems based on catalytic peptide formation and hydrogenation

PatentActiveUS10562767B2

Innovation

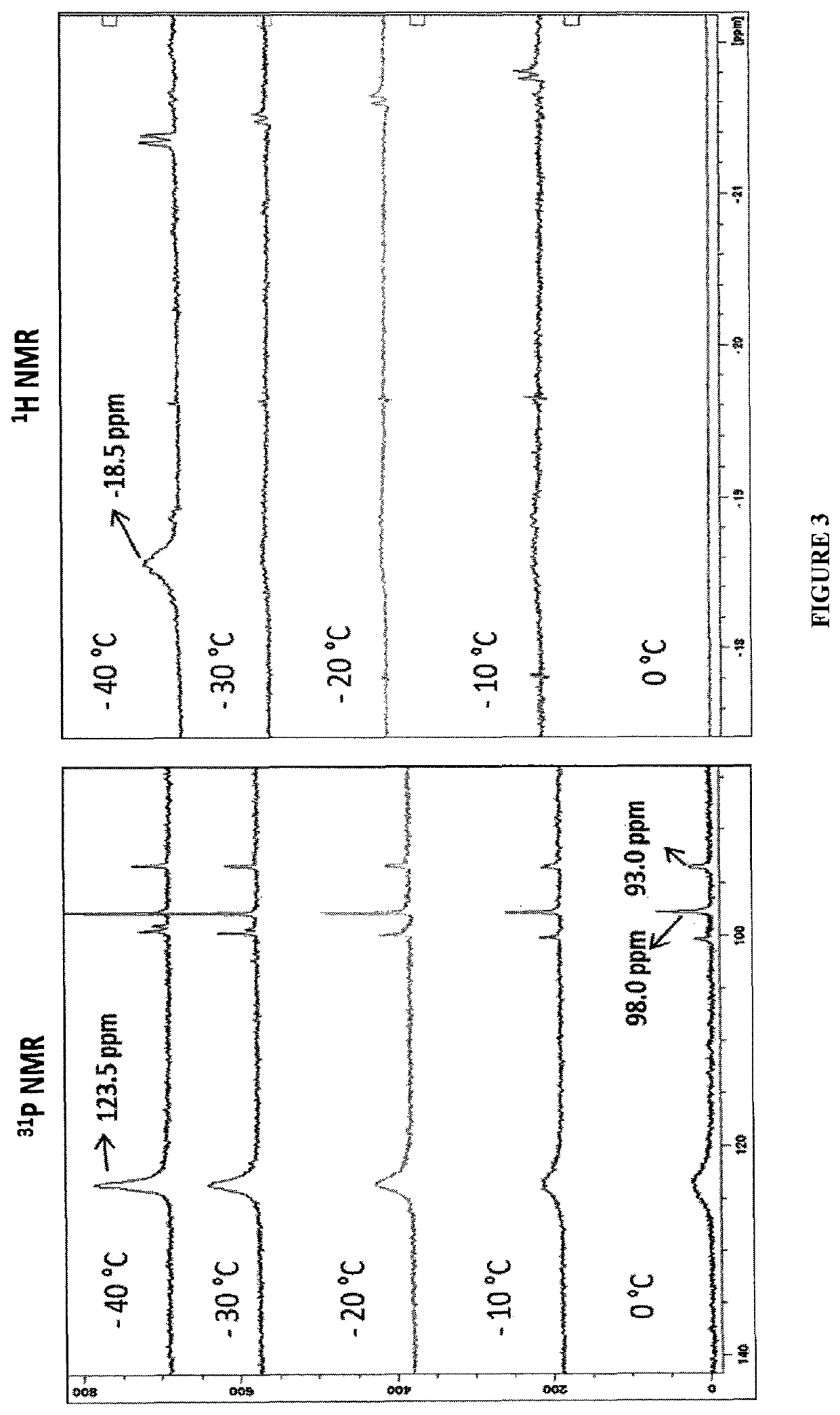

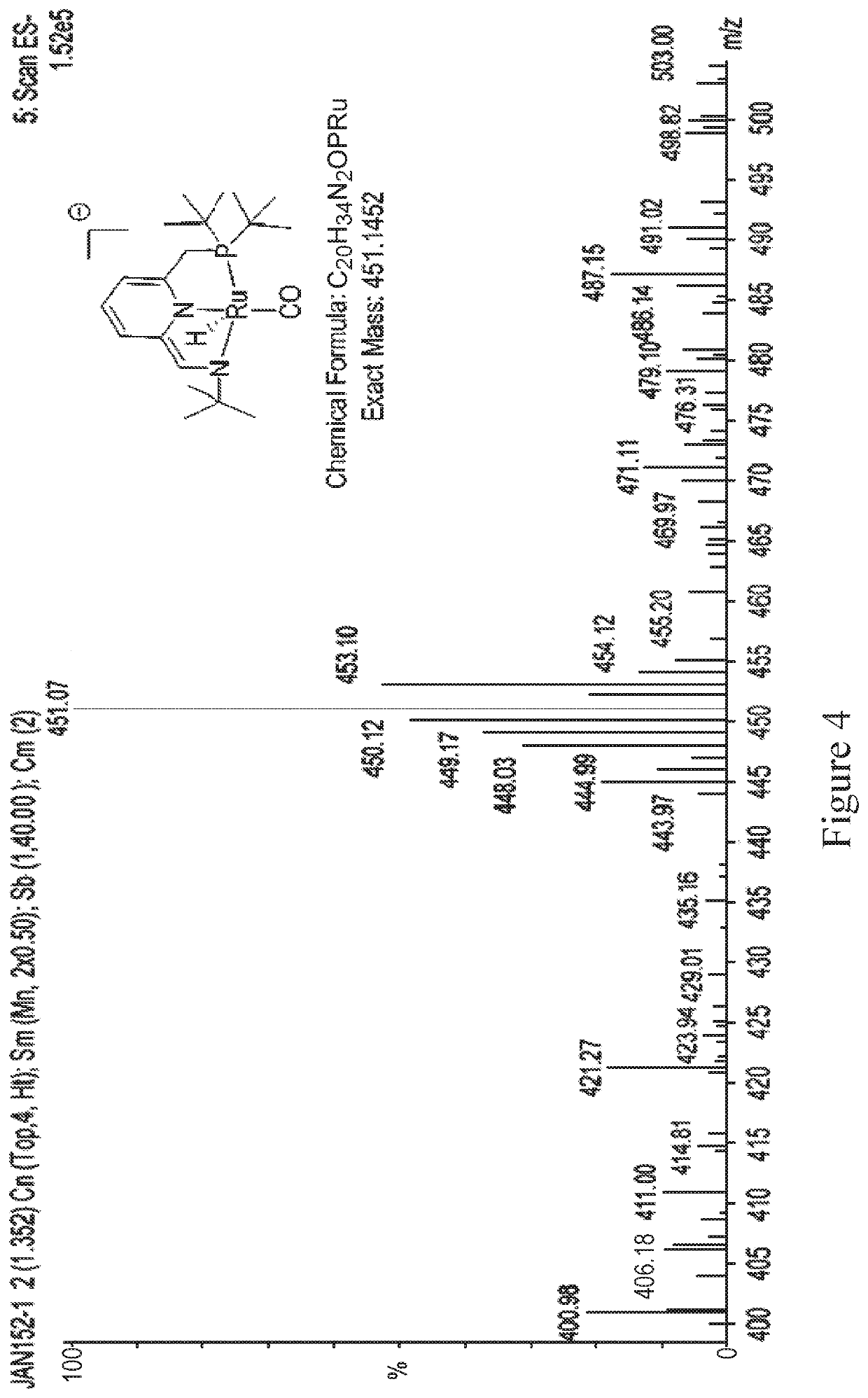

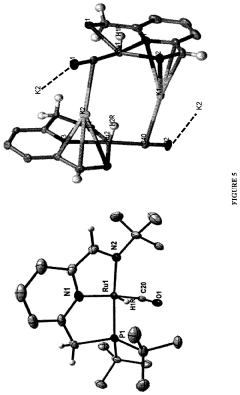

- The development of a system using aminoalcohol and diaminoalkane liquid-organic hydrogen carriers (LOHCs) that undergo dehydrogenative coupling and hydrogenation reactions catalyzed by Ruthenium complexes, allowing for efficient storage and release of hydrogen with high capacity and low catalyst loading.

Safety Standards and Risk Assessment for LOHC Systems

The safety landscape for Liquid Organic Hydrogen Carrier (LOHC) systems requires comprehensive standards and risk assessment protocols to ensure operational integrity. Current regulatory frameworks governing LOHC systems draw from established hydrogen handling standards (ISO/TC 197, NFPA 2) while incorporating specific considerations for liquid organic carriers. These standards address critical aspects including storage parameters, handling procedures, and transportation requirements tailored to the unique properties of LOHC materials.

Risk assessment methodologies for LOHC systems employ systematic approaches such as HAZOP (Hazard and Operability Study), FMEA (Failure Mode and Effects Analysis), and quantitative risk assessment techniques. These methodologies help identify potential failure modes related to material compatibility issues and corrosion risks that could compromise system integrity. The assessment process typically evaluates both normal operating conditions and potential upset scenarios to establish appropriate safety margins.

Material-specific safety considerations form a crucial component of LOHC safety standards. These include detailed protocols for managing potential leakage scenarios, thermal management during hydrogenation/dehydrogenation processes, and specific handling requirements for different carrier molecules. The standards establish clear thresholds for material degradation indicators that trigger maintenance interventions before safety is compromised.

Monitoring and detection systems represent another critical element in LOHC safety frameworks. Current standards mandate continuous monitoring of key parameters including temperature, pressure, and material integrity indicators. Advanced detection systems utilizing spectroscopic techniques and electrochemical sensors provide early warning of potential corrosion or material compatibility issues before they escalate to safety incidents.

Emergency response protocols for LOHC systems address the unique challenges posed by these materials, including specialized containment strategies for carrier molecules and appropriate neutralization techniques. Training requirements for personnel handling LOHC systems emphasize the specific chemical properties and reactivity patterns of carrier materials under various conditions.

Industry certification processes for LOHC equipment and facilities incorporate rigorous testing regimes that specifically evaluate material compatibility over extended operational periods. These certification standards are continuously evolving as operational data from early commercial LOHC deployments provides valuable insights into long-term safety considerations and material performance under real-world conditions.

Risk assessment methodologies for LOHC systems employ systematic approaches such as HAZOP (Hazard and Operability Study), FMEA (Failure Mode and Effects Analysis), and quantitative risk assessment techniques. These methodologies help identify potential failure modes related to material compatibility issues and corrosion risks that could compromise system integrity. The assessment process typically evaluates both normal operating conditions and potential upset scenarios to establish appropriate safety margins.

Material-specific safety considerations form a crucial component of LOHC safety standards. These include detailed protocols for managing potential leakage scenarios, thermal management during hydrogenation/dehydrogenation processes, and specific handling requirements for different carrier molecules. The standards establish clear thresholds for material degradation indicators that trigger maintenance interventions before safety is compromised.

Monitoring and detection systems represent another critical element in LOHC safety frameworks. Current standards mandate continuous monitoring of key parameters including temperature, pressure, and material integrity indicators. Advanced detection systems utilizing spectroscopic techniques and electrochemical sensors provide early warning of potential corrosion or material compatibility issues before they escalate to safety incidents.

Emergency response protocols for LOHC systems address the unique challenges posed by these materials, including specialized containment strategies for carrier molecules and appropriate neutralization techniques. Training requirements for personnel handling LOHC systems emphasize the specific chemical properties and reactivity patterns of carrier materials under various conditions.

Industry certification processes for LOHC equipment and facilities incorporate rigorous testing regimes that specifically evaluate material compatibility over extended operational periods. These certification standards are continuously evolving as operational data from early commercial LOHC deployments provides valuable insights into long-term safety considerations and material performance under real-world conditions.

Lifecycle Analysis and Environmental Impact of LOHC Materials

Liquid Organic Hydrogen Carrier (LOHC) systems represent a promising technology for hydrogen storage and transportation, yet their environmental impact throughout the lifecycle requires thorough assessment. The lifecycle analysis of LOHC materials encompasses raw material extraction, synthesis, operational use, and end-of-life disposal or recycling, providing crucial insights into their overall sustainability profile.

Primary LOHC materials such as dibenzyl toluene, N-ethylcarbazole, and dibenzyltoluene demonstrate varying environmental footprints. Research indicates that the production phase of these carriers typically accounts for 40-60% of their total environmental impact, with energy-intensive synthesis processes being the primary contributor. The hydrogen loading and unloading cycles, which may occur hundreds of times during a carrier's lifetime, constitute an additional 25-35% of the environmental burden.

Comparative analyses with alternative hydrogen storage technologies reveal that LOHC systems generally exhibit lower global warming potential than compressed hydrogen storage when considering full lifecycle emissions. However, they may present higher impacts in categories such as water consumption and land use, particularly when carrier synthesis involves petrochemical feedstocks.

The environmental benefits of LOHC systems are significantly enhanced through material recycling and regeneration. Studies demonstrate that effective recycling protocols can extend carrier lifespans by 3-5 times, substantially reducing the need for virgin material production. Advanced purification techniques have achieved recovery rates exceeding 95% for certain carriers, minimizing waste generation and resource depletion.

Energy efficiency across the LOHC lifecycle remains a critical consideration. The hydrogenation process typically requires 0.3-0.5 kWh per kg of hydrogen stored, while dehydrogenation demands 0.8-1.2 kWh per kg released. These energy requirements must be factored into comprehensive environmental assessments, particularly when considering grid electricity sources.

Toxicity and ecotoxicity profiles vary significantly among LOHC materials. While carriers like dibenzyl toluene demonstrate relatively low acute toxicity, potential long-term environmental persistence raises concerns about bioaccumulation. Recent developments in bio-based LOHC materials show promise for reducing environmental hazards, though these alternatives often face challenges in hydrogen storage capacity and cycle stability.

Regulatory frameworks increasingly require lifecycle impact documentation for emerging energy technologies. The EU's Sustainable Product Initiative and similar global regulations are establishing stricter environmental performance standards that will influence LOHC material selection and system design. Forward-looking LOHC development must therefore prioritize not only technical performance but also environmental compatibility throughout the complete material lifecycle.

Primary LOHC materials such as dibenzyl toluene, N-ethylcarbazole, and dibenzyltoluene demonstrate varying environmental footprints. Research indicates that the production phase of these carriers typically accounts for 40-60% of their total environmental impact, with energy-intensive synthesis processes being the primary contributor. The hydrogen loading and unloading cycles, which may occur hundreds of times during a carrier's lifetime, constitute an additional 25-35% of the environmental burden.

Comparative analyses with alternative hydrogen storage technologies reveal that LOHC systems generally exhibit lower global warming potential than compressed hydrogen storage when considering full lifecycle emissions. However, they may present higher impacts in categories such as water consumption and land use, particularly when carrier synthesis involves petrochemical feedstocks.

The environmental benefits of LOHC systems are significantly enhanced through material recycling and regeneration. Studies demonstrate that effective recycling protocols can extend carrier lifespans by 3-5 times, substantially reducing the need for virgin material production. Advanced purification techniques have achieved recovery rates exceeding 95% for certain carriers, minimizing waste generation and resource depletion.

Energy efficiency across the LOHC lifecycle remains a critical consideration. The hydrogenation process typically requires 0.3-0.5 kWh per kg of hydrogen stored, while dehydrogenation demands 0.8-1.2 kWh per kg released. These energy requirements must be factored into comprehensive environmental assessments, particularly when considering grid electricity sources.

Toxicity and ecotoxicity profiles vary significantly among LOHC materials. While carriers like dibenzyl toluene demonstrate relatively low acute toxicity, potential long-term environmental persistence raises concerns about bioaccumulation. Recent developments in bio-based LOHC materials show promise for reducing environmental hazards, though these alternatives often face challenges in hydrogen storage capacity and cycle stability.

Regulatory frameworks increasingly require lifecycle impact documentation for emerging energy technologies. The EU's Sustainable Product Initiative and similar global regulations are establishing stricter environmental performance standards that will influence LOHC material selection and system design. Forward-looking LOHC development must therefore prioritize not only technical performance but also environmental compatibility throughout the complete material lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!